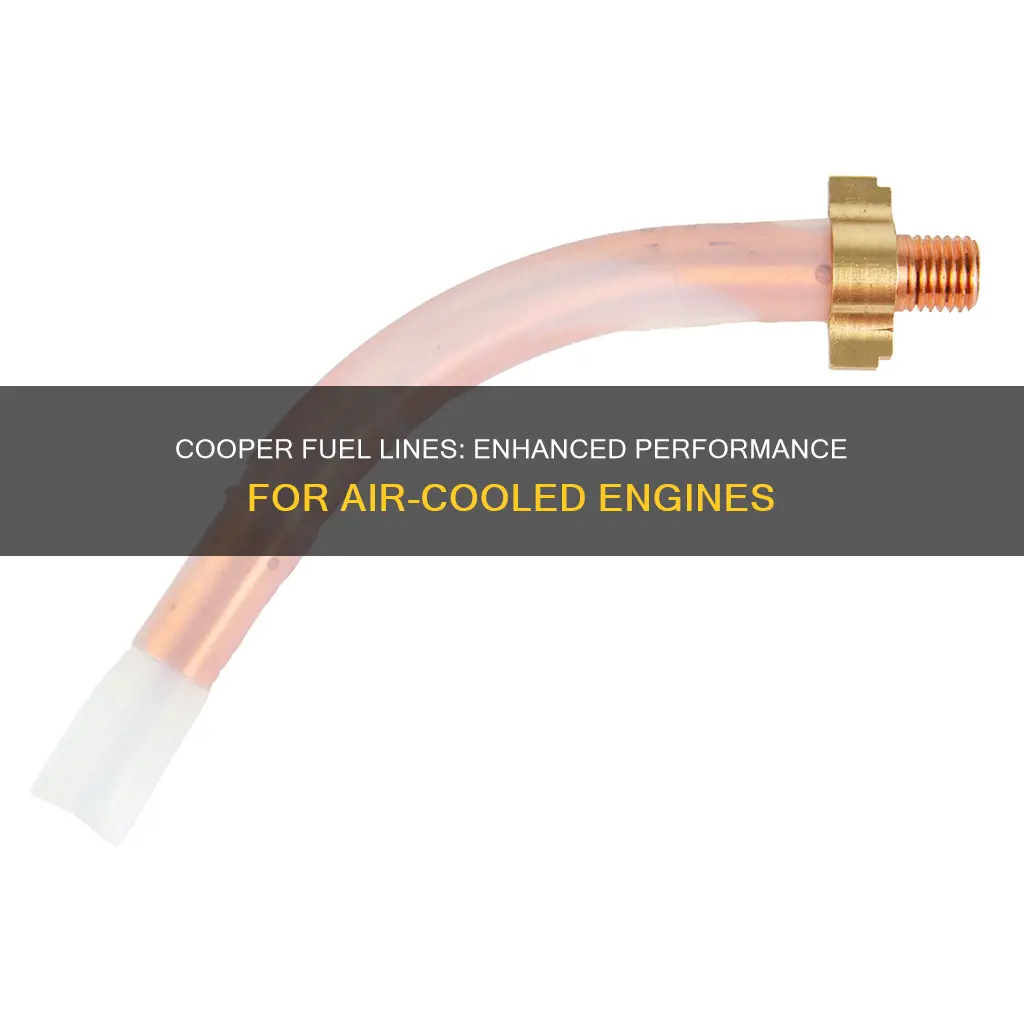

Cooper fuel lines are a popular choice for air-cooled engines, and many enthusiasts believe they offer several advantages over traditional rubber or plastic fuel lines. These lines are known for their superior flexibility, durability, and resistance to heat and fuel degradation. The unique construction of Cooper fuel lines, often made from a blend of synthetic fibers and rubber, provides excellent flexibility, allowing for easier installation and reduced stress on the engine components. Additionally, their heat resistance ensures that the fuel lines can withstand high temperatures, which is crucial for air-cooled engines that rely on efficient cooling. This makes Cooper fuel lines a preferred option for those seeking to optimize their air-cooled engine's performance and longevity.

| Characteristics | Values |

|---|---|

| Material | Copper |

| Advantages | - Improved heat dissipation - Enhanced fuel flow and pressure stability - Corrosion resistance |

| Disadvantages | - Higher cost compared to steel lines - Requires careful installation to avoid kinking |

| Compatibility | Air-cooled engines, especially high-performance applications |

| Durability | High, but may require more frequent inspection due to potential for oxidation |

| Flexibility | Moderate, can be bent but may require additional support |

| Weight | Heavier than steel lines, but provides better thermal management |

| Maintenance | Regular cleaning and inspection to prevent fuel contamination |

| Performance | Superior fuel delivery and engine performance, especially in high-temperature environments |

| Applications | Racing, high-performance vehicles, and classic car restoration |

| Considerations | Ensure proper ventilation and fuel line routing to prevent overheating |

What You'll Learn

- Performance: Cooper fuel lines offer enhanced performance for air-cooled engines, improving power and efficiency

- Durability: These lines are known for their durability, resisting heat and pressure for long-lasting use

- Flexibility: The flexible design of Cooper lines allows for easy installation and adjustment in tight spaces

- Heat Resistance: They can withstand high temperatures, ensuring optimal engine operation even in extreme conditions

- Compatibility: Cooper fuel lines are compatible with various air-cooled engine models, providing a versatile solution

Performance: Cooper fuel lines offer enhanced performance for air-cooled engines, improving power and efficiency

Cooper fuel lines are specifically designed to optimize the performance of air-cooled engines, which are commonly found in classic cars, motorcycles, and other vintage vehicles. These fuel lines are engineered to provide a superior solution for fuel delivery, resulting in improved power output and overall engine efficiency. The key advantage lies in their ability to minimize fuel pressure drop, ensuring a consistent and precise fuel supply to the engine's combustion chamber.

In air-cooled engines, efficient heat dissipation is crucial to maintain optimal operating temperatures. Cooper fuel lines excel in this aspect by incorporating a unique design that reduces heat transfer from the fuel to the engine block. This feature is particularly beneficial as it prevents overheating, allowing the engine to operate at its peak performance without the risk of fuel degradation or loss of power due to excessive heat. By maintaining the fuel at an ideal temperature, these lines contribute to a more stable and powerful engine.

The performance benefits of Cooper fuel lines extend beyond temperature control. Their construction includes a high-quality material that ensures minimal fuel evaporation and leakage. This is essential for air-cooled engines, as it helps maintain a consistent fuel-air mixture, leading to improved combustion and power delivery. The lines' ability to provide a steady and controlled fuel flow results in a more responsive engine, delivering power when and where it's needed.

Furthermore, Cooper fuel lines are designed with a flexible yet robust structure, allowing them to withstand the rigors of air-cooled engine operation. This flexibility ensures that the fuel lines can adapt to the engine's movements without restricting fuel flow or causing unnecessary pressure drops. The durability of these lines is a significant advantage, as it ensures long-lasting performance and reliability, even in demanding environments.

In summary, Cooper fuel lines are an excellent choice for air-cooled engines, offering a range of performance enhancements. From improved fuel efficiency and power output to better temperature control and engine responsiveness, these fuel lines are tailored to meet the unique demands of vintage and classic vehicle enthusiasts. By investing in Cooper fuel lines, owners can ensure their air-cooled engines perform at their very best, delivering the power and efficiency that these vehicles are renowned for.

Red Kote Fuel Tank Liner: A Step-by-Step Guide to Installation

You may want to see also

Durability: These lines are known for their durability, resisting heat and pressure for long-lasting use

Cooper fuel lines are renowned for their exceptional durability, making them an excellent choice for air-cooled engines. These fuel lines are designed to withstand the harsh conditions of high-performance applications, ensuring long-lasting performance and reliability. The construction of Cooper fuel lines involves a combination of high-quality materials and advanced manufacturing techniques. The inner diameter is typically made from a durable, heat-resistant material, often a special type of rubber or a synthetic compound, which provides excellent flexibility and resistance to fuel degradation. This inner layer is then encased in a protective outer jacket, usually made from a robust, heat-resistant material like nylon or a specialized rubber compound. This dual-layer construction ensures that the fuel lines can handle the extreme temperatures and pressures associated with air-cooled engines, where heat dissipation is a critical factor.

The durability of Cooper fuel lines is further enhanced by their ability to resist pressure and abrasion. The inner diameter is carefully designed to maintain its shape and flexibility even under high pressure, ensuring a consistent fuel flow without any blockages. Additionally, the outer jacket provides protection against mechanical damage, such as nicks and cuts, which could compromise the integrity of the fuel line. This protective layer also helps to prevent fuel leaks, a common issue with cheaper, less durable fuel lines.

In high-performance applications, where engines operate at their limits, the durability of fuel lines becomes even more critical. Air-cooled engines, in particular, generate a significant amount of heat, which can cause traditional fuel lines to degrade over time. Cooper fuel lines, with their heat-resistant construction, can withstand these extreme conditions, ensuring that the fuel supply remains reliable and consistent. This is especially important in racing or high-performance driving scenarios, where every second counts, and any fuel-related issues can be detrimental to performance.

The long-lasting nature of Cooper fuel lines also translates to cost savings in the long run. While the initial investment might be slightly higher compared to standard fuel lines, the durability and reliability of Cooper lines mean they will last much longer. This not only reduces the frequency of replacements but also minimizes the risk of fuel leaks, which can be costly to repair and potentially dangerous.

In summary, Cooper fuel lines are an excellent choice for air-cooled engines due to their superior durability. Their heat and pressure resistance, combined with the ability to withstand abrasion and maintain fuel flow, ensures a reliable and consistent fuel supply. This makes them a popular choice among enthusiasts and professionals who demand the highest performance and longevity from their vehicle's fuel system.

Fuel Line Experts: Who Can Fix Your 1998 F150?

You may want to see also

Flexibility: The flexible design of Cooper lines allows for easy installation and adjustment in tight spaces

The flexibility of Cooper fuel lines is a significant advantage, especially when dealing with air-cooled engines, where space constraints can be a challenge. This feature allows for a more adaptable and user-friendly installation process, ensuring that the fuel lines can be maneuvered and positioned with ease.

In many air-cooled engine setups, the available space for fuel lines is limited due to the engine's compact design and the presence of other components. The flexibility of Cooper lines enables technicians and mechanics to navigate around these obstacles effortlessly. This is particularly useful when connecting the fuel lines to the fuel pump, injectors, or other engine components, as it allows for precise and tailored routing.

During the installation process, the ability to bend and adjust the fuel lines is crucial. This flexibility ensures that the lines can be tailored to fit the specific layout of the engine bay, accommodating any unique or challenging angles and curves. By doing so, the risk of damage to the fuel lines during installation is reduced, and the overall efficiency of the process is improved.

Moreover, the flexible nature of Cooper fuel lines also comes into play during maintenance and repairs. When an engine requires servicing, the flexible lines can be easily manipulated to access hard-to-reach areas. This accessibility simplifies the task of replacing or repairing damaged fuel lines, ensuring that the engine's performance and reliability are maintained.

In summary, the flexibility of Cooper fuel lines is a key factor in their suitability for air-cooled engines. It simplifies the installation process, allowing for easy maneuvering in tight spaces, and ensures that the fuel lines can be customized to fit the engine's unique layout. This feature also contributes to efficient maintenance, making Cooper fuel lines an excellent choice for those working with air-cooled engine systems.

Understanding the Dual Fuel Lines in Your Chainsaw: A Guide

You may want to see also

Heat Resistance: They can withstand high temperatures, ensuring optimal engine operation even in extreme conditions

Cooper fuel lines are renowned for their exceptional heat resistance, a feature that significantly contributes to their superiority over other fuel lines, especially in air-cooled engine applications. This heat resistance is a critical aspect of their performance, ensuring that the fuel lines can handle the extreme temperatures encountered in such engines without compromising their integrity.

The ability to withstand high temperatures is a direct result of the materials used in the construction of Cooper fuel lines. These lines are typically made from high-quality, heat-resistant materials such as stainless steel or specialized polymers. The choice of material is crucial as it determines the line's ability to resist degradation and maintain its structural integrity under intense thermal conditions. For instance, stainless steel offers excellent corrosion resistance and can endure extreme temperatures, making it an ideal choice for fuel lines in air-cooled engines.

In air-cooled engines, where the engine block and other components are exposed to the air, temperatures can fluctuate rapidly and reach very high levels. Cooper fuel lines are designed to operate optimally in these conditions, ensuring that the fuel delivery system remains efficient and reliable. This is particularly important as it helps prevent fuel leaks, which can be a significant issue in high-temperature environments. The heat resistance of these fuel lines also contributes to the overall longevity of the engine, as it reduces the risk of fuel system failures due to thermal stress.

Furthermore, the heat resistance of Cooper fuel lines is not just about withstanding high temperatures but also about maintaining performance over a wide temperature range. This means that the fuel lines can handle not only the extreme heat but also the rapid temperature changes that occur during engine operation. This versatility ensures that the fuel lines remain effective and reliable, even when the engine is subjected to varying environmental conditions.

In summary, the heat resistance of Cooper fuel lines is a key factor in their effectiveness, especially in air-cooled engine applications. This feature ensures that the fuel lines can operate optimally in extreme temperatures, contributing to improved engine performance, reliability, and longevity. By choosing Cooper fuel lines, engine enthusiasts can benefit from a fuel delivery system that is both robust and efficient, even in the most challenging thermal environments.

Honda Foreman 450 Fuel Line: Size and Compatibility Guide

You may want to see also

Compatibility: Cooper fuel lines are compatible with various air-cooled engine models, providing a versatile solution

Cooper fuel lines are renowned for their compatibility with a wide range of air-cooled engines, making them a versatile and reliable choice for vehicle owners and enthusiasts. This compatibility is a significant advantage, as it ensures that these fuel lines can be used across different engine models and applications, offering a one-size-fits-most solution. Whether you're working on a classic car, a vintage motorcycle, or a modern air-cooled engine, Cooper fuel lines are designed to seamlessly integrate and provide optimal performance.

The compatibility of Cooper fuel lines is achieved through their construction and material selection. These fuel lines are typically made from high-quality materials such as rubber or synthetic compounds, which offer excellent flexibility and durability. This flexibility is crucial for air-cooled engines, as it allows the fuel lines to accommodate the engine's natural movement and vibrations during operation. The material's resistance to heat and fuel degradation ensures long-lasting performance, even in demanding environments.

In terms of engine models, Cooper fuel lines are compatible with various air-cooled engines, including those found in classic cars like the Volkswagen Beetle, Porsche 911, and classic American muscle cars. They are also suitable for motorcycles, such as the iconic Harley-Davidson models and vintage British motorcycles. Additionally, these fuel lines can be used in modern applications, such as air-cooled generators, water pumps, and even some marine engines. The versatility extends to different fuel types, including gasoline, diesel, and even ethanol blends, making them adaptable to various fuel systems.

The compatibility of Cooper fuel lines is further enhanced by their design and construction. These fuel lines often feature a braided or reinforced structure, providing additional strength and flexibility. The braiding helps to prevent kinking and ensures a smooth flow of fuel, which is essential for optimal engine performance. Moreover, the lines may have a protective outer covering to shield against heat, UV radiation, and other environmental factors, ensuring their longevity.

By choosing Cooper fuel lines, vehicle owners and enthusiasts can benefit from a reliable and versatile solution for their air-cooled engines. The compatibility with various models and fuel types simplifies the installation process and ensures a consistent performance level. This compatibility is a key factor in the popularity of Cooper fuel lines, as it caters to a broad range of applications, making them a go-to choice for anyone seeking to upgrade or maintain their air-cooled vehicle's fuel system.

Fuel Return Line: Uncovering the Mystery of the 2000 Model

You may want to see also

Frequently asked questions

Cooper fuel lines are a type of fuel delivery system component designed for air-cooled engines. They are known for their durability and resistance to fuel degradation, making them a popular choice for classic car enthusiasts and restorers.

Cooper fuel lines are specifically engineered to handle the unique challenges of air-cooled engines. They offer improved fuel flow, reduced pressure drop, and enhanced heat resistance, ensuring a reliable and efficient fuel supply to the engine.

While Cooper fuel lines are versatile and widely used, compatibility may vary depending on the specific engine model and year. It is recommended to consult the manufacturer's guidelines or seek expert advice to ensure proper fitment.

Regular maintenance is essential to keep Cooper fuel lines in optimal condition. This includes checking for leaks, inspecting the lines for damage, and ensuring proper fuel filtration. Proper care will help extend the lifespan of the fuel lines and maintain engine performance.

Yes, Cooper fuel lines can be a valuable upgrade for modern engines, especially those with air-cooling systems. They can improve fuel efficiency, enhance engine performance, and provide a more reliable fuel supply, making them a popular choice for performance enthusiasts.