When it comes to dirt bikes, one crucial aspect of maintenance is ensuring the proper attachment of the fuel line to the carburetor. This process might seem straightforward, but it's essential to get it right to avoid any performance issues or even engine damage. In this guide, we'll explore the steps involved in attaching the fuel line to the carburetor on a dirt bike, providing a comprehensive overview for both beginners and experienced riders.

What You'll Learn

- Carburetor Location: Identify the carb's position on the bike for fuel line attachment

- Hose Routing: Plan the path of the fuel line to avoid interference

- Clamps and Fittings: Use appropriate clamps and fittings for a secure connection

- Fuel Filter: Consider the placement of a fuel filter for optimal performance

- Engine Mounting: Ensure the fuel line doesn't interfere with engine components

Carburetor Location: Identify the carb's position on the bike for fuel line attachment

When it comes to attaching a fuel line to the carburetor on a dirtbike, the first crucial step is to locate the carburetor itself. The carburetor is a vital component of the bike's fuel system, responsible for mixing air and fuel and delivering it to the engine. Its position can vary depending on the make and model of the dirtbike, but it is typically found near the engine's center.

To identify the carburetor's location, start by examining the engine compartment. Look for a cylindrical or rectangular component that is usually positioned close to the engine block. It might be mounted vertically or horizontally, depending on the bike's design. The carburetor often has a distinct appearance, with a series of openings and a throttle body attached.

Once you've located the carburetor, you'll need to determine the best spot to attach the fuel line. The fuel line is a flexible tube that connects the fuel source (usually a tank) to the carburetor. It should be routed in a way that ensures a secure and efficient connection. Typically, the fuel line is attached to a small opening or port on the carburetor, often referred to as the 'fuel inlet' or 'carburetor inlet'. This port is specifically designed to allow fuel to enter the carburetor and is usually located near the throttle body.

The position of this inlet can vary, but it is often found on the side or top of the carburetor. It might be a small opening with a screw or clamp to secure the fuel line. When attaching the fuel line, ensure that it is routed away from any moving parts to prevent damage and maintain a secure connection.

Remember, proper carburetor location knowledge is essential for a successful fuel line attachment. Take your time to inspect the bike and locate the carburetor before proceeding with the installation process. This detailed approach will ensure a smooth and efficient fuel delivery system for your dirtbike.

Fads' Fuel Line: Unveiling the Secret to Their Success

You may want to see also

Hose Routing: Plan the path of the fuel line to avoid interference

When it comes to routing the fuel line on a dirtbike with a carburetor, careful planning is essential to ensure optimal performance and reliability. The primary goal is to avoid any interference with other components, especially moving parts, to prevent potential damage or performance issues. Here's a detailed guide on how to approach hose routing:

Assess the Layout: Begin by thoroughly examining the engine bay and the layout of your dirtbike. Identify the various components, including the carburetor, fuel tank, engine block, and any other nearby parts. Understanding the physical arrangement will help you determine the best route for the fuel line. Look for any potential obstacles or areas where the hose might get pinched or damaged.

Minimize bends: Fuel lines should be routed in a straight line as much as possible. Excessive bending can lead to kinks and restrict fuel flow. Aim to keep the hose straight, especially in areas where it passes over or under other components. You can use flexible fuel line kits that come with pre-formed loops and bends to make the installation easier and more efficient.

Avoid high-stress areas: The fuel line should be routed away from areas with high vibration or movement. For instance, it should not run alongside the exhaust pipe, as the heat and vibrations can cause damage over time. Similarly, avoid routing the hose near the kickstand or any other part that might come into contact with the ground during riding. These high-stress areas can lead to premature wear and potential fuel leaks.

Use appropriate attachments: Ensure that the fuel line is securely attached to the carburetor and the fuel tank. Use appropriate fittings and clamps to prevent the hose from coming loose. The attachment points should be sturdy and able to withstand the vibrations and movements of the bike. Consider using rubber or plastic hose clips that provide a snug fit without causing damage to the hose or surrounding components.

Consider the fuel pump: If your dirtbike is equipped with a fuel pump, it's crucial to route the fuel line accordingly. The pump should be positioned to ensure a consistent and steady supply of fuel to the carburetor. Avoid placing the pump in a location that might get clogged or damaged by dirt and debris. Proper routing of the fuel line will ensure efficient operation and longevity of the fuel pump system.

By carefully planning the hose routing, you can ensure that the fuel line on your dirtbike's carburetor is secure, well-protected, and free from interference. This attention to detail will contribute to a reliable and high-performing engine, allowing you to focus on the thrill of the ride.

Suzuki Eiger Fuel Line: Size and Compatibility Guide

You may want to see also

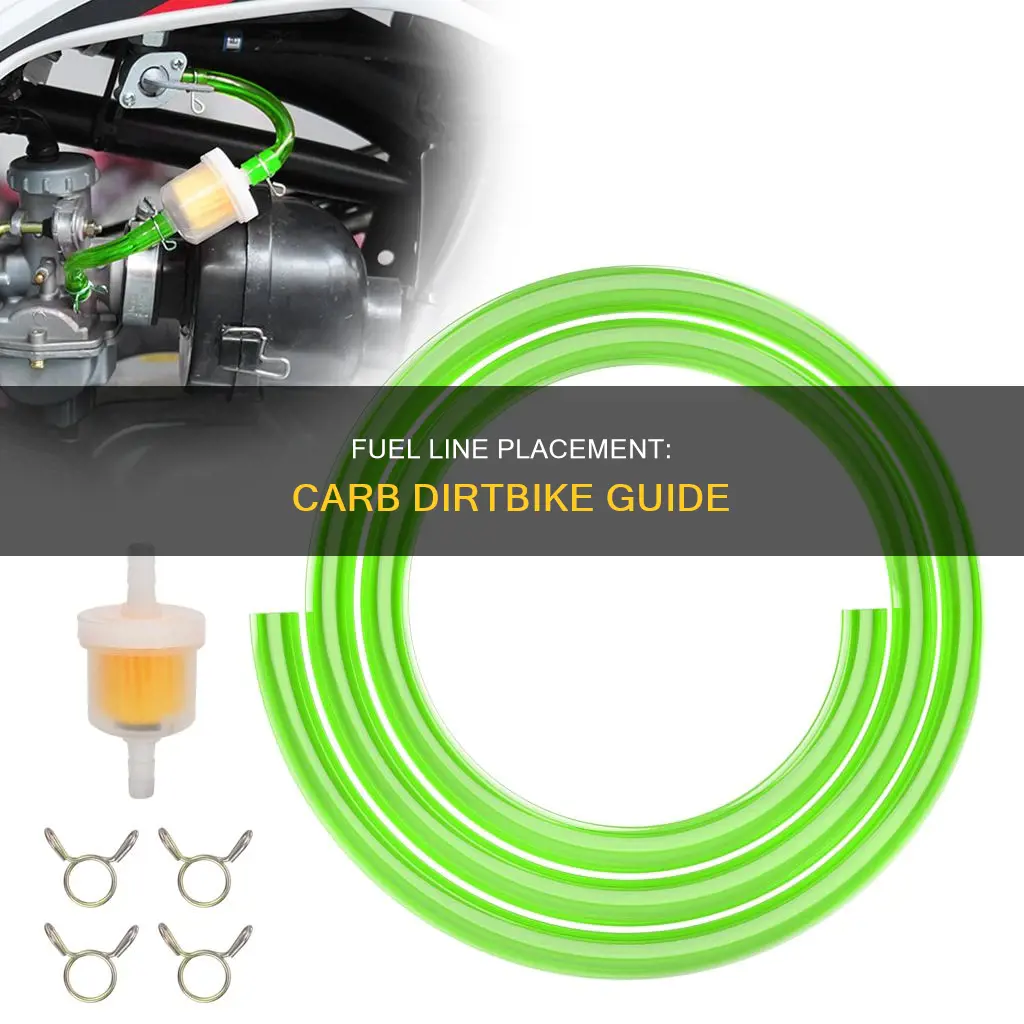

Clamps and Fittings: Use appropriate clamps and fittings for a secure connection

When it comes to attaching a fuel line to a carburetor on a dirtbike, using the right clamps and fittings is crucial for a secure and reliable connection. The primary goal is to ensure that the fuel line is tightly held in place, preventing any leaks or disconnections during the ride. Here's a detailed guide on how to achieve this:

Choose the Right Clamps: Select a clamp that is specifically designed for fuel lines and can provide a tight grip. The most common type of clamp used for this purpose is the "fuel line clamp" or "fuel line tie." These clamps are typically made of durable materials like stainless steel or aluminum, ensuring they can withstand the vibrations and harsh conditions of off-road riding. Look for clamps with a smooth interior surface to avoid damaging the fuel line.

Size and Fit: Ensure that the chosen clamp is the appropriate size for your fuel line diameter. Fuel lines come in various sizes, and using a clamp that is too small may not provide adequate security, while a larger one might restrict the flow of fuel. Measure the fuel line and select a clamp that offers a snug fit. Most fuel line clamps have adjustable screws or nuts to customize the grip, allowing you to fine-tune the connection.

Installation Process: Start by cleaning the fuel line and the carburetor area to ensure a proper connection. Then, slide the fuel line through the appropriate hole or opening in the carburetor. Position the clamp over the fuel line, ensuring it covers the entire length of the connection. Tighten the clamp securely using the provided screws or nuts, being careful not to overtighten, as it may damage the fuel line. A good rule of thumb is to apply firm pressure, but only until the clamp is snug.

Consider Fittings: In some cases, you might need to use fittings, especially if the fuel line needs to make a turn or if there are specific requirements for the connection. Fittings can provide additional support and flexibility. For example, a 90-degree elbow fitting can be used to change the direction of the fuel line, while a tee fitting can be used to split the line into multiple branches. Ensure that the fittings are compatible with your fuel line material and choose high-quality fittings to avoid leaks.

Regular Inspection: Even with the right clamps and fittings, it's essential to inspect the fuel line connection regularly. Over time, clamps can loosen due to vibrations, and fuel lines may develop small leaks. Periodically check for any signs of damage, corrosion, or wear, and replace the clamps or fittings if necessary. This proactive approach will help maintain a reliable fuel supply to your dirtbike's carburetor.

Fuel Line Freeze: Causes, Symptoms, and Solutions

You may want to see also

Fuel Filter: Consider the placement of a fuel filter for optimal performance

When it comes to optimizing the performance of your dirtbike's carbureted engine, one crucial aspect often overlooked is the placement of the fuel filter. The fuel filter plays a vital role in ensuring that your engine receives clean and unrestricted fuel, which directly impacts its overall performance and longevity. Here's a detailed guide on why and how to consider the placement of a fuel filter for optimal results.

The primary function of a fuel filter is to remove contaminants from the fuel before it reaches the carburetor. Over time, fuel can accumulate impurities such as water, sediment, and debris, which can lead to engine issues. By installing a fuel filter, you create a barrier that traps these contaminants, ensuring that only clean fuel enters the carburetor. This is especially important in dirt bikes, where the engine is exposed to various environmental conditions and can be susceptible to fuel-related problems.

Now, let's discuss the optimal placement of the fuel filter. The ideal location for the fuel filter is close to the fuel tank and before the fuel line connects to the carburetor. Placing the filter in this position allows for efficient filtration of the fuel as it exits the tank. It also ensures that the filter is easily accessible for maintenance and replacement. Regularly checking and replacing the fuel filter is essential to maintain its effectiveness, especially in high-mileage or frequently used bikes.

When installing the fuel filter, ensure that the fuel line is securely attached to both the filter and the carburetor. A tight connection is crucial to prevent fuel leaks and maintain optimal pressure. Consider using fuel line connectors that are compatible with your bike's specifications to ensure a reliable seal. Additionally, check for any potential obstructions or kinks in the fuel line that could affect flow and performance.

In summary, the placement of the fuel filter is a critical consideration for dirt bike enthusiasts aiming to optimize their carbureted engine's performance. By placing the filter close to the fuel tank and before the carburetor, you create an efficient filtration system. Regular maintenance, including checking and replacing the filter, ensures that your engine receives clean fuel, resulting in improved performance and a longer-lasting engine. Remember, a well-placed and maintained fuel filter is an essential component in the overall care of your dirt bike.

The Ultimate Guide to Lubricating Fuel Line O-Rings

You may want to see also

Engine Mounting: Ensure the fuel line doesn't interfere with engine components

When it comes to engine mounting and fuel line placement on a dirtbike with a carburetor, it's crucial to consider the engine's layout and the potential interference that a fuel line could cause. The primary goal is to ensure the fuel line doesn't impede the engine's performance or compromise its integrity. Here's a detailed guide on how to approach this:

Understanding the Engine's Anatomy: Before making any modifications or attachments, familiarize yourself with the dirtbike's engine. Different models may vary, but typically, a dirtbike's engine has various components like the cylinder, head, and various valves. The fuel line should be positioned in a way that avoids direct contact with these critical parts. For instance, it should not run alongside the cylinder or directly above the engine's hot components to prevent potential damage or fuel leaks.

Mounting the Fuel Line: The ideal placement for the fuel line is often along the side of the engine, away from the main components. This position allows for easy access and ensures that the line doesn't interfere with the engine's operation. You can secure the fuel line using rubber or plastic mounts to prevent it from chafing against the engine casing. These mounts should be positioned at regular intervals to provide support and maintain the line's shape.

Avoiding Interference: One of the critical aspects of engine mounting is ensuring the fuel line doesn't interfere with the engine's moving parts. This includes the camshaft, valves, and any other components that move during operation. If the fuel line is too close to these parts, it could cause damage or even lead to a malfunction. Consider the engine's manual for specific clearance requirements to ensure the fuel line is mounted at the appropriate distance.

Flexibility and Routing: When routing the fuel line, allow for some flexibility to accommodate the engine's movement. This is especially important for dirtbikes that experience a lot of vibration during operation. The line should be routed in a way that it doesn't kink or twist, as this can restrict fuel flow and potentially cause issues. Keep the line as straight as possible while maintaining its flexibility.

Regular Inspection: After mounting the fuel line, it's essential to perform regular inspections to ensure its condition and positioning. Check for any signs of damage, such as cracks or leaks, and address any issues promptly. Additionally, inspect the line's mounting points to ensure they remain secure and intact over time.

By following these guidelines, you can ensure that the fuel line is properly mounted and positioned, allowing for optimal engine performance while minimizing the risk of interference with critical engine components.

Understanding Fuel Line Connector Numbers: A Comprehensive Guide

You may want to see also

Frequently asked questions

The fuel line should be attached to the carburetor's float bowl or the carburetor body. It is important to ensure a secure and tight connection to prevent fuel leaks.

It is recommended to use a fuel line specifically designed for motorcycles or ATVs. These lines are typically made of durable materials like rubber or vinyl and are compatible with gasoline. Avoid using garden hoses or other non-approved lines as they may not withstand the heat and pressure of the fuel system.

Start by cleaning the carburetor and fuel line to remove any dirt or debris. Then, slide the fuel line over the carburetor's fuel inlet, ensuring it is the correct size. Secure the line with a clamp or a fuel line fitting to keep it in place. Make sure there are no kinks or twists in the line during the installation.

If you notice any fuel leaking from the connection, immediately disconnect the line and inspect for damage or loose fittings. Clean the affected areas and reattach the fuel line securely. It is crucial to address leaks promptly to avoid potential engine issues.

You will need basic tools like a fuel line cutter, hose clamps, and a cleaning brush. A fuel line key or a similar tool can help you tighten the connections properly. Having these tools readily available will make the installation process smoother.