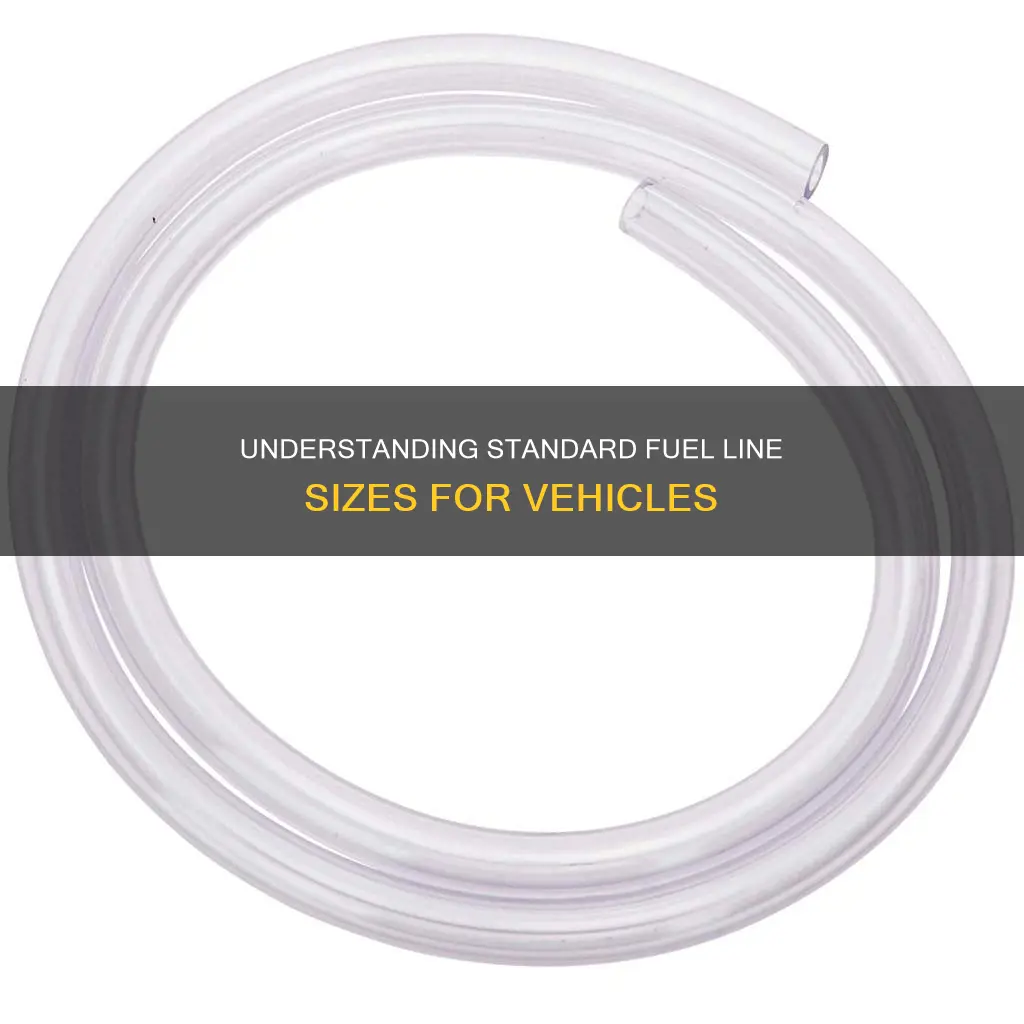

Understanding the size of a fuel line is crucial for ensuring optimal performance and safety in any vehicle. The diameter of a fuel line can vary depending on several factors, including the vehicle's make and model, engine requirements, and fuel delivery system. Typically, standard fuel lines range from 3/8 inch to 1/2 inch in diameter, with 1/4 inch being a common size for smaller engines. These dimensions are designed to handle the flow rate and pressure of the fuel required for efficient combustion. However, larger engines or high-performance vehicles may require larger fuel lines, often up to 3/4 inch in diameter, to accommodate increased fuel demands. Knowing the appropriate fuel line size is essential for proper fuel delivery, preventing engine issues, and maintaining the overall health of the vehicle's fuel system.

What You'll Learn

- Fuel Line Diameter: Standard fuel lines range from 3/8 to 1/2 in diameter

- Length Considerations: Fuel lines are typically 1-2 feet long, depending on vehicle type

- Material Choices: Common materials include steel, rubber, and plastic

- Pressure Ratings: Fuel lines must withstand fuel pressure, usually up to 100 psi

- Compatibility: Ensure fuel line size matches engine requirements and fuel pump specifications

Fuel Line Diameter: Standard fuel lines range from 3/8 to 1/2 in diameter

When it comes to fuel lines in vehicles, the diameter plays a crucial role in determining the efficiency and safety of the fuel delivery system. The standard fuel line diameter typically ranges from 3/8 to 1/2 inch, which is an important consideration for vehicle owners and mechanics alike. This range is designed to balance the need for adequate fuel flow with the constraints of space and weight in a vehicle's engine bay.

A fuel line with a diameter of 3/8 inch is often used in smaller vehicles or those with less demanding fuel requirements. This smaller diameter allows for more compact installation, making it suitable for engines with limited space. However, it's important to note that a 3/8-inch line may not provide the same level of performance as larger diameters, especially in high-performance or high-output applications.

As we move up to a 1/2-inch diameter, the fuel line becomes more robust and capable of handling higher fuel flow rates. This larger diameter is commonly found in larger vehicles, trucks, or those equipped with high-performance engines. The increased size reduces the risk of fuel pressure drop, ensuring a steady and efficient supply of fuel to the engine. It also provides better resistance to fuel line wear and tear, especially in high-temperature environments.

The choice of fuel line diameter is not arbitrary; it is a critical decision that impacts the overall performance and reliability of a vehicle's fuel system. A well-designed fuel line system should consider factors such as engine power, fuel type, and environmental conditions to ensure optimal performance. For instance, high-performance vehicles often require larger fuel lines to accommodate the increased fuel demands of powerful engines.

In summary, the standard fuel line diameter of 3/8 to 1/2 inch is a common specification, offering a balance between space efficiency and performance. Understanding this range is essential for vehicle owners and mechanics when selecting and installing fuel lines to ensure the vehicle's fuel system operates optimally and safely.

Understanding 3/8 Fuel Line Dimensions: Inside Diameter Explained

You may want to see also

Length Considerations: Fuel lines are typically 1-2 feet long, depending on vehicle type

When it comes to fuel lines, length is a critical factor to consider, especially when it comes to vehicle performance and safety. The standard length of a fuel line can vary depending on the type of vehicle and its specific requirements. Typically, fuel lines are designed to be around 1 to 2 feet long, which might seem short, but it's an essential component of the fuel delivery system. This length is crucial to ensure efficient and safe fuel transfer from the fuel tank to the engine.

In most cases, the fuel line's length is determined by the vehicle's engine configuration and the position of the fuel tank. For instance, in front-engine vehicles, the fuel line is usually shorter, as the tank is often located in the front or behind the engine compartment. On the other hand, rear-engine vehicles may require longer fuel lines to accommodate the distance between the tank and the engine. This length consideration is vital to prevent fuel line damage, ensure proper fuel pressure, and maintain overall vehicle performance.

The 1-2 feet length is a general guideline, and it can vary based on the vehicle's make and model. For example, classic cars or older vehicles might have shorter fuel lines due to their design and engine placement. In contrast, modern vehicles, especially those with larger engines, may require longer lines to meet the fuel delivery demands. It's essential for mechanics and car enthusiasts to be aware of these length considerations to ensure proper installation and maintenance.

During fuel line installation, it's crucial to route the line correctly to avoid any obstructions or damage. The line should be positioned away from heat sources, sharp edges, or components that could cause wear and tear. Proper routing ensures that the fuel line remains flexible and doesn't restrict fuel flow. Additionally, the line's length should be sufficient to allow for easy access during maintenance or repairs, ensuring that the fuel system remains reliable over time.

Understanding the typical length of fuel lines is essential for anyone working on vehicle fuel systems. It ensures that the right-sized components are used, promoting optimal performance and safety. Whether it's a routine maintenance task or a custom fuel system installation, knowing the standard length provides a solid foundation for successful execution.

Mastering Fuel Line Clamps: A Comprehensive Guide to Installation and Maintenance

You may want to see also

Material Choices: Common materials include steel, rubber, and plastic

When it comes to fuel lines, the choice of material is crucial for ensuring optimal performance and longevity. Common materials used for fuel lines include steel, rubber, and plastic, each offering distinct advantages and disadvantages.

Steel: This is a robust and durable material, often used in high-pressure applications. Steel fuel lines are known for their strength and ability to withstand extreme temperatures. They are less flexible compared to rubber or plastic, which can make installation more challenging. However, steel is highly resistant to corrosion and can handle aggressive chemicals, making it ideal for use with high-octane fuels. Its rigidity also ensures that the fuel line maintains its shape, reducing the risk of leaks or damage over time.

Rubber: Rubber fuel lines are a popular choice due to their flexibility and ease of installation. They can accommodate slight movements and vibrations, making them suitable for various vehicle types. Rubber is also resistant to most fuels and chemicals, ensuring a long-lasting seal. The flexibility of rubber allows for a more customized fit, reducing the chances of fuel line damage during vehicle operation. However, rubber can be more susceptible to cracking over time, especially in harsh environments or with certain fuel types.

Plastic: Plastic fuel lines are lightweight and offer good flexibility, making them easy to route and install. They are often used in modern vehicles due to their cost-effectiveness and ease of manufacturing. Plastic is generally resistant to most fuels and chemicals, but it may not be as durable as steel or rubber. Plastic fuel lines are less likely to corrode, making them a suitable choice for vehicles with fuel systems that require low maintenance. However, they might not be as strong as metal options, and extreme temperatures can affect their performance.

The choice between these materials depends on the specific requirements of the fuel system, including the type of vehicle, fuel usage, and environmental conditions. Each material has its own set of advantages and trade-offs, and understanding these can help ensure the right fuel line material is selected for optimal performance and longevity.

Turbo LS Fuel Line Sizing: Expert Guide for Optimal Performance

You may want to see also

Pressure Ratings: Fuel lines must withstand fuel pressure, usually up to 100 psi

When it comes to fuel lines, one of the critical factors to consider is their pressure ratings. Fuel lines are designed to transport fuel from the tank to the engine, and they must be able to withstand the pressure generated by the fuel as it flows through the system. This is especially important in high-performance vehicles or those with larger fuel tanks, where the pressure can be significantly higher.

The pressure rating of a fuel line is typically measured in pounds per square inch (psi). Most fuel lines are designed to handle a maximum pressure of around 100 psi. This is a standard pressure rating that ensures the fuel lines can safely and efficiently deliver fuel to the engine without any issues. It's important to note that this pressure rating is a general guideline, and specific vehicle requirements may vary.

To ensure that the fuel lines can handle the pressure, manufacturers often use materials with high tensile strength and flexibility. These materials can withstand the force exerted by the fuel pressure without compromising the integrity of the line. Common materials used for fuel lines include steel, aluminum, and various types of rubber or synthetic compounds. The choice of material depends on factors such as temperature resistance, flexibility, and cost.

In high-performance applications, where fuel pressure can exceed 100 psi, specialized fuel lines with higher pressure ratings are required. These lines are designed to handle the increased stress and are often made from more robust materials. It's crucial to select fuel lines with the appropriate pressure rating to prevent fuel leaks, engine damage, or even dangerous situations.

Additionally, fuel lines should be properly secured and routed to avoid excessive stress or damage. They should be installed with enough slack to allow for engine movement and temperature changes. Regular inspections and maintenance are essential to ensure that the fuel lines remain in good condition and continue to meet the required pressure ratings.

Sealing Fuel Lines: Is Seal Tape the Answer?

You may want to see also

Compatibility: Ensure fuel line size matches engine requirements and fuel pump specifications

When it comes to fuel lines, compatibility is key to ensuring optimal performance and safety. The size of a fuel line is a critical factor that directly impacts the efficiency and reliability of your engine's fuel delivery system. It's essential to understand that the fuel line's diameter and length must be carefully matched to the specific requirements of your engine and fuel pump.

Engine manufacturers design their engines with particular fuel line specifications in mind. These specifications include the required fuel line diameter, which is typically measured in inches or millimeters. For instance, a common fuel line size for many automotive applications is 3/8 inches in diameter. This size ensures a smooth and efficient flow of fuel from the tank to the engine, providing the necessary power and performance. However, it's crucial to consult your engine's manual or manufacturer guidelines to determine the exact fuel line dimensions that are compatible with your specific model.

The fuel pump also plays a significant role in this compatibility. The pump's output capacity and design should be considered when selecting a fuel line. If the fuel line is too small, it may restrict the flow, leading to reduced engine performance and potential fuel starvation. Conversely, an oversized fuel line might cause excessive fuel flow, resulting in wasted fuel and potential engine damage. Therefore, it is imperative to choose a fuel line that matches the pump's specifications, ensuring a balanced and efficient fuel delivery system.

To ensure compatibility, it's recommended to consult the vehicle's manual or seek professional advice. These sources will provide detailed information on the engine's fuel system requirements, including the appropriate fuel line size. Additionally, considering the material of the fuel line is essential. Common materials include rubber, vinyl, and braided steel, each offering different advantages in terms of flexibility, durability, and resistance to fuel degradation.

In summary, when dealing with fuel lines, compatibility is paramount. Matching the fuel line size to the engine's and fuel pump's specifications is crucial for optimal performance and safety. By carefully considering the engine's requirements and seeking the right advice, you can ensure a well-functioning fuel system, providing reliable power to your vehicle's engine.

Spray Test: A Simple Way to Check Fuel Line Leaks

You may want to see also

Frequently asked questions

The standard fuel line diameter for cars varies depending on the vehicle's make and model, but it generally ranges from 3/8 inch to 1/2 inch. This size ensures efficient fuel delivery while maintaining flexibility and durability.

While using a larger fuel line might seem like an upgrade, it is not always recommended. The engine's fuel system is designed with specific line sizes to optimize performance and fuel efficiency. Using a larger line can lead to increased pressure, potential fuel spillage, and may even cause engine issues. It's best to consult the vehicle's manual or seek professional advice for any modifications.

The appropriate fuel line size can be found in the vehicle's service manual or specifications sheet. These resources provide detailed information about the recommended fuel line dimensions for your specific car model. If you're unsure, consulting a mechanic or a trusted automotive expert is advisable to ensure you choose the right size for your engine's needs.