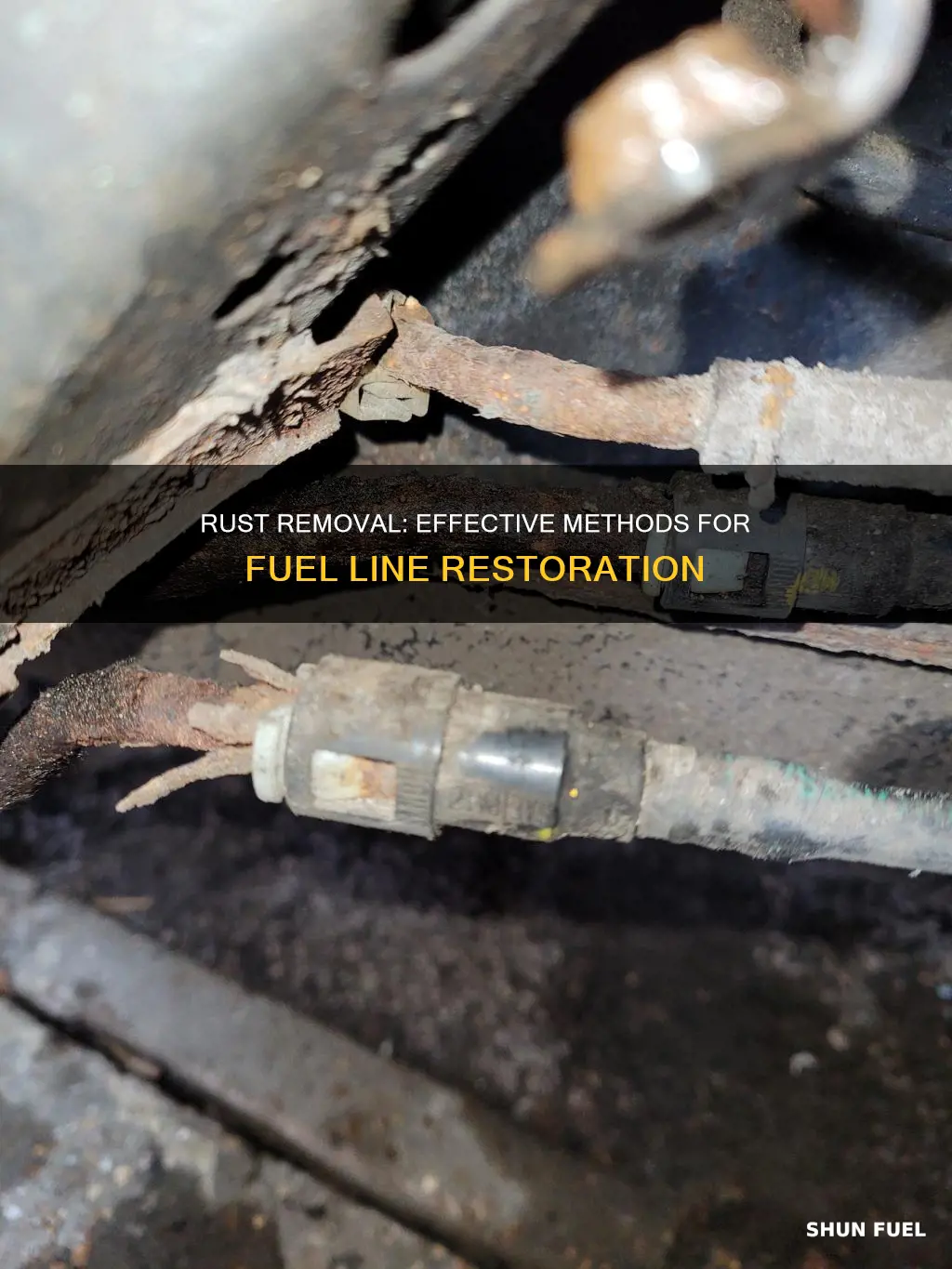

Rust in fuel lines can be a common issue for vehicle owners, especially those with older cars. It can lead to reduced fuel efficiency, engine performance issues, and even potential damage to the engine over time. Dissolving rust in fuel lines is a process that requires careful consideration and the right approach to ensure the safety and longevity of the vehicle. This guide will provide a step-by-step approach to effectively remove rust from fuel lines, including the use of appropriate chemicals and methods to restore the fuel system's functionality.

What You'll Learn

- Chemical Solutions: Use acid-based cleaners or rust inhibitors to dissolve rust

- Mechanical Cleaning: Scrub and sand the fuel line to remove rust deposits

- Heat Application: Apply heat to the fuel line to soften and remove rust

- Pressure Washing: High-pressure water can force rust out of the fuel line

- Replacement: If rust damage is extensive, consider replacing the affected fuel line

Chemical Solutions: Use acid-based cleaners or rust inhibitors to dissolve rust

When dealing with rust in fuel lines, chemical solutions can be an effective method to dissolve and remove the corrosion. Acid-based cleaners are particularly useful as they can break down the rust and restore the integrity of the fuel line. Here's a step-by-step guide on how to use these chemical solutions:

Preparation and Safety: Before beginning, ensure you have the necessary safety gear, including gloves, goggles, and a respirator to protect yourself from any fumes. It is crucial to work in a well-ventilated area or outdoors to avoid inhaling harmful chemicals. Gather the required materials, including the acid-based cleaner, a suitable container, and a tool for applying the solution, such as a spray bottle or a brush.

Application Process: Start by flushing the fuel line with a mild acid-based cleaner. You can use a commercial product specifically designed for this purpose, following the manufacturer's instructions. Alternatively, a diluted solution of sulfuric acid or hydrochloric acid can be prepared, ensuring it is mixed according to the recommended ratio. Apply the acid-based cleaner to the affected areas of the fuel line, allowing it to sit for a specified period, usually around 10-15 minutes. This contact time is essential for the chemical reaction to occur.

Dissolving Rust: After the specified time, use a brush or a similar tool to scrub the fuel line, removing any loose rust particles. The acid-based cleaner will have dissolved the rust, making it easier to clean. Rinse the fuel line thoroughly with clean water to remove any remaining acid and ensure no chemical residue is left behind.

Rust Inhibitors: To prevent future rust buildup, consider using rust inhibitors. These products create a protective layer on metal surfaces, inhibiting corrosion. Apply a rust inhibitor to the cleaned fuel line, following the product's instructions. This step is crucial for maintaining the fuel line's condition and preventing further rust formation.

Remember, when using chemical solutions, always follow safety guidelines and wear appropriate protective gear. It is recommended to test the solution on a small section of the fuel line first to ensure it doesn't cause any damage or adverse reactions. Proper ventilation and caution are key to a successful and safe process.

Mastering Rubber Fuel Line Measurement: A Comprehensive Guide

You may want to see also

Mechanical Cleaning: Scrub and sand the fuel line to remove rust deposits

Mechanical cleaning is a hands-on approach to tackling rust deposits in fuel lines, offering a physical method to remove the stubborn deposits. This process involves a systematic and thorough cleaning to ensure the fuel line is free from rust, which can cause significant issues if left untreated. Here's a step-by-step guide to effectively scrub and sand the fuel line:

Preparation: Before beginning, ensure you have the necessary tools and safety equipment. This includes gloves, safety goggles, and a respirator to protect yourself from any potential dust or fumes. You'll also need a suitable cleaning solvent, such as a strong acid or a specialized rust remover, and a source of power sandpaper or a small wire brush.

Disassembly: Start by carefully disconnecting the fuel line from the engine and any other connected components. This step requires caution to avoid any spills or damage. Once disconnected, you can begin the cleaning process.

Scrubbing: Use a wire brush or a small drill with a wire brush attachment to scrub the interior walls of the fuel line. Focus on areas where rust deposits are most likely to accumulate, such as bends, joints, and areas with previous damage. Apply firm pressure and move the brush in a circular motion to effectively remove the rust. Ensure you cover the entire length of the fuel line.

Sandpaper Technique: For a more precise and controlled cleaning, use fine-grit sandpaper. Wrap the sandpaper around a smooth, hard surface, such as a flat piece of wood, to create a cylindrical tool. Insert this into the fuel line and carefully rotate it, sanding the interior surface. This method allows for better access to narrow areas and provides a more even cleaning.

Rinse and Repeat: After scrubbing and sanding, rinse the fuel line thoroughly with clean water to remove any loose rust particles and cleaning agents. Repeat the scrubbing and sanding process if necessary, especially if significant rust buildup is present. This iterative process ensures a comprehensive clean.

Reassembly: Once the fuel line is clean, reassemble it carefully, ensuring all connections are secure. Test the fuel line for any leaks before reconnecting it to the engine.

Mechanical cleaning is a labor-intensive but effective method to dissolve and remove rust from fuel lines. It requires patience and a systematic approach, but the results can be highly satisfactory, ensuring the longevity and optimal performance of the fuel system.

Mastering the Art of Fuel Line Conversion: 5/16 to 3/8 Made Easy

You may want to see also

Heat Application: Apply heat to the fuel line to soften and remove rust

Applying heat to the fuel line is a common and effective method to dissolve rust and restore the line's functionality. This technique works by softening the rusted area, allowing it to be more easily removed. Here's a step-by-step guide on how to use heat for this purpose:

Preparation: Before you begin, ensure you have the necessary safety gear, including gloves and safety goggles, to protect yourself from any potential splashes or fumes. It's also advisable to wear old clothing that you don't mind getting stained. Gather the required tools, such as a heat gun or a torch, and a heat-resistant cloth or mat to place under the fuel line to prevent damage to surfaces.

Heat Application: Start by locating the section of the fuel line with the rusted area. Use the heat gun or torch to apply direct, controlled heat to the affected section. Hold the heat source a few inches away from the fuel line to avoid overheating and potential damage. Gradually increase the heat intensity, moving the heat source along the line in small sections. The heat will cause the rust to soften and become more pliable. Be cautious not to overheat the surrounding areas, as this could lead to damage.

Rust Removal: Once the rust has softened, use a wire brush or a rust removal tool to carefully scrub the area. This step helps to remove the loose rust particles. Ensure you work in a well-ventilated area or outdoors to avoid inhaling any rust dust. If the rust is particularly stubborn, you may need to reapply heat and repeat the scrubbing process until the rust is completely removed.

Cooling and Inspection: After removing the rust, allow the fuel line to cool down naturally. Avoid rapid cooling, as this can cause stress on the material. Once cooled, inspect the line for any remaining rust or damage. If any issues persist, repeat the heating and removal process until the line is clear of rust.

Prevention: To prevent future rust buildup, consider using a fuel line inhibitor or a protective coating. These products can be applied to the fuel line to create a barrier against moisture and corrosion. Regularly inspecting and maintaining your fuel line can also help identify and address any issues before they become major problems.

Ferrell An6 Fuel Line Placement: Expert Guide

You may want to see also

Pressure Washing: High-pressure water can force rust out of the fuel line

Pressure washing is an effective method to remove rust from fuel lines, especially when combined with other cleaning techniques. The high-pressure water jet can dislodge and flush out rust particles, providing a thorough cleaning. Here's a step-by-step guide on how to use pressure washing for this purpose:

Preparation: Before starting, ensure you have the necessary equipment, including a pressure washer, a suitable detergent or cleaning agent, and protective gear such as gloves and safety goggles. It is crucial to wear appropriate safety gear to protect yourself from any potential hazards.

Process: Begin by disconnecting the fuel line from the vehicle's fuel tank and any other connected components. This step is essential for safety and to prevent any accidental fuel spillage. Once disconnected, locate the fuel line and identify the areas affected by rust. Apply the detergent or cleaning agent to the fuel line, ensuring an even coverage. The detergent will help loosen and dissolve the rust. Then, activate the pressure washer and direct the high-pressure water stream onto the fuel line. Start from one end and work your way along the length, applying pressure to dislodge the rust. The high-pressure water will force the rust particles out of the line, carrying them away with the flow.

Rinsing and Inspection: After the pressure washing, thoroughly rinse the fuel line to remove any remaining detergent and loose rust particles. Ensure that all traces of cleaning agents are washed away to prevent any potential corrosion. Inspect the fuel line for any remaining rust or damage. If any issues are identified, consider further treatment or professional assistance.

Prevention and Maintenance: To prevent future rust buildup, consider using a fuel line protector or coating. This can be especially useful in areas with high humidity or salt in the air, as these conditions can accelerate rust formation. Regular maintenance and cleaning can also help identify and address any issues early on.

Remember, when dealing with fuel lines, it is crucial to follow safety protocols and seek professional advice if needed. Pressure washing is a powerful tool, but it should be used with caution to avoid any potential damage or hazards.

Mastering Fuel Line Sealing: The Ultimate Guide to Tube Nuts

You may want to see also

Replacement: If rust damage is extensive, consider replacing the affected fuel line

If you've identified significant rust damage in your fuel line, it's crucial to address the issue promptly to prevent further deterioration and potential engine problems. In such cases, replacement is often the most effective solution. Here's a step-by-step guide on how to approach this process:

Assess the Damage: Before proceeding with replacement, thoroughly inspect the fuel line to understand the extent of the rust. Look for any visible signs of corrosion, such as a reddish-brown color, pitting, or flaking. Also, check for any leaks or reduced fuel flow, as these could indicate severe damage.

Prepare the Necessary Tools and Materials: Replacing a fuel line requires a few essential tools and supplies. You'll need a new fuel line that is compatible with your vehicle's specifications, a fuel line cutter or a suitable cutting tool, a fuel line crimper or clamp, and a fuel filter (if needed). Ensure you have the correct measurements and type of fuel line to avoid compatibility issues.

Locate and Remove the Affected Fuel Line: Start by identifying the fuel line section that requires replacement. This often involves accessing the underbody of the vehicle, where the fuel lines are typically located. Carefully cut the damaged section of the fuel line, leaving enough length to connect the new line. Disconnect any clamps or fittings securing the old line.

Install the New Fuel Line: Begin by attaching the new fuel line to the fuel source, ensuring a secure connection. Use the appropriate tools to crimp or clamp the line to maintain a tight seal. Route the new line through the vehicle's frame, following the original path of the old line. Ensure it is securely fastened and protected from any potential damage.

Test and Verify: Once the new fuel line is installed, start the vehicle and check for any leaks or unusual noises. Verify that the fuel system is functioning correctly, including the fuel pump and injectors. It's essential to test the system to ensure there are no further issues before considering the replacement complete.

Remember, replacing a fuel line is a specialized task, and if you're unsure about any step, consulting a professional mechanic is advisable. Properly addressing extensive rust damage will help maintain the integrity of your fuel system and ensure optimal engine performance.

Can Brass Fittings Be Used with Propane Fuel Lines?

You may want to see also

Frequently asked questions

Rust in fuel lines can be a common issue, especially in older vehicles. To dissolve rust, you can use a fuel line cleaner or a mixture of white vinegar and water. Pour the solution into the fuel line and let it sit for a few minutes, then flush it out with clean water. Repeat this process a few times to ensure the rust is completely removed.

Yes, you can try using a mixture of baking soda and water. Create a paste by mixing baking soda with a small amount of water, then apply it to the rusted area. Let it sit for a while, and then scrub it gently with a brush. Rinse thoroughly with water to remove any residue.

It is recommended to use a fuel line cleaner specifically designed for this purpose. These products are typically safe for fuel lines and can effectively dissolve rust. Always follow the instructions on the product label and wear protective gear when handling chemicals. After using the cleaner, flush the line with clean fuel to remove any remaining debris.