Checking for a stuck fuel line on a riding lawn mower is a crucial step in maintaining the engine's performance and preventing potential issues. A stuck fuel line can lead to fuel starvation, causing the engine to stall or run poorly. This guide will provide a step-by-step process to inspect and address this problem, ensuring your lawn mower operates efficiently and reliably. By following these instructions, you can quickly identify and resolve the issue, saving time and effort in maintaining your lawn care equipment.

What You'll Learn

- Visual Inspection: Check for blockages, kinks, or bends in the fuel line

- Fuel Flow Test: Use a fuel flow meter to measure pressure and flow rate

- Engine Performance: Observe engine behavior, such as stalling or erratic operation

- Fuel Pump Check: Inspect the pump for proper operation and debris

- Fuel Filter Replacement: Regularly replace filters to prevent clogs

Visual Inspection: Check for blockages, kinks, or bends in the fuel line

A visual inspection is a crucial step in identifying issues with your riding lawn mower's fuel line. It's a simple yet effective method to ensure your machine runs smoothly and efficiently. Here's a detailed guide on how to perform this inspection:

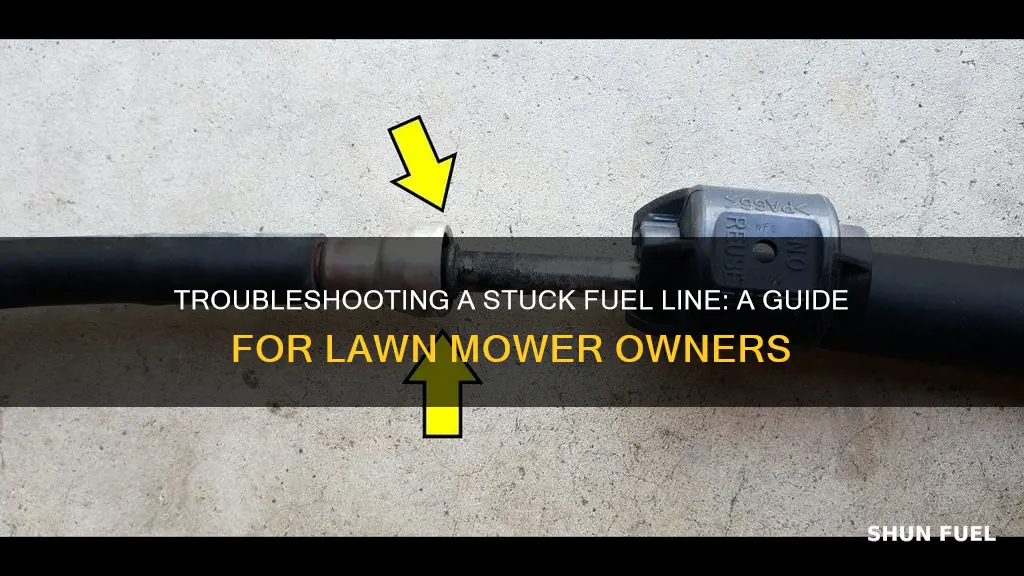

Start by locating the fuel line, which is typically a flexible tube that connects the fuel tank to the engine. It is often black or dark in color and can be found running along the frame of the mower. Carefully examine the fuel line for any visible signs of damage or obstruction. Look for blockages, which could be caused by dirt, debris, or even small objects that may have entered the line. Check for kinks or bends in the fuel line, as these can restrict fuel flow and potentially lead to starting issues. Ensure that the line is not pinched or compressed, as this can also cause problems.

Pay close attention to any visible wear and tear. Over time, the fuel line can deteriorate due to exposure to sunlight, heat, and chemicals in the fuel. Look for cracks, splits, or signs of corrosion. If you notice any damage, it's essential to replace the fuel line to prevent further issues. Additionally, inspect the connections between the fuel line and the fuel tank and engine. Ensure they are secure and free from any leaks or corrosion.

During your visual inspection, also check for any signs of fuel contamination. This can occur if the fuel line is not properly sealed or if there are leaks in the system. Contaminated fuel can lead to engine performance issues and may require a fuel filter replacement.

Remember, a thorough visual inspection can help you identify potential problems early on, preventing costly repairs and ensuring your lawn mower operates optimally. If you notice any issues during this process, it's recommended to consult a professional or refer to your mower's manual for further guidance.

Is Aluminum Fuel Line Legal for NHRA Competition?

You may want to see also

Fuel Flow Test: Use a fuel flow meter to measure pressure and flow rate

A fuel flow test is a crucial diagnostic step when dealing with a riding lawn mower that may have a stuck fuel line. This test involves using a fuel flow meter to measure the pressure and flow rate of fuel as it passes through the system. Here's a detailed guide on how to perform this test:

Step 1: Prepare the Equipment

Before you begin, ensure you have the necessary tools and equipment. You'll need a fuel flow meter, which can be rented or purchased from hardware stores or online retailers. Make sure it is compatible with your lawn mower's fuel system. Additionally, have a fuel pump primer or a small hand pump to prime the fuel lines temporarily.

Step 2: Locate the Fuel Flow Meter

Identify the fuel lines on your lawn mower. The fuel flow meter will be connected to these lines. Typically, there will be a primary fuel line leading from the fuel tank to the engine and smaller lines branching off for various engine components. Locate the point where the fuel flow meter can be connected without disrupting the engine's operation.

Step 3: Prime the Fuel System

With the engine off, prime the fuel system to ensure a steady supply of fuel for the test. Use the fuel pump primer or hand pump to create a small amount of pressure in the fuel lines. This step is essential to ensure accurate measurements during the test.

Step 4: Connect the Fuel Flow Meter

Carefully connect the fuel flow meter to the fuel lines. Ensure a tight seal to prevent any fuel leaks. The meter will have indicators or displays to show the pressure and flow rate. Set the meter to the appropriate units (e.g., gallons per minute or liters per second) for your region.

Step 5: Start the Engine and Measure

Turn on the lawn mower's engine and allow it to idle. Observe the fuel flow meter's readings. A healthy fuel flow should show a steady pressure and flow rate. If the flow rate is significantly lower than expected, it may indicate a restriction or blockage in the fuel line, including a potential stuck fuel line.

Step 6: Interpret the Results

Compare the measured flow rate with the expected values for your specific lawn mower model. If the flow rate is significantly reduced, it could be a sign of a stuck fuel line or another issue within the fuel system. Take note of any unusual noises or behavior during the test, as these can provide additional clues.

Step 7: Further Investigation

If the fuel flow test reveals a low flow rate, further investigation is necessary. Check for any visible blockages or restrictions in the fuel lines. Inspect the fuel filter and ensure it is clean and free of debris. Consider consulting the lawn mower's manual or seeking professional advice to identify and resolve the issue.

Remember, this fuel flow test is a valuable tool for diagnosing fuel-related problems in riding lawn mowers. It provides a clear understanding of the fuel system's performance and can help pinpoint issues like stuck fuel lines, ensuring prompt and effective repairs.

Audi Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Engine Performance: Observe engine behavior, such as stalling or erratic operation

When dealing with a riding lawn mower, one of the most critical aspects to consider is engine performance. Stalling or erratic behavior can often be attributed to issues with the fuel system, particularly the fuel line. Here's a step-by-step guide on how to observe and address these engine performance issues:

- Engine Stalling: If your lawn mower's engine stalls frequently, it could be a sign of a stuck fuel line. When the fuel line is clogged or partially blocked, it restricts the flow of fuel to the engine, causing it to run out of fuel and stall. Start by checking the fuel line for any visible blockages or debris. Inspect the line for any signs of damage, kinks, or clogs. Ensure that the fuel line is properly attached to the fuel tank and the carburetor. If you notice any issues, it's essential to clean or replace the affected parts. You can use a fuel line cleaner or a compressed air gun to blow out any debris. For more stubborn blockages, consider replacing the fuel line to ensure optimal performance.

- Erratic Operation: Engine erratic behavior, such as sudden stops or unpredictable acceleration, can also be linked to fuel line problems. When the fuel line is not functioning correctly, it may cause inconsistent fuel delivery, leading to these unusual operating patterns. Pay close attention to how the engine responds during operation. Does it hesitate or surge unexpectedly? If so, it's likely due to a stuck or partially clogged fuel line. In this case, you should inspect the fuel line for any signs of damage or blockages, especially around the carburetor and fuel injectors. Cleaning or replacing the carburetor might be necessary if it's clogged. Ensure that the fuel filter is also checked and replaced if it's dirty or old, as it can restrict fuel flow.

- Fuel Delivery Inspection: To further diagnose the issue, you can perform a simple fuel delivery test. Start the engine and let it run for a few minutes. Then, slightly increase the throttle and observe the engine's response. If the engine stumbles or stalls, it indicates a potential fuel delivery problem. This test helps isolate whether the issue is with the fuel line or another component in the fuel system. If the engine responds normally, the problem might be elsewhere, but if it stalls or hesitates, it's a strong indication of a stuck or clogged fuel line.

- Professional Assistance: If you're unsure about the cause of the engine issues or if the problem persists despite your troubleshooting efforts, it's advisable to consult a professional mechanic. They can perform a thorough inspection and diagnose the exact cause of the stalling or erratic behavior. A mechanic will have the tools and expertise to identify and fix the issue, ensuring your lawn mower runs smoothly and reliably.

Remember, regular maintenance and timely attention to engine performance issues can save you from more significant problems and costly repairs in the long run.

Cool Fuel Lines: The Ultimate Guide to Choosing the Right Lines

You may want to see also

Fuel Pump Check: Inspect the pump for proper operation and debris

When it comes to maintaining your riding lawn mower, ensuring that the fuel system is in good working order is crucial. One critical component of this system is the fuel pump, which plays a vital role in delivering fuel from the tank to the engine. Over time, debris, dirt, and even small clogs can accumulate in the fuel pump, potentially leading to engine issues. Therefore, it's essential to regularly inspect and maintain the fuel pump to keep your lawn mower running smoothly.

To check the fuel pump for proper operation and debris, you'll need to access the pump itself. This process may vary slightly depending on the make and model of your lawn mower, so it's always a good idea to consult the owner's manual for specific instructions. Typically, you'll need to locate the fuel pump, which is usually positioned near the fuel tank or along the fuel lines. Once you've located it, carefully inspect the pump for any visible signs of damage, corrosion, or debris buildup.

Start by removing any debris that might be present around the pump. This could include leaves, dirt, or even small stones that may have found their way into the system. Use a soft-bristled brush or a compressed air canister to gently clean the area around the pump. Pay close attention to any openings or filters that might be present, as these can accumulate dirt and require cleaning as well.

Next, inspect the fuel pump itself. Check for any cracks, warping, or signs of corrosion on the pump's housing. These issues could indicate potential failure or reduced performance. Additionally, look for any visible damage to the pump's internal components, such as the impeller or the check valve. If you notice any damage, it may be necessary to replace the pump to ensure optimal engine performance.

While inspecting the pump, also listen for any unusual noises. A healthy fuel pump should operate quietly and smoothly. Any rattling, buzzing, or hissing sounds could indicate internal issues or debris causing the pump to malfunction. If you detect any unusual noises, it's advisable to consult a professional mechanic to diagnose and resolve the problem.

Remember, regular maintenance and inspection of the fuel pump can help prevent costly engine repairs and ensure your lawn mower's longevity. By taking the time to check for proper operation and debris, you can identify potential issues early on and take the necessary steps to keep your mower running efficiently.

Mopar Fuel Line Replacement: A Step-by-Step Guide for a Smooth Engine

You may want to see also

Fuel Filter Replacement: Regularly replace filters to prevent clogs

Fuel filters are an essential component of your riding lawn mower's fuel system, and their primary role is to ensure that only clean, unclogged fuel reaches the engine. Over time, fuel filters can become clogged with dirt, debris, and contaminants, leading to various performance issues. Regularly replacing the fuel filter is a proactive maintenance task that can help prevent these problems and ensure your mower operates efficiently.

Here's a step-by-step guide on how to replace the fuel filter on your riding lawn mower:

- Safety First: Before you begin, ensure you are working in a well-ventilated area and wear appropriate personal protective equipment, such as gloves and safety goggles. It's also a good idea to drain the fuel tank to remove any old, contaminated fuel. You can do this by disconnecting the fuel line and allowing the tank to drain into a suitable container.

- Locate the Fuel Filter: The fuel filter is typically located near the fuel tank and may be accessible from the outside of the mower or require removal of a panel or cover. Consult your mower's manual if you're unsure of its exact location.

- Remove the Old Filter: Using the appropriate tools, carefully remove the old fuel filter. Take note of the filter's orientation and any connections or clips that hold it in place. Be gentle to avoid damaging the fuel lines.

- Install the New Filter: Take your new fuel filter and align it with the fuel lines. Ensure it is the correct size and orientation. Secure the new filter using the appropriate clips or fasteners. Tighten any connections securely but be careful not to overtighten, as this can damage the fuel lines.

- Reassemble and Test: Once the new filter is in place, carefully reassemble any panels or covers you removed. Reconnect the fuel lines and ensure they are properly attached. Start the mower and let it run for a few minutes to ensure the fuel system is functioning correctly. Check for any leaks or unusual noises.

Regularly replacing the fuel filter is a simple yet effective way to maintain your riding lawn mower's performance and longevity. It helps prevent fuel-related issues, such as engine misfires, reduced power, and even engine damage caused by contaminated fuel. By incorporating this maintenance task into your regular care routine, you can ensure your mower is always ready for the job.

Mastering Maintenance: A Guide to Running Your Ryobi Trimmer's Fuel Line

You may want to see also

Frequently asked questions

A stuck or clogged fuel line can cause your mower to stall, run poorly, or not start at all. Common signs include a sudden loss of power, difficulty in starting, or inconsistent idling. You might also notice a strong fuel odor or hear a rattling sound coming from the fuel tank or lines.

If you observe any of the aforementioned symptoms, it's best to inspect the fuel line for blockages. Start by checking the fuel filter and replacing it if it's dirty or clogged. Then, carefully examine the fuel line for any kinks, bends, or obstructions. You can use a fuel line brush to gently clean the interior of the line, ensuring there are no blockages.

You'll need a few basic tools to inspect and potentially clear the fuel line. A fuel line brush, which is a flexible brush with bristles, is ideal for cleaning the interior of the line. Additionally, have a fuel filter replacement and a funnel to make the process easier. It's also a good idea to wear gloves and safety goggles to protect yourself during the process.

Yes, a fuel pressure gauge can be a useful tool to diagnose fuel line issues. If the pressure gauge shows low or inconsistent fuel pressure, it may indicate a blockage in the fuel line. However, it's important to note that low pressure could also be caused by other factors, so further inspection is recommended.

If you confirm that the fuel line is clogged or blocked, you can try to clear it by using a fuel line cleaner or a compressed air gun to blow out any debris. If the issue persists, it's advisable to consult a professional mechanic or lawn mower repair specialist to ensure proper diagnosis and repair.