When it comes to vehicle maintenance, one common task that often arises is the need to wrap fuel lines with rubber hoses. This practice is not only a practical solution but also a cost-effective one. Rubber hoses are versatile and can be easily installed to protect fuel lines from potential damage caused by vibration, heat, or other environmental factors. By wrapping the fuel lines with rubber hoses, you can ensure the longevity and reliability of your vehicle's fuel system, making it a valuable technique for any car owner to know.

| Characteristics | Values |

|---|---|

| Safety | Wrapping a fuel line with a rubber hose is generally not recommended as it can lead to fuel leaks and potential fire hazards. Rubber hoses are not designed for fuel containment and may degrade over time, releasing harmful chemicals. |

| Durability | Rubber hoses are flexible and can withstand some mechanical stress, but they are not as robust as specialized fuel lines. They may crack or become brittle with age, especially in harsh environments. |

| Compatibility | Ensure the rubber hose is compatible with the fuel type and temperature range. Different fuels have varying properties, and some hoses may not be suitable for certain fuels. |

| Cost | Wrapping a fuel line with a rubber hose is a temporary and cost-effective solution, but it may not be as reliable or long-lasting as professional fuel line installations. |

| Maintenance | Regular inspection and replacement of the rubber hose are necessary to ensure safety. Over time, the hose may need to be replaced due to wear and tear. |

| Legal Considerations | In some regions, modifying fuel lines without proper authorization or using non-standard components may be illegal. Always check local regulations. |

What You'll Learn

- Fuel Line Material: Rubber hoses are suitable for fuel lines due to their flexibility and resistance to fuel degradation

- Installation Process: Wrapping fuel lines with rubber hoses involves careful routing and secure fastening to prevent leaks

- Safety Considerations: Ensure proper insulation and compatibility to prevent fuel leaks and potential fire hazards

- Environmental Impact: Rubber hoses are eco-friendly, but proper disposal is crucial to avoid environmental contamination

- Maintenance Tips: Regular inspection and replacement are essential to maintain the integrity of the fuel line and hose

Fuel Line Material: Rubber hoses are suitable for fuel lines due to their flexibility and resistance to fuel degradation

When it comes to fuel line materials, rubber hoses offer a practical and reliable solution for various applications. The flexibility of rubber hoses is a key advantage, allowing for easy installation and adjustments in different engine compartments. This flexibility is crucial, especially in vehicles with complex engine layouts or those that require frequent movement during operation. By using rubber hoses, you can ensure a snug fit without causing any strain or damage to the fuel lines.

One of the primary reasons rubber hoses are suitable for fuel lines is their resistance to fuel degradation. Fuel, especially in older vehicles, can contain various contaminants and volatile compounds. Over time, these substances can break down the materials used in fuel lines, leading to leaks, reduced performance, and potential engine damage. Rubber hoses, however, are designed to withstand the corrosive nature of fuel. They provide a protective barrier, preventing the fuel from directly interacting with the metal or plastic components of the fuel lines, thus maintaining the integrity of the system.

The durability of rubber hoses is another critical factor. These hoses are typically made from high-quality materials that can withstand the harsh conditions inside an engine bay. They are resistant to heat, oil, and other chemicals commonly found in fuel, ensuring long-lasting performance. This durability is essential to guarantee a reliable fuel supply and prevent any potential issues that may arise from the degradation of the fuel lines.

Furthermore, rubber hoses offer a cost-effective solution for fuel line replacements or modifications. They are readily available in various sizes and lengths, making it convenient for DIY enthusiasts and professionals alike. The ease of installation and the ability to wrap or secure the hoses in place further contribute to a straightforward and efficient process. This accessibility and affordability make rubber hoses an attractive option for those looking to upgrade or repair their fuel line systems.

In summary, rubber hoses are an excellent choice for fuel lines due to their flexibility, which simplifies installation and accommodates engine movement. Their resistance to fuel degradation ensures the longevity of the fuel system, preventing potential issues caused by fuel-related corrosion. Additionally, the durability and cost-effectiveness of rubber hoses make them a practical and reliable solution for various fuel line applications, providing a safe and efficient fuel supply for engines.

Online Fuel Assistance: Applying for Help in Winchester, VA

You may want to see also

Installation Process: Wrapping fuel lines with rubber hoses involves careful routing and secure fastening to prevent leaks

The process of wrapping fuel lines with rubber hoses is a practical method to ensure the integrity of your fuel system, especially in situations where a permanent solution is not feasible or cost-effective. This technique is particularly useful for temporary fixes, modifications, or when dealing with classic vehicles that require specific parts. Here's a step-by-step guide to help you through the installation process:

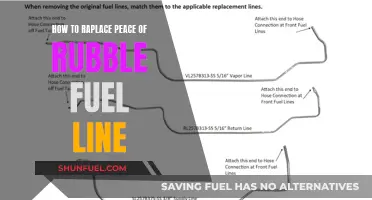

Preparation: Before you begin, ensure you have the necessary tools and materials, including the rubber hose, fuel line, and appropriate fasteners like clips, ties, or straps. Inspect the fuel line for any existing damage or leaks, and if possible, replace it with a new one to ensure optimal performance. Clean the area around the fuel line to remove any dirt or debris that might interfere with the installation.

Routing the Hose: Carefully plan the path of the rubber hose to wrap around the fuel line. The goal is to create a secure and stable arrangement without restricting fuel flow. Start by identifying the sections of the fuel line that require additional protection or support. For example, areas near the engine, under the dashboard, or where the line crosses other components. Route the hose along these sections, ensuring it is not too tight or too loose. You want to allow enough space for the hose to move slightly without causing strain on the fuel line.

Wrapping and Securing: Begin wrapping the rubber hose around the fuel line, using the appropriate fasteners to secure it in place. Start from one end of the fuel line and work your way along, ensuring the hose is tightly wrapped but not overly tight, as this can cause damage. Use the fasteners to hold the hose in position, creating a neat and secure bundle. It's crucial to maintain a consistent and tight wrap to prevent any potential leaks. Consider the direction of the fuel flow and wrap the hose in the same direction to avoid creating unnecessary pressure points.

Final Checks: Once the wrapping is complete, perform a thorough inspection to ensure the installation is secure. Check for any sharp bends or kinks in the fuel line that might cause issues over time. Look for any loose fasteners and retighten them if necessary. Test the system by starting the engine and monitoring for any unusual noises or vibrations, which could indicate a potential issue. If everything appears stable and secure, you can now enjoy the benefits of your wrapped fuel line, knowing that you've taken a proactive approach to maintaining your vehicle's performance and safety.

Remember, this method is a temporary solution, and for long-term use, professional installation of a more permanent fuel system is recommended. Always prioritize safety and consult a mechanic if you're unsure about any step during the installation process.

Polaris Ranger 570 Fuel Line Fittings: A Comprehensive Guide

You may want to see also

Safety Considerations: Ensure proper insulation and compatibility to prevent fuel leaks and potential fire hazards

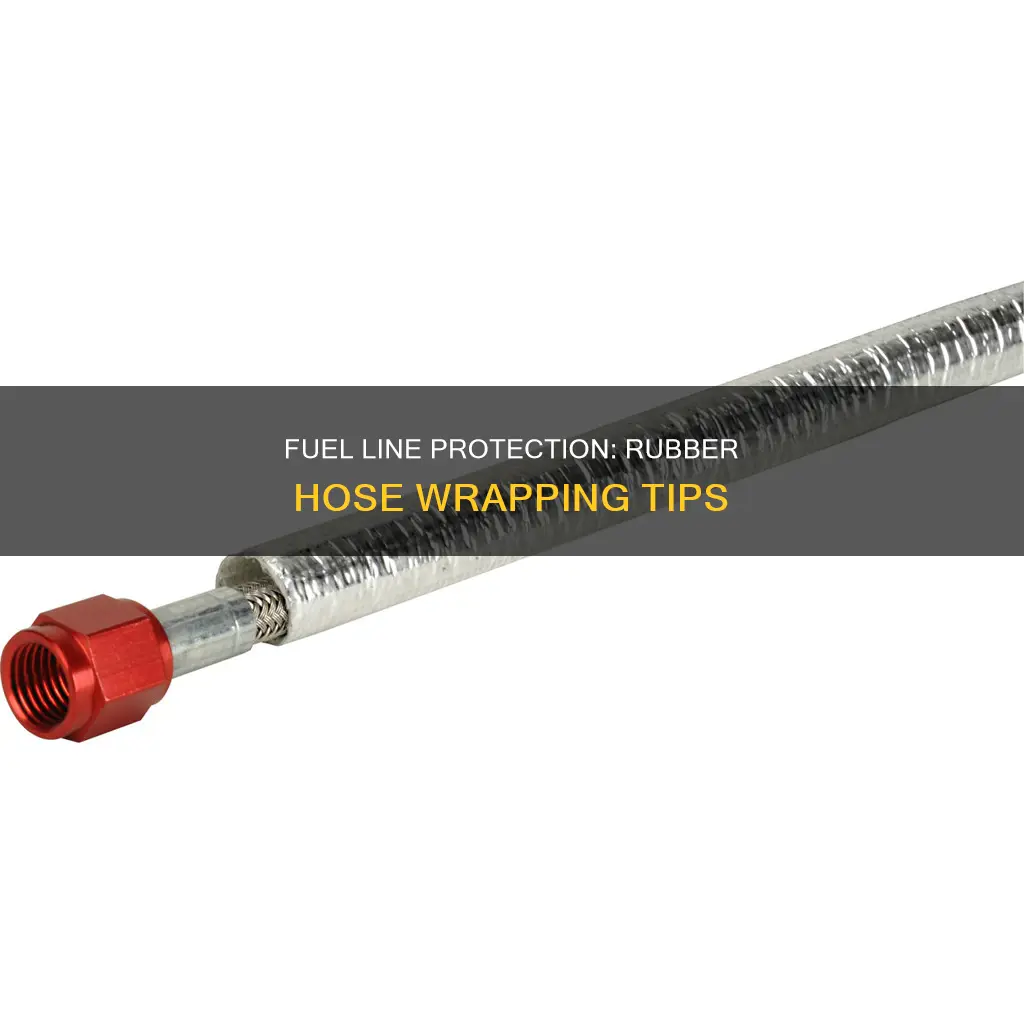

When considering the use of rubber hoses to wrap fuel lines, it is crucial to prioritize safety to prevent any potential hazards. Fuel lines carry flammable substances, and any compromise in their integrity can lead to serious consequences. One of the primary safety considerations is ensuring proper insulation. Rubber hoses, while flexible and easy to work with, may not provide the necessary insulation required for fuel lines. Insulation is essential to protect against extreme temperatures, vibrations, and potential impacts that could damage the fuel line and lead to leaks.

To address this, it is recommended to use specialized insulation materials designed for fuel lines. These materials are often made of high-temperature-resistant compounds that can withstand the harsh environment of fuel systems. Wrapping the fuel line with a layer of this insulation material will create a protective barrier, reducing the risk of damage and potential leaks. Additionally, ensuring a secure and tight fit between the rubber hose and the fuel line is vital. Any gaps or loose connections can create opportunities for fuel to seep out, leading to environmental contamination and potential fire risks.

Compatibility is another critical factor. Rubber hoses should be compatible with the fuel type being used. Different fuels have varying chemical compositions, and some may react with rubber over time, causing degradation and potential leaks. It is essential to choose a rubber hose specifically designed for the fuel in question, ensuring it meets the necessary standards and specifications. This compatibility ensures that the hose can withstand the chemical properties of the fuel without deteriorating or becoming permeable.

Furthermore, proper installation techniques are vital to maintaining safety. When wrapping the fuel line with a rubber hose, it should be securely fastened and supported to prevent any movement or vibration that could loosen connections. The hose should be routed away from high-heat sources and potential impact areas to avoid damage. Regular inspections and maintenance are also recommended to identify any signs of wear, tear, or damage, ensuring that the fuel system remains safe and reliable.

In summary, while wrapping fuel lines with rubber hoses may provide some flexibility, it is essential to adhere to safety guidelines. Proper insulation, compatibility with the fuel type, and secure installation are key to preventing fuel leaks and potential fire hazards. By taking these precautions, you can ensure the safe operation of fuel systems and mitigate the risks associated with working with flammable substances.

O-Ring Mystery: Trailblazer Fuel Line Diagram Decoded

You may want to see also

Environmental Impact: Rubber hoses are eco-friendly, but proper disposal is crucial to avoid environmental contamination

The use of rubber hoses for fuel lines is a practical solution for many applications, offering flexibility and durability. However, when it comes to environmental considerations, it's important to understand the potential impact of these hoses and the importance of responsible disposal. While rubber hoses are generally considered eco-friendly due to their natural composition, improper disposal can lead to significant environmental contamination.

Rubber hoses are typically made from synthetic or natural rubber, which are derived from renewable resources. This makes them a more sustainable option compared to hoses made from other materials. However, the environmental benefits of rubber hoses can be compromised if they are not disposed of correctly. When rubber hoses are discarded in landfills, they can take a significant amount of time to decompose, and during this process, they may release harmful chemicals and substances into the surrounding environment. These chemicals can leach into the soil and potentially contaminate groundwater, posing risks to ecosystems and human health.

To minimize the environmental impact, it is crucial to follow proper disposal methods. One effective approach is to recycle rubber hoses whenever possible. Many recycling centers and automotive shops accept used hoses and can process them for reuse. By recycling, you ensure that the rubber is given a new life instead of ending up in landfills. Additionally, when hoses are no longer functional, they should be removed from the fuel line and treated as hazardous waste. This is especially important if the hoses have been exposed to fuel or other chemicals, as these substances can leach into the environment during decomposition.

Proper disposal methods may vary depending on your location and local regulations. It is essential to research and adhere to the guidelines provided by your waste management authorities. Some regions may have specific programs for disposing of automotive parts, including rubber hoses. By taking the time to dispose of rubber hoses responsibly, you contribute to a more sustainable and environmentally conscious approach to vehicle maintenance.

In summary, while rubber hoses offer eco-friendly benefits, their environmental impact can be mitigated through proper disposal practices. Recycling and treating hoses as hazardous waste when necessary are essential steps to ensure that these hoses do not contribute to environmental contamination. By being mindful of disposal methods, individuals can contribute to a greener and more sustainable future.

Braided Fuel Line Upgrade: A Step-by-Step Guide to Switching

You may want to see also

Maintenance Tips: Regular inspection and replacement are essential to maintain the integrity of the fuel line and hose

Regular maintenance and inspections are crucial for ensuring the longevity and safety of your vehicle's fuel system, especially when it comes to the fuel lines and hoses. These components are responsible for transporting fuel from the tank to the engine, and any damage or deterioration can lead to serious issues. Here are some essential maintenance tips to keep in mind:

Visual Inspections: Start by performing regular visual checks of the fuel lines and hoses. Look for any signs of wear and tear, such as cracks, brittleness, or visible damage. Inspect the lines for any bulging or softening, especially where they connect to the fuel tank and the engine. Over time, fuel lines can degrade due to exposure to fuel, heat, and vibration, making visual inspections a simple yet effective way to catch potential problems early on.

Check for Leaks: A common issue with fuel lines and hoses is the development of small leaks. These leaks can go unnoticed until they cause significant damage or even engine failure. During your inspection, look for any signs of fuel seepage around the connections or along the length of the lines. Leaks can be caused by worn-out components, corrosion, or improper installation, so addressing them promptly is vital.

Replace Worn-Out Components: If you notice any damage or wear during your inspections, it's crucial to replace the affected fuel line or hose immediately. Worn-out components can lead to fuel leaks, engine misfires, or even complete engine failure. Keep a record of the condition of your fuel system and replace any parts that show signs of deterioration. This proactive approach will help prevent unexpected breakdowns and costly repairs.

Consider Environmental Factors: The environment in which your vehicle operates can impact the condition of the fuel lines and hoses. Extreme temperatures, exposure to sunlight, and chemical contaminants can accelerate the degradation of these components. If your vehicle is used in harsh conditions or in areas with high levels of pollution, more frequent inspections and replacements may be necessary.

Professional Assistance: While regular inspections are essential, it's also beneficial to have a professional mechanic inspect your fuel system during routine maintenance checks. They can provide expert advice and ensure that all components are in good working order. Professionals can also identify potential issues that may not be visible to the untrained eye, ensuring that your vehicle's fuel system remains reliable and safe.

By following these maintenance tips and staying vigilant, you can ensure that your fuel lines and hoses remain in optimal condition. Regular inspections and timely replacements will help maintain the integrity of the fuel system, prevent costly repairs, and ultimately keep your vehicle running smoothly and efficiently.

Air in Paperstroke Return Fuel Line: A Cause for Concern?

You may want to see also

Frequently asked questions

Wrapping a fuel line with a rubber hose is generally not recommended as it can lead to several issues. Rubber hoses are not designed for fuel lines and may not provide the necessary protection against fuel leaks, corrosion, or temperature changes.

The primary risks include the potential for fuel leaks, which can be dangerous and cause environmental damage. Rubber hoses may also degrade over time due to fuel exposure, leading to cracks and potential fuel loss. Additionally, the hose may not withstand temperature fluctuations, causing it to become brittle or melt.

Yes, there are several alternatives. One common method is to use fuel line protective sleeves or jackets made from materials like rubber, PVC, or braided steel. These provide insulation, protection from abrasion, and can even help with noise reduction.

Proper installation and regular maintenance are key. Use appropriate fuel line clips or ties to secure the hose and prevent it from moving or coming loose. Regularly inspect the fuel line for any signs of damage, cracks, or leaks, and replace the hose if necessary.

While it might seem like a quick fix, using a rubber hose for temporary repairs is not ideal. It's best to use specialized fuel line repair kits or consult a professional mechanic for a more permanent and safe solution. Temporary fixes may not provide long-term reliability and could lead to fuel-related issues.