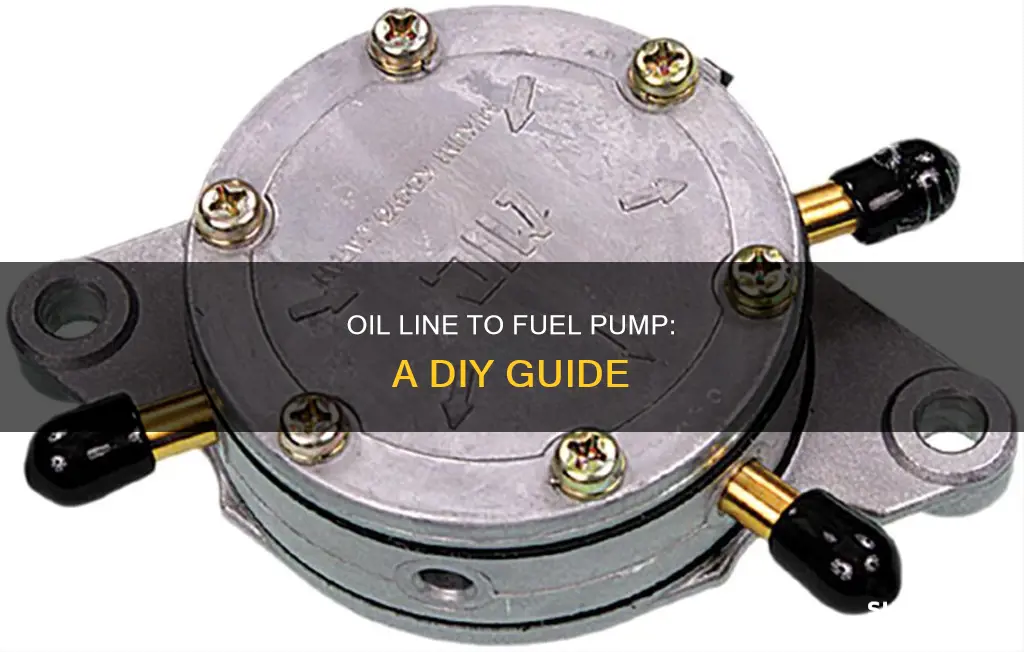

If you're a car enthusiast or a mechanic, you might have encountered the challenge of troubleshooting fuel delivery systems. One common issue that arises is the malfunction of the fuel pump, which can lead to poor engine performance or even prevent the engine from starting. In this context, many car owners and mechanics have explored the idea of using oil lines as a temporary solution to bypass a faulty fuel pump. This practice, however, raises questions about its feasibility and safety. In this article, we will delve into the topic of whether it is possible to plug an oil line onto a Mikuni fuel pump and discuss the potential implications and alternatives to consider.

| Characteristics | Values |

|---|---|

| Compatibility | May not be compatible with all Mikuni fuel pumps; consult specific model specifications |

| Oil Line Function | Can provide additional lubrication to the fuel pump, especially in high-performance applications |

| Maintenance | Regularly check and replace the oil line to prevent contamination and ensure optimal pump performance |

| Material | Typically made of rubber or plastic, chosen for its flexibility and resistance to fuel degradation |

| Installation | Requires careful alignment and secure attachment to the fuel pump and oil reservoir |

| Pressure Considerations | Ensure the oil line can handle the pressure of the fuel system to prevent leaks |

| Customization | Some fuel pump kits offer adjustable or replaceable oil lines for tailored performance |

What You'll Learn

- Compatibility: Check if your Mikuni fuel pump can accommodate an oil line

- Installation: Follow a step-by-step guide for proper oil line connection

- Materials: Use appropriate materials for a secure and leak-free connection

- Pressure: Ensure the oil line can handle the pump's pressure

- Maintenance: Regularly inspect and maintain the oil line for optimal performance

Compatibility: Check if your Mikuni fuel pump can accommodate an oil line

When considering the compatibility of your Mikuni fuel pump for an oil line installation, it's crucial to understand the specific requirements and limitations of your pump. Mikuni fuel pumps are designed to efficiently deliver fuel to the engine, and while they may have provisions for certain modifications, adding an oil line requires careful evaluation.

The first step is to consult the manufacturer's documentation or technical specifications for your Mikuni fuel pump. This resource will provide detailed information about the pump's design, including any existing ports or connections that could be utilized for an oil line. Look for diagrams or descriptions that indicate where the oil line might be connected, such as near the pump's inlet or outlet. Understanding the pump's anatomy will help you determine if the necessary connections are already present.

If your Mikuni fuel pump lacks the required ports or connections, you may need to consider modifications. However, it's essential to approach this with caution. Adding an oil line without proper planning and expertise can lead to issues such as fuel contamination or reduced pump performance. If modifications are necessary, consult experienced mechanics or fuel pump specialists who can ensure the work is done safely and effectively. They can advise on the best methods to integrate the oil line while maintaining the pump's functionality.

Additionally, consider the type of oil line you plan to use. Different materials and diameters can impact the pump's performance and longevity. Ensure that the chosen oil line is compatible with the pump's specifications and the engine's requirements. Using the right materials and dimensions will prevent potential issues like excessive wear or reduced fuel flow.

In summary, checking the compatibility of your Mikuni fuel pump for an oil line is a critical step. Refer to the manufacturer's resources, assess the pump's design, and consider any necessary modifications. By taking these precautions, you can ensure a successful and safe integration of the oil line while maintaining the pump's efficiency and reliability.

Amplifying Safety: The Fuel Line Clip Lock Advantage

You may want to see also

Installation: Follow a step-by-step guide for proper oil line connection

Before you begin the installation process, it's crucial to understand the specific requirements and compatibility of your Mikuni fuel pump and the oil line you intend to use. Ensure that the oil line is designed to fit your pump and that it meets the necessary specifications. This initial step is essential to avoid any potential issues during installation and to ensure optimal performance.

Step 1: Gather the Necessary Tools and Materials

- Oil line (specifically designed for your Mikuni fuel pump)

- Fuel pump assembly

- Wrench or appropriate tool for tightening connections

- Clean rags or cloth for wiping surfaces

- Penetrating oil or lubricant (optional)

Step 2: Prepare the Fuel Pump and Oil Line

- Inspect the fuel pump assembly for any signs of damage or wear. Ensure it is in good working condition.

- Clean the fuel pump and the oil line connection points to remove any dirt or debris. Use clean rags to wipe down the surfaces.

- If using penetrating oil, apply a small amount to the threads and connection points to facilitate the assembly process.

Step 3: Connect the Oil Line

- Locate the oil line connection port on your Mikuni fuel pump. It is typically a small opening or fitting.

- Carefully insert the oil line into the connection port, ensuring it is aligned correctly.

- Tighten the connection using the appropriate tool. Be cautious not to overtighten, as it may damage the threads or the pump.

- Double-check the connection to ensure it is secure and tight.

Step 4: Test and Verify

- After the installation, start the engine and check for any leaks around the oil line connection.

- Monitor the fuel pump's performance and listen for any unusual noises.

- If everything appears to be functioning correctly, you can proceed with further engine testing and adjustments.

Remember, proper installation and regular maintenance are key to ensuring the longevity and optimal performance of your Mikuni fuel pump. Always refer to the manufacturer's guidelines and consult a professional if you encounter any challenges during the installation process.

Choosing the Right Size: Steel Fuel Line for Your 1000cc Engine

You may want to see also

Materials: Use appropriate materials for a secure and leak-free connection

When dealing with fuel systems, especially those involving a Mikuni fuel pump, it's crucial to understand the importance of using the right materials for a secure and leak-free connection. The fuel pump is a critical component in the engine's fuel delivery system, and any modifications or connections should be made with precision and care.

One of the key materials to consider is the type of tubing used for the fuel lines. For a Mikuni fuel pump, it is generally recommended to use fuel-grade rubber or silicone tubing. These materials are designed to withstand the high pressure and temperature fluctuations that fuel can experience. Rubber or silicone tubing ensures that the fuel lines remain flexible yet robust, capable of withstanding the dynamic nature of the engine's operation.

Additionally, the fittings and connectors should be made from durable materials such as brass or stainless steel. These metals are known for their corrosion resistance and ability to withstand the corrosive properties of fuel. Brass fittings, in particular, offer a good balance between strength and cost-effectiveness. They provide a secure seal and are less likely to leak compared to other materials. It is essential to ensure that the fittings are properly tightened to create a tight seal, preventing any potential fuel leaks.

Another important aspect is the use of appropriate seals and gaskets. These components play a vital role in maintaining a leak-free connection. For fuel lines, rubber or silicone gaskets are commonly used to create a secure seal between the fittings and the tubing. These gaskets should be properly sized and positioned to ensure a tight fit, preventing any fuel from escaping.

Furthermore, when working with the oil line, it is crucial to use materials that are compatible with both fuel and oil. The oil line should be made of a material that can withstand the different properties of oil, such as its viscosity and temperature range. Using the wrong material can lead to premature failure and potential engine damage. Consulting the vehicle's manual or seeking expert advice can help determine the most suitable materials for the specific application.

Troubleshooting Clogged Fuel Lines: Common Causes and Solutions

You may want to see also

Pressure: Ensure the oil line can handle the pump's pressure

When considering the idea of plugging an oil line into your Mikuni fuel pump, it's crucial to prioritize safety and performance. One critical aspect often overlooked is the pressure that the fuel pump generates and how it interacts with the oil line. The Mikuni fuel pump is designed to deliver fuel at a specific pressure to ensure optimal engine performance. This pressure can vary depending on the pump model and engine specifications, but it typically ranges from 40 to 60 psi (pounds per square inch).

The oil line, which connects the fuel pump to the engine, must be able to withstand this pressure to function correctly. If the oil line is not rated to handle the pump's pressure, it can lead to several issues. Firstly, the line may not be able to maintain a consistent fuel flow, causing potential fuel starvation to the engine, especially during high-load conditions. This can result in reduced power, poor engine performance, and even potential engine damage.

To ensure the oil line can handle the pump's pressure, it's essential to check the manufacturer's specifications for both the fuel pump and the oil line. Most fuel pump manufacturers provide guidelines on the recommended oil line diameter and material to ensure optimal performance and safety. Using a line that meets or exceeds these specifications is crucial. For instance, if the pump requires a specific oil line diameter, using a smaller or thinner line could lead to pressure drops and potential fuel delivery issues.

Additionally, the material of the oil line is vital. Common materials used include steel, brass, and various types of rubber or silicone. Each material has different pressure ratings and flexibility, so choosing the right one is essential. For high-pressure applications, a more robust material like steel or a high-pressure-rated rubber/silicone blend might be necessary.

In summary, when plugging an oil line into your Mikuni fuel pump, don't overlook the importance of pressure compatibility. Always refer to the manufacturer's guidelines and specifications to ensure the oil line can handle the pump's pressure, ensuring reliable fuel delivery and optimal engine performance. This simple check can save you from potential issues and ensure your engine runs smoothly.

Optimal Fuel Line Size for Efficient Beckett Oil Furnace Performance

You may want to see also

Maintenance: Regularly inspect and maintain the oil line for optimal performance

The Mikuni fuel pump is a crucial component in your vehicle's fuel system, and ensuring its proper maintenance is essential for optimal performance and longevity. One specific aspect that requires regular attention is the oil line, which plays a vital role in lubricating the pump and preventing excessive wear. Here's a guide on how to maintain the oil line for the best results:

Regular inspections are the cornerstone of maintenance. It is recommended to check the oil line at least once a month or whenever you perform routine vehicle maintenance. Start by locating the oil line, which is typically a small diameter tube connected to the fuel pump. Inspect it for any signs of damage, cracks, or leaks. Look for any visible wear, such as brittleness or discoloration, as these could indicate potential issues. Additionally, ensure that the connections are secure and free from corrosion. If you notice any problems, it's crucial to address them promptly to prevent further complications.

When inspecting, pay close attention to the condition of the oil line's fittings and connections. Over time, these parts can become loose or corroded, leading to reduced performance. Tighten any loose fittings and consider using a high-quality lubricant to ensure a secure connection. If corrosion is present, carefully clean the affected areas to restore proper functionality. Remember, a well-maintained connection will contribute to the overall efficiency of your fuel pump.

In addition to visual inspections, it's beneficial to monitor the oil line's condition during regular vehicle operation. Listen for any unusual noises coming from the fuel pump, as this could indicate improper lubrication or potential damage. Also, keep an eye on the engine's performance, as a poorly maintained oil line might result in reduced power or fuel efficiency. Addressing these signs early can save you from more significant issues down the line.

To ensure optimal performance, consider replacing the oil line periodically, especially if it shows signs of wear or damage. High-quality replacement lines are readily available and can be installed following the manufacturer's guidelines. Regularly replacing the oil line will help maintain the integrity of your fuel system and ensure that your Mikuni fuel pump operates at its peak.

In summary, maintaining the oil line on your Mikuni fuel pump is a critical task that requires regular attention. By inspecting for damage, ensuring secure connections, and monitoring performance, you can keep your fuel system in excellent condition. Remember, proper maintenance will contribute to the overall reliability and efficiency of your vehicle's fuel delivery system.

Blue Clips on Ford Fuel Lines: Quick Removal Tips

You may want to see also

Frequently asked questions

No, it is not recommended to use an oil line for your fuel pump. Oil lines are designed to handle lubricating oil and have different specifications and materials compared to fuel lines. Using an oil line can lead to issues with fuel flow, pressure, and potential contamination. It's best to use a dedicated fuel line designed for the specific application.

Plugging an oil line into the fuel pump can result in several problems. Firstly, the oil line may not provide the necessary pressure and flow rate required for the pump, leading to inadequate fuel delivery. Secondly, the oil line's material might not withstand the corrosive nature of fuel, causing degradation over time. This can result in fuel leaks, pump damage, and reduced performance.

Yes, when connecting a fuel line to the Mikuni fuel pump, it is crucial to use a line that meets the pump's specifications. The fuel line should be made of compatible materials, such as rubber or vinyl, and have the appropriate diameter to ensure optimal fuel flow. It's recommended to consult the pump's manual or seek advice from a mechanic to determine the correct fuel line size and type.

Modifying the fuel pump to accommodate an oil line is not a recommended practice. Fuel pumps are designed to work with specific fuel lines, and altering their design or using the wrong line can lead to performance issues and potential safety hazards. It's best to source and install the correct fuel line for your Mikuni fuel pump to ensure reliable operation.