A clogged fuel line can be a frustrating and potentially dangerous issue for vehicle owners. When the fuel line becomes blocked, it can lead to a variety of problems, including reduced engine performance, stalling, and even engine damage. Understanding the causes and effects of a clogged fuel line is essential for vehicle maintenance. This paragraph will explore the common reasons for fuel line clogs, such as debris, corrosion, or blockages from contaminants, and provide insights into how to identify and address this issue to ensure optimal vehicle operation.

What You'll Learn

- Clogged Fuel Pump: Check for debris or blockages in the fuel pump

- Clogged Filter: Inspect and clean or replace the fuel filter regularly

- Leaking Fuel Injectors: Inspect for leaks and ensure proper fuel flow

- Sediment Build-Up: Remove sediment from the fuel tank to prevent clogs

- Fuel Line Damage: Inspect for cracks or damage in the fuel lines

Clogged Fuel Pump: Check for debris or blockages in the fuel pump

If you suspect that your fuel pump is clogged, it's important to address the issue promptly to avoid potential engine problems. The fuel pump is a critical component responsible for delivering fuel from the tank to the engine, and any blockage can lead to reduced performance or even engine failure. Here's a step-by-step guide on how to check for debris or blockages in the fuel pump:

- Inspect the Fuel Pump and Lines: Start by visually inspecting the fuel pump and its associated lines. Over time, dirt, rust, or other contaminants can accumulate in the fuel system, including the pump. Look for any signs of corrosion, rust, or debris buildup around the pump and fuel lines. Check for any visible blockages or restrictions in the lines, ensuring that the flow of fuel is unobstructed.

- Remove the Fuel Pump: To gain better access, you may need to remove the fuel pump. This process can vary depending on your vehicle's make and model. Consult your vehicle's manual or seek professional guidance if you're unsure about the removal process. Once the pump is removed, you can inspect it more closely. Look for any signs of clogging, such as a buildup of carbon deposits, dirt, or debris inside the pump.

- Clean or Replace the Fuel Pump: If you find any debris or blockages, it's crucial to clean the fuel pump thoroughly. Use a fuel pump cleaner or a compressed air gun to blow out any contaminants. Ensure that you follow the manufacturer's instructions for the cleaning process. If the pump is heavily clogged or damaged, it might be necessary to replace it. Consider consulting a mechanic for this step, especially if you're not experienced with vehicle repairs.

- Reassemble and Test: After cleaning or replacing the fuel pump, carefully reassemble the fuel system, ensuring all components are properly connected. Refill the fuel tank and start the engine to check for any improvements in performance. Monitor the engine's behavior, as a clogged fuel pump can cause symptoms like reduced power, poor acceleration, or rough idling. If the issue persists, further investigation may be required.

Remember, regular maintenance and fuel system cleaning can help prevent clogs and ensure optimal engine performance. If you're unsure about any step or encounter complex issues, it's always best to consult a professional mechanic who can provide expert assistance tailored to your vehicle.

Emergency Fuel Line Fixes: Quick Solutions for Leaks & Clogs

You may want to see also

Clogged Filter: Inspect and clean or replace the fuel filter regularly

A clogged fuel filter can be a common issue that affects the performance and efficiency of your vehicle. Over time, the filter can become blocked with contaminants, such as dirt, debris, and varnish, which can restrict the flow of fuel to the engine. This problem is often overlooked, but it can lead to various symptoms and potential damage if left unattended. Here's a guide on how to address a clogged fuel filter:

Regular maintenance is key to preventing this issue. It is recommended to inspect and clean or replace the fuel filter at regular intervals, typically every 30,000 to 50,000 miles or as per your vehicle's manufacturer's guidelines. Start by locating the fuel filter, which is usually positioned along the fuel line, often near the engine or the fuel tank. You can use a fuel filter inspection tool to check for any signs of clogging. If you notice any blockages or excessive dirt accumulation, it's time to take action.

To clean the fuel filter, you'll need to drain the fuel system to prevent any spills. Start by removing the fuel filter and placing it in a clean container. Rinse the filter with a fuel filter cleaner to remove any built-up contaminants. Ensure you follow the instructions provided with the cleaner. After cleaning, inspect the filter for any signs of damage or excessive wear. If the filter is severely clogged or shows signs of deterioration, it is best to replace it with a new one.

When replacing the fuel filter, ensure you use the correct type and size as specified for your vehicle. Properly secure the new filter and bleed the fuel system to remove any air bubbles. After the replacement, start the vehicle and check for any leaks. Test-drive the car to ensure the fuel system is functioning correctly and that there are no performance issues.

Remember, regular maintenance and timely attention to a clogged fuel filter can help prevent engine misfires, reduced power, and other performance problems. It is a relatively simple task that can save you from potential breakdowns and costly repairs. Always refer to your vehicle's manual for specific instructions and recommendations regarding fuel filter maintenance.

Fuel Line Protests: Dakota's Burning Questions

You may want to see also

Leaking Fuel Injectors: Inspect for leaks and ensure proper fuel flow

Leaking fuel injectors are a common issue that can lead to reduced engine performance and potential damage if left unattended. It is crucial to inspect and address these leaks promptly to maintain the health of your vehicle's engine. Here's a comprehensive guide on how to tackle this problem:

When dealing with suspected leaking fuel injectors, the first step is to locate them. Fuel injectors are typically found near the engine, and they are responsible for spraying fuel into the engine's intake system. These injectors are often small, cylindrical components with a precise spray pattern. Visually inspect each injector for any signs of damage, corrosion, or debris. Look for any visible cracks, blockages, or discolouration, as these could indicate potential leaks. It is essential to wear protective gear, such as gloves and goggles, when handling fuel-related components to ensure personal safety.

To confirm the presence of a leak, perform a fuel pressure test. This test will help you understand the severity of the issue and guide your next steps. Start by disconnecting the fuel line from the injector and attaching a fuel pressure gauge. Ensure the engine is off and in a cool state before proceeding. Turn the engine on and monitor the fuel pressure reading. A healthy fuel pressure should be within the manufacturer's specified range. If the pressure is significantly lower or unstable, it may indicate a leaking injector. Repeat this process for each injector to identify the problematic one(s).

Once you've identified the leaking fuel injectors, it's time to take action. Start by disconnecting the fuel lines from the injectors and temporarily blocking the fuel supply to the affected areas. This step is crucial to prevent further fuel wastage and potential engine damage. Then, carefully inspect the injectors for any visible signs of damage or debris. Use a fine brush or compressed air to clean the injectors, ensuring you remove any dirt or contaminants. If the injectors show significant wear or damage, they may need to be replaced. Consult your vehicle's manual or seek professional advice for the appropriate replacement process.

After addressing the leaking injectors, it's essential to ensure proper fuel flow throughout the system. Start by reconnecting the fuel lines and allowing the engine to idle. Monitor the engine's performance and listen for any unusual noises. Check for any signs of fuel leakage around the connections and ensure all components are securely attached. If the engine runs smoothly and without issues, you've successfully resolved the leaking fuel injector problem. However, if any symptoms persist, further investigation may be required to identify and rectify the underlying cause.

Regular maintenance and inspection of fuel injectors can prevent such issues. Keep your vehicle's fuel system clean and well-maintained to avoid clogs and leaks. By promptly addressing leaking fuel injectors, you can ensure optimal engine performance and extend the lifespan of your vehicle's critical components. Remember, when working with fuel, safety should always be a top priority.

Nova Fuel Tank Lines: Unlocking Engine Power and Efficiency

You may want to see also

Sediment Build-Up: Remove sediment from the fuel tank to prevent clogs

Sediment build-up in the fuel tank is a common issue that can lead to fuel line clogs, causing various performance problems in your vehicle. Over time, dirt, debris, and water can accumulate at the bottom of the fuel tank, especially if your vehicle is used in dirty or dusty environments. This sediment can gradually work its way through the fuel system, leading to blockages and reduced fuel flow.

To prevent sediment-related clogs, it is essential to regularly maintain your vehicle's fuel system. One of the most effective ways to address this issue is by performing a fuel tank sediment removal procedure. This process involves draining the fuel tank and removing the sediment that has settled at the bottom. Here's a step-by-step guide to help you through this process:

- Prepare the Vehicle: Park your vehicle on a level surface and ensure it is in a position where you can access the fuel tank. Locate the fuel tank drain valve, which is usually a small opening near the bottom of the tank.

- Drain the Fuel: Place a suitable container under the drain valve to catch the sediment and fuel that will be released. Open the drain valve and allow the sediment and old fuel to drain out. This process may take some time, and you might need to prime the fuel pump to ensure a steady flow.

- Remove Sediment: After draining, carefully inspect the sediment that has been collected. You may notice a dark, gritty substance, which is the sediment and any accumulated contaminants. If the sediment is significant, consider using a fuel filter cleaner or a sediment removal tool to ensure a thorough cleaning.

- Re-fill and Run the Engine: Once the sediment is removed, carefully pour clean fuel back into the tank, ensuring it is full. Start the engine and let it run for a few minutes to ensure the fuel system is flushed and any remaining sediment is dislodged.

By regularly performing this sediment removal process, you can significantly reduce the risk of fuel line clogs. It is a simple yet effective maintenance task that can help maintain your vehicle's performance and fuel efficiency. Remember, preventing clogs is always more convenient and cost-effective than dealing with the consequences of a clogged fuel line.

Winterizing Outboard: Fuel Line Disconnect: A Wise Move?

You may want to see also

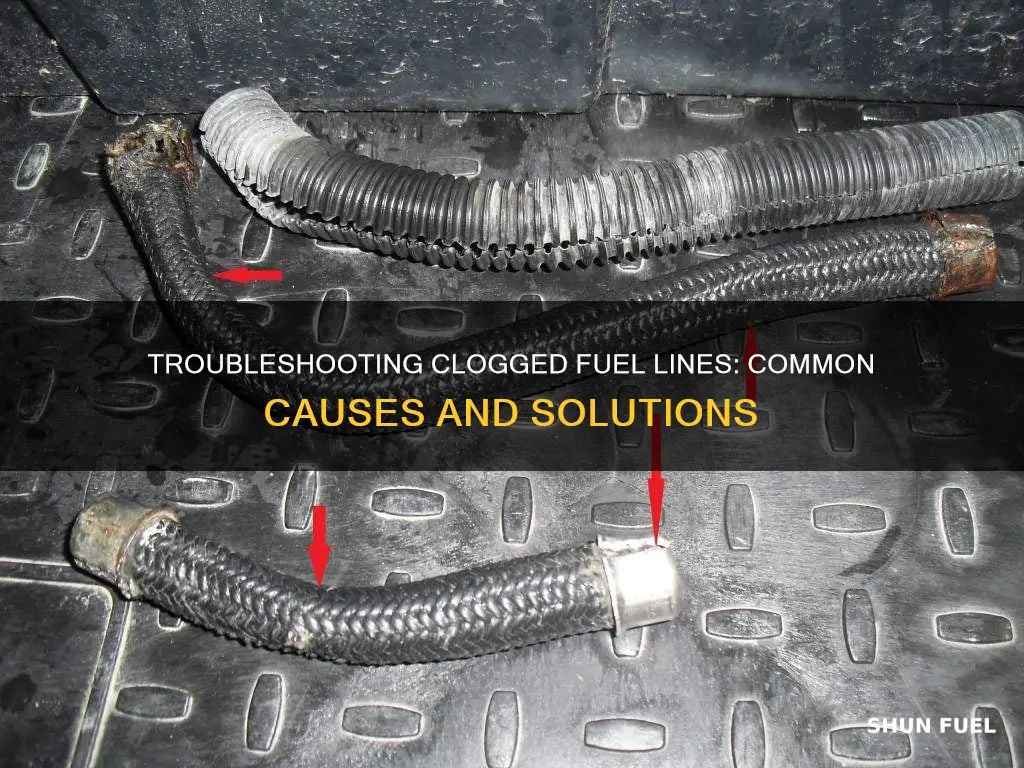

Fuel Line Damage: Inspect for cracks or damage in the fuel lines

Fuel lines are an essential component of your vehicle's fuel system, and damage to these lines can lead to serious performance issues and potential safety hazards. It's crucial to regularly inspect your fuel lines to ensure they are in good condition and to identify any potential problems early on. Here's a detailed guide on how to inspect for cracks or damage in the fuel lines:

Visual Inspection: Start by visually examining the fuel lines for any visible signs of damage. Look for cracks, splits, or any unusual wear and tear. Fuel lines are typically made of rubber or plastic, and over time, they can degrade due to exposure to heat, cold, and various chemicals. Check for any discoloration or hardening of the material, as this could indicate the presence of cracks that may not be immediately visible. Pay close attention to areas where the fuel lines connect to the fuel tank, pumps, and injectors, as these connections are more prone to damage.

Pressure Test: Conducting a pressure test is an effective way to identify hidden cracks or damage in the fuel lines. You can either use a professional diagnostic tool or a simple air compressor and gauge. Start the engine and allow it to idle. Then, apply pressure to the fuel lines using the air compressor. Listen for any hissing or whistling sounds, which could indicate a leak or damaged line. If you hear such noises, it's essential to inspect the affected area thoroughly. Additionally, check for any fuel dripping or pooling around the vehicle, as this could be a sign of a serious issue.

Feel for Leaks: Another method to inspect for fuel line damage is by feeling for leaks. Park your vehicle on a level surface and engage the parking brake. Turn the ignition to the 'on' position, but do not start the engine. After a few minutes, feel along the fuel lines for any warm spots, as this could indicate a fuel leak. If you detect a warm area, it's crucial to investigate further, as it may be a sign of a damaged line.

Use a Flashlight: During your inspection, use a flashlight to illuminate dark areas under the vehicle. This is especially important if you suspect a hidden crack or damage. Look for any signs of corrosion, rust, or debris that might indicate a problem. Remember to inspect all fuel lines, including those that run along the frame, under the seats, and behind the engine.

Regular Maintenance: Regular maintenance is key to preventing fuel line damage. Keep your vehicle's fuel system clean and free of debris. Use the recommended fuel additives to maintain the integrity of the fuel lines. Additionally, ensure that you regularly check and replace any worn-out fuel filters, as they can contribute to fuel line issues if left unattended.

Fuel Injector Linearity: A Matter of Efficiency and Precision

You may want to see also

Frequently asked questions

A clogged fuel line can cause a variety of issues with your vehicle's performance. Common symptoms include difficulty starting the engine, poor fuel efficiency, engine stalling, and a strong smell of gasoline or fuel vapor. If you notice any of these signs, it's essential to inspect the fuel line for blockages or damage.

Unclogging a fuel line can be a delicate process and should be approached with caution. Start by identifying the source of the clog, which could be a restriction in the line itself, a blocked filter, or a faulty fuel pump. If the clog is due to a filter, replace it with a new one. For a clogged line, you may need to flush the system with a fuel line cleaner or use a fuel line brush to manually remove any debris. It's recommended to consult a professional mechanic for complex fuel line issues.

Regular maintenance can help prevent fuel line clogs. Ensure you use the correct type of fuel recommended by your vehicle manufacturer. Over time, fuel can accumulate moisture, leading to corrosion and blockages. Using a fuel stabilizer can help mitigate this issue. Additionally, keeping your fuel tank relatively full can prevent vacuum conditions that might draw contaminants into the fuel system. Regularly checking and replacing the fuel filter as per the manufacturer's schedule is also crucial for maintaining a healthy fuel line.