When it comes to maintaining a Beckett oil furnace, one crucial aspect is ensuring the fuel line is the appropriate size. The size of the fuel line directly impacts the efficiency and performance of the furnace. In this paragraph, we will explore the factors to consider when determining the ideal fuel line size for your Beckett oil furnace, including the impact of flow rate, pressure, and the specific requirements of your heating system. Understanding these considerations will help you make an informed decision to optimize the functionality of your furnace.

What You'll Learn

- Fuel Line Diameter: Choose the right size based on furnace capacity

- Material Compatibility: Ensure the fuel line material suits the fuel type

- Length and Routing: Properly measure and route the fuel line

- Installation Techniques: Follow manufacturer guidelines for secure installation

- Maintenance and Inspection: Regularly check for leaks and damage

Fuel Line Diameter: Choose the right size based on furnace capacity

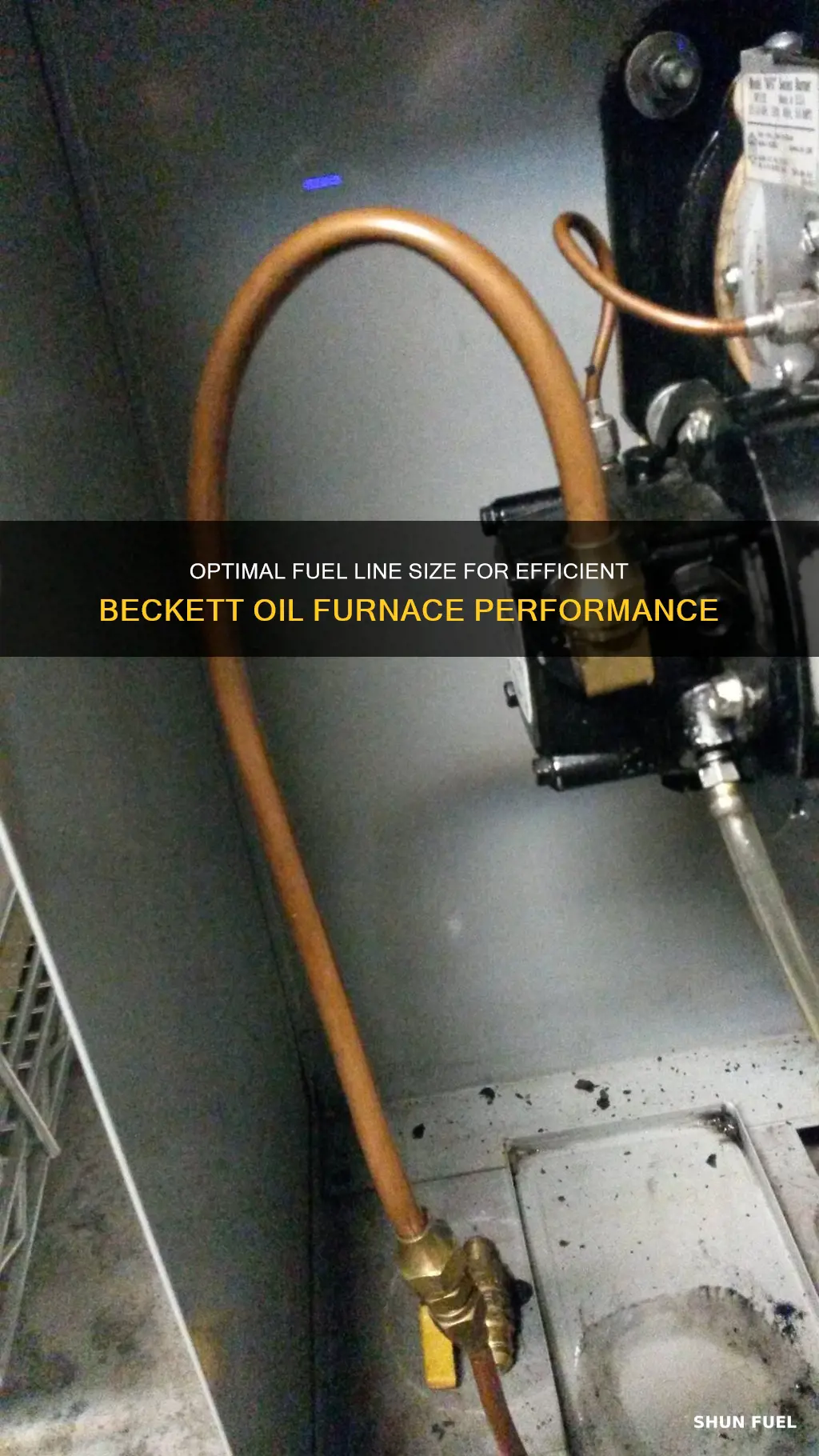

When it comes to selecting the appropriate fuel line for your Beckett oil furnace, the diameter of the fuel line is a critical factor that directly impacts the efficiency and performance of your heating system. The size of the fuel line should be chosen based on the capacity of your furnace to ensure optimal operation and prevent potential issues.

The capacity of your Beckett oil furnace is typically measured in terms of its heating output, often expressed in BTUs (British Thermal Units). This output determines the amount of fuel required to heat your space effectively. For instance, a larger furnace with a higher BTU rating will need a more substantial fuel supply, which is where the fuel line diameter comes into play.

The fuel line diameter is measured in inches, and it is essential to match this size to the furnace's requirements. A smaller diameter fuel line may restrict fuel flow, leading to inadequate heating and potential safety hazards. On the other hand, an oversized fuel line can result in unnecessary fuel consumption and increased operational costs. Therefore, it is crucial to choose a diameter that allows for efficient fuel delivery while maintaining safety standards.

To determine the right fuel line diameter, consult the manufacturer's guidelines or specifications for your specific Beckett oil furnace model. These guidelines often provide a recommended diameter range based on the furnace's capacity. For example, a furnace with a higher BTU rating might require a larger diameter fuel line, such as 3/8 inches or even 1/2 inches, to ensure a steady and sufficient fuel supply.

Additionally, consider the length of the fuel line. Longer fuel lines may require a larger diameter to compensate for potential pressure drops. It is advisable to use a fuel line calculator or consult with a professional to ensure the correct sizing for your specific setup. By carefully selecting the appropriate fuel line diameter based on your furnace's capacity, you can optimize its performance, ensure efficient heating, and maintain a safe and cost-effective operation.

Optimizing Performance: Choosing the Right Fuel Line for Your Mahle 145 Engine

You may want to see also

Material Compatibility: Ensure the fuel line material suits the fuel type

When it comes to choosing the right fuel line for your Beckett oil furnace, material compatibility is a critical factor that should not be overlooked. The fuel line is responsible for transporting fuel from the tank to the burner, and using the wrong material can lead to a host of problems, including fuel leaks, reduced efficiency, and even safety hazards.

The compatibility of the fuel line material with the fuel type is essential. Different fuels have varying chemical compositions and properties, and some materials may react with or degrade over time when exposed to certain fuels. For example, if you are using kerosene as your fuel, you should avoid materials like rubber or plastic, as these can become brittle and crack over time, leading to potential fuel leaks. Instead, opt for materials like stainless steel or brass, which are known for their durability and resistance to chemical corrosion.

For oil-based fuels, such as heating oil, the fuel line material should be able to withstand the fuel's properties, including its viscosity and potential for contamination. Materials like PVC (polyvinyl chloride) or certain types of rubber can be suitable for oil-based fuels, but it's crucial to ensure that the specific grade and formulation of the material are compatible. Always refer to the manufacturer's guidelines or consult a professional to determine the best material for your specific fuel type.

Additionally, consider the temperature and pressure requirements of your fuel system. Some materials may not be able to handle the extreme temperatures or pressures associated with certain fuel types. For instance, if your Beckett oil furnace operates at high temperatures, you might need a fuel line material with excellent heat resistance, such as a high-temperature plastic or a metal alloy.

In summary, when selecting a fuel line for your Beckett oil furnace, pay close attention to material compatibility with the fuel type. Research and choose materials that are known to be compatible with your specific fuel, ensuring longevity, efficiency, and safety in your heating system. Always consult the manufacturer's recommendations or seek expert advice to make an informed decision.

Braided Fuel Line Security: Tools and Techniques for a Tight Fit

You may want to see also

Length and Routing: Properly measure and route the fuel line

When it comes to installing or replacing the fuel line for your Beckett oil furnace, ensuring the correct length and routing is crucial for safe and efficient operation. Here's a detailed guide on how to properly measure and route the fuel line:

Measuring the Required Length:

The first step is to determine the appropriate length of the fuel line. Start by locating the existing fuel line (if you're replacing it) or identifying the points where the new line will connect. Measure the distance between the fuel supply valve (usually located near the furnace) and the burner assembly. This measurement should include the length of the existing line and any additional length needed to reach the burner. It's important to have a slightly longer line than required to allow for flexibility during installation.

Routing Considerations:

Fuel lines should be routed in a way that minimizes potential damage and ensures easy access for maintenance. Here are some key points to consider:

- Keep the line as straight as possible to reduce the risk of kinks and blockages. Avoid sharp bends or turns that could restrict fuel flow.

- Route the line away from heat sources, such as radiators or hot water pipes, to prevent overheating and potential damage.

- If the furnace is located outdoors, ensure the fuel line is protected from weather elements and potential damage from lawn care equipment. Consider using a protective covering or burying the line underground.

- Allow for a slight slope in the line to facilitate proper drainage and prevent the accumulation of debris or water.

Securing the Fuel Line:

Once you've measured and planned the routing, it's time to secure the fuel line. Use appropriate fittings and clamps to ensure a tight and leak-free connection. Make sure the line is properly supported at regular intervals to avoid excessive strain.

Remember, proper measurement and routing are essential for the safe and efficient operation of your Beckett oil furnace. Always refer to the manufacturer's guidelines and consult a professional if you're unsure about any aspect of the installation process.

Fuel Filter Lines: Understanding the Connections and Their Roles

You may want to see also

Installation Techniques: Follow manufacturer guidelines for secure installation

When installing a fuel line for a Beckett oil furnace, it is crucial to adhere to the manufacturer's guidelines to ensure a secure and efficient setup. These guidelines are designed to provide the best performance and safety for your heating system. Here's a step-by-step guide on how to follow these instructions:

- Gather the Required Materials: Before you begin, ensure you have all the necessary components as specified by the manufacturer. This includes the fuel line itself, fittings, clamps, and any additional tools or accessories recommended. Having everything ready will make the installation process smoother.

- Prepare the Fuel Line: Carefully examine the fuel line for any visible damage or defects. Check for cracks, leaks, or any signs of deterioration. If any issues are found, replace the fuel line with a new one to avoid potential problems during operation. Ensure the fuel line is the correct size and type as specified for your Beckett furnace.

- Secure Installation:

- Locate the appropriate mounting points on the furnace and the wall or structure where the fuel line will be attached.

- Follow the manufacturer's instructions to secure the fuel line using the provided fittings and clamps. Tighten the connections securely but avoid over-tightening to prevent damage.

- Ensure the fuel line is positioned away from any heat sources or potential hazards to prevent overheating or fire risks.

- Check for any obstructions or interference that might affect the fuel flow.

Testing and Inspection: After the installation, it is essential to test the system to ensure everything functions correctly. Turn on the furnace and monitor the fuel supply. Check for any leaks or unusual noises. Inspect all connections and fittings to ensure they are tight and secure. If any issues are detected, refer to the manufacturer's troubleshooting guide or consult a professional for assistance.

By following the manufacturer's guidelines, you can ensure a proper and safe installation of the fuel line for your Beckett oil furnace. This approach guarantees optimal performance and longevity of your heating system, providing efficient and reliable warmth during the colder months. Remember, proper installation is key to maintaining the safety and efficiency of your home's heating system.

Understanding Standard Outboard Primer Fuel Lines: A Comprehensive Guide

You may want to see also

Maintenance and Inspection: Regularly check for leaks and damage

When it comes to maintaining your Beckett oil furnace, regular inspection and maintenance are crucial to ensure optimal performance and longevity. One critical aspect of this maintenance routine is checking for leaks and damage to the fuel line. The fuel line is responsible for transporting oil from the tank to the furnace, and any issues with it can lead to inefficient operation or even safety hazards.

Start by locating the fuel line, which is typically a black or dark-colored hose connected to the oil tank and running along the side of the furnace. Inspect the line for any visible signs of damage, such as cracks, punctures, or kinks. Over time, fuel lines can deteriorate due to age, extreme temperatures, or physical damage from rodents or other pests. Look for any frayed or exposed areas that might indicate wear and tear.

Regularly checking for leaks is another essential part of this process. Start by shutting off the oil supply to the furnace and then carefully inspect the connection points between the fuel line and the tank as well as the furnace itself. Apply a small amount of soapy water to the connections and observe if any bubbles appear. Bubbles indicate a leak, and you should address this issue promptly. Leaks can lead to oil wastage, increased fuel costs, and potential environmental contamination.

Additionally, pay attention to any signs of corrosion or rust around the fuel line connections. Corrosion can weaken the integrity of the line, leading to potential leaks or even a complete rupture. If you notice any corrosion, consider replacing the affected section of the fuel line. It's also a good practice to check for any signs of oil accumulation or residue around the line, as this could be an indicator of a leak or improper operation.

Remember, regular maintenance and inspection can help prevent unexpected breakdowns and costly repairs. By taking the time to check for leaks and damage to the fuel line, you can ensure that your Beckett oil furnace operates efficiently and safely, providing reliable heat during the colder months.

Optimizing Fuel Delivery: Choosing the Right Line Size for Your Subaru

You may want to see also

Frequently asked questions

The fuel line size for a Beckett oil furnace typically ranges from 3/8 inch to 1/2 inch in diameter. The specific size may vary depending on the model and the fuel delivery system. It's important to consult the manufacturer's guidelines or a professional technician to determine the appropriate size for your particular furnace.

Using a larger fuel line than recommended is generally not advisable. The fuel line size is designed to match the flow rate and pressure requirements of the furnace. A larger line may lead to excessive fuel flow, causing potential issues with fuel pressure regulation and safety. It's best to stick to the manufacturer's specifications to ensure optimal performance and safety.

If you're unsure about the fuel line size, it's recommended to consult the furnace's user manual or contact the manufacturer's customer support. They can provide specific details about the recommended fuel line dimensions for your model. Alternatively, a qualified technician can inspect the furnace and fuel system to determine the correct size and make any necessary adjustments.