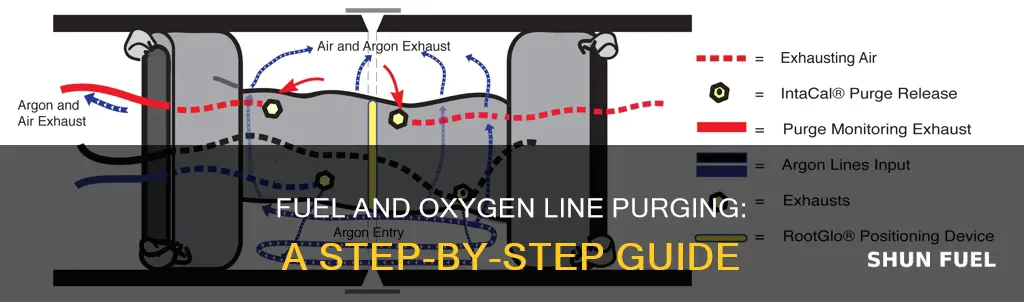

Fuel and oxygen lines are essential components of any combustion engine, and keeping them in good condition is crucial for optimal performance. Over time, these lines can become clogged with contaminants, leading to reduced efficiency and potential engine issues. Purging these lines is a process that involves removing any built-up debris, moisture, or other impurities to ensure clean and efficient operation. This guide will provide a step-by-step process for effectively purging fuel and oxygen lines, ensuring your engine runs smoothly and reliably.

What You'll Learn

- Preparation: Ensure engine is off and fuel is disconnected

- Fuel Line Access: Locate and remove fuel line connectors and clamps

- Oxygen Line Identification: Find and isolate oxygen sensor lines

- Bleeding Process: Use a fuel purge tool to release trapped air

- Testing: Verify flow and pressure with a gauge after purging

Preparation: Ensure engine is off and fuel is disconnected

Before you begin the process of purging fuel and oxygen lines, it is crucial to ensure that the engine is in a safe and controlled state. The first step in this process is to turn off the engine and disconnect the fuel supply. This is an essential safety measure to prevent any accidental fuel release or engine operation during the purging process.

When the engine is off, it eliminates the risk of any sudden movements or vibrations that could potentially damage the lines or cause fuel to spray unexpectedly. Additionally, disconnecting the fuel supply means you won't have any fuel pressure building up in the lines, which could lead to splashing or spilling during the purging process.

To disconnect the fuel supply, locate the fuel lines, which are typically found near the engine's fuel tank or fuel pump. These lines are often made of rubber or plastic and may have metal fittings or clips holding them in place. Carefully remove any clips or fasteners securing the lines to ensure they can be moved without causing damage. Then, gently pull the lines away from the engine and fuel source, being mindful of any sharp bends or kinks that could restrict flow.

Once the fuel lines are disconnected, it's a good practice to place a container or rag under the lines to catch any residual fuel that may have accumulated in the system. This simple step helps to prevent any fuel from spilling onto the ground or causing damage to the surrounding area.

By taking these preparatory steps, you ensure that the purging process can be carried out safely and effectively, minimizing the risk of accidents or damage to the vehicle. It also allows you to focus on the specific task of purging the lines without the added concern of potential hazards.

Teguar ClampD: A Fuel Line Alternative?

You may want to see also

Fuel Line Access: Locate and remove fuel line connectors and clamps

When it comes to purging fuel and oxygen lines, one crucial step is gaining access to the fuel lines themselves. This involves carefully locating and removing the various connectors and clamps that secure the lines in place. Here's a step-by-step guide to help you through this process:

Step 1: Identify the Fuel Lines

Start by identifying the fuel lines in your vehicle. These lines are typically made of rubber or plastic and carry fuel from the tank to the engine. They are often located beneath the vehicle, running along the frame and towards the engine bay. Locate the fuel lines that connect to the fuel pump, injectors, or any other fuel-related components.

Step 2: Locate the Connectors and Clamps

Fuel lines are secured in place using various connectors and clamps. These can include rubber or plastic connectors, metal clips, or clamps. Carefully inspect the fuel lines to identify these fasteners. They are usually positioned at regular intervals along the length of the line, ensuring a secure connection. Take note of the specific locations of these connectors and clamps, as you will need to remove them systematically.

Step 3: Remove the Clamps and Connectors

Now, it's time to carefully remove these fasteners. Start with the clamps or clips, as they are often the most challenging to remove. Use a pair of pliers or a specialized fuel line removal tool to grip the clamp and twist it counterclockwise. Be gentle to avoid damaging the fuel line. Once the clamp is loosened, carefully pull it away from the line. Repeat this process for each connector and clamp along the fuel line. Take your time to ensure you don't force anything, as this can lead to damage.

Step 4: Inspect and Clean (Optional)

After removing the fasteners, you might want to inspect the fuel lines for any signs of damage, cracks, or contamination. If you notice any issues, consider replacing the affected sections. Additionally, you can clean the fuel lines at this stage. Use a fuel line cleaner or a mild detergent to remove any built-up fuel residue or deposits. This step is especially important if you're preparing for a long-term storage period or a major engine overhaul.

Remember, when working with fuel lines, it's essential to exercise caution and patience. Take your time to locate and remove each connector and clamp, ensuring a thorough purge of the fuel and oxygen lines. This process contributes to maintaining a healthy fuel system and optimizing engine performance.

Perfect Fuel Line Size for Suzuki DT 140

You may want to see also

Oxygen Line Identification: Find and isolate oxygen sensor lines

Identifying and isolating the oxygen sensor lines is a crucial step in the process of purging fuel and oxygen lines. This task requires a systematic approach to ensure you locate the correct lines and avoid any potential hazards. Here's a step-by-step guide to help you through this process:

Locate the Oxygen Sensor Lines: Start by familiarizing yourself with the vehicle's engine bay and the layout of its components. Oxygen sensors are typically located in the exhaust system, often near the catalytic converter or downstream of it. These sensors are designed to measure the oxygen content in the exhaust gases. Look for the following indicators to find the oxygen lines:

- Color-coded Lines: Oxygen sensor lines are usually color-coded to distinguish them from other fuel lines. Common colors include green, blue, or yellow. Check your vehicle's manual or a reliable online resource to identify the specific colors used in your car.

- Sensor Mounting Positions: Sensors are often mounted in specific positions. For example, some vehicles have sensors positioned vertically, while others might have them horizontally. Locate these mounting positions to find the corresponding lines.

- Exhaust System Components: Follow the exhaust system from the engine to the tailpipe. The oxygen sensors are typically located along this path, and you might see the lines connecting to these sensors.

Isolating the Lines: Once you've identified the oxygen lines, it's essential to isolate them to ensure a safe and controlled purging process. Here's how:

- Locate the Sensor Connections: Find the points where the oxygen sensor lines connect to the engine and the exhaust system. These connections are usually secured with clamps or fittings.

- Remove Clamps or Fittings: Carefully remove the clamps or fittings to expose the lines. Take note of the positions of these connections to ensure you can reattach them later.

- Cover Surrounding Areas: To prevent any fuel or oxygen from spilling, cover the surrounding areas with rags or absorbents. This step is crucial to maintain a safe working environment.

- Use a Fuel/Oxygen Line Tool (Optional): Consider using a specialized tool designed for purging fuel and oxygen lines. These tools can help you isolate the lines further and provide a more controlled environment for the purging process.

Remember, when working with fuel and oxygen lines, it's essential to exercise caution and follow safety guidelines. Always ensure the engine is in a safe condition before proceeding with any purging procedures.

Rubber vs. Steel Fuel Lines: When to Choose Each

You may want to see also

Bleeding Process: Use a fuel purge tool to release trapped air

The bleeding process, specifically using a fuel purge tool to release trapped air, is a crucial step in ensuring optimal engine performance and fuel efficiency. This method is particularly useful when dealing with fuel lines that have been idle or have experienced a sudden change in temperature, leading to the accumulation of air bubbles. Here's a step-by-step guide to effectively purge fuel and oxygen lines using this technique:

Start by locating the fuel purge tool, which is typically a specialized device designed for this purpose. It often consists of a long, flexible tube with a pressure gauge or a simple release valve. Ensure you have a clear understanding of the tool's functionality and any specific instructions provided by the manufacturer.

Identify the fuel lines you intend to purge. These lines are usually located near the engine and may be visible as hoses or tubes. Locate the fuel pump, as it is often the starting point for the bleeding process. The fuel pump is responsible for sending fuel to the engine, and any air bubbles in the line can disrupt this process.

Attach the fuel purge tool to the fuel line, ensuring a secure connection. The tool should be positioned near the fuel pump to facilitate the release of air. Apply gentle pressure to the tool's release valve, allowing it to draw fuel from the pump. This action will create a vacuum, pulling air out of the line. Listen for any hissing sounds, indicating the release of air.

Continue the process by moving the tool along the fuel line, section by section. This systematic approach ensures that air is purged from the entire length of the line. Take note of any changes in the sound or feel of the tool, as these can indicate the presence of air bubbles. The goal is to eliminate any air pockets, ensuring a smooth and continuous flow of fuel.

Once you've covered the entire fuel line, repeat the process for the oxygen lines, if applicable. Oxygen lines are responsible for delivering oxygen to the engine, and they may also require bleeding to optimize performance. Remember to always refer to your vehicle's manual for specific line locations and any unique requirements.

By following these steps and utilizing a fuel purge tool, you can effectively remove trapped air from fuel and oxygen lines, contributing to improved engine performance and overall vehicle efficiency. This method is a valuable technique for any vehicle owner or mechanic to master, ensuring a well-maintained and reliable engine.

Troy Bilt 200 Gas Fuel Line Filter: Essential or Not?

You may want to see also

Testing: Verify flow and pressure with a gauge after purging

After completing the purging process, it's crucial to verify the effectiveness of the procedure by testing the flow and pressure in the fuel and oxygen lines. This step ensures that any contaminants or air pockets have been successfully removed, allowing for optimal performance. Here's a detailed guide on how to perform this test:

Preparation: Before initiating the test, ensure you have the necessary tools and equipment. You will need a fuel pressure gauge, an oxygen sensor tester (if applicable), and a reliable power source for any electronic components. Additionally, have a clean workspace to prevent any contamination during the testing process.

Step-by-Step Testing: Begin by starting the engine and allowing it to reach operating temperature. This step is essential as it simulates real-world conditions. Once the engine is warm, locate the fuel lines and oxygen sensors (if present). Connect the fuel pressure gauge to the fuel line, ensuring a secure connection. Turn on the gauge and observe the reading. The pressure should be within the specified range for your vehicle's make and model. If the pressure is significantly lower or higher than the expected value, it may indicate a blockage or malfunction in the fuel system.

Next, focus on the oxygen lines (if applicable). Use the oxygen sensor tester to check for proper sensor functionality. The tester will provide a reading indicating the sensor's efficiency in detecting oxygen levels. Compare the results with the manufacturer's specifications. If the sensor reading is outside the acceptable range, it might suggest a faulty sensor or a need for further purging.

Troubleshooting: If the pressure or flow test reveals any issues, troubleshooting can begin. Check for clogs or restrictions in the lines, as they could be the cause of inadequate flow or pressure. Inspect the lines for any signs of damage, corrosion, or leaks. In some cases, replacing certain components might be necessary to restore optimal performance.

Drill Out Blocked Fuel Line: A Step-by-Step Guide for Motorcyclists

You may want to see also

Frequently asked questions

Purging these lines is essential to remove contaminants, such as water, air, and debris, which can accumulate over time. This process ensures that the fuel and oxygen systems in an engine or vehicle are clean and free from any potential issues that may cause performance problems or damage.

Signs that indicate the need for purging include engine misfires, poor fuel efficiency, hard starting, or unusual noises from the fuel system. If you notice any of these symptoms, it's advisable to inspect the lines and consider a purge procedure.

You will typically need a fuel pump primer bulb, a fuel filter bypass tool (if applicable), a pressure gauge, and a container to collect any drained fluid. Some vehicles may also require specific purging tools provided by the manufacturer.

While some basic purging can be done by vehicle owners, it is often recommended to seek professional assistance, especially for complex systems or if you lack experience. Professionals have the knowledge and tools to ensure a thorough purge and can identify any underlying issues.

The process usually involves turning the ignition to the 'on' position without starting the engine, then using the primer bulb to prime the fuel system. For oxygen lines, you may need to disconnect and reconnect lines or use a dedicated purging tool. Always refer to your vehicle's manual for manufacturer-specific instructions.