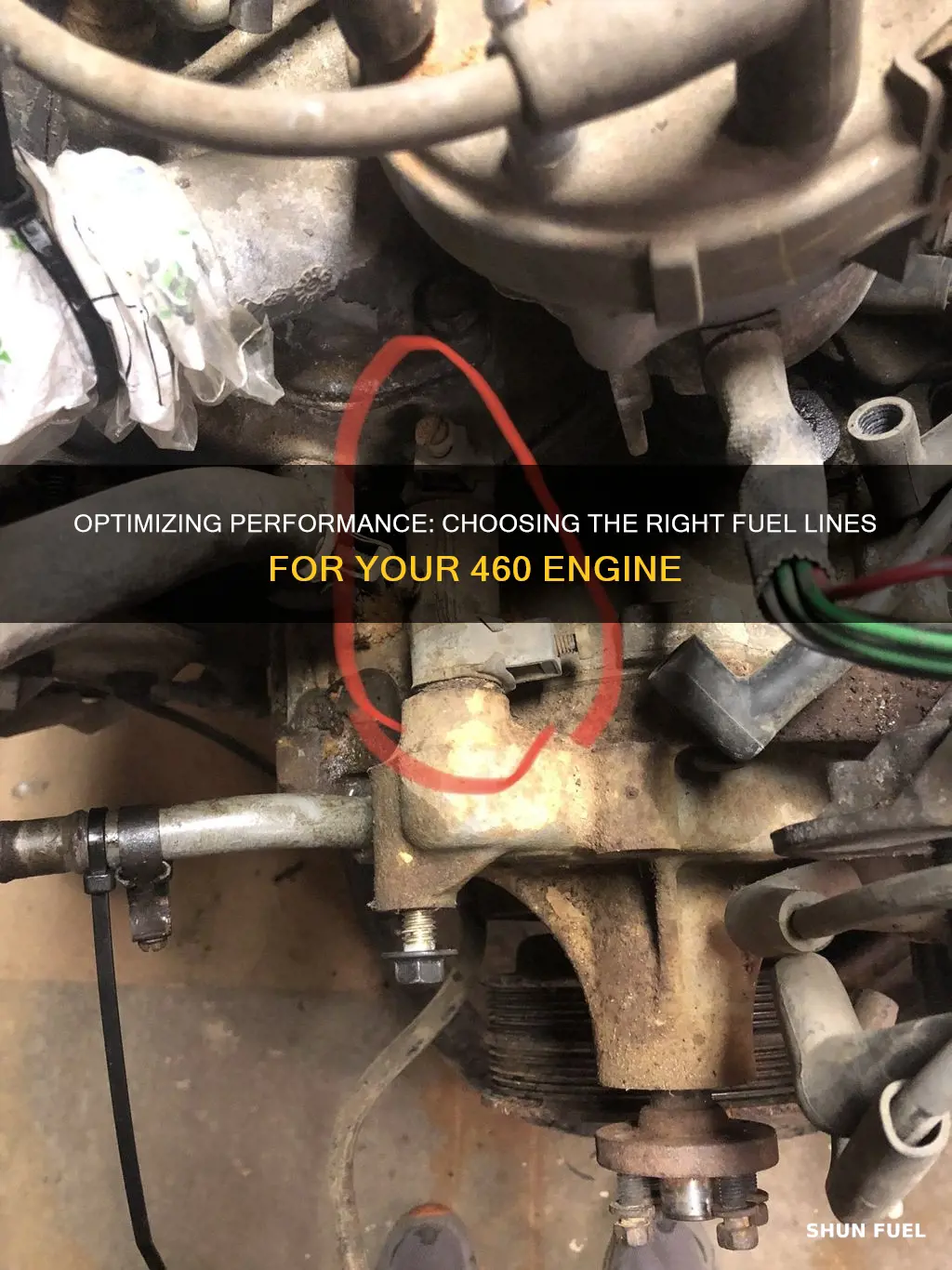

When it comes to engine performance, fuel delivery is crucial. For a 460 engine, the right fuel lines are essential to ensure optimal power and efficiency. The size of the fuel lines needed for a 460 engine depends on several factors, including the engine's power output, fuel pump specifications, and the overall fuel system design. In this guide, we'll explore the recommended fuel line sizes for a 460 engine, helping you make informed decisions to enhance your vehicle's performance.

| Characteristics | Values |

|---|---|

| Typical fuel line size for a 460 engine | 3/8" to 1/2" ID (inside diameter) |

| Material | Steel or stainless steel |

| Length | Varies depending on engine location and configuration |

| Routing | Direct from the fuel pump to the carburetor or fuel injectors |

| Pressure rating | 150-200 psi (pounds per square inch) or higher |

| Compatibility | Specific to the engine model and year |

| Installation | May require fuel line connectors and fittings |

What You'll Learn

- Engine Displacement: 460 cubic inches requires larger fuel lines to handle increased volume

- Fuel Pump Location: Proximity to the engine affects line size for optimal performance

- Flow Rate: Higher flow rates demand thicker fuel lines to prevent restriction

- Material: Stainless steel or aluminum lines offer durability and corrosion resistance

- Length: Customized lengths ensure proper routing and clearance in the engine bay

Engine Displacement: 460 cubic inches requires larger fuel lines to handle increased volume

For those with a 460 cubic inch engine, ensuring the right fuel lines are in place is crucial for optimal performance. This engine displacement is significantly larger than the average, and as such, it demands specific fuel line requirements to handle the increased volume of fuel required. The primary goal is to facilitate efficient fuel delivery to meet the engine's higher demands without compromising performance or fuel efficiency.

When it comes to fuel lines, the size is directly related to the engine's needs. For a 460 cubic inch engine, larger-diameter fuel lines are essential. The standard fuel line size for this engine is typically 3/8 inch in diameter, which is a significant upgrade from the usual 1/4 inch lines found in smaller engines. This larger diameter allows for increased fuel flow, ensuring that the engine receives the necessary volume of fuel to operate at its peak.

The increased engine displacement means a higher capacity for fuel, and thus, the fuel lines need to accommodate this. The longer and more robust fuel lines provide a smoother fuel flow, reducing the risk of fuel starvation, especially during high-performance driving conditions. This is particularly important for high-performance vehicles, where the engine's power output is maximized, and fuel delivery must be seamless to maintain optimal performance.

Upgrading to larger fuel lines is a recommended modification for those with a 460 cubic inch engine. It ensures that the engine receives the required fuel volume efficiently, promoting better performance and potentially increasing horsepower. Additionally, larger fuel lines can improve fuel efficiency by reducing the engine's need to work harder to draw fuel, thus saving on fuel costs in the long run.

In summary, for a 460 cubic inch engine, larger fuel lines are a necessary upgrade to handle the increased fuel volume. The 3/8 inch diameter fuel lines are designed to provide efficient fuel delivery, ensuring the engine operates at its best. This modification is a valuable investment for enthusiasts and performance-minded drivers, as it directly impacts the engine's performance and overall driving experience.

YZ 78 Fuel Line: Choosing the Right Size for Optimal Performance

You may want to see also

Fuel Pump Location: Proximity to the engine affects line size for optimal performance

The location of the fuel pump in relation to the engine is a critical factor in determining the appropriate size of fuel lines for a 460 engine. When the fuel pump is located closer to the engine, it requires smaller fuel lines to ensure efficient fuel delivery. This proximity allows for shorter lines, reducing the risk of fuel pressure loss and maintaining optimal performance. Smaller lines are ideal as they minimize the potential for fuel vaporization, which can lead to reduced engine power and efficiency.

In contrast, if the fuel pump is positioned farther from the engine, larger fuel lines become necessary. Longer lines are required to accommodate the increased distance, ensuring that fuel can be delivered effectively without significant pressure drops. This scenario is common in vehicles with fuel pumps located in the fuel tank or behind the engine bay, where the pump is not directly adjacent to the engine block.

The key principle here is that the closer the fuel pump is to the engine, the smaller the fuel lines can be, and vice versa. This relationship is essential to understand when designing or modifying a fuel system for a 460 engine. Engineers and enthusiasts must consider the pump's location to select the appropriate line sizes, ensuring that fuel is delivered efficiently and effectively to the engine.

In practice, this means that for a 460 engine with a fuel pump near the engine block, using smaller fuel lines, such as 3/8-inch or 1/2-inch ID lines, is often sufficient. These lines provide a direct and efficient path for fuel, minimizing pressure losses and ensuring optimal engine performance. However, for engines with the fuel pump farther away, larger lines, such as 5/16-inch or 3/8-inch ID lines, might be necessary to maintain the required fuel pressure and flow.

Understanding the impact of fuel pump location on line size is crucial for anyone working on a 460 engine's fuel system. It allows for informed decisions regarding fuel line selection, ensuring that the engine receives the necessary fuel for optimal performance and longevity. Proper line sizing, based on the pump's proximity to the engine, is a fundamental aspect of maintaining a well-functioning fuel system.

Metal Fuel Lines: Unlocking Engine Performance and Reliability

You may want to see also

Flow Rate: Higher flow rates demand thicker fuel lines to prevent restriction

When it comes to fuel lines for a 460 engine, flow rate is a critical factor that determines the size and thickness of the lines required. Higher flow rates, which are often associated with more powerful engines, demand thicker fuel lines to ensure optimal performance and prevent any restrictions. This is because the increased flow rate requires a larger diameter fuel line to accommodate the higher volume of fuel being delivered to the engine.

The primary concern with higher flow rates is the potential for fuel restriction, which can significantly impact engine performance. Restriction occurs when the fuel line's diameter is too small to handle the volume of fuel, leading to reduced flow and potential engine issues. Thicker fuel lines, with larger diameters, are designed to handle higher flow rates without restricting the fuel's path to the engine. This ensures that the engine receives the necessary fuel for efficient operation, especially during high-performance driving conditions.

To determine the appropriate thickness, it's essential to consider the engine's specifications and the fuel pump's capabilities. The fuel pump is a crucial component in this process, as it generates the pressure required to move the fuel through the system. A more powerful fuel pump can handle higher flow rates, allowing for the use of thinner lines, but it's still important to match the line's thickness to the pump's capacity. Consulting the engine manufacturer's guidelines or seeking expert advice is recommended to ensure the correct specifications are met.

In practice, thicker fuel lines are often made from high-quality materials that can withstand the pressure and temperature changes associated with high-performance engines. These lines are designed to be more flexible, ensuring they can bend and move with the engine's components without restricting flow. The choice of material is crucial, as it directly impacts the line's durability and ability to handle the fuel's properties.

In summary, for a 460 engine, higher flow rates necessitate thicker fuel lines to prevent fuel restriction and ensure optimal performance. This is a critical aspect of engine maintenance and modification, requiring careful consideration of the engine's specifications and the fuel system's capabilities. By addressing this factor, enthusiasts can optimize their engine's power and efficiency while maintaining a reliable and safe fuel delivery system.

Chevy S10 Fuel Line Sizing: A Comprehensive Guide

You may want to see also

Material: Stainless steel or aluminum lines offer durability and corrosion resistance

When it comes to choosing the right fuel lines for a 460 engine, material selection is crucial for ensuring optimal performance and longevity. Stainless steel and aluminum are two popular materials that offer distinct advantages in this regard.

Stainless steel fuel lines are renowned for their exceptional durability and resistance to corrosion. This material is highly resistant to the effects of fuel, including ethanol-blended gasoline, which is commonly used in modern vehicles. The inherent strength of stainless steel ensures that the fuel lines can withstand the pressure and temperature fluctuations associated with engine operation. Additionally, stainless steel's corrosion-resistant properties mean that the fuel lines will not degrade over time due to exposure to fuel, moisture, or road salt, ensuring a long-lasting and reliable fuel supply.

Aluminum fuel lines also provide excellent durability and corrosion resistance. They are lightweight and offer good heat dissipation, which can be beneficial in high-performance applications. Aluminum's natural corrosion resistance is further enhanced by the application of protective coatings, ensuring that the fuel lines remain in excellent condition even in harsh environments. While aluminum may not be as strong as stainless steel, it is still capable of withstanding the demands of a 460 engine, making it a viable option for many vehicle owners.

Both materials offer superior protection against fuel leaks, which is a critical aspect of engine performance and safety. The choice between stainless steel and aluminum often comes down to specific application requirements and personal preferences. For instance, stainless steel might be preferred for its slightly higher cost and superior strength, while aluminum could be chosen for its lightweight nature and ease of installation.

In summary, when considering the material for fuel lines in a 460 engine, both stainless steel and aluminum offer excellent durability and corrosion resistance. The decision should be based on the specific needs of the vehicle, the desired performance characteristics, and the trade-offs between material strength, weight, and cost.

Optimizing Performance: Choosing the Right Fuel Line for Weber Progressive 32/36

You may want to see also

Length: Customized lengths ensure proper routing and clearance in the engine bay

When it comes to fuel lines for a 460 engine, one of the most critical aspects is ensuring the correct length. Customized lengths are essential to guarantee proper routing and clearance within the engine bay, which is crucial for optimal performance and safety.

The engine bay of a 460 is a confined space with various components and systems. Fuel lines need to be carefully routed to avoid interference with moving parts, such as the engine block, intake manifold, and other accessories. Customized lengths allow for precise placement, ensuring that the fuel lines are neither too tight nor too loose, which could lead to performance issues or potential damage.

Proper routing also considers the clearance between the fuel lines and the surrounding components. Insufficient clearance can result in rubbing or interference, causing wear and tear on the fuel lines or even leading to potential hazards. By tailoring the length, mechanics can ensure that the fuel lines have adequate space to move freely without coming into contact with other parts.

Furthermore, customized lengths enable the fuel lines to be positioned in a way that facilitates easy access for maintenance and repairs. This is particularly important for high-performance engines, where regular maintenance and tuning may be required. With the right length, mechanics can quickly identify and address any issues without having to manipulate the fuel lines excessively.

In summary, opting for customized fuel line lengths is a practical approach to ensure the 460 engine's fuel system operates efficiently and safely. It allows for optimal routing, clearance, and accessibility, contributing to the overall performance and longevity of the engine.

Buick Century Fuel Line Size: A Comprehensive Guide

You may want to see also

Frequently asked questions

The fuel lines for a 460 engine typically range from 5/16" to 3/8" in diameter, depending on the specific application and performance requirements. It's important to choose the correct size to ensure optimal fuel flow and pressure.

To find the appropriate fuel line size, consider factors such as the engine's power output, fuel pump specifications, and the desired fuel pressure. Consulting the vehicle's manual or seeking advice from automotive experts can provide valuable guidance.

Using smaller fuel lines than recommended can restrict fuel flow, leading to reduced performance and potential engine issues. It's crucial to select fuel lines that meet or exceed the engine's requirements for efficient operation.

Larger fuel lines can improve fuel delivery, especially in high-performance applications, by reducing pressure drop and allowing for smoother fuel flow. However, it's essential to ensure that the engine's fuel system can handle the increased volume.

Fuel lines for 460 engines are often made from materials like steel, stainless steel, or high-temperature rubber compounds to withstand fuel pressure and temperature variations. The choice of material depends on the specific engine and environmental conditions.