Removing fuel lines from a sending unit can be a crucial step in engine maintenance or repair. This process involves carefully disconnecting the fuel lines to access or replace the sending unit, which measures the fuel level in a vehicle's tank. To ensure a smooth and safe procedure, it's essential to follow a step-by-step guide that includes identifying the correct tools, understanding the layout of the fuel lines, and taking necessary safety precautions to avoid fuel spills or engine damage. This guide will provide a detailed process to help you efficiently and safely remove the fuel lines from the sending unit.

What You'll Learn

- Locate the Sending Unit: Identify the sending unit and its fuel lines

- Disconnect Fuel Lines: Loosen and remove fuel lines from the sending unit

- Release Clamps: Carefully release any clamps holding the lines in place

- Inspect for Damage: Check for any signs of damage or corrosion

- Reinstall Fuel Lines: Properly reconnect the lines and secure them

Locate the Sending Unit: Identify the sending unit and its fuel lines

To begin the process of removing fuel lines from a sending unit, you must first locate the sending unit itself. The sending unit, also known as the fuel pump module, is a crucial component in your vehicle's fuel system. It is typically located near the engine, often in the engine compartment or behind the rear panel. Identifying its exact position will be the first step in your project.

The sending unit is responsible for regulating the fuel flow to the engine, ensuring the correct amount of fuel is delivered. It is usually connected to the fuel tank via a fuel line, which carries the fuel from the tank to the sending unit. This line is often a flexible hose or a rigid tube, depending on the vehicle's design. Another fuel line connects the sending unit to the engine, delivering fuel to the injectors or carburetor. These lines are critical to the engine's performance and must be handled with care.

Identifying the sending unit and its fuel lines is essential for a successful removal process. You can often find the sending unit by following the fuel lines from the fuel tank. The lines will lead you to a small, rectangular or cylindrical component with various sensors and valves. The fuel lines are typically color-coded or labeled to indicate their purpose, making it easier to identify the correct lines.

Once you've located the sending unit, carefully inspect the fuel lines. Ensure you understand the layout and connections of each line. Take note of any bends, kinks, or signs of damage. This information will be crucial when you start the removal process, as you'll need to carefully manage the lines to avoid any damage during disconnection.

Remember, the key to a successful removal is patience and a systematic approach. Take your time to locate and understand the sending unit and its fuel lines. This detailed understanding will make the subsequent steps, such as disconnecting the lines and removing the sending unit, much smoother and safer.

Gravely 812 Fuel Line: Sources for Your Outdoor Power Equipment

You may want to see also

Disconnect Fuel Lines: Loosen and remove fuel lines from the sending unit

To disconnect fuel lines from the sending unit, you'll need to follow a systematic approach to ensure a safe and efficient process. Here's a step-by-step guide:

Step 1: Prepare the Vehicle

Start by ensuring the vehicle is parked on a level surface and the engine is cool. This is crucial for safety and to avoid any potential fuel leaks. Locate the sending unit, which is typically a small box-like component attached to the fuel tank. Identify the fuel lines connected to it; there might be two or more lines, each with a different purpose.

Step 2: Locate the Fuel Lines

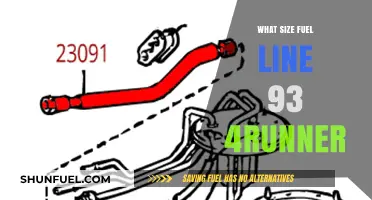

Carefully inspect the sending unit and locate the fuel lines. They are usually rubber or plastic hoses with metal fittings. Note the position of these lines to ensure you reconnect them correctly later. You might need to remove some panels or access panels to get a clear view of the connections.

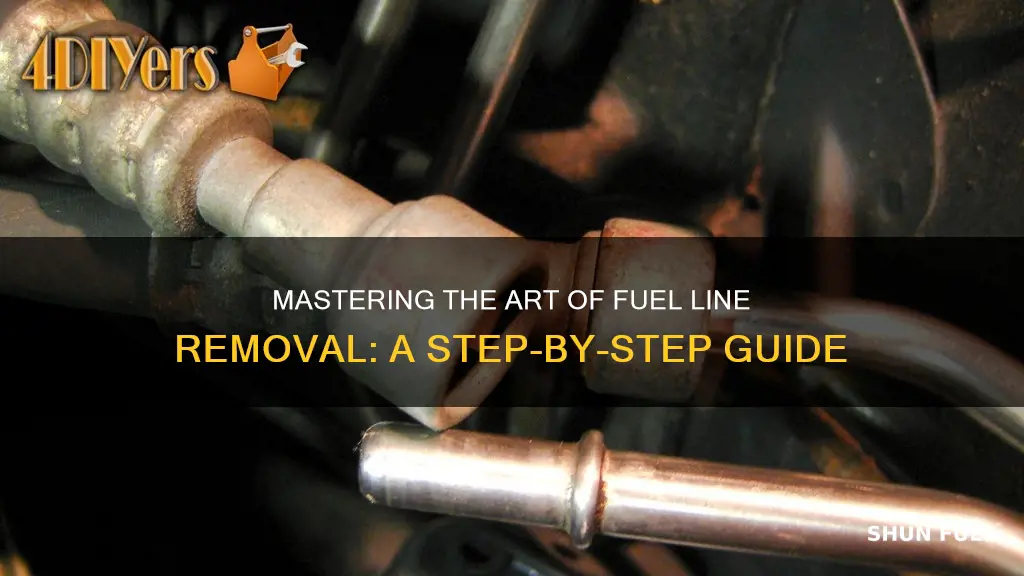

Step 3: Loosen the Fuel Lines

Using a fuel line removal tool or a pair of adjustable pliers, carefully loosen the fittings that secure the fuel lines to the sending unit. Turn the fittings counterclockwise to release the tension. Be gentle to avoid damaging the lines or the sending unit. If the lines are particularly tight, you may need to apply some force, but be cautious not to strip the threads.

Step 4: Remove the Fuel Lines

Once the fittings are loosened, carefully pull the fuel lines away from the sending unit. You might need to wiggle the lines slightly to free them from any tight spots. Ensure you don't pull too hard, as this could damage the lines or the sending unit's connections. Set the removed fuel lines aside, labeling or marking them to remember their positions.

Step 5: Clean and Inspect

Before reconnecting, it's a good practice to clean the sending unit's connections and the fuel lines. Use a fuel line cleaner or a mild detergent to remove any debris or contaminants. Inspect the lines for any signs of damage, cracks, or leaks. If you notice any issues, consider replacing the fuel lines to ensure optimal performance.

Step 6: Reconnect and Secure

Now, carefully reconnect the fuel lines to the sending unit, ensuring they are aligned correctly. Tighten the fittings securely but be careful not to overtighten, as this can cause damage. Double-check your connections to ensure they are tight and secure.

Remember, when working with fuel lines, always exercise caution and wear protective gear, especially when dealing with hot or under pressure systems. If you're unsure or uncomfortable with any step, consult a professional mechanic to ensure the job is done safely and correctly.

Where to Find 5/16 Fuel Line: A Comprehensive Guide

You may want to see also

Release Clamps: Carefully release any clamps holding the lines in place

When it comes to removing fuel lines from a sending unit, one of the crucial steps is releasing the clamps that hold the lines in place. This process requires careful attention to detail and a systematic approach to ensure a successful and safe removal. Here's a step-by-step guide on how to release these clamps effectively:

Start by identifying the clamps that secure the fuel lines to the sending unit. These clamps are typically made of metal or plastic and are designed to provide a tight grip on the fuel lines. Locate the clamps along the length of the fuel lines, as they are usually positioned at regular intervals to ensure a secure fit. It is essential to understand the layout of the fuel lines and their connections to the sending unit to locate the correct clamps.

Once the clamps are identified, use a pair of adjustable pliers or a clamp release tool to carefully release them. Apply gentle force to the pliers, turning the handles in a counterclockwise direction to loosen the clamp. Be cautious not to apply excessive force, as it may damage the fuel lines or the sending unit. The goal is to carefully disengage the clamp from the fuel line without causing any harm. If the clamp is particularly tight, you might need to apply a small amount of lubricant to the clamp's pivot point to facilitate the release process.

As you release each clamp, inspect the fuel line for any signs of damage or wear. It is essential to ensure that the fuel lines are in good condition before proceeding with the removal process. If you notice any cracks, leaks, or other issues, address them accordingly before continuing.

Remember, the key to successfully removing fuel lines from a sending unit is patience and a gentle approach. Take your time to release each clamp carefully, and always be mindful of the fuel lines' condition. By following these steps, you can efficiently remove the fuel lines while minimizing the risk of damage to the vehicle's components.

Freezing Fuel: The Impact of Water in Fuel Lines

You may want to see also

Inspect for Damage: Check for any signs of damage or corrosion

When inspecting the fuel lines and sending unit for damage, it's crucial to be thorough and methodical. Start by visually examining the fuel lines for any visible signs of wear, tear, or damage. Look for cracks, punctures, or kinks along the length of the lines. These issues can lead to fuel leaks, which are not only dangerous but can also cause engine performance problems. Check for any signs of corrosion or rust, especially at the connections and bends in the lines. Corrosion can weaken the fuel lines over time, making them more susceptible to damage. If you notice any corrosion, it may indicate that the sending unit has been exposed to moisture or fuel contamination, which can lead to further issues.

Next, inspect the sending unit itself. This unit is responsible for measuring the fuel level and sending the information to the fuel gauge. Check for any visible damage, such as cracks or warping, especially around the fuel level sensor. Ensure that the sending unit is securely attached to the fuel tank and that all connections are tight and free from corrosion. If the sending unit is loose or shows signs of damage, it may need to be replaced to ensure accurate fuel level readings.

Pay attention to the fuel tank as well. Inspect the tank for any signs of damage, especially around the sending unit's mounting area. Look for rust or corrosion on the tank's interior, as this can affect the overall health of the fuel system. If you notice any significant damage or corrosion, it may be necessary to clean or replace the fuel tank to prevent further issues.

Additionally, check for any signs of fuel contamination. Over time, fuel can degrade and become contaminated with water or other substances, leading to corrosion and potential damage to the fuel system. If the fuel appears discolored or has a strong odor, it may indicate contamination. In such cases, it's advisable to flush the fuel system and replace the fuel filter to ensure optimal performance.

Remember, regular inspection and maintenance of the fuel lines and sending unit are essential to prevent costly repairs and ensure the longevity of your vehicle's fuel system. By being proactive and addressing any signs of damage or corrosion, you can maintain a reliable and efficient fuel system.

Nylon Fuel Line: Choosing the Right Material for Optimal Performance

You may want to see also

Reinstall Fuel Lines: Properly reconnect the lines and secure them

Reinstalling fuel lines after removing them from the sending unit requires careful attention to detail and a systematic approach to ensure a secure and proper connection. Here's a step-by-step guide to help you through the process:

Prepare the Necessary Tools and Materials: Before you begin, ensure you have the required tools and materials readily available. This includes the appropriate fuel line connectors, wrenches or pliers for tightening, and any specific tools recommended for your vehicle's make and model. Having everything organized will make the reinstallation process smoother.

Locate the Sending Unit and Fuel Lines: Visually inspect the engine bay and locate the sending unit, which is typically a cylindrical component attached to the fuel tank. Identify the fuel lines connected to the sending unit. These lines are usually made of rubber or a flexible material and may have different colors or markings to indicate their purpose.

Reconnect the Fuel Lines: Start by aligning the fuel lines with their respective ports on the sending unit. Ensure that the lines are properly oriented and positioned correctly. Slide the connectors onto the fuel lines and push them onto the sending unit's ports until they are fully seated. Make sure the connections are snug and secure.

Secure the Fuel Lines: After reconnecting the lines, it's crucial to secure them in place. Use the appropriate fasteners or ties provided with the fuel lines to keep them in position. Tighten the fasteners securely, but be careful not to overtighten, as it may damage the fuel lines. Ensure that the lines are taut and cannot move excessively, providing a stable connection.

Test the Fuel System: Once the fuel lines are reinstalled and secured, it's essential to test the fuel system to ensure proper functionality. Start the engine and monitor for any leaks or unusual noises. Check the fuel gauge to confirm that it reads correctly. If everything is in order, your vehicle should now have a reliable fuel supply.

Remember, proper reinstallation of fuel lines is critical to maintaining a safe and efficient fuel system. Take your time, follow the manufacturer's guidelines, and double-check each connection to ensure a successful outcome.

Understanding Fuel Lines: The Return Line's Role

You may want to see also

Frequently asked questions

A sending unit, also known as a fuel level sensor, is a component in a vehicle's fuel system that measures the amount of fuel in the tank. It is crucial for accurate fuel gauge readings and ensuring the engine doesn't run out of fuel. Removing fuel lines from the sending unit might be necessary during maintenance, repairs, or when replacing the unit itself.

Safety is essential when working with fuel systems. Here's a general procedure: Ensure the engine is off and the vehicle is in a secure position. Locate the fuel lines connected to the sending unit, usually found near the fuel tank. Use the appropriate tools, such as fuel line cutters or wrenches, to carefully cut or loosen the connections. Take note of the positions of the lines to ensure proper reattachment later.

Yes, having the right tools can make the process easier. You'll likely need fuel line cutters or a fuel line removal kit, which includes various sizes of cutters and seals. Wrenches or pliers might also be useful for tightening or loosening connections. Additionally, have a clean workspace and consider wearing protective gear to avoid fuel spills.

After successfully removing the fuel lines, you can proceed with the necessary repairs or replacements. If you're replacing the sending unit, ensure you have the correct part and follow the manufacturer's instructions. When reinstalling, make sure to attach the fuel lines securely and correctly. It's essential to test the fuel system and gauge accuracy after any modifications to ensure optimal performance.