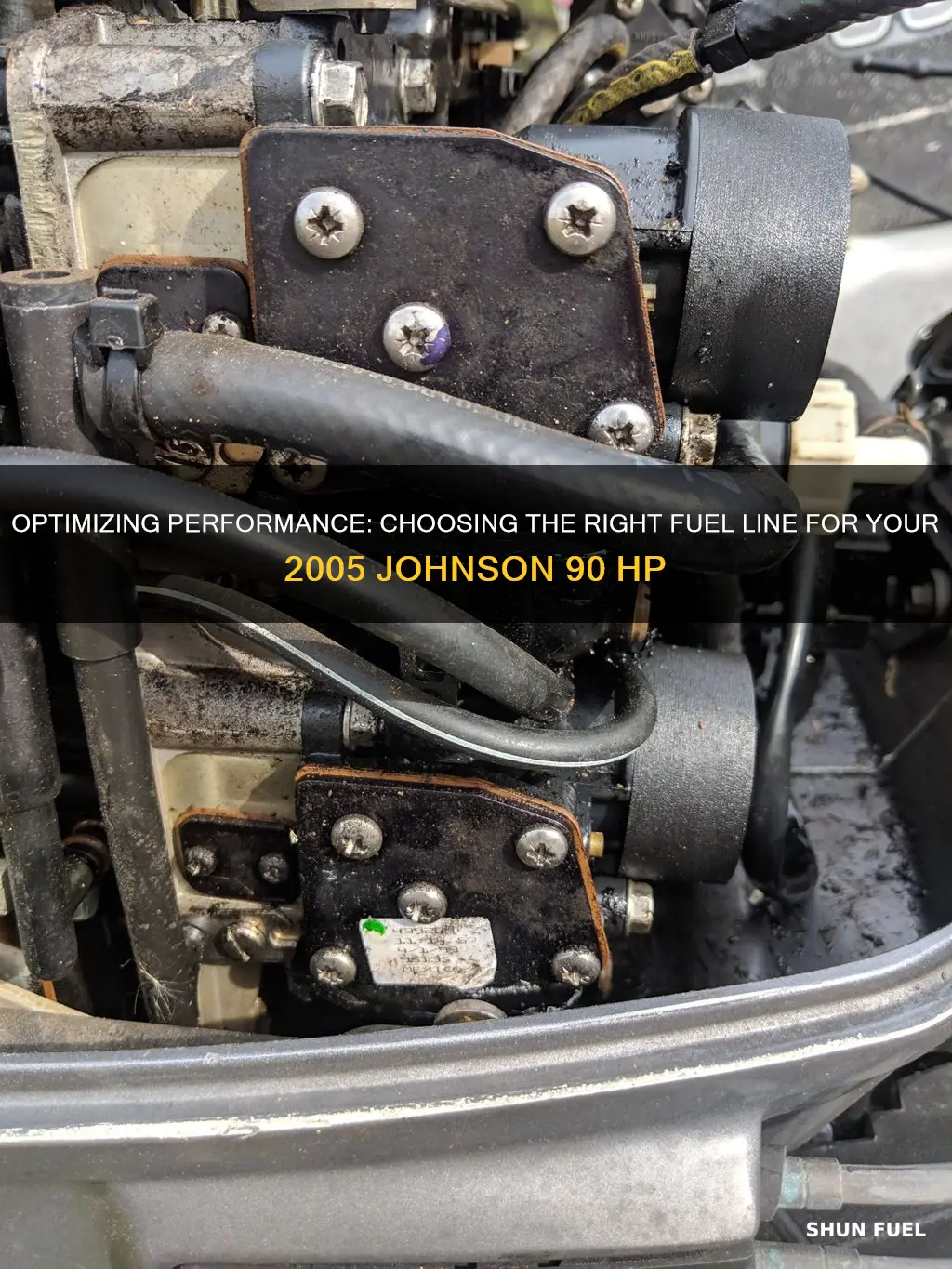

When it comes to maintaining a 2005 Johnson 90 HP engine, one crucial aspect is ensuring the fuel system is properly equipped. The fuel line plays a vital role in delivering gasoline to the engine, and using the correct size is essential for optimal performance. In this discussion, we will explore the ideal fuel line dimensions for this specific engine model, providing valuable insights for boat owners and enthusiasts. Understanding the right specifications will help ensure a smooth and efficient operation, making it a key consideration for anyone looking to keep their watercraft running smoothly.

| Characteristics | Values |

|---|---|

| Engine Model | Johnson 90 HP |

| Year | 2005 |

| Fuel Line Diameter | Typically 5/16" or 3/8" |

| Length | Varies depending on the specific application and boat layout |

| Material | High-quality fuel-resistant materials like rubber or vinyl |

| Compatibility | Designed for use with 2005 Johnson 90 HP engines |

| Pressure Rating | Usually 10-15 psi for optimal performance |

| Installation | Easy to install with basic tools and knowledge |

| Maintenance | Regular cleaning and inspection to ensure longevity |

What You'll Learn

Engine Capacity: Determine the engine's fuel requirements

When it comes to ensuring optimal performance and longevity of your 2005 Johnson 90 HP engine, understanding the fuel requirements is crucial. The engine capacity, which refers to the volume of the combustion chamber, plays a significant role in determining the appropriate fuel line size. Here's a detailed guide to help you determine the fuel requirements for your engine:

Engine Displacement and Fuel Needs: The 2005 Johnson 90 HP engine is likely a four-stroke or two-stroke design, and its displacement (volume) will directly impact its fuel consumption. Generally, larger engines with higher displacement require more fuel to operate efficiently. For a 90 HP engine, a typical displacement range could be between 150cc and 250cc. It's essential to consult the engine's manual or specifications to confirm the exact displacement. Once you have this information, you can estimate the fuel requirements.

Calculating Fuel Needs: To determine the engine's fuel needs, you can use the following formula: Fuel Consumption (in liters per hour) = (Engine Displacement in cc) / (Engine RPM * Load Factor). The RPM (revolutions per minute) at which the engine operates and the load factor (representing the engine's load) are crucial factors. Higher RPMs and increased load will demand more fuel. For a 90 HP engine, you might aim for a fuel consumption rate of around 1-2 liters per hour at a specific RPM and load. Adjustments can be made based on the engine's operating conditions and desired performance.

Fuel Line Size Considerations: The size of the fuel line is directly related to the engine's fuel requirements. A larger engine with higher fuel consumption will necessitate a fuel line with a corresponding diameter to handle the increased flow rate. For a 2005 Johnson 90 HP, a fuel line with a diameter of 3/8 inch or 10mm is commonly recommended. However, it's essential to consider the engine's operating conditions and potential future modifications. If you plan to upgrade the engine or increase its power output, allowing for higher fuel flow, you might opt for a larger fuel line size.

Testing and Adjustments: Determining the exact fuel line size might require testing and adjustments. Start with the recommended size and monitor the engine's performance. If you notice any fuel-related issues, such as poor acceleration or fuel leaks, you may need to adjust the fuel line size accordingly. It's a process of trial and error, ensuring that the fuel line can supply the engine with the required fuel volume without causing any performance or safety concerns.

Remember, these guidelines provide a starting point for determining the fuel requirements and fuel line size for your 2005 Johnson 90 HP engine. Always refer to the manufacturer's recommendations and consult with marine engine experts for precise specifications tailored to your specific engine model and application.

Optimizing Fuel Delivery: Choosing the Right Fuel Line Size for 5/16 Nipple Applications

You may want to see also

Fuel Pump Capacity: Match the pump's flow rate

When it comes to ensuring optimal performance in your 2005 Johnson 90 HP engine, matching the fuel pump's flow rate is crucial. The fuel pump is responsible for delivering the required amount of fuel to the engine, and its capacity directly impacts the engine's power and efficiency. Here's a detailed guide on how to match the fuel pump's flow rate:

Understanding Flow Rate: The flow rate of a fuel pump is measured in gallons per minute (GPM). It indicates the volume of fuel the pump can deliver in one minute. For a 90 HP Johnson engine, it's essential to match the flow rate to the engine's requirements. A typical 90 HP engine may require around 2.5 to 3.5 GPM of fuel flow for optimal performance. However, this can vary depending on the specific engine setup and modifications.

Checking the Engine's Requirements: Start by consulting the engine's manual or specifications. Johnson engines often provide recommended fuel flow rates for different models and horsepower ranges. This information will give you a baseline to work with. For instance, if your 2005 Johnson 90 HP engine requires 3.0 GPM, you should aim for a fuel pump with a similar or slightly higher flow rate.

Assessing the Fuel Pump: To match the flow rate, you need to assess the existing fuel pump or the one you plan to install. If you're replacing the pump, ensure you choose a replacement with a flow rate that meets or exceeds the engine's requirements. For instance, a 3.2 GPM pump would be suitable for a 90 HP engine. When installing a new pump, consider factors like the engine's age, any modifications, and the overall fuel system setup.

Testing and Adjustments: In some cases, you might need to test the fuel pump's flow rate to ensure it meets the engine's needs. This can be done using a flow meter or by monitoring the engine's performance. If the engine is running rich (over-fuelling), it may indicate a higher flow rate than required. Conversely, a running lean (under-fuelling) condition suggests a lower flow rate. Adjustments can then be made by replacing the pump or modifying the fuel system to achieve the optimal flow rate.

Remember, matching the fuel pump's flow rate is a critical aspect of engine maintenance, especially for high-performance applications. It ensures that the engine receives the right amount of fuel, resulting in improved power, efficiency, and overall engine health. Always refer to the manufacturer's guidelines and consult experts if needed to make the right choices for your specific engine setup.

Unveiling the Material Mystery: What Fuels Clear Fuel Lines?

You may want to see also

Line Diameter: Choose a diameter based on flow rate

When it comes to selecting the appropriate fuel line for your 2005 Johnson 90 HP engine, the diameter of the line is a critical factor to consider. The flow rate of fuel is directly related to the engine's performance and efficiency, so choosing the right diameter is essential for optimal operation.

The flow rate, measured in gallons per minute (GPM), determines how much fuel can pass through the line at any given time. For a 90 HP engine, a higher flow rate is often required to ensure efficient combustion and power delivery. As a general guideline, a fuel line diameter of 3/8 inch is commonly recommended for this engine size. This diameter provides a good balance between fuel flow and pressure, allowing for efficient delivery of gasoline to the engine.

However, it's important to note that the flow rate requirements can vary depending on specific engine conditions and modifications. If your 2005 Johnson has been modified to produce more power or has a larger fuel tank, you may need to consider a larger diameter fuel line. For instance, a 1/2 inch diameter line could be beneficial in such cases to accommodate the increased fuel demand.

To determine the appropriate diameter, consider the following: If your engine operates smoothly and efficiently with the existing 3/8 inch line, there might be no immediate need for an upgrade. However, if you notice any signs of fuel starvation, such as reduced power or rough idling, a larger diameter line could be the solution. Additionally, factors like fuel pressure, engine load, and the presence of any fuel-related modifications should be taken into account when making this decision.

In summary, when choosing a fuel line for your 2005 Johnson 90 HP, aim for a diameter that matches or slightly exceeds the recommended flow rate for your specific engine setup. This ensures that your engine receives the necessary fuel volume and pressure for optimal performance. Remember, consulting the manufacturer's guidelines and seeking professional advice can provide valuable insights tailored to your boat's unique requirements.

Poulan PP3516AVX Fuel Line Length: Expert Guide

You may want to see also

Length: Measure the distance from the fuel tank to the engine

To determine the appropriate fuel line size for your 2005 Johnson 90 HP engine, it's crucial to consider various factors, including the distance from the fuel tank to the engine. This measurement is essential because it directly impacts the flow rate and pressure required to deliver fuel efficiently. Here's a step-by-step guide on how to measure this distance:

- Locate the Fuel Tank and Engine: Start by identifying the fuel tank and the engine on your boat. The fuel tank is typically located near the front or side of the vessel, while the engine is the main component responsible for propulsion.

- Measure the Distance: Use a measuring tape or a flexible ruler to measure the straight-line distance from the center of the fuel tank to the engine's fuel intake port. Ensure that you measure along the path where the fuel line will run. This distance should be measured in inches or centimeters, depending on your preference.

- Consider Engine Requirements: Different engines have specific fuel line size recommendations. For a 90 HP Johnson engine, it's generally advised to use a fuel line with an inside diameter of 3/8 inches. However, this can vary based on factors like engine displacement, fuel system design, and desired performance. Always refer to the manufacturer's guidelines or consult a marine mechanic for precise recommendations.

- Calculate the Required Length: Add a few extra inches to your measured distance to account for potential bends, fittings, and any adjustments needed during installation. This ensures that you have sufficient fuel line length to connect the tank to the engine without excessive strain or the need for excessive bending.

- Choose the Right Fuel Line: Based on your measurements and engine requirements, select a fuel line with the appropriate inside diameter. Common sizes for marine applications include 3/8, 1/2, and 5/8 inches. Ensure that the fuel line material is suitable for marine environments, such as nylon, PVC, or stainless steel.

Remember, proper fuel line sizing is crucial for optimal engine performance and longevity. Always prioritize safety and consult with experts if you're unsure about any specific requirements for your boat's fuel system.

Street Avenger Fuel Line: Unleash the Power with the Right Choice

You may want to see also

Material: Select a durable material like nylon or vinyl

When it comes to choosing the right fuel line for your 2005 Johnson 90 HP engine, durability is key. The fuel line is a critical component in the fuel delivery system, and using a material that can withstand the rigors of marine environments is essential. Nylon and vinyl are excellent choices for this application.

Nylon is a popular choice for fuel lines due to its exceptional strength and flexibility. It is highly resistant to abrasion, chemicals, and UV radiation, making it ideal for outdoor use. This material can handle the constant flexing and movement associated with marine applications, ensuring a long-lasting and reliable fuel supply to your engine. Look for nylon fuel lines with a diameter suitable for your engine's requirements, typically ranging from 3/8" to 1/2" in diameter, depending on the specific model and year of your Johnson engine.

Vinyl, another durable option, offers excellent resistance to oil, gasoline, and other common fuels. It is lightweight, flexible, and can withstand a wide range of temperatures, making it a versatile choice. Vinyl fuel lines are often more cost-effective compared to nylon, but they might not be as flexible in low temperatures. For optimal performance, consider a vinyl fuel line with a similar diameter to the nylon option, ensuring it meets the engine's specifications.

Both materials offer excellent protection against fuel degradation and are less prone to cracking or leaking over time. When selecting the material, consider the specific needs of your engine and the environmental conditions it will be exposed to. For a 2005 Johnson 90 HP, a durable fuel line is crucial to ensure reliable performance and longevity.

Remember, proper installation and regular maintenance are also essential to ensure the fuel line's longevity. Always refer to the manufacturer's guidelines and consult a professional if needed to ensure the correct size and material are used for your specific engine model.

Unveiling the Material Secrets of Car Fuel Lines

You may want to see also

Frequently asked questions

The recommended fuel line size for a 2005 Johnson 90 HP engine is 3/8 inch in diameter. This size ensures efficient fuel delivery and minimizes pressure drop, allowing for optimal engine performance.

While using a larger fuel line might seem like an easy way to boost power, it is not a reliable method. The engine's performance is more closely tied to the fuel injection system, carburetor settings, and overall engine management. Upgrading the fuel line alone will not significantly impact power output.

The length of the fuel line depends on the specific setup of your boat and engine. It is essential to consider the distance between the fuel tank and the engine, as well as any bends or turns in the line. A rule of thumb is to keep the fuel line as short and straight as possible to minimize fuel vaporization and ensure a steady fuel supply.

Regular maintenance is crucial for the longevity of your fuel line. It is recommended to inspect the fuel line annually or every 5 years, depending on usage and environmental factors. If you notice any signs of damage, such as cracks, leaks, or corrosion, it is best to replace the fuel line promptly to prevent potential engine issues.