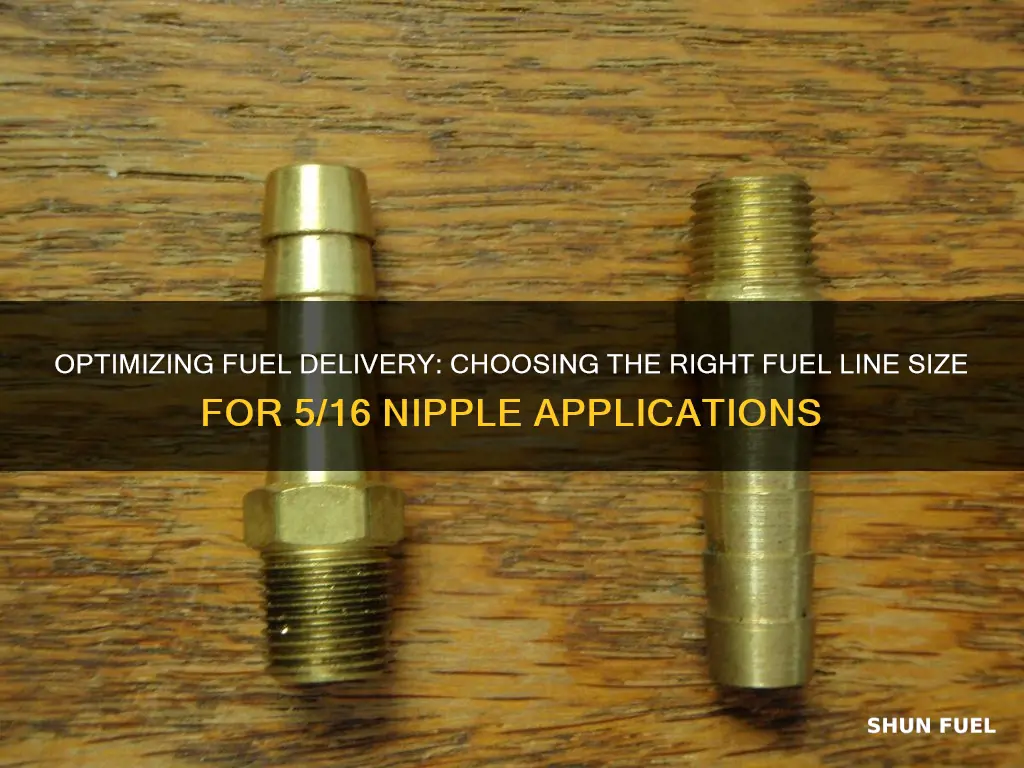

When it comes to choosing the right fuel line for your vehicle, understanding the specifications is crucial. In this context, we're focusing on the size of the fuel line that connects to a 5/16-inch nipple. This nipple is a common component in fuel systems, and selecting the appropriate fuel line diameter is essential for efficient and safe fuel delivery. The size of the fuel line directly impacts the flow rate and pressure, which can affect engine performance and overall reliability. Therefore, it's important to consider factors such as engine power, fuel requirements, and system design to determine the optimal fuel line size for your specific application.

| Characteristics | Values |

|---|---|

| Size | 3/8" |

| Material | Stainless Steel |

| Length | 10 feet |

| Inner Diameter | 0.25 inches |

| Outer Diameter | 0.375 inches |

| Wall Thickness | 0.031 inches |

| Working Pressure | Up to 150 psi |

| Temperature Range | -40°F to 400°F |

| Color | Natural (uncoated) |

| Application | Fuel Injection Systems |

| Compatibility | Universal fit for 5/16" (8mm) NPT nipples |

What You'll Learn

- Fuel Line Diameter: Choose diameter based on flow rate and pressure requirements

- NPSH Calculation: Ensure sufficient NPSH available for pump operation

- Material Compatibility: Select material compatible with fuel type and temperature

- Length Considerations: Account for length, bends, and fittings in fuel line installation

- Pressure Rating: Select fuel line with pressure rating exceeding system pressure

Fuel Line Diameter: Choose diameter based on flow rate and pressure requirements

When selecting the appropriate fuel line diameter for a 5/16-inch nipple, it's crucial to consider the flow rate and pressure requirements of your fuel system. The diameter of the fuel line directly impacts the volume of fuel that can be transported per unit of time, as well as the pressure it can withstand. A larger diameter fuel line will allow for a higher flow rate, which is essential for applications that require rapid fuel delivery, such as high-performance engines or racing vehicles. This is because a wider diameter provides more space for fuel to flow, reducing the resistance and allowing for a smoother and more efficient delivery.

The flow rate is typically measured in gallons per minute (GPM) or liters per second (L/s), and it represents the volume of fuel that passes through the line in a given time. For instance, if your engine requires a specific amount of fuel per minute to operate optimally, you'll need a fuel line that can accommodate that flow rate. A smaller diameter fuel line may not be able to handle the required flow, leading to potential performance issues or even engine damage.

Pressure is another critical factor. Fuel lines need to be able to withstand the pressure generated by the fuel pump and the engine's operation. High-pressure fuel systems, often used in racing or modified vehicles, require fuel lines with larger diameters to ensure the fuel can flow efficiently without excessive pressure drop. A pressure drop occurs when the fuel line's diameter is too small, causing the fuel to slow down and lose energy, which can lead to reduced performance and potential engine issues.

To determine the appropriate diameter, you can use flow rate and pressure calculations or consult manufacturer specifications. These specifications often provide guidelines based on the engine's power output and fuel requirements. For example, a high-performance engine might need a larger diameter fuel line to handle the increased fuel flow and pressure. It's essential to choose a diameter that meets or exceeds the recommended size to ensure optimal performance and safety.

In summary, selecting the right fuel line diameter for a 5/16-inch nipple involves balancing flow rate and pressure considerations. A larger diameter fuel line will improve performance by allowing for higher flow rates and accommodating the pressure demands of your fuel system. Always refer to the manufacturer's guidelines and specifications to ensure you choose the correct size for your specific application.

Understanding the Role of Fuel Return Lines in Engine Systems

You may want to see also

NPSH Calculation: Ensure sufficient NPSH available for pump operation

NPSH (Net Positive Suction Head) is a critical parameter in pump design and operation, ensuring efficient and reliable fluid transfer. It represents the energy required to move a fluid from the pump's suction point to the desired elevation or pressure. When calculating NPSH, it's essential to consider the specific requirements of your pump and system to ensure optimal performance and prevent issues like cavitation.

The calculation of NPSH involves several factors, primarily the pump's suction head and the fluid's properties. Suction head is the energy required to lift the fluid from the pump's suction point to the desired height. It is typically measured in feet of water column (fw-c) or meters of head (m). The pump's performance curve or data sheet provides the specific suction head required for a given flow rate and rotational speed. For instance, a pump might need 100 feet of suction head to operate efficiently at a certain flow rate.

Additionally, the fluid's characteristics play a significant role in NPSH calculation. These include the fluid's density, viscosity, and specific gravity. For example, water has a different density and viscosity than gasoline, which can affect the required NPSH. The fluid's properties can be determined through laboratory tests or referenced from fluid suppliers.

To ensure sufficient NPSH, you must consider the entire system, including the pump, piping, and fluid. The piping system should be designed to minimize pressure drops and maintain a consistent flow. The suction piping should be as short and straight as possible to reduce the potential for cavitation. Any bends or changes in direction should be minimized, as they can create flow separation and reduce NPSH.

In summary, calculating NPSH is a complex process that requires a thorough understanding of the pump, fluid, and system. By considering the specific suction head, fluid properties, and system design, engineers can ensure that the pump operates efficiently and reliably, preventing issues related to insufficient NPSH. Regular monitoring and adjustments may be necessary to maintain optimal performance, especially in dynamic operating conditions.

Understanding the Role of the Diesel Leak Off Fuel Line

You may want to see also

Material Compatibility: Select material compatible with fuel type and temperature

When it comes to selecting the right material for your fuel line, especially when dealing with a 5/16-inch nipple, compatibility is key. The material you choose must be able to withstand the specific conditions of your fuel type and temperature. Different fuels have varying properties, and the temperature at which they operate can significantly impact the choice of material. For instance, gasoline, ethanol blends, and diesel each have unique characteristics that require specific materials to ensure safe and efficient fuel transfer.

For gasoline, a common choice is to use a fuel line made from high-density polyethylene (HDPE) or a similar plastic material. HDPE is known for its flexibility, durability, and resistance to gasoline's corrosive effects. It can handle the typical operating temperatures of gasoline engines without becoming brittle or degrading over time. Another option is to use a fuel line made from stainless steel, which offers excellent corrosion resistance and can handle higher temperatures, making it suitable for a wide range of applications.

Ethanol blends, on the other hand, require materials that can withstand the higher alcohol content. Materials like HDPE or polypropylene (PP) are often used due to their ability to resist ethanol's corrosive properties. These materials ensure that the fuel line remains flexible and intact, even in the presence of higher ethanol concentrations. It's crucial to avoid materials that may react with ethanol, such as certain types of rubber or plastic, as they can degrade over time.

Diesel fuel presents a different set of challenges. It is generally more corrosive and has a higher operating temperature compared to gasoline. In such cases, materials like stainless steel or brass are preferred. These metals offer superior corrosion resistance and can handle the higher temperatures associated with diesel engines. Additionally, the use of fuel line materials with a higher flexibility, such as certain types of rubber compounds, can ensure a reliable connection and prevent leaks.

In summary, selecting the appropriate material for your fuel line involves considering the specific fuel type and its operating temperature. Each fuel has unique properties that require materials with specific characteristics to ensure compatibility and longevity. By understanding these requirements, you can make an informed decision when choosing the material for your 5/16-inch nipple fuel line, ensuring a safe and efficient fuel delivery system.

Engine Trouble: What Happens When Your Fuel Line Seals Fail

You may want to see also

Length Considerations: Account for length, bends, and fittings in fuel line installation

When installing a fuel line with a 5/16-inch nipple, it's crucial to consider the length of the line to ensure a proper fit and optimal performance. The length of the fuel line should be carefully measured and calculated to accommodate the distance between the fuel source and the engine. A common rule of thumb is to add a few extra inches to the measured length to account for any bends or fittings that may be required along the way. This extra length ensures that the fuel line can make the necessary turns and connections without being too tight or restrictive.

Bends in the fuel line are an essential aspect of the installation process. Each bend should be carefully planned and executed to avoid kinks or sharp turns that could restrict fuel flow. The radius of the bend should be sufficient to prevent any damage to the fuel line and to maintain a smooth flow of fuel. It is recommended to use a fuel line bending tool to achieve the desired radius and ensure a professional finish. Proper bending techniques will also help to reduce the risk of fuel line damage during installation.

Fittings play a significant role in fuel line installation, and their length and positioning should be carefully considered. The fittings, such as unions, elbows, and adapters, need to be long enough to allow for easy connection and disconnection without compromising the overall length of the fuel line. It's important to choose fittings that are compatible with the fuel line size and material to ensure a secure and leak-free connection. Additionally, the placement of fittings should be strategic, allowing for easy access during maintenance and providing a clear path for fuel flow.

To determine the appropriate length, start by measuring the distance from the fuel tank to the engine, including any existing fuel lines. Then, add a buffer of 2-3 inches to account for bends and fittings. Consider the location of the fuel pump and the engine's requirements to ensure the fuel line can reach the necessary points. It's also beneficial to visualize the installation route and plan for any potential obstacles or challenges that may affect the line's length.

In summary, when installing a fuel line with a 5/16-inch nipple, length considerations are vital. Accurate measurements, accounting for bends, and strategic placement of fittings are key to a successful installation. By carefully planning the length and route of the fuel line, you can ensure a reliable and efficient fuel supply to the engine, promoting optimal performance and longevity.

Air in Tractor Fuel Line: Causes and Solutions

You may want to see also

Pressure Rating: Select fuel line with pressure rating exceeding system pressure

When it comes to selecting the appropriate fuel line for your vehicle's fuel system, one crucial factor to consider is the pressure rating. This is especially important when dealing with a 5/16-inch nipple, as it directly impacts the performance and reliability of your fuel delivery. The pressure rating of a fuel line refers to its ability to withstand internal pressure without failing or leaking. It is essential to choose a fuel line with a pressure rating that exceeds the system pressure to ensure optimal performance and safety.

The system pressure can vary depending on the vehicle's make and model, as well as the specific fuel system configuration. It is recommended to consult the vehicle's manual or seek professional advice to determine the exact system pressure. As a general guideline, selecting a fuel line with a pressure rating that is at least 10-15% higher than the system pressure is a good practice. This extra margin ensures that the fuel line can handle any potential fluctuations or increases in pressure, providing a safer and more reliable fuel supply.

To understand why pressure rating is so critical, consider the following. Fuel lines are designed to carry gasoline or diesel under pressure to ensure efficient delivery to the engine. If the pressure rating is insufficient, the fuel line may become brittle or develop cracks over time, leading to fuel leaks or even complete failure. In extreme cases, this can result in engine misfires, reduced performance, or even engine damage. Therefore, it is imperative to choose a fuel line that can withstand the pressures exerted by the fuel system.

When purchasing a fuel line, look for specifications that include the pressure rating. This information is typically provided in pounds per square inch (PSI) or bar. Ensure that the fuel line's pressure rating matches or exceeds the system pressure requirements. Keep in mind that different fuel systems may have varying pressure needs, so it's crucial to match the fuel line's pressure rating accordingly.

In summary, when dealing with a 5/16-inch nipple and selecting a fuel line, the pressure rating is a critical specification. Opt for a fuel line with a pressure rating that surpasses the system pressure to guarantee reliable and safe fuel delivery. Always refer to the vehicle's manual or consult experts to determine the exact system pressure and choose the appropriate fuel line size and rating.

Understanding Rubber Fuel Line Sizes for CJ7s

You may want to see also

Frequently asked questions

The standard size of fuel line recommended for a 5/16-inch nipple is 3/8-inch. This size ensures a secure and reliable connection for fuel delivery in most automotive applications.

While it is technically possible to use a smaller fuel line, it is not recommended. A smaller line may restrict fuel flow, leading to potential performance issues and reduced engine power. Always choose the appropriate size to maintain optimal fuel delivery.

The fuel line diameter should be based on the vehicle's fuel system requirements and the desired flow rate. Consulting the vehicle's manual or seeking advice from automotive experts can help you select the right size to ensure efficient and safe fuel transfer.

Yes, it is crucial to choose a fuel line made from high-quality materials like stainless steel or fuel-resistant rubber. These materials ensure durability, flexibility, and resistance to fuel degradation, providing a long-lasting and reliable fuel supply.