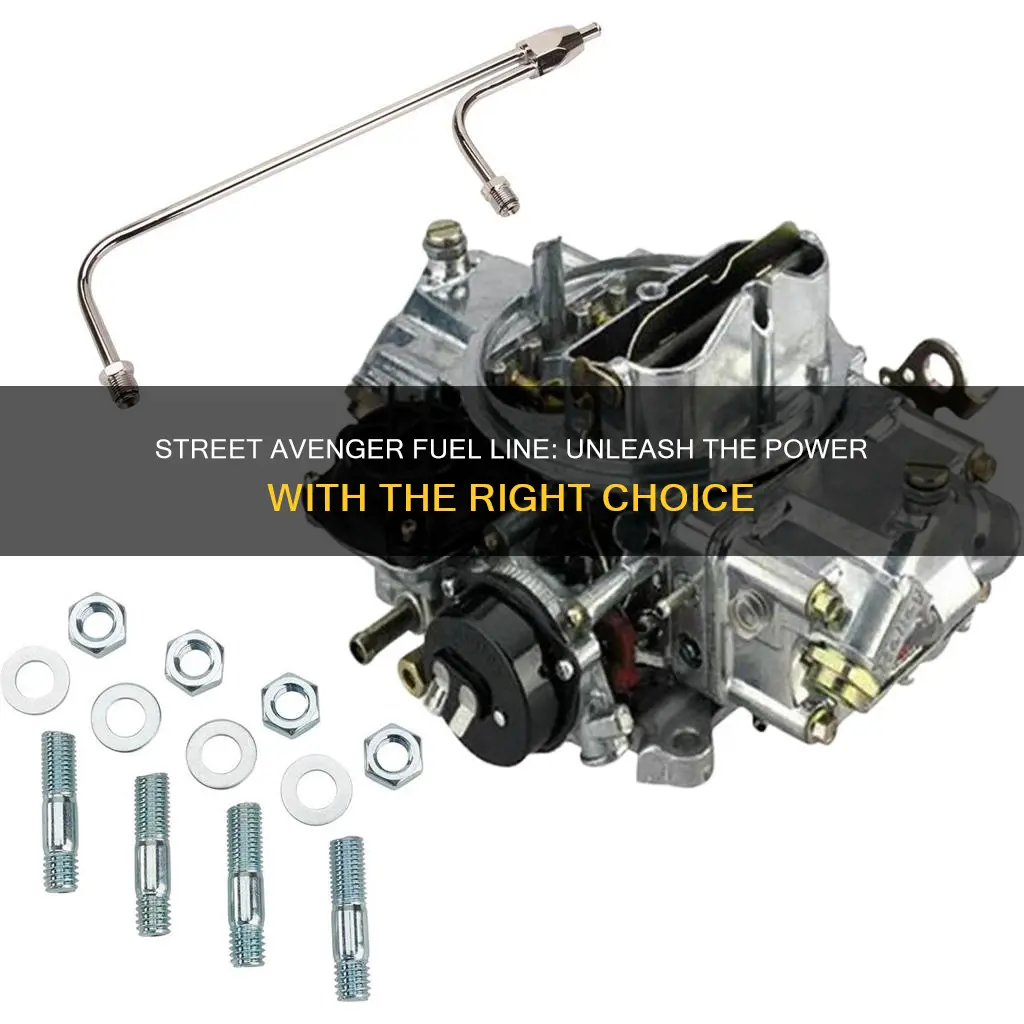

If you're a proud owner of a Street Avenger, you might be curious about the best fuel line options to enhance your vehicle's performance. The Street Avenger, known for its powerful engine, requires a fuel line that can handle the demands of daily driving and occasional track days. In this paragraph, we'll explore the factors to consider when choosing the right fuel line for your Street Avenger, ensuring it runs smoothly and efficiently on the street and track.

What You'll Learn

- Engine Type: Consider engine displacement and power output for optimal fuel line choice

- Fuel Pump: Ensure the fuel pump can handle the flow rate of the chosen fuel line

- Pressure Requirements: Match fuel line pressure ratings to engine needs for efficient performance

- Material Compatibility: Select fuel lines compatible with engine fuel type (gasoline, ethanol, etc.)

- Size and Routing: Properly size and route fuel lines for easy installation and reduced risk of damage

Engine Type: Consider engine displacement and power output for optimal fuel line choice

When it comes to choosing the right fuel lines for your Street Avenger, engine type is a critical factor to consider. Specifically, the engine displacement and power output will directly influence the diameter and material of the fuel lines you need to ensure optimal performance and safety.

Engine displacement, measured in cubic centimeters (cc) or liters, refers to the volume of air and fuel mixture that a cylinder can hold during the compression stroke. Higher displacement engines typically have more power and torque, which means they require more fuel to operate efficiently. As a result, fuel lines need to be able to handle the increased volume of fuel, often necessitating larger diameter lines to ensure a smooth and consistent flow. For instance, a 1000cc engine might require fuel lines with a larger diameter than a 600cc engine to accommodate the higher fuel demand.

Power output is another crucial aspect. Engines with higher power outputs generate more heat and require more robust fuel systems to manage the increased stress. This is where the material of the fuel lines comes into play. For high-performance applications, fuel lines made from materials like stainless steel or braided nylon are often preferred. These materials offer superior flexibility, durability, and heat resistance, ensuring that the fuel lines can withstand the demands of powerful engines without compromising performance or safety.

For example, if you're running a Street Avenger with a high-performance 1200cc engine, you might want to consider fuel lines with a larger diameter and a more robust construction. This could mean choosing fuel lines made from braided nylon or even stainless steel, which can handle the increased fuel flow and heat generated by the engine.

In summary, when selecting fuel lines for your Street Avenger, it's essential to consider the engine's displacement and power output. Higher displacement and power engines require larger diameter fuel lines and materials that can handle the increased stress and heat. By carefully matching the fuel lines to your engine's specifications, you can ensure optimal performance, fuel efficiency, and safety for your Street Avenger.

Mastering Snowmobile Fuel Direction: A Guide to Smooth Riding

You may want to see also

Fuel Pump: Ensure the fuel pump can handle the flow rate of the chosen fuel line

When modifying your Street Avenger for increased performance, one crucial aspect often overlooked is the fuel system. The fuel pump plays a vital role in ensuring that your engine receives the required fuel volume to meet the higher demands of modified engines. Here's a detailed guide on how to ensure your fuel pump can handle the flow rate of your chosen fuel line:

Assess the Required Fuel Flow: Before selecting a fuel line, determine the increased fuel flow rate your engine will require. This is especially important if you're planning to use a larger fuel pump. The flow rate is typically measured in gallons per minute (GPM) and can be calculated by considering the engine's displacement, compression ratio, and power output. For instance, a 5.7L HEMI engine might require a higher flow rate compared to a naturally aspirated 3.6L V6.

Choose the Right Fuel Pump: The fuel pump's capacity should match or exceed the required flow rate. High-performance fuel pumps are designed to deliver increased volumes of fuel, ensuring that your engine receives the necessary amount during acceleration and high-load conditions. When selecting a fuel pump, consider the following:

- Pump Type: Mechanical fuel pumps are commonly used for street applications due to their reliability and ease of installation. Electric pumps offer more precise control but may require additional wiring and sensors.

- Flow Rate: Look for a pump that can deliver the required GPM, often specified by the manufacturer. For high-performance builds, a pump with a higher flow rate is recommended to prevent fuel pressure drop and ensure optimal engine performance.

- Impeller Size: The impeller's size directly impacts the pump's performance. Larger impellers can handle higher flow rates, but they may also create more cavitation, which can lead to engine damage if not managed properly.

Consider Fuel Line Diameter: The diameter of your fuel line should complement the chosen fuel pump's flow rate. A larger fuel pump will require a proportionally larger fuel line to handle the increased volume. As a general rule, the fuel line diameter should be at least 1/4 inch larger than the pump's recommended line size to ensure efficient fuel delivery.

Install and Test: Once you've selected the appropriate fuel pump and line, proper installation is crucial. Ensure that all connections are secure and free from leaks. After installation, start the engine and monitor the fuel pressure using a gauge. The pressure should be within the recommended range for your specific application. If the pressure is too low, it may indicate a restriction in the fuel line or pump issues.

By carefully considering the fuel pump's capacity and matching it to your engine's requirements, you can ensure that your Street Avenger's fuel system is up to the task of supporting increased performance. This attention to detail will contribute to a more reliable and powerful driving experience.

Air in Tractor Fuel Line: Causes and Solutions

You may want to see also

Pressure Requirements: Match fuel line pressure ratings to engine needs for efficient performance

When it comes to optimizing the performance of your Street Avenger engine, understanding and matching fuel line pressure ratings is crucial. The pressure requirements for fuel lines are often overlooked but play a significant role in ensuring efficient power delivery. Here's a detailed guide to help you navigate this aspect:

Understanding Fuel Line Pressure: Fuel lines are responsible for transporting gasoline from the tank to the engine, and the pressure within these lines directly impacts the engine's performance. The pressure rating of a fuel line indicates its ability to withstand fuel pressure and deliver fuel efficiently. It is essential to match this rating with the engine's specific needs to avoid issues like fuel starvation or excessive pressure, both of which can lead to poor performance.

Engine Performance and Pressure: Different engines have varying pressure requirements. For instance, high-performance engines often demand higher fuel pressure to meet their power output needs. When using a fuel line with an inappropriate pressure rating, you risk either not providing enough fuel pressure for optimal combustion or, in some cases, causing excessive pressure, which can lead to fuel line damage. Therefore, it's crucial to consult your engine's specifications and choose fuel lines that match or exceed these requirements.

Matching Pressure Ratings: To ensure efficient performance, you should aim to match the fuel line pressure rating to the engine's needs. For high-performance Street Avenger engines, consider using fuel lines with higher pressure ratings. These lines can handle the increased fuel pressure required for optimal power output. Lower-pressure applications might benefit from standard or slightly higher-pressure fuel lines, ensuring a balance between performance and longevity.

Considerations for Street Use: For street-driven vehicles, it's essential to balance performance with everyday driving conditions. While high-pressure fuel lines can enhance performance, they might also be more susceptible to damage from minor collisions or road debris. In such cases, a compromise might be necessary, opting for fuel lines with moderate pressure ratings that offer a good balance between performance and durability.

Consultation and Expertise: Given the complexity of fuel system design, consulting with automotive experts or referring to manufacturer guidelines is highly recommended. They can provide specific recommendations based on your Street Avenger's engine type and intended use. This ensures that you make the right choices regarding fuel line pressure ratings, ultimately leading to a well-performing and reliable engine.

Kohler Engine Fuel Line Diameter: A Comprehensive Guide

You may want to see also

Material Compatibility: Select fuel lines compatible with engine fuel type (gasoline, ethanol, etc.)

When it comes to choosing the right fuel lines for your Street Avenger, material compatibility is a critical factor to consider. The fuel lines must be compatible with the type of fuel your engine is designed to run, whether it's gasoline, ethanol, or any other blend. Incompatible materials can lead to fuel leaks, contamination, and potential engine damage.

For gasoline engines, the most common and reliable material for fuel lines is rubber or a synthetic rubber compound. These materials are flexible, durable, and resistant to gasoline's corrosive properties. Look for fuel lines made from high-quality rubber compounds that are specifically designed for automotive use. Some manufacturers even offer fuel lines with a double-walled construction, providing an extra layer of protection against fuel leaks.

If your Street Avenger runs on ethanol-blended gasoline, the material compatibility becomes even more crucial. Ethanol is more corrosive than traditional gasoline, so fuel lines must be made from materials that can withstand its properties. Braided stainless steel fuel lines are an excellent choice for ethanol-compatible fuel lines. The stainless steel construction ensures durability and resistance to corrosion, making it ideal for fuel systems that use ethanol blends.

In some cases, you might also consider fuel lines made from flexible plastic compounds, such as PVC or polyetheretherketone (PEEK). These materials are lightweight and can offer good resistance to fuel degradation. However, it's essential to ensure that the specific plastic used is compatible with your engine's fuel type. Some plastics may not be suitable for ethanol-blended fuels and could lead to fuel absorption or degradation over time.

When selecting fuel lines, always refer to your Street Avenger's owner's manual or consult with a trusted mechanic to determine the recommended fuel line materials for your specific engine. They can provide guidance based on your vehicle's make and model, ensuring that you choose the most compatible and reliable fuel lines for your Street Avenger.

Understanding Impulse Fuel Lines: Powering Chainsaws Efficiently

You may want to see also

Size and Routing: Properly size and route fuel lines for easy installation and reduced risk of damage

When it comes to modifying your Street Avenger for high-performance use, one crucial aspect often overlooked is the fuel lines. Properly sizing and routing these lines is essential for a successful installation and to minimize the risk of fuel-related issues. Here's a comprehensive guide to help you get it right.

Size matters when it comes to fuel lines. The rule of thumb is to use a fuel line that is at least 1/4 inch in diameter for a standard fuel pump setup. For high-flow applications or modified engines, consider using a larger diameter, such as 3/8 inch or even 1/2 inch, to handle the increased fuel volume efficiently. Thicker fuel lines also provide better flexibility and reduce the chances of damage from sharp bends or vibrations.

Routing the fuel lines is an art that requires careful consideration. Start by identifying the optimal path from the fuel tank to the engine. Aim for a direct route, minimizing sharp turns and tight spaces. Avoid routing fuel lines near hot engine components to prevent potential damage. Use fuel line brackets or ties to secure the lines, ensuring they are taut and away from any moving parts. Proper routing also involves leaving enough slack to accommodate engine movement without causing excessive stress on the lines.

In the case of the Street Avenger, you might want to consider a few specific tips. If your engine has a high-pressure fuel pump, ensure the lines are robust enough to handle the increased pressure. Additionally, if you're running a modified intake or supercharger, the fuel lines should be long enough to reach the engine without being too tight or kinked. Properly sizing and routing the fuel lines will not only make the installation process smoother but also contribute to a more reliable and powerful performance.

Remember, the goal is to provide a clear and safe path for the fuel to travel while ensuring the lines are secure and protected. By following these guidelines, you'll be well on your way to a successful fuel system upgrade for your Street Avenger, maximizing its performance potential.

Understanding the Role of Fuel Return Lines in Engine Systems

You may want to see also

Frequently asked questions

For optimal performance and reliability, it is recommended to use a high-quality fuel line designed specifically for high-performance applications. Look for fuel lines made from durable materials like stainless steel or braided nylon, ensuring they can withstand the pressure and temperature fluctuations in your engine.

While it might be tempting to reuse parts, it's not advisable. Standard fuel lines may not have the necessary flexibility and durability to handle the increased fuel flow and pressure in a high-performance engine. Using the correct fuel line designed for your Street Avenger will ensure a reliable and efficient fuel delivery system.

Fuel lines can last for many years if properly maintained, but regular inspections are essential. Over time, fuel lines can degrade due to fuel contamination, heat, and vibration. It is recommended to replace the fuel line every 50,000 to 100,000 miles or whenever you notice signs of wear, such as cracks, leaks, or reduced performance.