Tying a secure and reliable knot for an aircraft fuel cell line is a critical task that requires precision and adherence to specific techniques. This guide will provide a step-by-step approach to achieving a strong and safe connection, ensuring the integrity of the fuel system. By following these instructions, you can create a knot that will withstand the rigors of aviation, providing a safe and efficient fuel supply for your aircraft.

What You'll Learn

- Knot Types: Identify and understand different types of knots for fuel cell lines

- Preparation: Prepare the line by cleaning and measuring for proper knot placement

- Tying Techniques: Learn step-by-step methods to tie various knots securely

- Tightening: Adjust tension to ensure a firm, reliable connection

- Testing: Verify knot strength and integrity through visual and physical checks

Knot Types: Identify and understand different types of knots for fuel cell lines

When working with aircraft fuel cell lines, understanding various knot types is crucial for ensuring secure and reliable connections. Knots play a vital role in maintaining the integrity of these lines, especially in high-stress environments. Here's an overview of some essential knot types and their applications:

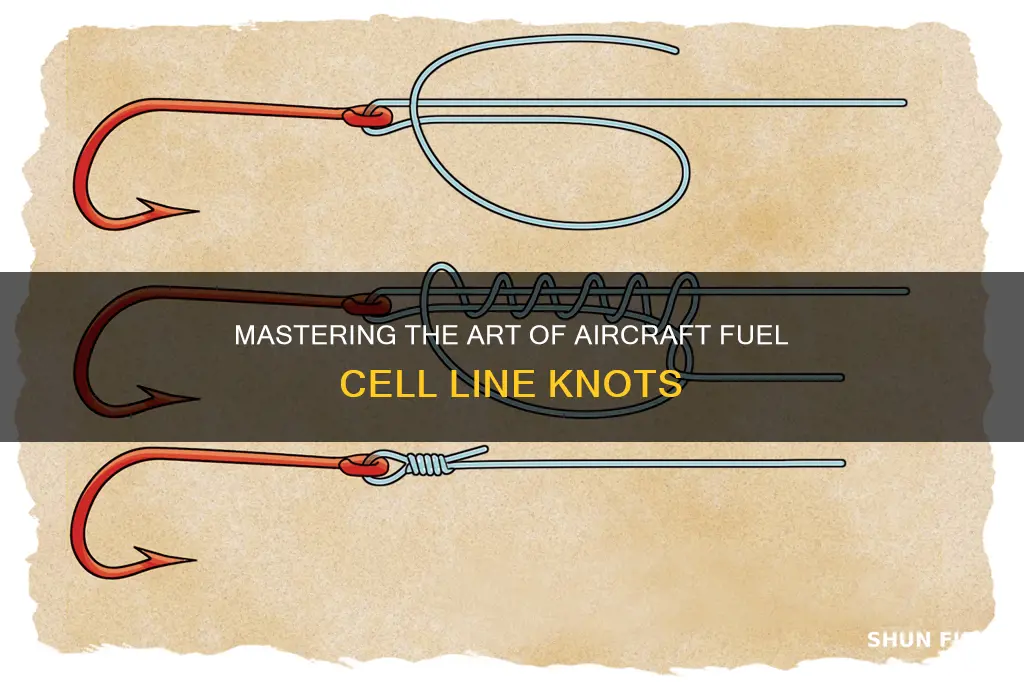

- Sheet Bend Knot: This knot is commonly used for joining fuel cell lines and is known for its strength and reliability. It involves creating a series of bends and turns, forming a secure loop. The process requires careful wrapping of the line around itself, creating a series of bends that interlock, providing a strong and durable connection. This knot is ideal for permanent installations and offers excellent resistance to shearing forces.

- Clove Hitch Knot: A versatile knot, the Clove Hitch, is excellent for temporary connections and adjustments. It is easy to tie and provides a secure grip on the line. This knot is particularly useful when you need to make quick adjustments or when working with flexible fuel cell lines. By wrapping the line around the object or another line, the Clove Hitch creates a firm hold, allowing for controlled movement and positioning.

- Figure-Eight Knot: As the name suggests, this knot forms a figure-eight pattern, offering excellent strength and security. It is commonly used for creating a fixed loop at the end of a fuel cell line. The Figure-Eight Knot provides a reliable connection, especially when combined with a stopper knot, ensuring the line remains taut and secure. This knot is widely recognized for its ability to withstand tension and is often used in critical applications.

- Bowline Knot: The Bowline is a classic knot known for its simplicity and reliability. It forms a fixed loop at the end of the line, making it ideal for creating a secure anchor point. This knot is easy to untie even under load, which is essential for quick release in emergency situations. When working with fuel cell lines, the Bowline ensures a strong and adjustable connection, allowing for easy adjustments without compromising strength.

Understanding these knot types is essential for aircraft mechanics and engineers to ensure the safety and efficiency of fuel cell line installations. Each knot has its unique characteristics, and choosing the right one depends on the specific requirements of the application. Proper knot selection and tying techniques contribute to the overall reliability of aircraft systems.

Understanding the Significance of the 3 Lines on Your Fuel Pump

You may want to see also

Preparation: Prepare the line by cleaning and measuring for proper knot placement

Before you begin tying the knot, it's crucial to ensure that the line is in optimal condition. Start by thoroughly cleaning the line to remove any dirt, debris, or contaminants that could affect the knot's performance. Use a soft brush or cloth to gently scrub the line, paying extra attention to the area where the knot will be tied. This step is essential to guarantee a clean and secure connection.

Next, measure the line to determine the appropriate length for the knot. The goal is to create a secure and compact knot, so measure carefully to ensure it meets the required specifications. Mark the measurement point with a temporary marker or a small piece of tape to indicate where the knot should be placed. This precise measurement will help you achieve the desired knot size and ensure the line's integrity.

Additionally, inspect the line for any signs of damage or wear. Check for any frayed or worn-out sections that might compromise the knot's strength. If you notice any issues, it's best to replace the line to maintain safety standards. Proper preparation and measurement are key to a successful knot, so take the time to get these steps right.

When measuring, consider the type of knot you plan to tie. Different knots require specific lengths, so refer to the appropriate knot-tying guide for aircraft fuel cell lines. This will ensure that you tie the knot correctly and achieve the desired tension and security. Remember, a well-prepared line is the foundation for a reliable and safe knot.

By taking the time to clean, measure, and inspect the line, you're setting the stage for a robust and secure knot. This preparation process is vital to ensure the knot's longevity and performance in the demanding environment of an aircraft fuel cell system.

Unraveling the Mystery: Detroit 6-71 Fuel Line's Location

You may want to see also

Tying Techniques: Learn step-by-step methods to tie various knots securely

When it comes to securing fuel cell lines in an aircraft, the choice of knot is critical. The right knot ensures a reliable and safe connection, while a poorly tied knot can lead to dangerous consequences. Here, we'll delve into the art of tying knots specifically designed for aircraft fuel cell lines, providing a comprehensive guide to ensure your connections are both secure and reliable.

Understanding the Basics

Before we dive into the tying techniques, it's essential to understand the fundamental principles of knot-tying. A well-tied knot should be:

- Secure: The knot should firmly hold the line in place, preventing it from slipping or coming loose under stress.

- Reliable: It should withstand the rigors of aircraft operation, including vibrations, temperature fluctuations, and fuel pressure.

- Easy to Tie: A knot that is too complex or difficult to tie quickly can be a hazard in an emergency situation.

- Visual Inspection: The knot should be easily visible to allow for quick inspection during pre-flight checks.

Common Knots for Fuel Cell Lines

Several knots are commonly used for securing fuel cell lines in aircraft. Here's a breakdown of some popular choices:

Figure-Eight Knot:

- This knot is a classic and reliable option.

- To tie it: Pass the line around the base of the knot twice, then cross it over itself, forming a figure-eight shape.

- Tighten the knot by pulling on the ends of the line.

- This knot provides excellent security and is easy to untie when needed.

Clove Hitch:

- Ideal for quick connections.

- To tie it: Wrap the line around the object (e.g., a fuel cell fitting) once, then pass the end of the line through the loop formed by the wrap.

- Pull the line to tighten the knot.

- This knot is easily adjustable and can be quickly untied.

Bowline Knot:

- A robust and secure knot, perfect for permanent connections.

- To tie it: Create a loop in the line, then pass the end of the line through the loop, forming a figure-eight shape.

- Pull the line through the figure-eight, then tighten the knot by pulling on the ends.

- This knot is virtually impossible to untie accidentally, making it ideal for critical applications.

Step-by-Step Tying Instructions:

Now, let's break down the tying process for each knot:

Figure-Eight Knot:

- Start with a Loop: Create a loop in the fuel cell line.

- Pass and Cross: Pass the line around the base of the loop twice, then cross it over itself to form the figure-eight.

- Tighten: Pull on the ends of the line to tighten the knot.

- Inspect: Ensure the knot is snug and secure.

Clove Hitch:

- Wrap: Wrap the line around the fuel cell fitting once.

- Pass Through: Pass the end of the line through the loop formed by the wrap.

- Tighten: Pull the line to tighten the knot.

- Adjust: If needed, adjust the knot for a secure fit.

Bowline Knot:

- Loop Creation: Create a loop in the line.

- Figure-Eight: Pass the end of the line through the loop, forming a figure-eight.

- Tighten: Pull the line through the figure-eight and tighten the knot by pulling on the ends.

- Final Check: Ensure the knot is secure and cannot be untied accidentally.

Safety Considerations:

- Always use the appropriate knot for the specific application.

- Regularly inspect knots for wear and damage, especially after high-stress operations.

- Keep knots tight to prevent slippage.

- In case of doubt, consult a qualified aviation technician for guidance.

Understanding Fuel Impulse Lines: Their Role in Engine Performance

You may want to see also

Tightening: Adjust tension to ensure a firm, reliable connection

When tightening a fuel cell line knot, it's crucial to achieve a secure and reliable connection to ensure the safe and efficient operation of the aircraft's fuel system. Here's a detailed guide on how to adjust the tension for a firm and dependable knot:

Understanding the Knot's Structure: Begin by familiarizing yourself with the specific type of knot you're working with. Different knots have unique characteristics and tightening methods. For instance, a common knot used in aviation might be the 'Cloverleaf' or 'Hitch' knot, which has multiple loops and requires precise tensioning. Understanding the knot's structure will help you identify the critical areas that need adjustment.

Initial Tightening: Start by giving the knot a gentle initial tighten. This initial step is essential to set the foundation for the knot's stability. Use your hands or a small tool to apply controlled pressure, ensuring that the knot is snug but not overly tight. The goal is to create a base tension that will be built upon.

Adjusting Tension: Now, it's time to fine-tune the tension. Carefully examine the knot and identify the areas where the lines intersect or form loops. Apply tension to these points, pulling steadily and evenly. The key is to maintain a consistent tension throughout the knot. Avoid pulling too hard in one spot, as this can create uneven stress and potentially damage the fuel cell lines. Instead, distribute the tension across multiple points to ensure a uniform and secure hold.

Testing the Connection: After tightening, it's crucial to test the knot's reliability. Gently rock the fuel cell line back and forth to ensure the knot remains intact and doesn't come loose. If you feel any play or looseness, further adjust the tension by tightening specific areas of the knot. This iterative process ensures that the connection is firm and secure.

Final Inspection: Once you're satisfied with the tension and the knot's stability, conduct a final inspection. Check for any signs of strain or damage to the fuel cell lines where they intersect the knot. Ensure that all connections are clean and free of debris. A thorough inspection at this stage will help identify any potential issues before the aircraft's operation.

Remember, the goal is to create a knot that is both strong and adjustable, allowing for fine-tuning to achieve the perfect tension. This meticulous approach to tightening ensures the safety and efficiency of the aircraft's fuel system.

Fuel Line Hose Connections: The Ultimate Guide to Choosing the Right Method

You may want to see also

Testing: Verify knot strength and integrity through visual and physical checks

When it comes to securing aircraft fuel cell lines, the knot's strength and integrity are of utmost importance to ensure the safety and efficiency of the fuel system. Here's a detailed guide on how to verify the knot's performance through visual and physical checks:

Visual Inspection: Begin by carefully examining the knot from all angles. Look for any signs of slippage or uneven tension. A well-tied knot should appear compact and symmetrical. Check for any visible gaps or spaces between the lines where the knot is located. These gaps could indicate improper tensioning and may compromise the knot's strength. Ensure that the knot is not twisted or tangled, as this can affect its functionality. A clean, neat appearance is a good indicator of a properly tied knot.

Physical Testing: This step involves hands-on evaluation to assess the knot's integrity. Start by applying firm pressure to the knot and pulling the lines in various directions. Test the knot's resistance to tension and ensure it holds firmly without slipping. Try to mimic real-world conditions by applying force in different directions, simulating potential stress points in the fuel cell line. The knot should remain secure and not come undone under these tests. Additionally, inspect the knot for any signs of wear or damage, especially if the lines have been in use for an extended period.

Comparative Analysis: Compare the tied knot with standard knot-tying techniques used in aviation. Refer to industry guidelines and manuals for recommended knot styles. Ensure that your knot follows the established practices, as these methods are designed to provide optimal strength and security. By comparing, you can identify any deviations from the correct technique and make the necessary adjustments.

Re-tightening and Re-inspection: If any issues are identified during the visual or physical checks, re-tighten the knot according to the proper procedure. Re-inspection is crucial to ensure the knot's integrity after adjustments. Repeat the visual and physical testing steps to verify that the knot now meets the required standards.

Remember, thorough testing is essential to guarantee the safety and reliability of aircraft fuel cell line connections. These checks help identify potential weaknesses and ensure that the knot can withstand the demands of the fuel system.

Unraveling the Ultimate Marine Fuel Line Flexibility: A Comprehensive Guide

You may want to see also

Frequently asked questions

A fuel cell line knot is a critical component in aviation, ensuring a secure and reliable connection between the fuel cell and the aircraft's fuel system. It prevents fuel leaks and maintains a tight seal, which is essential for safe and efficient operations.

Tying this specific knot requires precision and attention to detail. Start by wrapping the line around the fuel cell fitting several times, creating a secure base. Then, pass the line through the loop, forming a figure-eight knot. Tighten it by pulling on both ends, ensuring it is snug and secure. Repeat this process a few times to reinforce the knot.

Absolutely! To maximize strength, use a robust and flexible fuel cell line material. After tying the knot, inspect it regularly for any signs of wear or damage. Consider using a protective covering or sleeve around the knot to provide an extra layer of security, especially in high-stress environments. Regular maintenance and inspections are key to ensuring the knot's integrity.