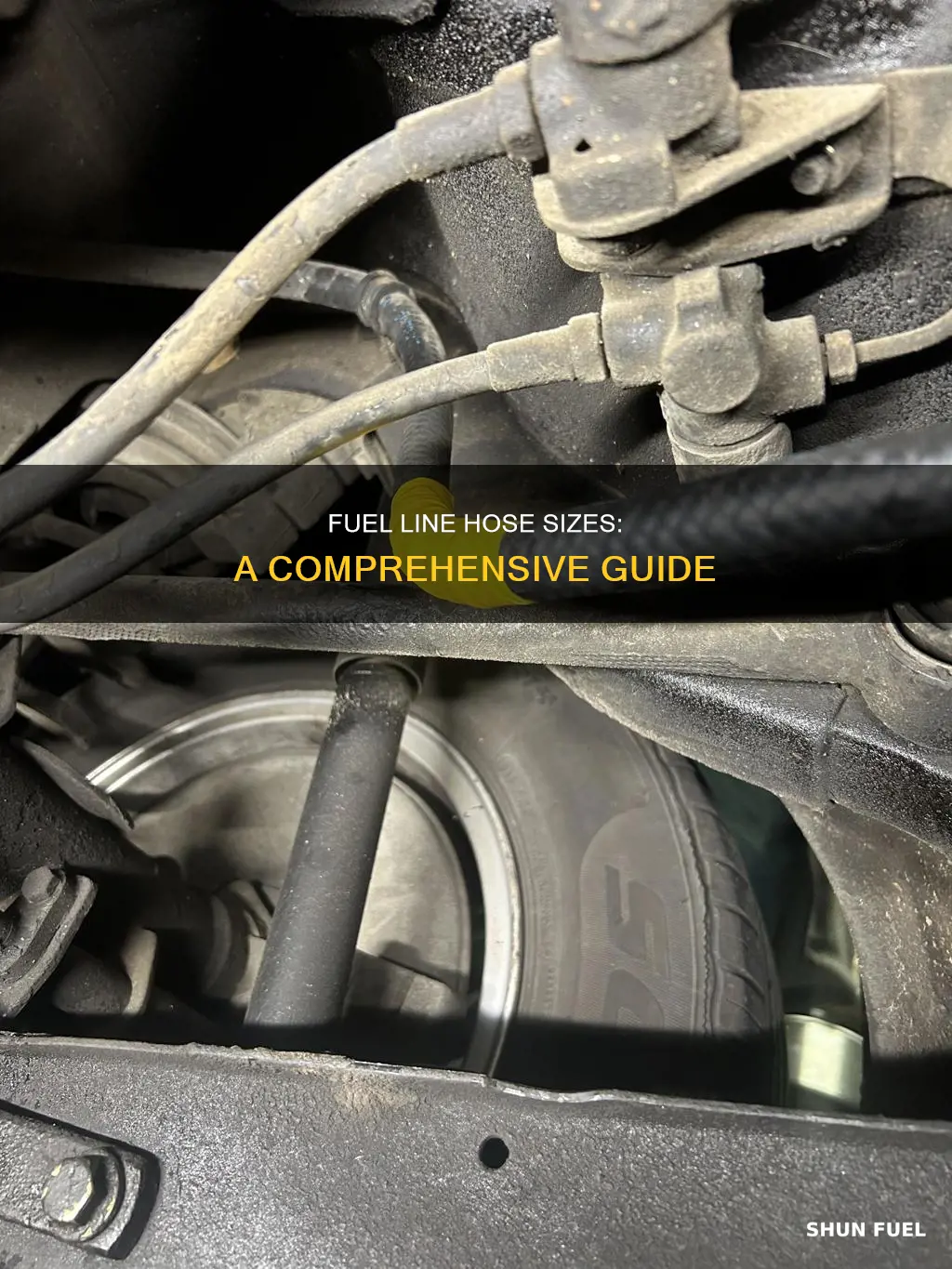

When it comes to fuel line hoses, understanding the various sizes available is crucial for ensuring optimal performance and safety in any vehicle. These hoses play a vital role in transporting fuel from the tank to the engine, and their size directly impacts the efficiency and reliability of the fuel delivery system. From small, compact cars to large, heavy-duty trucks, the size of the fuel line hose must be carefully considered to match the specific requirements of the vehicle's engine and fuel system. In this discussion, we will explore the different sizes of fuel line hoses and their applications, providing valuable insights for vehicle owners, mechanics, and enthusiasts alike.

What You'll Learn

- Standard Sizes: Fuel lines typically come in 1/4, 3/8, and 1/2 inch diameters

- Custom Options: Hoses can be made to specific lengths and diameters for unique applications

- Material Variations: Different materials like steel, rubber, and plastic offer varying benefits

- Pressure Ratings: Hoses are rated for specific pressure levels to handle different fuel types

- Compatibility: Sizes must match the fuel pump and engine requirements for optimal performance

Standard Sizes: Fuel lines typically come in 1/4, 3/8, and 1/2 inch diameters

When it comes to fuel line hoses, understanding the standard sizes is crucial for ensuring proper functionality and safety in any vehicle's fuel system. These hoses are designed to carry fuel efficiently and reliably, and their sizes play a significant role in this process. The most common diameters for fuel lines are 1/4, 3/8, and 1/2 inches. Each of these sizes serves a specific purpose and is chosen based on the fuel flow requirements of the vehicle.

The 1/4-inch diameter fuel line is one of the most popular choices for smaller vehicles, motorcycles, and some light-duty applications. It provides a good balance between fuel flow capacity and hose flexibility. This size is often used for fuel injection systems where a moderate fuel supply is required. Its small diameter allows for efficient fuel delivery while maintaining a reasonable level of pressure.

Moving up in size, the 3/8-inch diameter fuel line is commonly used in applications where higher fuel flow rates are necessary. This larger diameter can handle increased fuel pressure and volume, making it ideal for high-performance engines or vehicles with larger fuel tanks. The 3/8-inch hose provides a significant improvement in fuel delivery capacity compared to the 1/4-inch size, ensuring that the engine receives the necessary fuel for optimal performance.

At the top of the range, the 1/2-inch diameter fuel line is reserved for heavy-duty applications and high-performance vehicles. Its larger size allows for maximum fuel flow, making it suitable for powerful engines that require a substantial fuel supply. This size is often used in racing cars, trucks, and other performance-oriented vehicles where fuel efficiency and power output are critical.

Understanding these standard sizes is essential for anyone working on a vehicle's fuel system. Properly sizing the fuel lines ensures that the engine receives the correct amount of fuel at the right pressure, optimizing performance and fuel efficiency. It also helps prevent issues such as fuel starvation or excessive pressure, which can lead to engine problems. When replacing or upgrading fuel lines, always refer to the vehicle's specifications to choose the appropriate diameter to maintain the integrity of the fuel system.

Fuel Injector Line Maintenance: Is Cleaning Necessary?

You may want to see also

Custom Options: Hoses can be made to specific lengths and diameters for unique applications

When it comes to fuel line hoses, customization is key to ensuring a perfect fit for unique applications. The beauty of these hoses lies in their versatility and ability to be tailored to specific requirements. Whether you're working on a classic car restoration, a custom race car, or a specialized industrial project, the option to customize the hoses is invaluable.

One of the primary custom options available is the ability to choose the length of the hose. Standard fuel line hoses typically come in various lengths, but for unique applications, you might need a hose that is longer or shorter than the standard sizes. This customization ensures that the hose can be seamlessly integrated into your vehicle or system, providing an exact fit without any unnecessary excess. For example, in a classic car restoration, you might want to replicate the original hose length, ensuring a period-accurate restoration.

In addition to length, the diameter of the hose can also be customized. Fuel line hoses are available in different diameters, allowing you to select the appropriate size based on your specific needs. A smaller diameter might be suitable for high-performance racing applications where weight reduction is crucial, while a larger diameter could be required for heavy-duty industrial machinery. By choosing the right diameter, you can optimize the flow rate of fuel, ensuring efficient and reliable operation.

Customizing the hose's length and diameter is particularly useful for unique or rare vehicle models. For instance, when restoring an antique aircraft, you might need hoses that match the specific dimensions used in the original design. Customization also comes into play when dealing with non-standard fuel systems, where off-the-shelf hoses may not be compatible. By working with a reputable manufacturer or supplier, you can have the hoses made to your exact specifications, ensuring a seamless and professional finish.

Furthermore, customization allows for the use of specialized materials and coatings. Different applications may require hoses with specific properties, such as resistance to extreme temperatures, chemicals, or abrasion. Custom-made hoses can incorporate these specialized features, ensuring longevity and performance in demanding environments. Whether it's a high-temperature engine or a corrosive industrial setting, the ability to customize the hose's composition is a significant advantage.

Unveiling the Secrets: Red Line Fuel System Explained

You may want to see also

Material Variations: Different materials like steel, rubber, and plastic offer varying benefits

When it comes to fuel line hoses, the choice of material is a critical factor that can significantly impact performance, durability, and safety. Different materials offer unique advantages, and understanding these variations is essential for making an informed decision. Here's an overview of the key materials used in fuel line hoses and their respective benefits:

Steel:

Steel fuel line hoses are known for their exceptional strength and durability. This material is highly resistant to abrasion, making it ideal for harsh environments where the hose might come into contact with sharp edges or rough surfaces. Steel hoses are often used in high-performance applications, such as racing or heavy-duty machinery, where the fuel line needs to withstand extreme conditions. The rigidity of steel provides a robust solution, ensuring that the fuel delivery remains stable and secure. However, steel hoses can be heavier and more rigid compared to other materials, which might limit their use in certain applications where flexibility is required.

Rubber:

Rubber is a popular choice for fuel line hoses due to its flexibility and resilience. This material can accommodate slight bends and twists, making it easier to route the hose through various engine compartments. Rubber hoses are generally more pliable, allowing for better installation and reduced risk of damage during engine movement. Additionally, rubber offers good resistance to fuel degradation, ensuring that the fuel remains stable and fresh over time. Its natural ability to absorb vibrations can also contribute to a quieter and smoother fuel delivery system.

Plastic:

Plastic fuel line hoses are lightweight and offer excellent chemical resistance. This material is often used in applications where the hose needs to be flexible yet durable. Plastic hoses are known for their ability to resist corrosion and are less prone to cracking or brittleness compared to some other materials. They are commonly used in automotive applications, especially for fuel lines that require frequent movement and flexibility. The lightweight nature of plastic hoses makes them easier to install and replace, contributing to overall convenience.

The choice between steel, rubber, and plastic depends on the specific requirements of the fuel line application. For high-performance or heavy-duty use, steel provides the necessary strength and durability. Rubber is versatile and suitable for most automotive applications, offering flexibility and fuel stability. Plastic, with its lightweight and chemical resistance, is an excellent choice for modern vehicles and applications where weight reduction is a priority. Understanding these material variations allows for a tailored approach to fuel line hose selection, ensuring optimal performance and longevity.

Unraveling the Mystery: What's Beneath the Fuel Line in Elite: Dangerous

You may want to see also

Pressure Ratings: Hoses are rated for specific pressure levels to handle different fuel types

When it comes to fuel line hoses, understanding the pressure ratings is crucial for ensuring safe and efficient fuel delivery. These hoses are designed to withstand the specific pressures associated with different fuel types, such as gasoline, diesel, and aviation fuel. The pressure rating is typically measured in pounds per square inch (PSI) and indicates the maximum pressure a hose can handle without failing.

Hoses used for fuel lines are available in various pressure ratings to accommodate the varying demands of different fuel systems. For instance, gasoline fuel lines generally require lower pressure ratings compared to diesel or aviation fuel systems. Gasoline hoses are often rated for pressures up to 100-150 PSI, ensuring they can handle the typical fuel delivery pressures in most vehicles. On the other hand, diesel fuel lines may need higher pressure ratings, sometimes reaching 300-400 PSI or more, to manage the increased pressure associated with diesel engines.

The pressure rating is essential because it determines the hose's ability to handle the fuel's flow rate and potential surges in pressure. Higher-pressure fuel systems, like those in racing cars or aircraft, require hoses with correspondingly higher pressure ratings to prevent damage or failure. Using a hose with an inadequate pressure rating can lead to fuel leaks, reduced performance, or even catastrophic failure, emphasizing the importance of choosing the right hose for the specific fuel application.

Manufacturers provide detailed specifications for each hose, including its pressure rating, temperature range, and compatibility with various fuels. It is imperative to select a hose that meets or exceeds the requirements of the fuel system it will serve. Properly rated hoses ensure the longevity of the fuel system and the overall safety of the vehicle or aircraft.

In summary, pressure ratings are a critical aspect of fuel line hoses, allowing them to handle different fuel types and their associated pressures. Understanding these ratings and selecting the appropriate hose ensures optimal performance and safety in fuel delivery systems.

Fuel Rail Basics: Understanding the Line for Optimal Performance

You may want to see also

Compatibility: Sizes must match the fuel pump and engine requirements for optimal performance

When it comes to fuel line hoses, compatibility is key to ensuring optimal performance and preventing potential issues. The size of the fuel line hose must match the specific requirements of both the fuel pump and the engine it serves. This is a critical aspect of vehicle maintenance that should not be overlooked.

The fuel pump is responsible for delivering fuel from the tank to the engine, and its capacity and efficiency are directly related to the size of the fuel line hose. If the hose is too small, it may restrict fuel flow, leading to reduced engine performance and potential stalling. On the other hand, if the hose is too large, it can create unnecessary pressure, causing fuel to spray out of the hose and potentially leading to fuel wastage and engine misfires. Therefore, it is essential to choose a fuel line hose that matches the fuel pump's flow rate and pressure requirements.

Engine specifications also play a crucial role in determining the appropriate size of the fuel line hose. Different engines have varying fuel requirements, and using a hose that is not designed for the specific engine can result in suboptimal performance. For example, a high-performance engine may require a larger diameter hose to handle the increased fuel volume and pressure, while a smaller engine might need a more compact hose to ensure efficient fuel delivery without unnecessary bulk.

To ensure compatibility, it is recommended to consult the vehicle's manual or seek professional advice to determine the exact size and specifications required for your fuel pump and engine. Using the correct size fuel line hose will not only optimize engine performance but also contribute to better fuel efficiency and longer-lasting engine components.

In summary, when selecting fuel line hoses, it is imperative to prioritize compatibility by matching the hose size to the fuel pump and engine requirements. This attention to detail will help maintain a well-functioning engine and ensure a reliable and efficient driving experience.

NHRA Fuel Line Routing: Rules and Regulations Explained

You may want to see also

Frequently asked questions

Fuel line hoses are available in various sizes, typically measured in inches or millimeters. Common sizes include 3/8", 1/2", 3/4", and 1". The specific size you need will depend on your vehicle's requirements and the application of the hose.

Absolutely! Fuel line hoses are often sold in various lengths to accommodate different vehicle configurations. You can typically find hoses with lengths ranging from 1 foot to several feet, allowing for customization based on your specific needs.

When choosing fuel line hoses, it's essential to consider the pressure and temperature requirements of your fuel system. Some hoses are designed for high-pressure applications, while others are suitable for low-pressure systems. Additionally, ensure that the hose size matches the fuel pump's output and the fuel tank's inlet to prevent any performance issues.