Removing a small engine fuel line can be a straightforward process if you follow the right steps. This guide will provide a step-by-step approach to safely and effectively disconnect the fuel line, ensuring you have the necessary tools and safety precautions in place before beginning. Understanding the process is crucial to avoid any potential hazards and to ensure a successful repair or maintenance task.

| Characteristics | Values |

|---|---|

| Safety Precautions | - Wear safety gear, including gloves and eye protection. - Ensure the engine is cool and the fuel supply is disconnected. - Use a fuel drain kit or a funnel to catch any spilled fuel. |

| Tools Required | - Wrench or fuel line removal tool - Screwdrivers (if necessary) - Funnel - Rags or paper towels |

| Steps | 1. Locate the fuel line, often near the fuel tank or carburetor. 2. Use the appropriate tool to loosen and remove the fuel line connections. 3. Carefully pull the fuel line away from the engine and fuel source. 4. Inspect the fuel line for any damage or clogs. 5. Clean or replace the fuel line if necessary. |

| Tips | - Take photos of the fuel line connections for reference during reinstallation. - Use a fuel line cleaner to remove any deposits or contaminants. - Ensure a tight connection when reattaching the fuel line. |

| Common Issues | - Clogged fuel lines due to dirt or debris. - Leaking fuel lines. - Corroded or damaged fuel lines. |

| Reinstallation | Follow the reverse process of removal, tightening connections securely. |

What You'll Learn

- Prepare the Engine: Ensure the engine is off and cooled before starting the removal process

- Locate the Fuel Line: Identify the fuel line, often a small, flexible tube, on the engine

- Loosen Connections: Use a wrench to loosen and remove any connections or clips securing the fuel line

- Pull the Line: Carefully pull the fuel line away from the engine, being mindful of any connections

- Clean and Inspect: Clean the removed fuel line and inspect for any damage or blockages

Prepare the Engine: Ensure the engine is off and cooled before starting the removal process

Before attempting to remove the fuel line from a small engine, it is crucial to prioritize safety and ensure that the engine is in a controlled and secure state. The first step in this process is to turn off the engine and allow it to cool down. This initial step is often overlooked but is essential for several reasons. Firstly, an engine that is still hot can be extremely dangerous as it may cause burns or injuries if touched. Secondly, a hot engine can lead to fuel line damage during removal due to the potential for fuel to still be present in the system, which can cause leaks or splashes.

To begin, locate the engine's power source and switch it off. This could be a pull cord, a key, or an electric start button, depending on the engine's design. Once the engine is off, allow it to idle for a few minutes to ensure that any residual heat dissipates. This waiting period is important as it allows the engine to cool down to a safe temperature, reducing the risk of accidents.

While the engine is cooling, it is also a good time to inspect the fuel line for any visible damage or signs of wear. Look for any cracks, kinks, or leaks along the length of the fuel line. This inspection can help identify potential issues that may require attention before or during the removal process. If any damage is found, it is best to address it immediately to prevent further complications.

Additionally, ensure that the engine is in a stable position. If the engine is mounted on a vehicle or equipment, make sure it is securely fastened and will not move or tip during the removal process. This stability is crucial to maintaining control and preventing accidents. Once the engine has cooled sufficiently and you have completed the inspection, you can proceed with the fuel line removal, ensuring a safe and efficient process.

Craftsman Chainsaw Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Locate the Fuel Line: Identify the fuel line, often a small, flexible tube, on the engine

When it comes to removing a small engine fuel line, the first step is to locate the fuel line itself. This can be a challenging task, as fuel lines are often hidden beneath the engine and other components. However, with a bit of patience and the right tools, you can identify and access the fuel line.

The fuel line is typically a small, flexible tube that connects the fuel tank to the engine. It is designed to carry gasoline or diesel fuel from the tank to the engine's carburetor or fuel injection system. Identifying this line is crucial as it ensures you can safely and effectively disconnect it during the removal process.

To locate the fuel line, start by inspecting the engine and looking for any visible tubes or hoses. These components are usually color-coded or labeled to indicate their function. The fuel line may be a different color or have a unique identifier, making it stand out from other engine parts. It is often located near the engine's air filter or intake manifold. If you have access to the engine's manual or service guide, it can provide detailed diagrams and illustrations to help you pinpoint the exact location.

If you're having trouble finding the fuel line, consider the following tips: Check for any fuel leaks or spills around the engine, as this could indicate the line's position. Look for any connections or fittings that are attached to the engine block or cylinder head, as these might be part of the fuel line system. In some cases, you may need to remove other engine components to gain better access to the fuel line.

Once you've identified the fuel line, it's important to understand its connection points. The fuel line is typically secured in place using clamps or fittings. Carefully inspect these connections to ensure you can safely remove them without causing any damage. It's a good idea to take notes or take photos of the assembly to remember the order and configuration of the components.

Dirt Bike Fuel Line Sizing: Essential Guide for Optimal Performance

You may want to see also

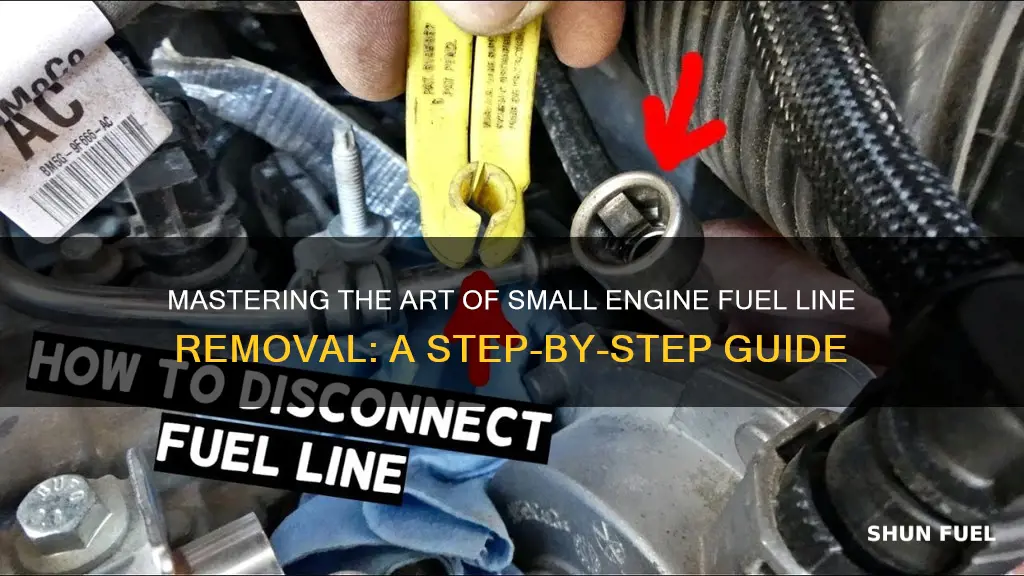

Loosen Connections: Use a wrench to loosen and remove any connections or clips securing the fuel line

When tackling the task of removing a small engine fuel line, it's crucial to start by identifying and loosening any connections or clips that secure the fuel line in place. This step is essential as it allows for the safe and controlled detachment of the fuel line, preventing any potential damage to the engine or fuel system.

Begin by locating the fuel line connections, which are typically found along the length of the fuel line. These connections can vary in type, but they often include clips, screws, or quick-release fasteners. Carefully inspect each connection to determine the type of fastener used. For clips or screws, you will need a suitable wrench or screwdriver to loosen them.

Using a wrench, apply a gentle but firm force to loosen the connections. Be cautious not to over-tighten or force the wrench, as this can damage the fuel line or connections. The goal is to create enough slack to remove the fuel line without straining the connections. If you encounter resistance, ensure that you are applying the correct amount of force and using the right size wrench for the job.

As you loosen the connections, take note of their positions and orientations. This information will be valuable when reinstalling the fuel line, ensuring that it is connected correctly and securely. Once all the connections are loosened, carefully remove the fuel line from the engine and set it aside.

Remember, when working with fuel lines, it's essential to exercise caution and patience. Take your time to carefully loosen and remove each connection, and always replace the fuel line in the same manner to ensure a proper fit. By following these steps, you can effectively remove the small engine fuel line while minimizing the risk of damage to the engine or fuel system.

The Ultimate Guide to Choosing Lubricant for Rubber Fuel Lines

You may want to see also

Pull the Line: Carefully pull the fuel line away from the engine, being mindful of any connections

When removing the fuel line from a small engine, it's crucial to approach this task with precision and care. Start by identifying the fuel line's connection points. These are typically located near the engine's fuel tank and may involve screws, clips, or quick-release fittings. Carefully inspect the connections to ensure you understand their nature. Some lines might have a simple clamp that can be easily loosened, while others may require specific tools for removal.

Once you've identified the connections, it's time to begin the process of disconnecting the fuel line. Gently grasp the fuel line and apply steady pressure while pulling it away from the engine. Take your time here; rushing could lead to damage or dislodging connections. As you pull, observe the line for any signs of damage, such as cracks or kinks, which could indicate previous issues or potential future problems.

As you work, maintain a clear view of the surrounding area to avoid accidentally pulling on any other components that might be connected to the fuel line. It's a delicate operation, and taking your time will ensure a successful outcome. If you encounter any resistance or feel the line is stuck, check for any obstructions or tight fittings that might require adjustment or the use of a suitable tool.

Remember, the goal is to remove the fuel line without causing any damage to the engine or the line itself. Taking a methodical approach will help you achieve this. If you're unsure about any step, consult the engine's manual or seek guidance from a professional to ensure you're following the correct procedure.

After successfully disconnecting the fuel line, you can proceed with the rest of the removal process, ensuring that you handle the line with care throughout.

VW Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Clean and Inspect: Clean the removed fuel line and inspect for any damage or blockages

When you've removed the fuel line from a small engine, it's crucial to thoroughly clean and inspect it to ensure optimal performance and longevity. Start by disconnecting the fuel line from both the fuel tank and the engine. This step is essential to prevent any accidental fuel spillage during the cleaning process. Once disconnected, carefully remove the fuel line from the engine and lay it aside.

The next step is to clean the fuel line. You can use a simple household cleaner or a specialized fuel line cleaner. Apply the cleaner to the inside of the fuel line, ensuring an even coating. Allow the cleaner to sit for a few minutes to loosen any built-up deposits or contaminants. Then, use a small brush or a cleaning tool to gently scrub the interior of the fuel line, removing any dirt, grime, or old fuel residue. Rinse the fuel line thoroughly with clean water to eliminate any remaining cleaner and debris. Ensure that you check for any blockages or kinks in the fuel line during this process.

After cleaning, it's time to inspect the fuel line for any damage or issues. Carefully examine the fuel line for any signs of wear, cracks, or punctures. Look for any areas where the fuel line might have been damaged during removal or installation. Check for any blockages that might have formed due to debris or old fuel residue. Ensure that the fuel line is free-flowing and not constricted in any part. If you notice any damage or blockages, it's essential to address them promptly. You may need to replace the fuel line if significant damage is observed.

Additionally, consider using a fuel line inspection tool, such as a borescope, to get a clear view of the interior of the fuel line. This tool can help you identify any internal damage or blockages that might not be visible to the naked eye. If you're unsure about the condition of the fuel line, it's always a good idea to consult a professional mechanic for guidance.

By following these steps, you can ensure that the fuel line is clean, free of damage, and ready for reinstallation, contributing to the overall performance and reliability of your small engine. Remember, proper maintenance and inspection of fuel lines are vital to prevent engine issues and ensure efficient operation.

Fuel Line Size for CJ7 258 Engine: Quick Guide

You may want to see also

Frequently asked questions

When removing a small engine fuel line, it's crucial to prioritize safety. Start by disconnecting the fuel line from the fuel tank or the carburetor. Ensure you have a suitable container to catch any remaining fuel. Use a fuel line cutter or a pair of sharp scissors to carefully cut the line, leaving a small portion attached to the engine for now.

You'll typically need a fuel line cutter or a set of sharp scissors, gloves to protect your hands, and possibly a funnel or a container to collect any spilled fuel. It's also a good idea to have a rag or cloth to wipe away any fuel residue.

Reusing a fuel line is generally not recommended unless it is in excellent condition. Over time, fuel lines can degrade, develop cracks, or become contaminated. It's best to replace the fuel line if possible to ensure optimal performance and safety.

Yes, safety is key. Always work in a well-ventilated area to avoid inhaling fuel vapors. Keep children and pets away from the work area. Be cautious when handling sharp tools, and ensure you dispose of any used fuel lines or containers responsibly, following local regulations for fuel waste management.