The Silverado, a popular full-size pickup truck, relies on a network of fuel lines to deliver gasoline from the tank to the engine. Understanding the layout of these fuel lines is crucial for maintenance and troubleshooting. One specific line that plays a vital role in the fuel supply system is the line that runs with the supply fuel line. This line is responsible for transporting fuel from the fuel pump to the engine, ensuring a steady and reliable fuel supply for optimal performance. Identifying and maintaining this line is essential to keep the Silverado running smoothly and efficiently.

What You'll Learn

- Fuel Delivery: Silverado's fuel pump and filter ensure continuous fuel supply

- Fuel Tank: The tank stores fuel, and the line connects it to the engine

- Fuel Injectors: These inject fuel into the engine's cylinders for combustion

- Fuel Pressure: Maintaining proper pressure is crucial for efficient engine operation

- Fuel Lines Material: Silverado's fuel lines are typically made of durable materials like steel or rubber

Fuel Delivery: Silverado's fuel pump and filter ensure continuous fuel supply

The fuel delivery system in a Silverado is a critical component that ensures your vehicle receives the necessary fuel for optimal performance. At the heart of this system is the fuel pump and filter, which work together to maintain a continuous and reliable fuel supply. Here's a breakdown of their roles and how they contribute to efficient fuel delivery.

The fuel pump is responsible for drawing fuel from the tank and sending it to the engine. It is typically located inside the fuel tank or close to it, ensuring that the fuel is pumped under pressure to meet the engine's demands. This pump is designed to operate continuously, providing a steady flow of fuel to the engine, which is essential for maintaining power and performance. When the engine is running, the pump operates at a specific rate, ensuring that the fuel is delivered efficiently without any interruptions.

In conjunction with the pump, the fuel filter plays a vital role in maintaining the quality of the fuel. It is positioned in the fuel line, usually near the engine, and acts as a barrier to trap contaminants and impurities. Over time, fuel can accumulate dirt, water, and other debris, which can lead to engine issues. The filter ensures that only clean, high-quality fuel reaches the engine, preventing potential damage and maintaining optimal performance. Regular replacement of the fuel filter is recommended to ensure its effectiveness.

Together, the fuel pump and filter work in harmony to provide a consistent and reliable fuel supply. The pump's ability to deliver fuel under pressure ensures that the engine receives the required amount, while the filter's presence guarantees that only clean fuel is utilized. This system is designed to handle the demands of the engine, providing the necessary power and performance while also protecting the engine from potential fuel-related issues.

For Silverado owners, understanding the fuel delivery system is essential for maintaining their vehicle's health. Regular checks and maintenance, including replacing the fuel filter at recommended intervals, can help ensure that the fuel pump and filter function optimally. This will contribute to a more reliable and efficient fuel supply, ultimately enhancing the overall performance and longevity of the Silverado.

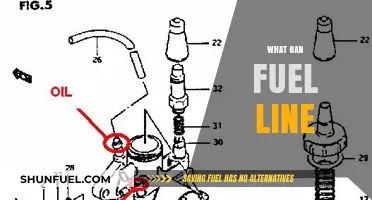

Fuel Filter Lines: Understanding the Connections and Their Roles

You may want to see also

Fuel Tank: The tank stores fuel, and the line connects it to the engine

The fuel tank in a Silverado is a crucial component of the vehicle's fuel system, designed to store the gasoline that powers the engine. It is typically located in the rear of the vehicle, often in the bed or behind the rear seat. The fuel tank's primary function is to hold the fuel, which is then supplied to the engine through a network of lines and components.

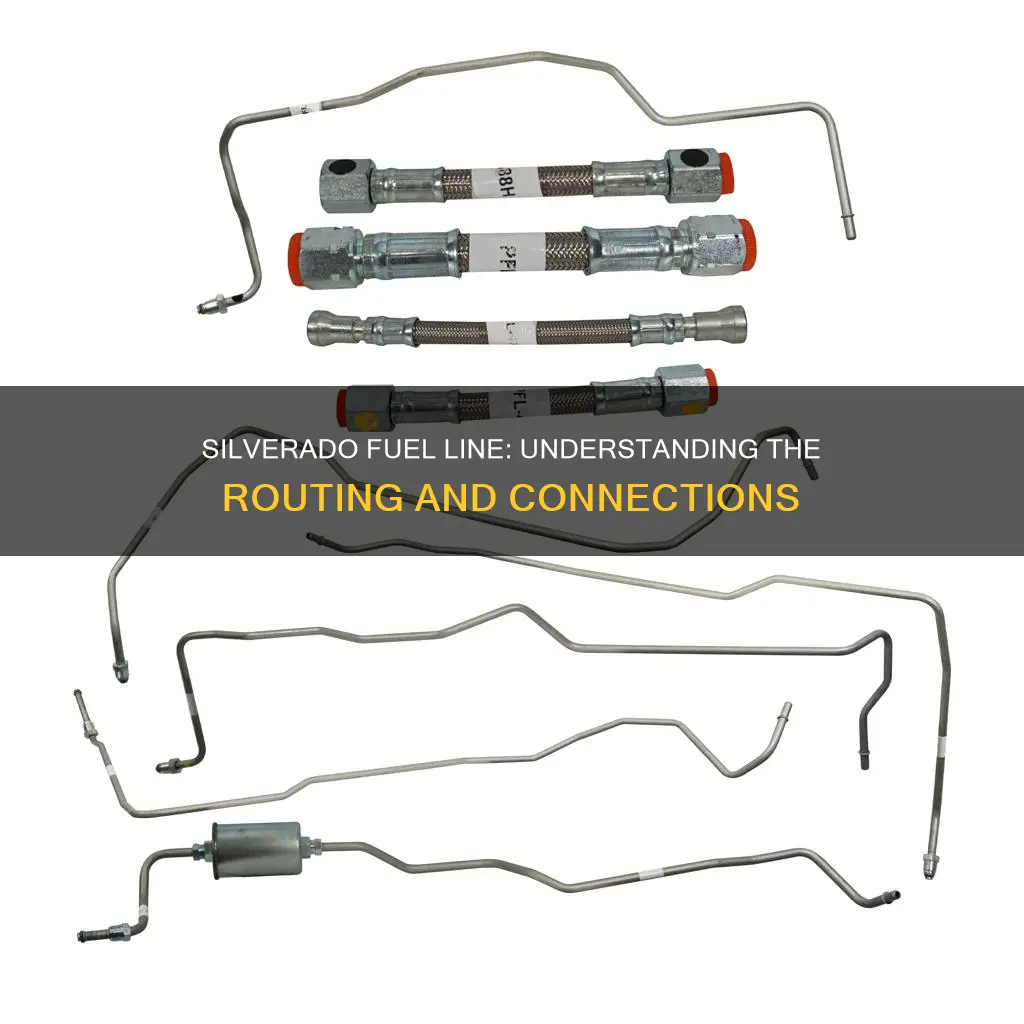

One of the most important lines associated with the fuel tank is the supply fuel line. This line is responsible for delivering the fuel from the tank to the engine, ensuring a continuous supply of gasoline for combustion. The supply fuel line is usually made of durable materials like steel or aluminum to withstand the pressure and temperature variations within the fuel system. It is designed with a specific diameter and length to optimize fuel flow while minimizing pressure drop.

The fuel tank is equipped with a fuel pump, which is a vital component in the fuel delivery process. The pump is located inside or near the tank and is responsible for creating the necessary pressure to push the fuel through the supply line and into the engine. When the engine is running, the fuel pump operates continuously to maintain a steady fuel supply. It is essential to ensure that the fuel pump is in good working condition to prevent fuel starvation and potential engine issues.

In addition to the supply fuel line, there are other lines connected to the fuel tank, such as the return line and the vent line. The return line is used to drain excess fuel from the engine back into the tank, ensuring proper fuel level management. The vent line allows air to enter the tank, facilitating the release of pressure and preventing vacuum buildup. These lines work together with the supply fuel line to create a well-functioning fuel system.

Regular maintenance and inspection of the fuel tank and its associated lines are crucial for the overall performance and longevity of the Silverado. It is recommended to check for any signs of damage, corrosion, or leaks in the fuel lines and ensure that the fuel pump is functioning correctly. Proper care will help prevent fuel-related issues and ensure a reliable fuel supply for the engine.

Unveiling the Mystery: What Exactly is 6AN Fuel Line?

You may want to see also

Fuel Injectors: These inject fuel into the engine's cylinders for combustion

The fuel supply system in a Silverado is a complex network designed to deliver the correct amount of fuel to the engine at the right time for optimal performance. One crucial component of this system is the fuel injectors, which play a vital role in the combustion process. These injectors are responsible for precisely metering and injecting fuel into the engine's cylinders, ensuring efficient and powerful performance.

Fuel injectors are typically located near the engine block, strategically positioned to deliver fuel directly into the combustion chambers. When the engine is running, the fuel injectors receive a signal from the engine control unit (ECU), which calculates the ideal fuel-air mixture based on various engine parameters. This signal triggers the injectors to open and spray a fine mist of fuel into the cylinders. The timing and amount of fuel injected are critical to achieving the desired power output and fuel efficiency.

The design of fuel injectors varies, but they generally consist of a nozzle, a solenoid valve, and a high-pressure chamber. When activated, the solenoid valve opens, allowing high-pressure fuel from the supply line to enter the chamber. This fuel is then atomized and directed through the nozzle, creating a fine spray. The spray is carefully controlled to ensure it mixes thoroughly with the air in the cylinder, promoting efficient combustion.

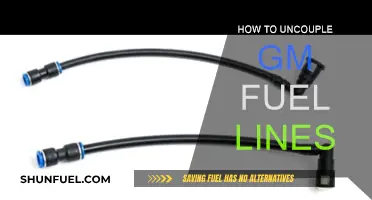

In a Silverado, the fuel supply line is typically a high-pressure hose that connects the fuel pump to the injectors. This line is crucial for delivering the required fuel pressure to the injectors, ensuring they can operate effectively. The fuel pump is usually located in the fuel tank or near the engine, and it draws fuel from the tank and pressurizes it before sending it through the supply line. Proper maintenance of this line is essential to prevent fuel leaks and ensure the engine receives the necessary fuel supply.

Understanding the role of fuel injectors and their relationship with the fuel supply line is essential for Silverado owners and mechanics. Regular maintenance, including checking for leaks and ensuring the injectors are functioning correctly, can help optimize engine performance and longevity. By keeping the fuel system in top condition, you can ensure that your Silverado's engine operates efficiently, delivering the power and reliability you expect from this capable vehicle.

The Strange Sound of Frozen Fuel Lines: A Guide

You may want to see also

Fuel Pressure: Maintaining proper pressure is crucial for efficient engine operation

The fuel pressure in a vehicle, such as the Silverado, is a critical aspect of engine performance and efficiency. It is responsible for ensuring that the engine receives the correct amount of fuel at the right pressure to achieve optimal combustion. Maintaining proper fuel pressure is essential for several reasons. Firstly, it directly impacts the engine's power output and overall performance. Insufficient fuel pressure can lead to poor engine operation, reduced power, and even engine stall. On the other hand, excessive fuel pressure can result in inefficient combustion, leading to wasted fuel and increased emissions.

In a Silverado, the fuel pressure is regulated by a fuel pressure regulator, which is typically located near the fuel tank. This regulator ensures that the fuel pressure remains within a specific range, usually between 40-60 psi (pounds per square inch) at idle and up to 80-90 psi during acceleration. The regulator adjusts the pressure based on engine load and speed, ensuring a steady supply of fuel to the engine. It is designed to maintain a consistent pressure, which is vital for the engine's ability to start, run smoothly, and deliver optimal performance.

Over time, fuel pressure regulators can wear out or become contaminated, leading to improper pressure regulation. This issue may go unnoticed until the engine starts to exhibit symptoms of poor performance. Common signs of fuel pressure problems include hard starting, poor acceleration, rough idling, and decreased fuel efficiency. If any of these symptoms are noticed, it is essential to inspect the fuel pressure regulator and ensure it is functioning correctly. Regular maintenance and inspections can help prevent such issues and ensure the engine operates at its best.

To maintain proper fuel pressure, regular fuel system maintenance is recommended. This includes checking and replacing the fuel filter, ensuring the fuel tank is clean and free of contaminants, and inspecting the fuel lines for any signs of damage or leaks. Additionally, using the correct type and grade of fuel recommended by the manufacturer is crucial. Using lower-quality fuel or fuel with incorrect octane ratings can lead to improper combustion and pressure issues.

In summary, proper fuel pressure is a critical factor in the efficient operation of a Silverado engine. It ensures optimal combustion, improves performance, and contributes to the overall longevity of the vehicle. Regular maintenance and attention to fuel system components, such as the fuel pressure regulator and fuel lines, are essential to keep the engine running smoothly and avoid potential issues related to fuel pressure. By understanding the importance of fuel pressure and implementing the necessary maintenance practices, Silverado owners can ensure their vehicles perform at their best.

Echo PB 200 Fuel Line Size: A Comprehensive Guide

You may want to see also

Fuel Lines Material: Silverado's fuel lines are typically made of durable materials like steel or rubber

The fuel lines in a Silverado, a popular full-size pickup truck, are an essential component of its fuel system, ensuring the efficient delivery of gasoline or diesel to the engine. These lines are designed to withstand the rigors of everyday use, including varying temperatures, vibrations, and fuel pressures. Understanding the materials used in these lines is crucial for maintenance and troubleshooting.

Silverados fuel lines are primarily constructed from two types of materials: steel and rubber. Each material offers unique advantages and is chosen based on the specific requirements of the fuel system. Steel fuel lines are known for their exceptional durability and strength. They are less flexible but highly resistant to corrosion and abrasion, making them ideal for high-pressure applications and environments with potential contaminants. These lines are often used for the primary fuel supply, ensuring a robust and reliable connection from the fuel tank to the engine.

On the other hand, rubber fuel lines provide flexibility and vibration damping. They are commonly used for secondary fuel lines, such as those connecting the fuel pump to the engine or for routing around sharp bends. Rubber is lightweight, flexible, and can absorb vibrations, reducing the risk of fuel line damage over time. This material is also resistant to fuel degradation, ensuring the longevity of the fuel system.

The choice between steel and rubber depends on the specific needs of the Silverado's fuel system. For critical applications requiring maximum durability, steel lines are preferred. In contrast, rubber lines offer a more flexible and vibration-damping solution, which can be beneficial in certain engine compartments. It is essential to use the correct type of fuel line material to maintain the performance and reliability of the vehicle's fuel system.

Regular inspection and maintenance of fuel lines are recommended to ensure the Silverado's optimal performance. Over time, fuel lines can degrade due to fuel contamination, extreme temperatures, or physical damage. Replacing worn or damaged lines with high-quality, compatible materials will help prevent fuel leaks and maintain the efficiency of the fuel system.

Unraveling the Mystery: Why Motorcycles Pop Pinholes in Fuel Lines

You may want to see also

Frequently asked questions

The fuel line in a Silverado is a crucial component of the fuel system, responsible for transporting gasoline from the fuel tank to the engine. It ensures that the engine receives the necessary fuel for combustion, allowing the vehicle to run smoothly.

Identifying the right fuel line involves checking the vehicle's manual or consulting with a professional mechanic. They can provide specific details about the fuel line's diameter, length, and compatibility with your Silverado model. Look for markings or labels on the fuel line itself, which may indicate the part number or specifications.

While some vehicle owners might attempt DIY fuel line replacements, it is generally recommended to have this task performed by qualified mechanics. Fuel lines require precise installation, and any mistakes can lead to fuel leaks or engine performance issues. Professionals have the necessary tools and expertise to ensure a safe and successful replacement.

Fuel line problems in a Silverado can arise from various factors, including age, corrosion, damage from accidents, or poor maintenance. Over time, fuel lines may develop cracks, become brittle, or suffer from fuel contamination. Regular inspections and timely replacements can help prevent issues.

It is advisable to inspect the fuel line periodically, especially if your vehicle is older or has been in challenging conditions. Look for any signs of damage, leaks, or corrosion. If you notice any issues, have the fuel line checked and potentially replaced by a professional to ensure optimal engine performance and safety.