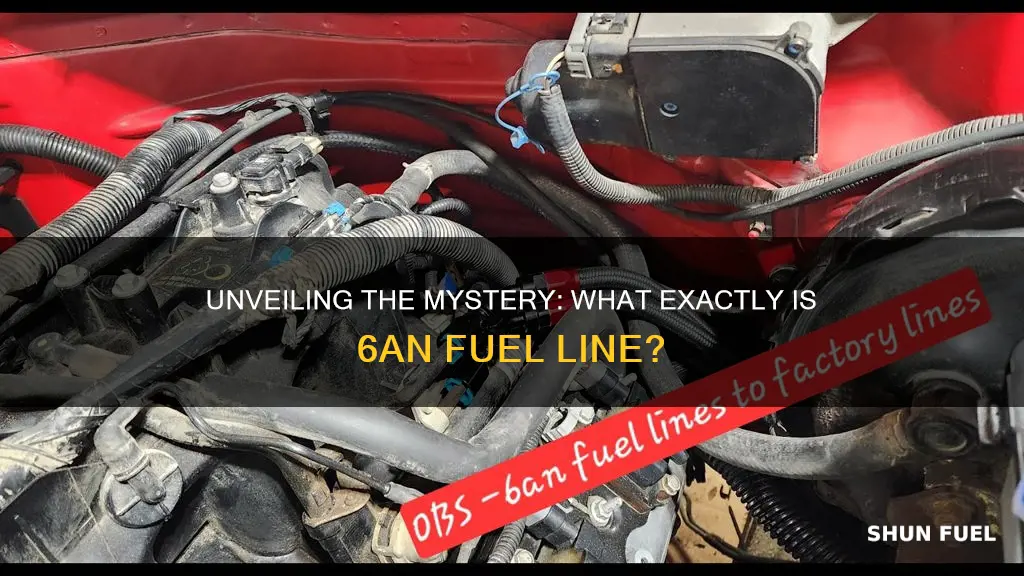

A 6AN fuel line is a specific type of fuel line commonly used in automotive applications, particularly in vehicles that utilize a 6AN (6-AN) thread size. This fuel line is designed to connect the fuel tank to the engine's fuel injectors or carburetor, ensuring a reliable and efficient fuel supply. The 6AN thread size is a standard measurement used in the automotive industry, allowing for easy installation and compatibility with various vehicle models. Understanding the specifications and compatibility of a 6AN fuel line is essential for mechanics and car enthusiasts when replacing or upgrading fuel lines to optimize engine performance and fuel efficiency.

What You'll Learn

- Definition: 6AN fuel lines are a type of fuel line used in automotive applications

- Size: 6AN fuel lines are typically 6/10 inches in diameter

- Pressure Rating: These lines can handle up to 300 psi

- Material: Common materials include steel, aluminum, and rubber

- Applications: 6AN fuel lines are used in high-performance engines and racing cars

Definition: 6AN fuel lines are a type of fuel line used in automotive applications

6AN fuel lines are an essential component in the fuel delivery system of many automotive vehicles. These fuel lines are specifically designed to meet the requirements of high-performance engines, where they play a critical role in ensuring efficient and reliable fuel supply. The '6AN' designation refers to the internal diameter of the fuel line, which is typically 6/32 inches or 0.5 inches in diameter. This standard size is widely used in the automotive industry and is an industry-recognized term for this specific type of fuel line.

These fuel lines are constructed with a durable and flexible material, often a type of rubber or synthetic rubber compound, which allows them to withstand the rigors of the automotive environment. The flexibility is crucial for accommodating the various movements and vibrations experienced during vehicle operation, ensuring that the fuel lines remain intact and secure. The inner diameter of 6AN fuel lines is carefully chosen to optimize fuel flow while maintaining pressure, which is vital for efficient engine performance.

In automotive applications, 6AN fuel lines are commonly used to connect the fuel pump to the engine, delivering the required amount of fuel at the precise moment it is needed. They are also utilized in fuel injection systems, where they route fuel from the fuel rail to the individual cylinders. The design of these fuel lines often includes a protective outer layer, such as a braided or steel reinforcement, to prevent damage from engine components, road debris, or other potential hazards.

One of the key advantages of 6AN fuel lines is their compatibility with a wide range of fuel types, including gasoline, diesel, and even alternative fuels like ethanol. This versatility allows vehicle manufacturers to design engines that can utilize different fuel sources without requiring specialized fuel lines. Additionally, these fuel lines are often designed with ease of installation in mind, ensuring that mechanics and DIY enthusiasts can quickly and efficiently fit them into existing fuel systems.

Overall, 6AN fuel lines are a critical component in the complex network of an automobile's fuel system, ensuring that the engine receives the right amount of fuel at the right time. Their design, construction, and performance characteristics make them a reliable and widely used solution for automotive fuel delivery applications. Understanding the specifications and benefits of 6AN fuel lines is essential for anyone working on or maintaining high-performance vehicles.

Fuel Line Clog Symptoms: Engine Issues Revealed

You may want to see also

Size: 6AN fuel lines are typically 6/10 inches in diameter

The 6AN fuel line is a specific type of fuel line commonly used in automotive applications, particularly for high-performance engines. This particular size, 6AN, refers to the diameter of the fuel line, which is a critical dimension to consider when selecting the right components for your vehicle's fuel system.

In the world of automotive performance, fuel lines play a vital role in delivering fuel from the tank to the engine. The size of the fuel line directly impacts the flow rate and pressure of the fuel, which can significantly affect engine performance. 6AN fuel lines are designed to provide an optimal balance between fuel delivery and flexibility, making them a popular choice for modifications and upgrades.

When it comes to dimensions, 6AN fuel lines typically have an internal diameter of 6/10 inches, which is equivalent to 0.6 inches. This standard size is widely recognized and used in various automotive applications, ensuring compatibility and ease of installation. The 6/10-inch diameter allows for efficient fuel flow while maintaining a reasonable level of flexibility, which is essential for accommodating engine vibrations and movement.

The 6AN specification is often associated with high-performance vehicles, where increased power and precision are desired. These fuel lines are commonly used in racing applications, modified street cars, and performance-oriented builds. By using 6AN fuel lines, enthusiasts can ensure that their fuel system is capable of delivering the required volume and pressure to support enhanced engine performance.

It's important to note that the size of the fuel line is just one aspect to consider when upgrading or modifying a vehicle's fuel system. Other factors, such as material quality, reinforcement, and overall length, also play a crucial role in ensuring optimal performance and reliability. Understanding the specifications and requirements of 6AN fuel lines can help enthusiasts make informed decisions when building or modifying their high-performance vehicles.

Aluminum or Steel: Choosing the Right Fuel Line Material

You may want to see also

Pressure Rating: These lines can handle up to 300 psi

The 6AN fuel line is a specific type of fuel line designed for use in automotive applications, particularly in high-performance vehicles. It is an essential component of the fuel delivery system, responsible for transporting fuel from the tank to the engine. One of the critical specifications of this fuel line is its pressure rating, which determines its ability to withstand the fuel pressure within the system.

When it comes to pressure rating, 6AN fuel lines are engineered to handle a wide range of fuel pressures, typically up to 300 psi (pounds per square inch). This high-pressure rating is crucial for vehicles with powerful engines that require a substantial amount of fuel to operate efficiently. The fuel pressure within the system can vary depending on the engine's requirements and the vehicle's operating conditions.

The ability to handle up to 300 psi is a significant advantage of 6AN fuel lines. It ensures that the fuel line can withstand the pressure generated by high-performance engines without compromising its structural integrity. This pressure rating is particularly important in racing or high-performance driving scenarios, where engines operate at their maximum capacity, generating substantial fuel pressure.

In addition to the pressure rating, 6AN fuel lines are also designed with other critical features. These lines are typically made from high-quality materials, such as reinforced rubber or synthetic compounds, to ensure durability and flexibility. The construction includes layers of protective materials to prevent fuel leakage and maintain the integrity of the fuel system.

Understanding the pressure rating of 6AN fuel lines is essential for vehicle owners and mechanics. It ensures that the fuel system is properly designed and maintained to handle the specific requirements of the engine. By choosing fuel lines with the appropriate pressure rating, vehicle owners can optimize performance, ensure reliable fuel delivery, and maintain the overall health of their high-performance vehicles.

Heated Fuel Lines: Preventing Engine Cold Starts and Fuel Gel

You may want to see also

Material: Common materials include steel, aluminum, and rubber

The 6AN fuel line is a crucial component in the fuel delivery system of many vehicles, particularly those with high-performance engines. It is designed to transport fuel from the tank to the engine, ensuring a steady and efficient supply of power. The choice of material for this fuel line is essential to its performance and longevity.

Steel: One of the most common materials used for 6AN fuel lines is steel. Steel is known for its strength and durability, making it an excellent choice for high-pressure fuel lines. It can withstand the rigorous demands of fuel transport, including varying temperatures and fuel pressures. Steel fuel lines are often used in racing applications and high-performance vehicles where reliability and strength are paramount. The material's ability to resist corrosion and maintain its structural integrity over time makes it a preferred option for demanding environments.

Aluminum: Aluminum is another popular material, offering a lightweight alternative to steel. This is particularly advantageous for vehicles where weight reduction is a priority, such as racing cars or aircraft. Aluminum fuel lines provide excellent heat resistance and can handle high fuel pressures without compromising performance. Its lightweight nature also reduces the overall weight of the vehicle, contributing to improved handling and acceleration. However, aluminum may require more frequent maintenance due to its susceptibility to corrosion in certain environments.

Rubber: Rubber is a versatile material commonly used for the inner lining or coating of 6AN fuel lines. It acts as a protective layer, ensuring that the fuel remains pure and free from contamination. Rubber is flexible, allowing it to accommodate slight movements and vibrations within the vehicle's engine bay. This flexibility is crucial to preventing fuel line damage and maintaining a consistent fuel supply. Additionally, rubber's resistance to heat and chemicals makes it ideal for protecting the fuel from potential contaminants.

The choice of material depends on various factors, including the specific vehicle requirements, environmental conditions, and performance expectations. Each material offers unique advantages, and engineers often select the most suitable option based on the application's needs. Whether it's the strength of steel, the lightweight benefits of aluminum, or the protective nature of rubber, these materials play a vital role in ensuring the efficient and reliable operation of the fuel delivery system.

NHRA Fuel Line Routing: Engine Compartment Rules Explained

You may want to see also

Applications: 6AN fuel lines are used in high-performance engines and racing cars

The 6AN fuel line is a specific type of fuel line designed for high-performance engines and racing applications. It is a crucial component in the fuel delivery system, ensuring efficient and reliable fuel supply to the engine under extreme conditions. This fuel line is known for its durability, flexibility, and ability to withstand high pressure and temperature, making it ideal for the demanding environment of racing and high-performance vehicles.

In the world of racing, where every second counts and performance is critical, the 6AN fuel line plays a vital role. It is engineered to handle the extreme power and torque produced by high-performance engines, ensuring a consistent and precise fuel supply. The line's construction often includes a sturdy inner diameter and a protective outer layer, which can be made from materials like steel or a specialized rubber compound, to resist wear and tear from high-speed operation and potential impacts.

One of the key advantages of using 6AN fuel lines in racing cars is their ability to maintain a steady fuel flow even under rapid acceleration and deceleration. This is crucial for optimizing engine performance and ensuring that the vehicle can respond quickly to driver inputs. The fuel line's design often incorporates a series of small, precise fuel injectors or pumps that deliver the correct amount of fuel at the right time, allowing for fine-tuning of the engine's power output.

High-performance engines, often found in sports cars and modified vehicles, also benefit significantly from 6AN fuel lines. These engines are designed to produce maximum power and torque, and the fuel line's ability to handle high pressure and temperature is essential. The 6AN line can accommodate the increased fuel flow rates required by these powerful engines, ensuring that the fuel reaches the combustion chamber efficiently. This results in improved engine performance, faster response times, and enhanced overall power delivery.

In addition to the performance benefits, 6AN fuel lines also offer a level of customization and tuning potential. Enthusiasts and engineers can select specific diameters and materials to suit the unique requirements of their high-performance vehicles. This customization allows for further optimization of the fuel delivery system, ensuring that the engine operates at its peak efficiency. As a result, 6AN fuel lines are a popular choice for those seeking to extract the maximum performance from their racing and high-performance vehicles.

Unveiling the Causes: Why Fuel Line Leaks Happen

You may want to see also

Frequently asked questions

6AN fuel line refers to a specific type of fuel line used in automotive applications, particularly in engines. It is a high-pressure fuel line designed to deliver fuel from the fuel pump to the engine's injectors or carburetor. This type of fuel line is commonly used in performance and racing applications where precise fuel delivery is crucial for optimal engine performance.

6AN fuel lines are typically made from high-quality materials such as steel or aluminum alloys, ensuring durability and resistance to fuel-related chemicals. They are designed with a specific inner diameter and wall thickness to handle the required fuel pressure, often ranging from 50 to 100 psi. The 6AN standard is widely recognized in the automotive industry, making it easier to source and install compatible fuel lines.

Yes, 6AN fuel lines can be used in regular cars, but it depends on the specific engine requirements and fuel system setup. If your car's engine has a high-pressure fuel system or requires a specific fuel line diameter, a 6AN line might be a suitable upgrade. However, it's essential to consult your vehicle's manual or seek professional advice to ensure compatibility and proper installation.