Uncoupling GM fuel lines can be a necessary step for various automotive maintenance tasks, such as replacing a fuel pump or performing a fuel system upgrade. This process involves carefully disconnecting the fuel lines to ensure a safe and efficient workflow. The following guide will provide a step-by-step approach to safely and effectively uncouple GM fuel lines, ensuring that the fuel system remains intact and functional throughout the process.

What You'll Learn

- Identify the Lines: Locate the GM fuel lines using a diagram or by inspecting the vehicle

- Remove Clamps: Carefully loosen and remove the clamps securing the lines to the fuel tank and engine

- Disconnect Hoses: Detach the hoses from the fuel pump and injectors, being mindful of any fuel spillage

- Inspect for Damage: Check for any signs of wear, cracks, or leaks in the lines before uncoupling

- Use the Right Tools: Employ appropriate tools like fuel line cutters or pliers to avoid damage during removal

Identify the Lines: Locate the GM fuel lines using a diagram or by inspecting the vehicle

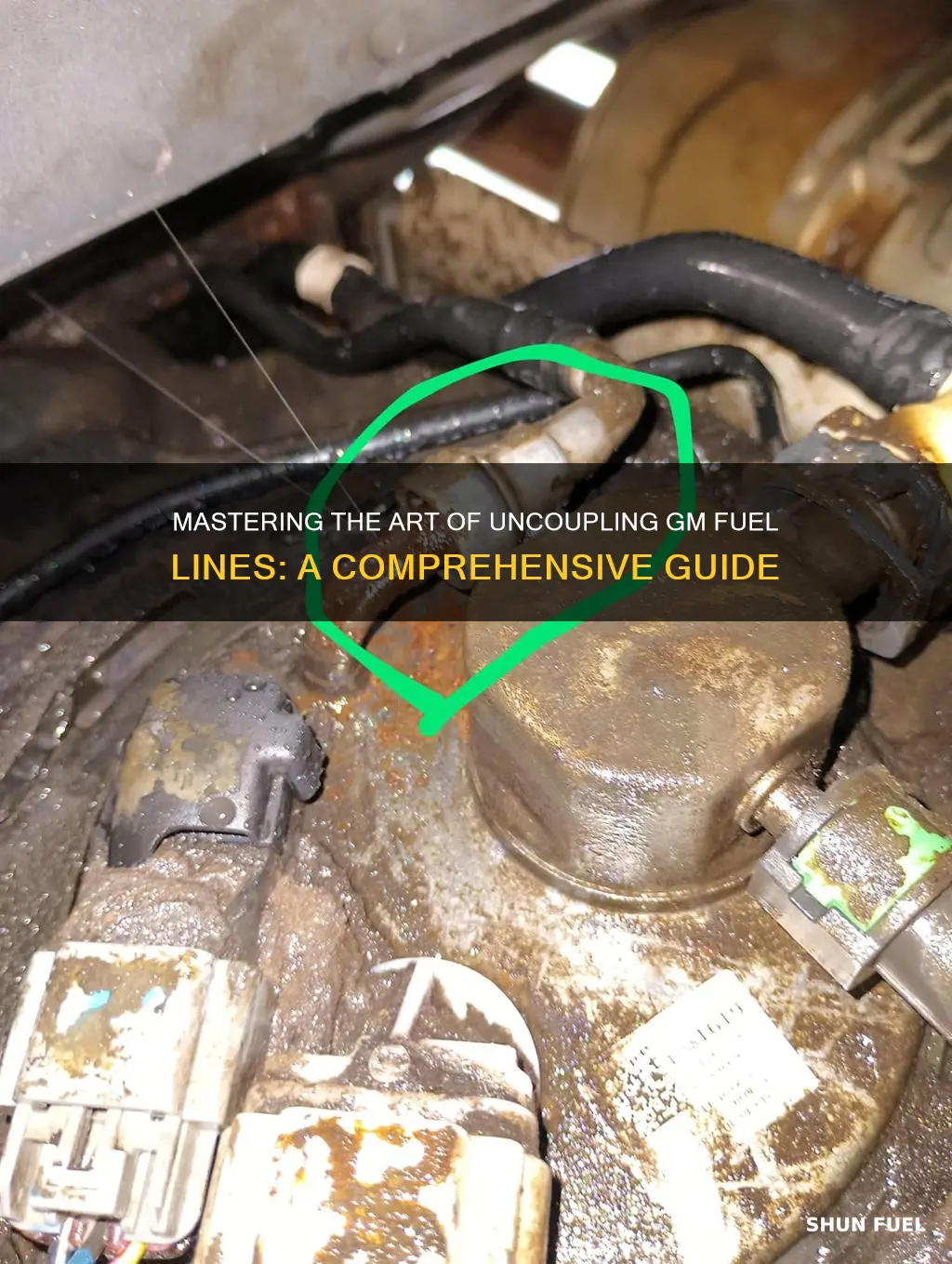

To begin the process of uncoupling GM fuel lines, it's crucial to first identify the specific lines you need to work with. This step is essential to ensure you don't accidentally disconnect the wrong lines, which could lead to engine issues or even dangerous situations.

One of the most reliable methods to identify the fuel lines is by using a detailed diagram of your GM vehicle's fuel system. These diagrams are often available in vehicle service manuals or can be found online through reputable automotive websites. The diagram will typically show the various components of the fuel system, including the fuel tank, fuel pump, injectors, and the lines connecting these components. Look for the lines that are labeled as 'fuel lines' or 'supply lines' to the engine. These lines are usually distinct and can be easily identified.

If you prefer a hands-on approach, you can inspect your vehicle's engine bay. GM vehicles often have fuel lines that are visible and accessible, especially if the engine is not covered by a heavy plastic cover. Locate the fuel tank, which is usually positioned at the front or rear of the vehicle, and look for the lines that connect it to the fuel pump and the engine. The fuel pump is typically located near the tank, and the lines will extend from the pump to the engine bay. These lines are usually made of rubber or a flexible material and can be identified by their color or a small label.

In some cases, you might need to remove certain components to gain better access to the fuel lines. For example, you may need to remove the air filter housing or the intake manifold to expose the lines that connect to the injectors. Once you've located the fuel lines, take note of their positions and any unique features, such as clips or brackets that hold them in place. This information will be invaluable when you start the uncoupling process.

Remember, the key to success in this task is thorough preparation. By using a diagram or inspecting your vehicle, you can ensure that you have a clear understanding of the fuel line layout, making the uncoupling process safer and more efficient.

Fuel Line Fabrication: Expert Services for Your Vehicle

You may want to see also

Remove Clamps: Carefully loosen and remove the clamps securing the lines to the fuel tank and engine

To begin the process of uncoupling GM fuel lines, it's crucial to prioritize safety and take the necessary precautions. Before you start, ensure that the engine is cool to avoid any potential burns or injuries. Additionally, locate the fuel lines that you intend to disconnect. Typically, these lines are connected to the fuel tank and the engine, and they are often secured by clamps.

The first step is to carefully identify and locate the clamps that hold the fuel lines in place. These clamps are usually made of metal or plastic and are designed to provide a secure and tight connection. You will need a set of appropriate tools to loosen and remove these clamps, such as adjustable wrenches or pliers. It's important to use the right tools to avoid damaging the clamps or the fuel lines.

Now, proceed with loosening the clamps. Start by placing the tool's jaws around the clamp, ensuring a firm grip. Apply gentle but firm pressure to loosen the clamp. Be cautious not to apply excessive force, as this might damage the fuel lines or the clamp itself. You may need to adjust your grip or use a different angle to get a better hold and loosen the clamp further. Repeat this process for each clamp, ensuring that all connections are carefully loosened.

Once the clamps are loosened, carefully remove them from the fuel lines. Keep the clamps aside, as you might need them for reinstalling the lines later. With the clamps removed, you should now have access to the fuel lines, allowing you to proceed with the uncoupling process. Remember to handle the fuel lines with care, as they can be delicate, and any damage could lead to fuel leaks or other issues.

After successfully removing the clamps, you can now disconnect the fuel lines from the fuel tank and engine. This step may vary depending on the specific GM vehicle model, so it's essential to consult the vehicle's manual or seek guidance from a professional mechanic if needed. Take your time and ensure that all connections are properly disconnected to avoid any potential hazards.

Fuel Line Returns: Uncovering Hidden Costs and Benefits

You may want to see also

Disconnect Hoses: Detach the hoses from the fuel pump and injectors, being mindful of any fuel spillage

To safely disconnect the fuel hoses from a GM vehicle, it's crucial to follow a systematic approach, ensuring you don't spill any fuel and that the process is done with care. Here's a step-by-step guide to help you through this task:

- Prepare Your Workspace: Begin by parking the vehicle on a level surface and engaging the parking brake. This ensures stability and prevents any accidental movement during the disconnection process. Gather the necessary tools, including a fuel drain pan or container to catch any spilled fuel. It's essential to have a well-lit area to ensure you can work safely and efficiently.

- Locate the Fuel Hoses: Identify the fuel hoses that need to be disconnected. These hoses typically run from the fuel pump, located in the fuel tank, to the injectors or carburetor, depending on the vehicle's setup. Locate the clamps or fittings securing these hoses and make a mental note of their positions for reattachment.

- Detach the Hoses: Carefully disconnect the hoses from the fuel pump and injectors. Start with the hose connected to the fuel pump, as this will likely be the most challenging to remove due to the pressure it exerts. Use a suitable tool, such as a fuel line disconnect tool or a pair of adjustable pliers, to loosen the fittings. Be gentle but firm to avoid damaging the fittings. Once the hose is loose, carefully pull it away from the connections, being mindful of any fuel that might start to flow.

- Manage Fuel Spillage: As you disconnect the hoses, keep a close eye on the fuel lines to prevent any spills. If you notice any fuel escaping, immediately place the drain pan or container under the hose to catch the fuel. This step is crucial to avoid fuel wastage and potential environmental hazards. Ensure you have adequate ventilation in the workspace to minimize the risk of inhaling fuel vapor.

- Clean and Inspect: After successfully disconnecting the hoses, take the time to clean any fuel residue from the connections and surrounding areas. This step ensures a proper seal when reattaching the hoses. Additionally, inspect the hoses for any signs of damage, cracks, or leaks. If any issues are found, it's best to replace the hoses to maintain the vehicle's performance and safety.

Remember, working with fuel requires caution and attention to detail. Always prioritize safety and take your time to avoid any accidents or fuel-related incidents. If you're unsure about any step, consult a professional mechanic who can provide guidance tailored to your specific vehicle.

The Ultimate Guide to Fuel Line O-Ring Colors

You may want to see also

Inspect for Damage: Check for any signs of wear, cracks, or leaks in the lines before uncoupling

Before attempting to uncouple GM fuel lines, it's crucial to inspect them for any signs of damage or deterioration. This step is essential to ensure the safety and efficiency of your fuel system. Start by visually examining the fuel lines for any visible wear and tear. Look for cracks, brittleness, or any discolouration that might indicate internal damage. Pay close attention to the connections and fittings, as these areas are prone to developing issues over time. Check for any signs of corrosion or rust, especially if the lines have been exposed to harsh weather conditions or are located in areas with high humidity.

Leakage is a critical issue that can lead to dangerous situations, so inspect the lines thoroughly for any signs of fuel escaping. Squeeze the lines gently with your hand to feel for any soft spots or areas of reduced pressure. If you notice any leaks, it's best to replace the affected lines immediately. Additionally, check for any signs of fuel contamination, such as a sweet or gasoline-like smell, which could indicate a breach in the line.

The condition of the fuel lines can also be assessed by examining the fittings and clips that secure them in place. Ensure that all clips and fasteners are intact and securely holding the lines in position. Over time, these small components can become damaged or worn out, leading to potential fuel leaks. If any clips are missing or the fasteners are loose, it's advisable to replace the entire line to prevent further complications.

In some cases, you might notice that the fuel lines have become stiff or rigid, making them difficult to manipulate. This could be a sign of internal damage or fuel contamination. If you encounter such issues, it's best to consult a professional mechanic to ensure the lines are safe to work with. Remember, the goal is to identify and address any potential problems before proceeding with the uncoupling process to maintain the integrity of your fuel system.

Volvo 240 Fuel Line Size: A Comprehensive Guide

You may want to see also

Use the Right Tools: Employ appropriate tools like fuel line cutters or pliers to avoid damage during removal

When dealing with GM fuel lines, it's crucial to use the right tools to ensure a safe and efficient removal process. The primary goal is to avoid any damage to the fuel lines and the surrounding components. Here's a detailed guide on how to employ the appropriate tools for this task:

Start by gathering the necessary tools. For uncoupling GM fuel lines, you'll typically need fuel line cutters or specialized pliers. These tools are designed to cut or grip fuel lines without causing damage. Fuel line cutters are especially useful as they provide a clean and precise cut, allowing for a secure connection during reinstallation. Look for cutters with adjustable jaws to accommodate different fuel line diameters. Alternatively, pliers with a serrated edge can be effective for gripping and removing fuel lines. Ensure you have a pair that fits your hand comfortably and provides a secure grip.

Before beginning the removal process, inspect the fuel lines for any signs of damage or deterioration. If you notice any cracks, leaks, or corrosion, it's essential to address these issues before proceeding. Clean the fuel lines and the surrounding areas to ensure a smooth and safe removal. This step is crucial to prevent any accidental damage during the uncoupling process.

Now, let's focus on the removal technique. When using fuel line cutters, position the tool around the fuel line, ensuring it is securely gripped. Apply gentle but firm pressure to cut through the line. Take your time to avoid applying excessive force, as this can lead to damage. For pliers, insert the serrated edge into the fuel line and grip it firmly. Pull the line away from the connection, being careful not to twist or kink it. Remember, the goal is to maintain the integrity of the fuel line during removal.

In summary, using the right tools is essential for safely uncoupling GM fuel lines. Fuel line cutters and pliers with the appropriate grip and cutting capabilities will ensure a damage-free removal process. By taking the time to gather the right equipment and following a careful removal technique, you can effectively disconnect the fuel lines without causing any harm. This approach will also contribute to a successful reinstallation, ensuring the fuel system operates optimally.

Optimizing Performance: Choosing the Right Dual Fuel Line for Your Holley Avenger Carb

You may want to see also

Frequently asked questions

There are several signs that may indicate the need for fuel line uncoupling. These include fuel leaks, engine misfires, reduced engine performance, or unusual noises from the fuel system. If you notice any of these symptoms, it's best to inspect the fuel lines for any damage or loose connections.

To uncouple GM fuel lines, you will typically need a fuel line disconnect tool or a pair of adjustable pliers. It's important to have a clean workspace and possibly a rag or cloth to catch any spills. Ensure you have the correct size and type of fuel line connectors for your specific vehicle model.

While it is possible to uncouple GM fuel lines as a DIY project, it can be challenging and may require some mechanical knowledge. If you are unsure or uncomfortable with the process, it is recommended to consult a professional mechanic or a qualified automotive technician who has experience with fuel system repairs. They can ensure the job is done safely and correctly.