Are you frustrated with persistent engine issues despite regular maintenance? Clogged fuel lines can be a common culprit behind poor performance and hard-to-start engines. While some DIY solutions exist, many car owners wonder if there's a specialized product that can effectively clean out these stubborn blockages. In this article, we'll explore the options available, from fuel line cleaners to mechanical methods, to help you decide the best approach to tackle this problem.

What You'll Learn

- Fuel Line Cleaning Methods: Techniques for removing debris and contaminants from fuel lines

- Chemical Cleaners: Overview of effective chemical solutions for fuel line maintenance

- Mechanical Cleaning: Using tools like brushes to physically clean fuel lines

- Fuel Line Inspection: Steps to identify clogs and potential sources of contamination

- Prevention Strategies: Tips to avoid fuel line clogs and maintain vehicle performance

Fuel Line Cleaning Methods: Techniques for removing debris and contaminants from fuel lines

Fuel lines play a critical role in delivering fuel from the tank to the engine, and over time, they can become clogged with debris, contaminants, and deposits, leading to reduced engine performance and potential breakdowns. Cleaning these fuel lines is essential to maintain optimal engine operation and longevity. Here are some effective methods to remove debris and contaminants from fuel lines:

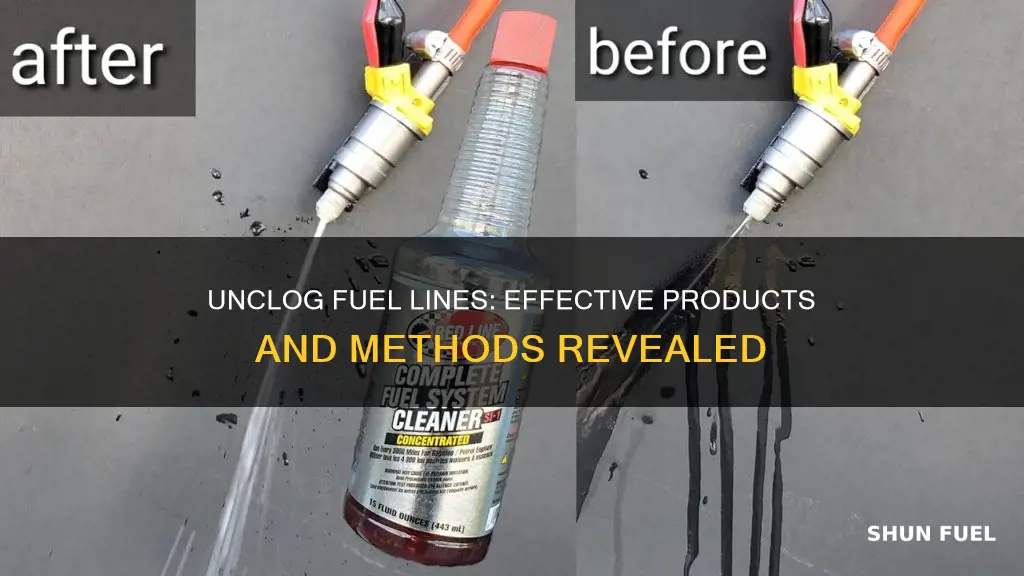

- Fuel Line Cleaning Products: One of the most common and convenient approaches is to use specialized fuel line cleaning products. These products are designed to dissolve and remove deposits, varnish, and contaminants from the fuel lines. They are typically in the form of a concentrated liquid that can be diluted with water or a solvent. When using these products, it is crucial to follow the manufacturer's instructions carefully. The process usually involves flushing the fuel lines with the cleaning solution, allowing it to sit for a specified time, and then draining the system. This method is accessible and can be performed without extensive mechanical knowledge.

- Mechanical Cleaning: For more stubborn blockages, mechanical cleaning techniques can be employed. This involves physically removing debris and contaminants from the fuel lines. One common method is to use a fuel line brush, which is a flexible brush with a long handle designed to navigate through the fuel lines. The brush is inserted into the fuel line and used to scrub away deposits and contaminants. This process requires careful maneuvering to avoid damaging the fuel lines. Another mechanical approach is to use a fuel line cleaner tool, which is a specialized device that can be inserted into the line to dislodge blockages. These tools often use a combination of brushes and air pressure to clean the lines effectively.

- Pressure Flushing: Pressure flushing is a technique that utilizes compressed air or water to flush out debris and contaminants from the fuel lines. This method is particularly useful for removing larger particles and varnish buildup. A high-pressure air or water jet is directed through the fuel lines, dislodging and removing deposits. It is important to use the correct pressure to avoid damaging the fuel lines. Pressure flushing can be done using specialized equipment or by connecting a high-pressure washer to the fuel line. This method is often employed in industrial settings or by professional mechanics.

- Chemical Cleaning: Chemical cleaning involves using specific chemicals to dissolve and remove contaminants from the fuel lines. This method is typically used for severe cases of contamination or when mechanical cleaning alone is insufficient. Chemical cleaners are carefully selected to target specific types of contaminants. For example, a varnish remover might be used to address heavy varnish buildup. It is crucial to choose the right chemicals and follow safety protocols, as some chemicals can be hazardous. Professional mechanics or fuel system specialists often perform chemical cleaning to ensure the process is done safely and effectively.

When cleaning fuel lines, it is essential to identify the root cause of the clogging to prevent recurring issues. Regular maintenance and the use of high-quality fuel can also help reduce the likelihood of fuel line blockages. By employing these methods, vehicle owners and mechanics can ensure that fuel lines remain clean and free-flowing, contributing to improved engine performance and reliability.

Gas Line Antifreeze: Unraveling the Fuel Stabilizer Mystery

You may want to see also

Chemical Cleaners: Overview of effective chemical solutions for fuel line maintenance

Chemical cleaners are an effective and widely used method to maintain and clean fuel lines, ensuring optimal performance and longevity. These solutions are specifically designed to dissolve and remove deposits, contaminants, and blockages that can accumulate over time within the intricate network of fuel lines. The process is particularly crucial for vehicles and machinery that rely on a consistent and clean fuel supply to function efficiently.

One of the key advantages of chemical cleaners is their ability to penetrate and break down stubborn deposits. Over time, fuel lines can become clogged with deposits of carbon, varnish, and other substances, which can restrict fuel flow and reduce engine performance. Chemical cleaners, often in the form of concentrated solutions, are formulated to dissolve these deposits, allowing for a thorough cleaning process. These cleaners typically work by utilizing powerful solvents and detergents that can cut through the grime and residue, ensuring a comprehensive clean.

When selecting a chemical cleaner, it is essential to consider the specific requirements of your fuel lines. Different cleaners are designed for various applications, such as gasoline, diesel, or even biofuel systems. For instance, a cleaner suitable for gasoline engines may contain different ingredients compared to one designed for diesel engines, as the fuel types can have distinct properties and requirements. It is crucial to choose a cleaner that is compatible with your fuel system to avoid any potential damage.

Application methods vary, but typically involve a process of injecting the chemical cleaner directly into the fuel lines. This can be done using specialized equipment, such as a fuel line cleaner injection kit, which ensures precise and controlled delivery of the cleaner. The cleaner is then allowed to circulate through the fuel system, dissolving and removing contaminants. After the cleaning process, it is essential to flush the system to remove any remaining cleaner and prevent potential corrosion.

In summary, chemical cleaners offer a powerful and efficient solution for maintaining and cleaning fuel lines. Their ability to dissolve deposits and contaminants makes them an invaluable tool for vehicle and machinery owners, ensuring optimal fuel flow and performance. With proper selection and application, chemical cleaners can help extend the life of fuel lines and improve overall engine efficiency.

Silverado Fuel Line Sizes: An In-Depth Guide for 2003 Models

You may want to see also

Mechanical Cleaning: Using tools like brushes to physically clean fuel lines

Mechanical cleaning is a hands-on approach to tackling clogged fuel lines, and it involves using various tools to physically remove debris and contaminants. This method is particularly useful for those who prefer a more active, DIY-oriented solution. Here's a step-by-step guide on how to employ mechanical cleaning techniques:

- Gather the Right Tools: Start by acquiring the necessary equipment. You'll need a fuel line brush, which is specifically designed to navigate the twists and turns of fuel lines. These brushes often feature a flexible, durable material that can reach deep into the lines. Additionally, a fuel line cleaner or solvent is essential to help dissolve any stubborn deposits.

- Locate the Fuel Lines: Identify the fuel lines in your vehicle that need cleaning. These lines typically run from the fuel tank to the engine, and they can be found beneath the car or in the engine compartment. Carefully inspect the lines for any visible blockages or signs of contamination.

- Disconnect and Prepare: Carefully disconnect the fuel lines from the fuel tank and the engine. This step requires caution to avoid spills or damage. Once disconnected, use a suitable container to catch any fuel that may drain out. Prepare the fuel line brush by soaking it in the fuel line cleaner, ensuring it is thoroughly coated.

- Brush and Clean: Insert the fuel line brush into the fuel lines, working it through the entire length. Apply gentle, firm strokes to dislodge any debris, such as dirt, rust, or varnish. The brush should be moved in the direction of the fuel flow to ensure effective cleaning. For more stubborn deposits, you may need to repeat this process or use a higher concentration of cleaner.

- Rinse and Reassemble: After cleaning, rinse the fuel lines with clean fuel or a suitable solvent to remove any remaining cleaner. Ensure that all traces of cleaner are eliminated to prevent any adverse effects on the engine. Once rinsed, carefully reconnect the fuel lines to the tank and engine.

- Test and Monitor: Start the engine and monitor its performance. Listen for any unusual noises and observe if the vehicle runs smoothly. If the engine is running poorly or exhibits strange behavior, further investigation may be required. Regularly check the fuel lines for any signs of re-clogging, especially if you frequently encounter fuel-related issues.

Mechanical cleaning is a practical solution for those who want to take a hands-on approach to maintaining their vehicle's fuel system. It requires patience and attention to detail but can be an effective way to keep fuel lines in optimal condition. Remember, always exercise caution when working with fuel to ensure safety and proper engine performance.

Fuel Line to Fitting: A Step-by-Step Guide to Success

You may want to see also

Fuel Line Inspection: Steps to identify clogs and potential sources of contamination

Fuel lines are an essential component of any vehicle's fuel system, and over time, they can become susceptible to clogs and contamination. Identifying these issues early is crucial to prevent engine performance problems and potential breakdowns. Here's a step-by-step guide to inspecting your fuel lines and addressing potential clogs and contaminants:

Step 1: Visual Inspection

Start by visually examining the fuel lines for any visible signs of damage, cracks, or kinks. These issues can often be identified by looking for discolored or brittle areas along the line. Pay close attention to bends and areas where the line connects to the fuel tank and engine. Even minor damage can lead to fuel leaks, which can cause environmental hazards and engine misfires.

Step 2: Check for Clogs

Fuel line clogs can be caused by various factors, including dirt, debris, rust, or even algae growth. To check for clogs, remove the fuel line from the engine and inspect it thoroughly. You can use a bright flashlight to shine into the line and look for any blockages. If you notice any obstructions, you may need to use a fuel line brush or a compressed air gun to clear the path. Ensure you follow the manufacturer's guidelines for the specific fuel line you are working with.

Step 3: Inspect the Fuel Filter

The fuel filter is another critical component in the fuel system that can contribute to clogs. Over time, the filter can become clogged with contaminants, leading to reduced fuel flow. Locate the fuel filter, which is typically found near the fuel tank or along the fuel line. Inspect it for any signs of contamination or excessive dirt accumulation. If the filter appears clogged, it may need to be replaced to ensure optimal fuel delivery.

Step 4: Check for Contamination

Contaminants such as water, dirt, and fuel additives can enter the fuel system and cause issues. Start by checking the fuel tank for any signs of water accumulation, as this can lead to corrosion and contamination. If you notice any water, it's essential to drain and clean the tank accordingly. Additionally, inspect the fuel lines and the engine's fuel injectors for any signs of contamination, such as dark or discolored fuel. This may indicate the presence of water or other impurities.

Step 5: Use Cleaning Products

If you identify clogs or contamination, there are specialized cleaning products available that can help address these issues. These products are designed to dissolve and remove deposits, dirt, and contaminants from fuel lines. When using these products, follow the manufacturer's instructions carefully. It's also a good practice to run the engine after cleaning to ensure the fuel system is functioning correctly.

Remember, regular maintenance and inspection of your fuel lines can help prevent unexpected breakdowns and ensure your vehicle's engine operates efficiently. If you're unsure about any step or encounter complex issues, consulting a professional mechanic is always recommended.

Reviving Your Ride: A Guide to Softening Hardened Fuel Lines

You may want to see also

Prevention Strategies: Tips to avoid fuel line clogs and maintain vehicle performance

Preventing fuel line clogs is essential for maintaining your vehicle's performance and longevity. Here are some effective prevention strategies to keep your fuel system in top shape:

Regular Fuel System Maintenance: One of the most crucial steps is to perform regular maintenance on your fuel system. This includes routine fuel line inspections to identify any signs of wear, cracks, or damage. Over time, fuel lines can deteriorate due to age, heat, and the corrosive effects of fuel. During inspections, look for any leaks, kinks, or blockages. If you notice any issues, have the fuel lines replaced promptly to prevent clogs and potential engine damage. Additionally, consider using a fuel system cleaner as part of your maintenance routine. These cleaners help remove deposits and contaminants that can accumulate in the fuel lines, ensuring optimal flow.

Use of Fuel Stabilizers: Fuel stabilizers are additives designed to maintain the quality of fuel over time. They are particularly useful for vehicles that are stored for extended periods or those used in regions with varying fuel quality. By adding a fuel stabilizer to your tank, you can reduce the risk of fuel degradation, which can lead to clogs and performance issues. These stabilizers prevent the formation of varnish and sludge, keeping the fuel lines clear and the engine running smoothly.

Proper Fuel Storage and Handling: Proper fuel storage and handling practices are vital to preventing clogs. Always store fuel in a clean, dry environment, away from direct sunlight and extreme temperatures. Contaminated or old fuel can lead to clogs and engine problems. When refueling, ensure you use a clean fuel filter and consider using a fuel additive to further protect the fuel system. Additionally, avoid overfilling the fuel tank, as this can introduce air bubbles, which may cause issues with fuel delivery.

Regular Engine Maintenance: Regular engine maintenance is key to overall vehicle health, including fuel system performance. Change your engine oil and oil filter as recommended by the manufacturer, as this helps maintain the cleanliness of the entire fuel system. Additionally, keep an eye on other engine components like the fuel pump and injectors. If you notice any signs of wear or malfunction, address them promptly to prevent clogs and potential engine damage.

Use of High-Quality Fuel: The quality of fuel you use can significantly impact your vehicle's performance and longevity. Opt for high-octane fuel if your vehicle requires it, and ensure it meets the recommended specifications. Lower-quality or contaminated fuel can lead to increased wear and tear on the fuel system, making it more susceptible to clogs. Always use fuel from reputable sources to maintain the integrity of your vehicle's fuel system.

By implementing these prevention strategies, you can minimize the chances of fuel line clogs and ensure your vehicle operates at its best. Regular maintenance, proper fuel management, and the use of appropriate additives can contribute to a healthy and efficient fuel system.

Fuel Injection Line Repair: A Step-by-Step Guide to Fixing Leaks

You may want to see also

Frequently asked questions

Yes, there are several products designed specifically for this purpose. These are often referred to as 'fuel line cleaners' or 'fuel system cleaners'. They typically contain powerful solvents and detergents that can dissolve and remove deposits, varnish, and gum from the fuel lines, ensuring optimal fuel flow.

These products work by dissolving and removing the deposits that accumulate over time due to fuel oxidation, moisture absorption, and the breakdown of additives. They can penetrate and break down the deposits, allowing for easier removal and restoring the fuel lines' functionality.

While regular multi-purpose cleaners might not be as effective for deep-seated clogs, professional fuel line cleaners are specifically formulated to handle the unique challenges of fuel lines. They are designed to be safe for use with various fuel types and can effectively clean without causing damage to the fuel system components.

Absolutely. Fuel line cleaners are compatible with both carbureted and fuel-injected systems. They can help maintain the health of the fuel injection system by ensuring clean and consistent fuel delivery, which is crucial for optimal engine performance and longevity.

It is recommended to use a fuel line cleaner as part of regular vehicle maintenance, especially if your car is prone to long-distance driving or has a history of fuel-related issues. Using a cleaner every few months or as per the manufacturer's guidelines can help prevent clogs and ensure a reliable fuel system.