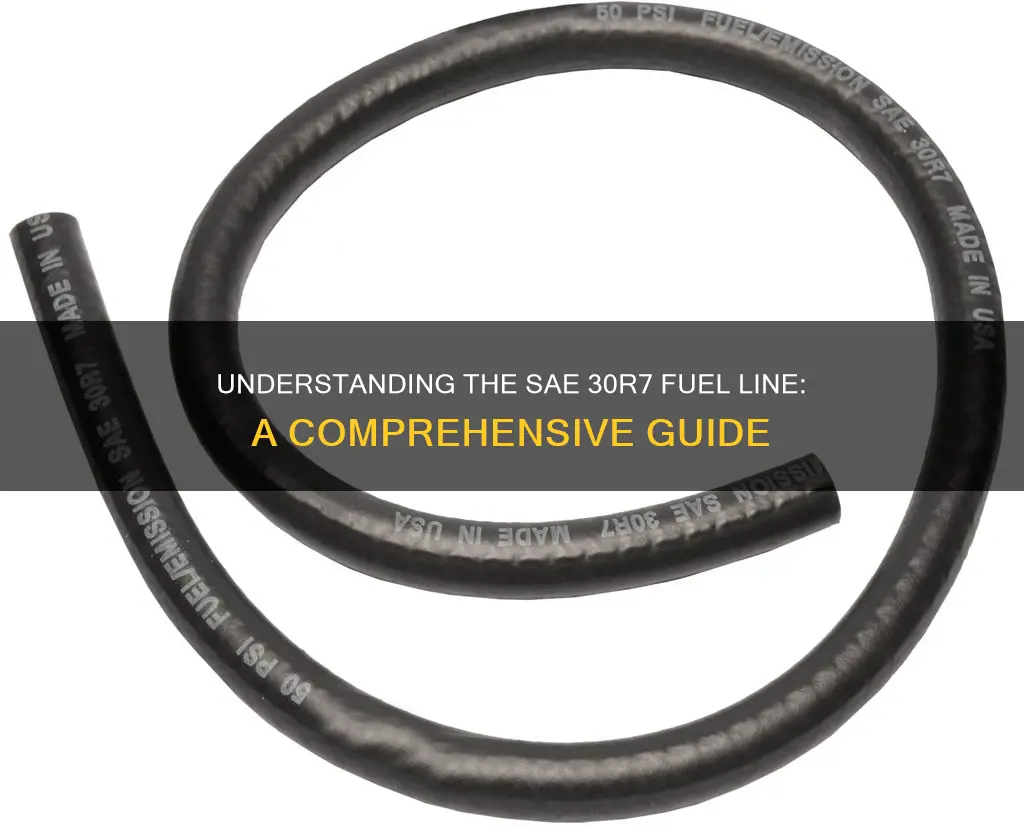

Sae 30R7 fuel lines are a specific type of fuel line designed to meet the rigorous standards set by the Society of Automotive Engineers (SAE). These fuel lines are engineered to withstand high temperatures and pressures, making them ideal for use in high-performance vehicles and applications where fuel lines are exposed to extreme conditions. The 30R7 designation indicates the line's resistance to a specific type of fuel, typically high-octane gasoline, and its ability to maintain flexibility and integrity over a wide temperature range. This product is crucial for ensuring the safe and efficient delivery of fuel to an engine, playing a vital role in the overall performance and reliability of a vehicle.

| Characteristics | Values |

|---|---|

| Material | Typically made of high-temperature resistant materials like stainless steel or aluminum alloys |

| Pressure Rating | Rated for high-pressure applications, often up to 3000 psi or more |

| Temperature Range | Capable of withstanding extreme temperatures, from -40°F to 400°F (-40°C to 204°C) |

| Flexibility | Designed to be flexible and bendable to accommodate engine movements |

| Corrosion Resistance | Resistant to corrosion from fuel and engine fluids |

| Size | Available in various sizes, commonly measured in inches or millimeters |

| Color | Often black or blue, depending on the manufacturer and application |

| Compatibility | Compatible with gasoline, diesel, and alternative fuels |

| Standard | Complies with SAE J1453 and other relevant industry standards |

| Application | Used in fuel injection systems, high-performance engines, and racing applications |

What You'll Learn

- Material: SAE 30R7 fuel lines are made from a specific rubber compound

- Pressure Rating: This fuel line is rated for high-pressure applications

- Temperature Range: It can withstand temperatures from -40°F to 250°F

- Flexibility: The line is flexible and resistant to kinking

- Compatibility: It is compatible with gasoline, diesel, and biofuels

Material: SAE 30R7 fuel lines are made from a specific rubber compound

Sae 30R7 fuel lines are an essential component in the fuel delivery system of many vehicles, particularly those with high-performance engines. These fuel lines are specifically designed to withstand the rigorous demands of automotive applications, ensuring reliable and efficient fuel transport. One of the key factors contributing to their performance is the material they are made from.

The SAE 30R7 fuel lines are crafted from a specialized rubber compound, carefully formulated to meet the rigorous standards set by the Society of Automotive Engineers (SAE). This rubber compound is engineered to possess exceptional properties that make it ideal for fuel line applications. It is designed to be resistant to the corrosive effects of gasoline and diesel fuels, ensuring that the fuel lines remain intact and functional over extended periods of use. The rubber's ability to withstand the harsh environment of the fuel system is crucial for maintaining the overall performance and longevity of the vehicle.

The specific rubber compound used in these fuel lines offers several advantages. Firstly, it provides excellent flexibility, allowing the lines to withstand temperature fluctuations without becoming brittle or cracking. This flexibility is essential for accommodating the various movements and vibrations experienced during vehicle operation. Additionally, the rubber compound's resistance to fuel degradation ensures that it maintains its structural integrity, preventing leaks and potential engine damage.

Furthermore, the material's durability is a critical aspect of its performance. SAE 30R7 fuel lines are designed to resist abrasion and wear, which is particularly important in high-pressure fuel systems. The rubber compound's ability to withstand the mechanical stresses of fuel delivery ensures that the lines remain intact, even in demanding operating conditions. This durability contributes to the overall reliability of the fuel system, reducing the risk of fuel leaks and engine misfires.

In summary, the material used in SAE 30R7 fuel lines, a specialized rubber compound, is a critical factor in their performance and longevity. Its ability to resist fuel corrosion, temperature changes, and mechanical stresses makes it an ideal choice for fuel line applications. By utilizing this carefully engineered material, vehicle manufacturers can ensure that the fuel delivery system operates efficiently and reliably, contributing to the overall performance and safety of the vehicle.

Exploring Rubber Fuel Line Hose Sizes: A Comprehensive Guide

You may want to see also

Pressure Rating: This fuel line is rated for high-pressure applications

The SAE 30R7 fuel line is a high-performance component designed to withstand demanding fuel delivery systems, particularly those with elevated pressure requirements. Its pressure rating is a critical aspect that ensures the line can handle the forces exerted by modern engines, especially those with fuel injection systems. This rating is a testament to the line's ability to maintain its structural integrity under intense pressure, which is essential for efficient and safe fuel distribution.

In the context of fuel lines, pressure rating refers to the maximum pressure a line can safely endure without compromising its structural integrity. For the SAE 30R7, this rating is specifically tailored to high-pressure applications, making it ideal for engines that require precise and rapid fuel delivery. This is particularly important in high-performance vehicles where engines operate at peak efficiency and demand a consistent and rapid fuel supply.

The high pressure rating of the SAE 30R7 fuel line is a result of its construction and material choice. It is typically made from high-strength materials, such as reinforced synthetic rubber or a composite blend, which provide excellent resistance to pressure and temperature changes. These materials are engineered to maintain their flexibility and durability even under extreme conditions, ensuring that the fuel line can withstand the forces exerted by the engine without compromising its performance or safety.

Furthermore, the pressure rating of this fuel line is not just a theoretical specification but a practical consideration that directly impacts the vehicle's performance. Engines with high-pressure fuel systems require lines that can handle the rapid and precise fuel delivery, ensuring optimal combustion and power output. The SAE 30R7's pressure rating is designed to meet these demands, providing a reliable and efficient fuel supply to the engine.

In summary, the pressure rating of the SAE 30R7 fuel line is a key feature that sets it apart in high-pressure fuel delivery systems. Its ability to withstand intense pressure makes it a reliable and efficient component, ensuring that modern engines can operate at their peak performance while maintaining safety and reliability. This rating is a testament to the line's quality and its role in enhancing the overall performance of the vehicle's fuel system.

Choosing the Right Fuel Line: Size Matters!

You may want to see also

Temperature Range: It can withstand temperatures from -40°F to 250°F

The SAE 30R7 fuel line is a critical component in many automotive and industrial applications, particularly those involving fuel systems. Its ability to withstand a wide temperature range is a key feature that ensures its reliability and longevity. This fuel line is designed to handle extreme conditions, making it suitable for a variety of environments and climates.

The temperature range of -40°F to 250°F is an impressive capability for a fuel line. It can endure the harshest winters, where temperatures drop to freezing and below, and still remain functional. This is essential for vehicles and equipment that operate in cold climates, ensuring that the fuel system remains intact and efficient. During the summer months, when temperatures soar, the SAE 30R7 fuel line can handle the heat without compromising its structural integrity. It can withstand the intense heat of up to 250°F, which is crucial for applications where engines or fuel systems are exposed to high temperatures.

This temperature resistance is a result of the fuel line's construction and the materials used. The line is typically made from high-quality rubber or a synthetic material that provides excellent flexibility and durability. These materials are carefully selected to maintain their properties across the specified temperature range, ensuring that the fuel line remains pliable and resistant to cracking or deterioration.

In addition to its temperature tolerance, the SAE 30R7 fuel line is also known for its ability to resist fuel-related chemicals, such as ethanol and methanol. This resistance is vital to prevent degradation and ensure the fuel line's longevity, especially in applications where fuel blends may vary. The fuel line's construction also includes a protective layer or coating that further enhances its resistance to chemicals and abrasion, ensuring it can withstand the rigors of everyday use.

Overall, the temperature range of -40°F to 250°F is a critical aspect of the SAE 30R7 fuel line's performance and suitability for various applications. Its ability to handle extreme temperatures makes it a reliable choice for fuel delivery systems, ensuring efficient and safe operation in diverse environmental conditions.

Unraveling the Mystery: What the Fuel Line Connects to

You may want to see also

Flexibility: The line is flexible and resistant to kinking

The flexibility of the SAE 30R7 fuel line is a crucial feature that ensures its reliability and performance in various automotive applications. This particular fuel line is designed with a high degree of flexibility, allowing it to navigate through tight spaces and complex engine compartments without compromising its structural integrity. The flexibility is achieved through a combination of materials and construction techniques.

The line's inner diameter is carefully calculated to provide a smooth and flexible interior, enabling it to bend and twist without excessive stress or strain. This is particularly important in high-performance engines where rapid acceleration and deceleration can put significant pressure on the fuel system. By maintaining flexibility, the SAE 30R7 fuel line ensures that fuel can flow efficiently even under extreme conditions, reducing the risk of fuel starvation or performance issues.

Furthermore, the material composition plays a vital role in its flexibility. The line is typically made from high-quality rubber or a synthetic material that possesses excellent elasticity. This material is carefully selected to withstand the rigors of the automotive environment, including exposure to heat, fuel vapors, and mechanical stress. The flexibility of the material allows it to absorb vibrations and movements within the engine bay, ensuring a secure and reliable connection between the fuel tank and the engine.

In addition to flexibility, the SAE 30R7 fuel line is engineered to be resistant to kinking, which is a common issue with fuel lines. Kinking occurs when the line is subjected to excessive bending or pressure, causing it to form a kink or crease. This can lead to reduced fuel flow, engine misfires, or even fuel system failures. To prevent kinking, the line's outer diameter is optimized to provide a balanced level of stiffness and flexibility. The construction may include reinforcing layers or braids to enhance structural integrity without sacrificing flexibility.

The combination of flexibility and kink resistance ensures that the SAE 30R7 fuel line can withstand the demanding conditions of automotive use. It allows for easy installation and maintenance, as the line can be routed around obstacles without the risk of damage or disconnection. This feature is particularly beneficial in high-performance vehicles or those with limited engine bay space, where maintaining a reliable fuel supply is critical for optimal performance.

Unveiling the Material Secrets of Diesel Fuel Lines

You may want to see also

Compatibility: It is compatible with gasoline, diesel, and biofuels

The SAE 30R7 fuel line is a versatile component designed to withstand a wide range of fuel types, making it a popular choice for various applications. Its compatibility with gasoline, diesel, and biofuels ensures that it can be used in a multitude of vehicles and fuel systems. This versatility is a significant advantage, especially in the automotive industry, where different fuel types are commonly used.

When it comes to gasoline, the SAE 30R7 fuel line is an excellent choice due to its ability to handle the unique properties of this fuel. Gasoline is known for its volatility and tendency to evaporate, and the fuel line's compatibility ensures that it can effectively contain and transfer this volatile fuel without compromising performance. The material used in the construction of the fuel line is carefully selected to resist the corrosive effects of gasoline, ensuring long-lasting durability.

Similarly, for diesel engines, this fuel line is highly suitable. Diesel fuel has a higher density and different chemical properties compared to gasoline, and the SAE 30R7 fuel line is engineered to accommodate these differences. It provides excellent resistance to the corrosive nature of diesel, ensuring that the fuel line remains intact and functional even in the presence of this more aggressive fuel.

Biofuels, which are derived from organic materials and often blended with traditional fuels, also benefit from the compatibility of the SAE 30R7 fuel line. Biofuels can vary in composition, and this fuel line's versatility allows it to handle the unique characteristics of these alternative fuels. Whether it's ethanol-blended gasoline or biodiesel, the fuel line's compatibility ensures reliable performance and safety.

In summary, the SAE 30R7 fuel line's compatibility with gasoline, diesel, and biofuels is a key feature that makes it an indispensable component in various fuel systems. Its ability to withstand the unique properties of different fuels ensures optimal performance and longevity, making it a reliable choice for automotive and industrial applications. This compatibility also contributes to the overall efficiency and safety of fuel delivery systems.

Cub Cadet Kohler Engine Fuel Line Diameter: A Comprehensive Guide

You may want to see also

Frequently asked questions

SAE 30R7 fuel line is a type of fuel hose or line designed for use with gasoline or alcohol-based fuels in automotive applications. It is commonly used in high-performance engines and racing cars due to its ability to handle high pressure and temperature, ensuring efficient fuel delivery while maintaining flexibility and durability.

This specific fuel line is identified by its SAE (Society of Automotive Engineers) rating of 30R7, which indicates its flexibility and resistance to fuel-related chemicals. It is designed to withstand the corrosive effects of ethanol-blended fuels, making it suitable for modern vehicles with ethanol-compatible engines. The 'R7' rating signifies its ability to operate reliably in high-temperature environments.

While primarily designed for fuel delivery systems, this fuel line can also be utilized for other high-pressure applications, such as brake lines or transmission lines, in vehicles that require flexible and durable hoses. However, it is essential to ensure that the fuel line is compatible with the specific fluid it will carry to avoid any potential issues.