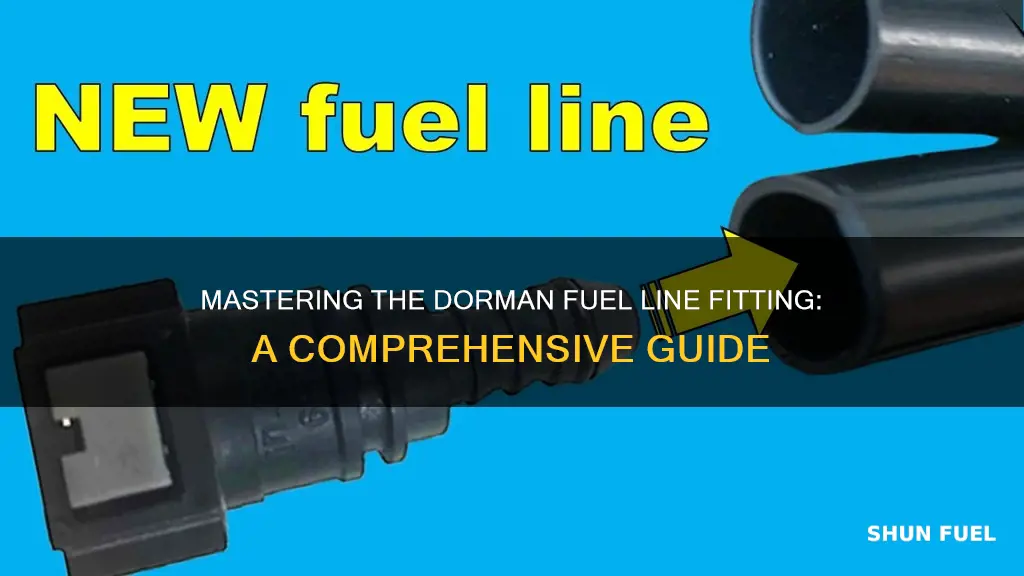

The Dorman 800-082 fuel line fitting is a versatile component designed for secure and efficient fuel line connections. This guide will provide a step-by-step approach to utilizing this fitting, ensuring a reliable and leak-free fuel system. By following these instructions, you can effectively install and maintain your fuel lines, enhancing the performance and longevity of your vehicle's fuel system.

| Characteristics | Values |

|---|---|

| Product Type | Fuel Line Fitting |

| Brand | Dorman |

| Part Number | 800-082 |

| Compatibility | Universal |

| Material | Brass |

| Color | Chrome |

| Design | Straight |

| Thread Size | 1/2-Inch NPT |

| Length | 1-1/2 Inches |

| Application | Fuel Injection Systems |

| Package Quantity | 1 |

| Warranty | Limited Lifetime Warranty |

| Note | Replaces OE Part Numbers: 15110-65020, 1511065020 |

What You'll Learn

- Preparation: Ensure fuel line is clean, dry, and free of debris

- Assembly: Follow manufacturer's instructions for correct fitting orientation

- Tightening: Use appropriate tools to tighten fittings securely

- Testing: Check for leaks and ensure proper fuel flow

- Maintenance: Regularly inspect and replace fittings as needed

Preparation: Ensure fuel line is clean, dry, and free of debris

Before you begin the process of installing the Dorman 800-082 fuel line fitting, it is crucial to ensure that the fuel line is in optimal condition. Start by thoroughly inspecting the fuel line for any signs of damage, such as cracks, punctures, or corrosion. If you notice any issues, it is essential to address them before proceeding. Clean the fuel line to remove any dirt, grime, or debris that may be present. This can be done using a mild detergent or a specialized fuel line cleaner. Ensure that the cleaner is compatible with the material of the fuel line to avoid any potential damage. Rinse the fuel line thoroughly to eliminate any residue from the cleaning process. Allow the fuel line to air dry completely before moving forward. Moisture or dampness can lead to corrosion or other issues, so ensure it is completely dry.

Once the fuel line is clean and dry, use a soft-bristled brush or a small vacuum to remove any remaining debris. Pay close attention to the areas where the fuel line connects to other components, as these spots may accumulate more dirt. Ensure that all debris is eliminated to prevent any interference during the installation process. It is also a good practice to double-check the fuel line's flexibility and ensure it is not kinked or twisted, as this can affect the overall performance and longevity of the fuel system.

After completing the cleaning and inspection process, you can now proceed with the installation of the Dorman 800-082 fuel line fitting. This preparation step is vital to guarantee a successful and secure connection, ensuring that the fuel line functions optimally and safely. By taking the time to properly prepare the fuel line, you can avoid potential issues and ensure a reliable fuel supply for your vehicle.

Where to Find 5/16 Fuel Line: A Comprehensive Guide

You may want to see also

Assembly: Follow manufacturer's instructions for correct fitting orientation

When assembling the Dorman 800-082 fuel line fitting, it is crucial to adhere to the manufacturer's instructions for optimal performance and safety. This fitting is designed to connect fuel lines and ensure a secure and leak-free connection. Here's a step-by-step guide on how to properly assemble it:

Start by ensuring you have the correct tools and materials. You will need the Dorman 800-082 fitting, fuel line connectors, and possibly a fuel line cutter or a suitable cutting tool. Prepare the fuel lines by cleaning them to remove any dirt or debris. Ensure the lines are free from any contaminants that could affect the connection.

Now, follow these assembly steps: Locate the male and female ends of the fitting. The male end typically has a threaded section, while the female end has a smooth interior. Align the male end of the fitting with the corresponding female end of the fuel line connector. Thread the male end into the female end until it is fully inserted and secure. Tighten the connection using the appropriate tool, ensuring you do not overtighten to avoid damage to the fitting or fuel line.

Pay close attention to the manufacturer's instructions for any specific torque specifications or assembly techniques. Different manufacturers may have unique requirements, so it's essential to follow their guidelines. For example, some fittings might require a specific torque value to ensure a tight seal, while others may have unique orientation instructions.

After assembly, inspect the connection to ensure it is secure and leak-free. Check for any signs of damage or improper installation. If everything looks correct, you can proceed with connecting the fuel lines to the engine or other fuel system components. Remember, proper assembly and orientation are critical to maintaining the integrity of the fuel system and preventing fuel leaks, which can be dangerous.

Visual Guide: Understanding the Appearance of a Fuel Line Clamp

You may want to see also

Tightening: Use appropriate tools to tighten fittings securely

When working with the Dorman 800-082 fuel line fitting, it's crucial to ensure a secure and tight connection to prevent any fuel leaks. The process of tightening these fittings requires the right tools and techniques to avoid damage and ensure a reliable seal. Here's a step-by-step guide on how to tighten the fitting effectively:

Start by gathering the necessary tools, which typically include a fuel line fitting kit or a set of appropriate wrenches. The specific tools required may vary depending on the size and type of fitting you are working with. Look for tools that match the fitting's thread size and have a good grip to ensure you can apply the necessary force without slipping.

Position the fitting onto the fuel line or component you are connecting. Ensure that the fitting is aligned correctly and that there are no obstructions or interference with other parts. Take a moment to inspect the fitting for any signs of damage or wear, as this could affect the tightness of the connection.

Now, it's time to tighten the fitting. Apply a steady and firm force using the appropriate tool. Start by turning the fitting in a clockwise direction, tightening it by hand or with the tool. The goal is to reach a secure connection without over-tightening, as this can lead to damage or stripping of the threads. Use a torque wrench if available to ensure you apply the correct amount of force. The recommended torque value for this specific fitting can usually be found in the product documentation or online resources.

As you tighten the fitting, you should feel resistance and hear a distinct 'click' or 'snap' sound, indicating that the connection is secure. If you encounter resistance and the fitting doesn't turn further, it's a sign that you've reached the correct tightness. However, if you can still turn the fitting, it might be necessary to apply a bit more force, but be cautious not to overdo it.

After tightening, inspect the fitting once more to ensure there are no visible signs of damage or uneven wear. Check for any leaks around the fitting by applying a small amount of fuel or a suitable sealant and observing if there are any drips. If everything looks secure and there are no leaks, your fuel line fitting is now ready for use. Remember, proper tightening techniques are essential to maintain the integrity of the fuel system and prevent potential issues.

Mastering Repairs: A Guide to Steel Fuel Line Fixes

You may want to see also

Testing: Check for leaks and ensure proper fuel flow

Before you begin the installation or repair process, it's crucial to test the fuel line fitting to ensure it functions correctly and prevents any potential fuel leaks. Here's a step-by-step guide on how to test the Dorman 800-082 fuel line fitting:

- Prepare the Necessary Tools and Materials: Gather the Dorman 800-082 fuel line fitting, a fuel pressure gauge (if available), a soapy water solution, and a clean rag. Ensure you have access to a fuel source and a suitable testing area.

- Inspect the Fitting: Visually examine the fuel line fitting for any signs of damage, cracks, or debris. Check for any bent or distorted parts that might affect its functionality. Make sure all components are in good condition before proceeding.

- Connect the Fuel Line: Attach the fuel line to the fitting according to the manufacturer's instructions. Ensure a secure and tight connection. You can use fuel line connectors or clamps to hold the line in place.

- Apply Soapy Water: Spray or pour the soapy water solution onto the connection points of the fuel line fitting. Pay close attention to the threads and any potential leak points. The soap will create a visible bubble if there's a leak, making it easier to identify.

- Check for Leaks: Inspect the area around the fitting and the fuel line for any bubbles or soapy water. Even a small leak can lead to significant issues over time. If you notice any bubbles, tighten the connection or consider replacing the fitting if the leak persists.

- Test Fuel Flow: If you have access to a fuel pressure gauge, connect it to the fuel line to measure the pressure. Ensure that the fuel flows smoothly and maintains the required pressure for your vehicle's engine. If the pressure is inconsistent or too low, it may indicate a problem with the fuel pump or the fitting itself.

- Disassemble and Reassemble: After testing, carefully disassemble the fuel line fitting and inspect the internal components. Look for any signs of wear or damage that could have caused the leak or improper fuel flow. Reassemble the fitting, ensuring all parts are aligned correctly.

By following these testing procedures, you can guarantee that the Dorman 800-082 fuel line fitting is installed correctly and will provide reliable fuel delivery to your vehicle's engine. Remember, proper testing and maintenance can help prevent costly repairs and ensure optimal engine performance.

Understanding Threaded 8N Fuel Lines: A Comprehensive Guide

You may want to see also

Maintenance: Regularly inspect and replace fittings as needed

Regular maintenance of your fuel system is crucial to ensure optimal performance and prevent potential issues. When it comes to the Dorman 800-082 fuel line fitting, a component that connects fuel lines to the engine, regular inspection and timely replacement are essential practices. This fitting is designed to withstand the pressure and temperature fluctuations associated with fuel systems, but over time, it can degrade and become susceptible to leaks or failure.

To maintain your vehicle's fuel system effectively, it is recommended to inspect the Dorman 800-082 fitting during routine maintenance checks. Start by visually examining the fitting for any signs of damage, corrosion, or wear. Look for cracks, brittleness, or any visible deterioration. Additionally, check for leaks by applying a small amount of diesel fuel or a suitable sealant to the fitting and observing if any fuel escapes. If you notice any issues, it's crucial to address them promptly.

If you identify any problems or decide to replace the fitting proactively, follow these steps. First, ensure you have the necessary tools, including a fuel line cutter, a fuel line crimper, and a replacement fitting. Carefully remove the old fitting by loosening the clamp or retaining clip, being cautious not to damage the surrounding fuel lines. Then, cut the fuel line to the appropriate length and insert the new fitting, ensuring a secure connection. Use the crimper to create a tight seal, and double-check the installation for any leaks.

Regularly scheduled maintenance intervals are ideal for inspecting and replacing the Dorman 800-082 fitting. Consider this a routine part of your vehicle's care, especially if you operate it in harsh conditions or frequently. By doing so, you can maintain a reliable fuel system, prevent unexpected breakdowns, and ensure your vehicle's performance remains at its best. Remember, proper maintenance can save you from potential fuel system failures and the associated costs of repairs or replacements.

Mastering Fuel Line Disconnect Pliers: A Comprehensive Guide

You may want to see also

Frequently asked questions

The Dorman 800-082 fuel line fitting is a replacement component designed to connect fuel lines in vehicles. It is commonly used in automotive applications to ensure a secure and leak-free connection for fuel delivery systems.

Yes, this fuel line fitting is generally compatible with gasoline and diesel fuel systems. However, it's always recommended to check the specific requirements of your vehicle's fuel system to ensure compatibility.

Installation typically involves the following steps: first, ensure you have the necessary tools like a fuel line cutter, crimping tool, and soapy water for leak testing. Cut the fuel line to the desired length, insert the fitting onto the line, and use the crimping tool to secure it. Finally, test for leaks and ensure a tight connection.

While the Dorman 800-082 fitting is designed for fuel lines, it is generally not recommended for high-pressure applications. For high-pressure systems, specialized fittings with higher pressure ratings should be used to ensure safety and optimal performance.

Regular maintenance is essential to ensure the longevity of the fitting. It's recommended to inspect the fitting periodically for any signs of damage, corrosion, or leaks. Keep the fuel lines and fittings clean to prevent contamination, and always use the appropriate fuel type to avoid degradation of the fitting's materials.