The 8N fuel line is an essential component in the maintenance and repair of classic Ford tractors, specifically the 8N model. It is a crucial part of the fuel delivery system, responsible for transporting fuel from the tank to the engine. One key aspect of this system is the thread, which is a critical feature that ensures a secure and leak-free connection. Understanding the thread specifications and compatibility is vital for any DIY enthusiast or mechanic working on these vintage machines to ensure optimal performance and longevity.

What You'll Learn

- Definition: Threaded 8N fuel lines are a type of fuel delivery system with a specific thread pattern for secure connections

- Compatibility: These lines are designed to fit 8N models, ensuring proper fuel flow and engine performance

- Materials: Common materials include stainless steel and aluminum for durability and corrosion resistance

- Installation: Proper threading and sealing techniques are crucial for a leak-free and efficient fuel supply

- Maintenance: Regular checks for tightness and damage are essential to maintain optimal engine operation

Definition: Threaded 8N fuel lines are a type of fuel delivery system with a specific thread pattern for secure connections

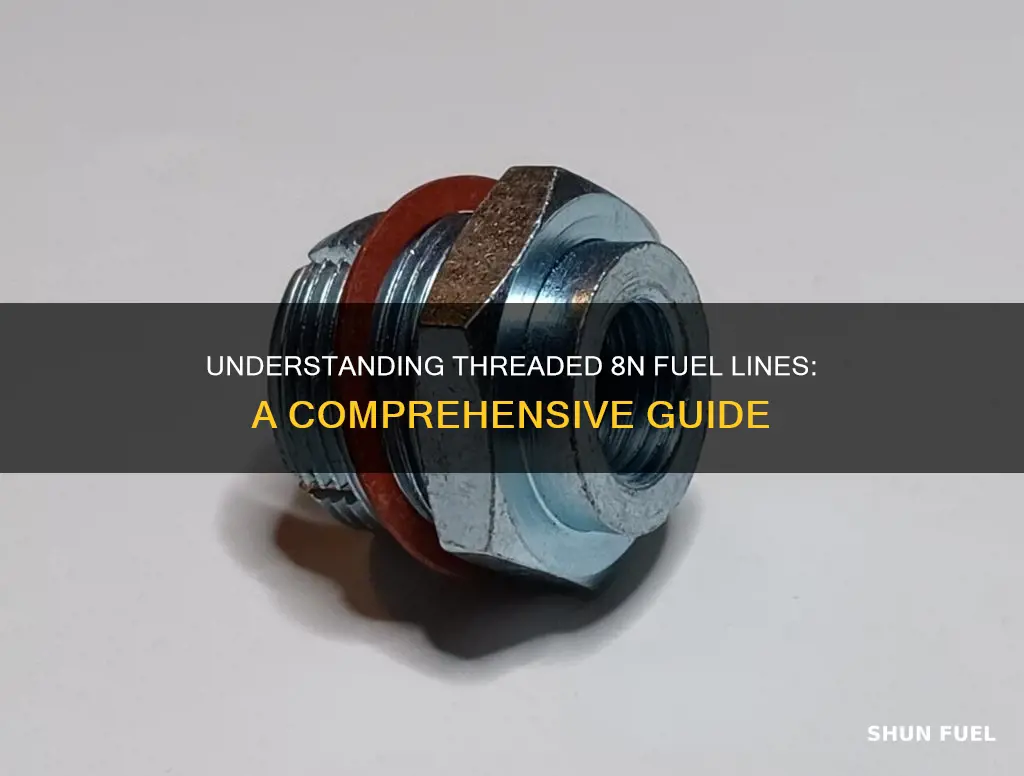

Threaded 8N fuel lines are an essential component in the fuel delivery system of certain vehicles, particularly those with a specific thread pattern designed for secure and reliable connections. This type of fuel line is characterized by its unique threading, which allows for a tight and leak-proof attachment to various parts of the engine and fuel system. The '8N' in the name refers to a particular thread standard, which is crucial for ensuring compatibility and proper function.

The threading on these fuel lines is meticulously designed to match specific engine requirements, providing a precise fit. This precision is vital as it enables the fuel lines to withstand the pressure and temperature variations within the engine compartment while maintaining a secure seal. The threads are typically made from durable materials such as stainless steel or aluminum, ensuring longevity and resistance to corrosion, which is essential for reliable fuel delivery.

When installing or replacing threaded 8N fuel lines, it is imperative to follow the manufacturer's guidelines. Proper installation ensures that the threads engage correctly, creating a robust connection. This process often involves the use of specialized tools and techniques to ensure a tight fit, preventing fuel leaks and potential engine damage. The specific thread pattern also facilitates easy disassembly for maintenance or repairs, allowing mechanics to access the fuel system without compromising the integrity of the connections.

In summary, threaded 8N fuel lines are a critical part of the fuel delivery system, offering a secure and reliable connection due to their unique thread pattern. This design ensures compatibility, durability, and a tight seal, making it an indispensable component in the proper functioning of specific vehicle engines. Understanding the importance of this thread standard is key to maintaining a safe and efficient fuel system.

The Ultimate Guide to Choosing the Best Fuel Line Clamps

You may want to see also

Compatibility: These lines are designed to fit 8N models, ensuring proper fuel flow and engine performance

When it comes to maintaining and upgrading your classic 8N Ford tractor, one crucial aspect is the fuel system, particularly the fuel lines. These lines play a vital role in ensuring your engine receives the necessary fuel for optimal performance. Specifically, the 'thread for 8N fuel line' refers to the compatibility and design of these fuel lines, tailored to fit the 8N model tractors.

The 8N Ford tractors, known for their reliability and durability, require specific fuel lines to maintain their performance over time. These fuel lines are engineered with precision to match the unique dimensions and requirements of the 8N engine. By using the correct fuel lines, you ensure a seamless connection between the fuel tank and the engine, allowing for efficient fuel delivery and combustion.

Compatibility is key when it comes to these fuel lines. They are designed to fit the 8N models exclusively, ensuring a perfect match in terms of size, thread type, and mounting points. This compatibility is essential to guarantee proper fuel flow, as any discrepancies could lead to reduced performance or even engine damage. The threads on these fuel lines are specifically engineered to securely connect to the corresponding ports on the 8N engine, providing a reliable and leak-free connection.

By using the correct thread for 8N fuel lines, you can expect improved engine performance and longevity. These lines are constructed to withstand the demands of agricultural use, ensuring durability and resistance to fuel-related degradation. Proper fuel flow is critical to maintaining the tractor's power output, fuel efficiency, and overall reliability.

In summary, the thread for 8N fuel lines is a critical component for 8N Ford tractor owners, ensuring compatibility, proper fuel flow, and engine performance. Investing in high-quality, compatible fuel lines is essential to keep your classic tractor running smoothly and efficiently.

Safe and Effective Methods to Thaw Frozen Car Fuel Lines

You may want to see also

Materials: Common materials include stainless steel and aluminum for durability and corrosion resistance

When it comes to fuel lines, especially those used in automotive applications like the 8N fuel line, the choice of materials is crucial for ensuring durability, reliability, and long-term performance. Two of the most commonly used materials for these fuel lines are stainless steel and aluminum, each offering unique advantages.

Stainless steel is a popular choice for fuel lines due to its exceptional corrosion resistance. This material is known for its ability to withstand the harsh environments that fuel lines often encounter, including exposure to various chemicals and fuels. The stainless steel used in these applications is typically a type that contains a high percentage of chromium, which forms a protective oxide layer on the surface, preventing corrosion. This makes it ideal for fuel lines that need to operate in demanding conditions without compromising performance.

Aluminum is another excellent material for fuel lines, particularly for those that require lightweight solutions. It offers a significant weight advantage over stainless steel, which is beneficial in applications where weight reduction is a priority. Aluminum is also known for its good corrosion resistance, especially in marine or outdoor environments where exposure to moisture and salt is common. The corrosion resistance of aluminum is further enhanced by its natural oxide layer, which forms on the surface and provides protection against further corrosion.

Both materials are designed to handle the high pressures and temperatures associated with fuel systems. Stainless steel, with its superior strength and durability, ensures that the fuel lines can withstand the rigors of everyday use, including vibrations and temperature fluctuations. Aluminum, while slightly more susceptible to corrosion, offers excellent fatigue resistance, making it a reliable choice for fuel lines that need to operate over extended periods without failing.

In summary, the choice between stainless steel and aluminum for 8N fuel lines depends on the specific requirements of the application. Stainless steel is ideal for its superior corrosion resistance and durability, making it perfect for harsh environments. Aluminum, on the other hand, provides a lightweight solution with good corrosion resistance, making it a popular choice for applications where weight is a critical factor. Both materials are carefully selected to ensure the fuel lines meet the necessary performance standards and provide long-lasting service.

Exploring Rubber Fuel Line Hose Sizes: A Comprehensive Guide

You may want to see also

Installation: Proper threading and sealing techniques are crucial for a leak-free and efficient fuel supply

When dealing with fuel lines, especially those designed for high-performance engines like the 8N model, proper threading and sealing techniques are absolutely essential to ensure a leak-free and efficient fuel supply. This is a critical aspect of engine maintenance and performance, as any leaks can lead to reduced power, increased emissions, and potential engine damage.

The threading on an 8N fuel line is specifically designed to create a tight, secure connection when joined with other components. This threading is often referred to as 'fuel line thread' or 'fuel line connector thread'. It is crucial to use the correct type of thread and ensure it is properly aligned and tightened to avoid any potential leaks. Over-tightening can damage the fuel line, while under-tightening can create a loose connection, leading to fuel leakage.

Sealing the fuel line connections is another vital step in the installation process. This is typically done using specialized fuel line seals or gaskets. These seals are designed to create a watertight barrier between the fuel line and the connecting components, preventing any fuel from escaping. It is important to ensure that the seals are properly positioned and that the connections are made with the correct torque to avoid any gaps that could lead to leaks.

In addition to the threading and sealing, it is also important to inspect the fuel line for any signs of damage or wear before and after installation. Look for any cracks, punctures, or signs of corrosion. If any damage is found, it is essential to replace the affected section of the fuel line to maintain the integrity of the fuel supply system.

By following these proper threading and sealing techniques, you can ensure that your 8N fuel line is installed correctly, providing a reliable and efficient fuel supply to your engine. This will help to maintain the performance and longevity of your vehicle, ensuring it runs smoothly and reliably for years to come.

Fuel Line Disconnect: Essential Tools and Methods for a Smooth Job

You may want to see also

Maintenance: Regular checks for tightness and damage are essential to maintain optimal engine operation

Regular maintenance is crucial for ensuring the longevity and optimal performance of your engine, especially when it comes to fuel lines. One critical aspect of this maintenance is checking the tightness and condition of the threads on the 8N fuel line. This simple yet essential practice can prevent a multitude of issues and ensure your engine runs smoothly.

The 8N fuel line, a component in many older model engines, is designed to deliver fuel efficiently to the engine's combustion chamber. Over time, however, this line can experience wear and tear, and the threads, which are often made of metal or a durable plastic, can loosen or become damaged. A loose connection can lead to fuel leaks, which not only waste fuel but also pose a safety hazard due to the potential for fuel vapor accumulation. Moreover, damaged threads can result in a poor seal, causing reduced engine performance and increased emissions.

To maintain the integrity of your engine, it is recommended to inspect the fuel line threads regularly. This can be done by hand or with the help of a small tool, such as a thread gauge, which can provide a more accurate measurement of the thread's condition. The goal is to ensure that the threads are tight and secure, providing a reliable connection. If you notice any looseness, it's essential to tighten the threads promptly. Over-tightening, however, can also be detrimental, potentially damaging the threads or the fuel line itself. Therefore, it's a delicate balance that requires careful attention.

In addition to checking tightness, look for any signs of damage, such as bends, cracks, or corrosion. These issues can compromise the fuel line's ability to deliver fuel effectively. If you identify any damage, it may be necessary to replace the fuel line to maintain optimal engine performance. Regularly scheduled maintenance checks can help identify these issues before they become major problems, saving you from potential breakdowns and costly repairs.

In summary, maintaining the threads on your 8N fuel line is a vital part of engine care. By regularly checking for tightness and damage, you can ensure that your engine operates efficiently and safely. This simple maintenance practice can save you from potential headaches and expenses, making it an essential habit for any vehicle owner. Remember, when it comes to engine maintenance, prevention is often the best medicine.

Air in Diesel Fuel Lines: Causes and Solutions

You may want to see also

Frequently asked questions

The 8N fuel line thread is a specific type of connector used in fuel systems, particularly for the Ford 8N tractor. It is designed to securely attach fuel lines to the engine, ensuring a tight and leak-free connection. This thread is crucial for maintaining the fuel supply and preventing any fuel loss, which could lead to engine performance issues.

Identifying the correct thread size involves measuring the diameter of the existing fuel line or the hole in the engine block where the line connects. The 8N fuel line thread is typically a 1/4-inch NPT (National Pipe Thread) size. It's important to use a thread gauge or a caliper to get an accurate measurement, ensuring a proper fit for the replacement fuel line.

While it might be tempting to use a regular fuel line, it is not recommended for the 8N tractor. The 8N fuel line thread is unique and requires a specific thread size and shape to ensure compatibility and a secure connection. Using the wrong thread size can lead to fuel leaks, engine misfires, or even damage to the fuel system components.

Regular maintenance is essential to keep the 8N fuel line thread in good condition. It's recommended to inspect the threads periodically for any signs of wear, damage, or corrosion. Cleaning the threads with a thread cleaner or soap and water can help remove debris and ensure a tight seal. Applying a small amount of thread sealant can also provide extra protection against leaks.