Fuel line disconnect pliers are essential tools for safely and efficiently disconnecting fuel lines in automotive repair and maintenance. These specialized pliers are designed to grip and release fuel lines without causing damage or leakage. They provide a secure and controlled method for disconnecting fuel lines, which is crucial when working on vehicles with fuel systems. By using these pliers, mechanics can ensure a safe and efficient process, reducing the risk of accidents and minimizing the potential for fuel spills. This guide will provide a step-by-step overview of how to use fuel line disconnect pliers effectively and safely.

| Characteristics | Values |

|---|---|

| Purpose | To safely disconnect fuel lines from fuel tanks or pumps without causing damage or injury. |

| Design | Pliers with a specialized jaw design to grip and release fuel lines securely. |

| Material | Typically made of durable materials like steel or aluminum to withstand fuel line pressures. |

| Handle | Ergonomic handle for comfortable and controlled grip during use. |

| Safety Features | May include insulated handles to prevent electrical shock and protect against hot surfaces. |

| Compatibility | Designed to work with various fuel line sizes and types, including common automotive applications. |

| Ease of Use | Simple and straightforward operation, allowing for quick disconnections. |

| Durability | Built to last, with the ability to withstand repeated use and harsh environments. |

| Maintenance | Requires minimal maintenance, often just cleaning after use. |

| Storage | Often comes with a protective case or pouch for safe storage and transport. |

What You'll Learn

- Safety Precautions: Always wear safety gear and ensure the engine is off before using the pliers

- Tool Familiarity: Understand the pliers' design and function for effective fuel line disconnection

- Grip Technique: Apply firm pressure to the pliers handle for a secure grip

- Fuel Line Location: Identify the fuel line and its connection point for precise disconnection

- Release Mechanism: Know how to activate the pliers' release mechanism to disconnect the fuel line

Safety Precautions: Always wear safety gear and ensure the engine is off before using the pliers

When working with fuel line disconnect pliers, it is crucial to prioritize safety to prevent any accidents or injuries. Here are some essential safety precautions to follow:

Personal Protective Equipment (PPE): Always wear appropriate safety gear, including heat-resistant gloves and safety goggles. Fuel lines can be under pressure, and the process of disconnecting them may involve sharp edges or hot components. Gloves provide a protective barrier, ensuring a secure grip and preventing cuts or burns. Safety goggles shield your eyes from any potential debris or splashes that could occur during the operation.

Engine Safety: Prioritize engine safety by ensuring it is completely off before attempting any fuel line work. Never use the pliers while the engine is running or hot. The pressure and heat can cause the fuel lines to expand, making them more difficult to handle and potentially leading to explosions or fires. Allow sufficient time for the engine to cool down to a safe temperature before proceeding.

Secure Environment: Work in a well-ventilated and clear area to minimize the risk of inhaling harmful fumes or getting any fuel-related substances on your skin. Keep flammable materials and open flames away from the work area to prevent accidents. Ensure that the surrounding area is free from trip hazards to maintain a safe working environment.

Proper Technique: Familiarize yourself with the correct technique for using the fuel line disconnect pliers. Apply the appropriate amount of force and use controlled movements to avoid slipping or losing grip. Be mindful of the fuel line's position and angle to prevent damage to surrounding components. Always follow the manufacturer's guidelines for your specific tool to ensure safe and effective usage.

By adhering to these safety precautions, you can significantly reduce the risks associated with fuel line disconnect pliers and ensure a secure working environment. Remember, taking the necessary safety measures is essential to protect yourself and those around you.

Perfect Fuel Line Size for Your 1992 Dodge D150 Pickup

You may want to see also

Tool Familiarity: Understand the pliers' design and function for effective fuel line disconnection

When it comes to working on fuel systems, having the right tools is essential, and one such tool is the fuel line disconnect pliers. These specialized pliers are designed to safely and efficiently disconnect fuel lines, ensuring a smooth and secure process. Understanding the design and function of these pliers is crucial to using them effectively and safely.

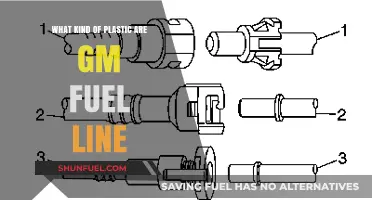

The fuel line disconnect pliers typically feature a set of sharp, serrated jaws that are specifically engineered to grip and cut fuel lines. These jaws are usually made of durable materials like hardened steel, ensuring they can withstand the pressure and heat associated with fuel systems. The design often includes a comfortable grip handle, providing users with a secure hold during the disconnection process. This handle may also incorporate a textured or ergonomic design for improved control and reduced slippage.

One key aspect of the pliers' design is the ability to apply precise force. When disconnecting a fuel line, it's important to cut the line at the correct location to avoid damage to the fuel system or nearby components. The pliers are designed to allow users to exert the necessary force to cut through the fuel line without applying excessive pressure, which could lead to accidents or damage. This balance between force and control is a critical feature of the pliers' functionality.

Furthermore, the pliers often include safety mechanisms to prevent accidental cuts or injuries. Some models have a locking mechanism that secures the jaws in the open position, allowing for easy access to the fuel line. This feature ensures that the pliers remain in a safe and controlled state when not in use. Additionally, the jaws might have a safety stop to prevent over-tightening, reducing the risk of damage to the fuel line or the pliers themselves.

To use fuel line disconnect pliers effectively, it's essential to familiarize yourself with their design. Take the time to inspect the pliers, understanding the location of the jaws, the handle's grip, and any safety features. Practice using the pliers on non-fuel line components to get a feel for the force required and the precision needed. This familiarity will ensure that you can safely and efficiently disconnect fuel lines, minimizing the risk of errors or accidents during automotive repairs or maintenance.

Toro Trimmer Fuel Line Sizing: A Comprehensive Guide

You may want to see also

Grip Technique: Apply firm pressure to the pliers handle for a secure grip

When working with fuel line disconnect pliers, a strong and secure grip is essential to ensure a successful and safe disconnection. The grip technique you employ can make a significant difference in your ability to handle the task effectively. Here's a detailed guide on how to apply firm pressure to the pliers handle for a secure grip:

Start by positioning your hand around the pliers handle. Ensure that your fingers are wrapped comfortably around the handle, providing a solid base for your grip. The key is to create a firm and stable hold without gripping too tightly, as this can lead to hand fatigue and potential slippage. Apply pressure to the handle by squeezing your hand around it. Imagine you are trying to grip a small object; this action will help you understand the correct technique. The goal is to create a firm, controlled pressure that allows you to maintain a steady grip throughout the process.

To enhance your grip, consider using your other hand to support the pliers. Place your other hand's thumb and forefinger on the pliers' jaws, providing an additional anchor point. This technique, often referred to as a 'two-handed grip,' offers more control and stability, especially when dealing with thicker or more stubborn fuel lines. By combining pressure on the handle with this additional support, you can ensure a secure hold, even when facing challenging disconnection scenarios.

Remember, the goal is to maintain a firm grip without causing discomfort or strain. Practice this technique to develop a sense of control and precision. With time, you'll be able to adjust the pressure and angle of your grip to suit the specific requirements of each fuel line disconnection task. Always prioritize safety and comfort to avoid any unnecessary strain on your hands or wrists.

In summary, applying firm pressure to the pliers handle is a fundamental aspect of mastering the use of fuel line disconnect pliers. It enables you to exert the necessary force while maintaining control and stability. By incorporating this grip technique, you'll be well-equipped to handle various fuel line disconnection tasks with confidence and efficiency.

Unveiling the Milwaukee Fuel Line: Powering Your Projects

You may want to see also

Fuel Line Location: Identify the fuel line and its connection point for precise disconnection

When working on a vehicle's fuel system, it's crucial to locate the fuel line and its connection point accurately to ensure a safe and efficient disconnection process. The fuel line is a critical component that carries gasoline or diesel from the tank to the engine, and identifying its location is the first step in safely disconnecting it.

Start by consulting your vehicle's manual or a reliable online resource specific to your car's make and model. These sources will provide detailed diagrams or illustrations showing the fuel lines' routing and their various connections. Look for the fuel line that runs from the fuel tank to the engine compartment. It is often a distinct color-coded line, making it easier to identify. The fuel line may be connected to various components, such as the fuel pump, fuel filter, or injectors.

In the engine compartment, locate the fuel rail or the area where the fuel injectors are mounted. This is where the fuel line connects to the engine's fuel system. The connection point can vary depending on the vehicle's design. It might be a quick-connect fitting, a clamp, or a bolt-on connection. Carefully inspect the fuel line to find the specific point where it is secured.

Once you've identified the fuel line and its connection, you can proceed with the disconnection process using the appropriate tools, including fuel line disconnect pliers. Remember to exercise caution and wear protective gear to avoid any fuel spills or splashes. Properly identifying the fuel line location is essential to ensure a safe and successful disconnection, allowing you to work on the fuel system or perform maintenance without the risk of fuel leaks.

Quick Disconnect Fuel Line Repair: A Step-by-Step Guide

You may want to see also

Release Mechanism: Know how to activate the pliers' release mechanism to disconnect the fuel line

When working with fuel line disconnect pliers, understanding the release mechanism is crucial to ensure a safe and efficient disconnection process. These specialized pliers are designed to provide a secure grip on the fuel line fitting, allowing for a controlled and safe release without causing damage or spillage. Here's a detailed guide on how to activate the release mechanism:

Grip and Positioning: Begin by firmly gripping the fuel line disconnect pliers. Ensure that the pliers are positioned correctly around the fuel line fitting. The pliers should have a secure hold on the fitting, typically a nut or a ferrule, without applying excessive force. This initial grip is essential to initiate the release process.

Activation of the Release Mechanism: The release mechanism is often a lever or a button located on the pliers. It is designed to unlock the grip and allow for the disconnection. Locate this release mechanism and press it firmly. You might feel a slight resistance or click as you activate it. This action will cause the pliers to release the grip on the fuel line fitting, allowing you to disconnect the line.

Controlled Disconnection: Once the release mechanism is activated, carefully pull the pliers away from the fuel line. The pliers should now be able to move freely around the fitting. This step requires precision to avoid sudden movements that could lead to fuel spillage. Take your time and ensure a smooth disconnection.

Releasing the Fuel Line: After the pliers are disconnected from the fitting, you will have access to the fuel line. This is the point where you can safely disconnect the line from the vehicle's fuel system. Remember to exercise caution and avoid any sudden movements that could cause fuel to spray out.

Releasing the Pliers: To complete the process, release the pressure on the release mechanism, and the pliers should retract, securely holding the disconnected fuel line fitting. This mechanism ensures that the pliers remain in place until you are ready to reconnect the fuel line. Always follow safety protocols when working with fuel lines to prevent accidents.

Determining the Perfect Fit: Your Fuel Line Tube Size Guide

You may want to see also

Frequently asked questions

Fuel line disconnect pliers are specialized tools designed to safely and effectively disconnect fuel lines from fuel tanks, pumps, or other fuel system components. They provide a secure grip and leverage to release connections without damaging the fuel lines or causing spills.

Safety is crucial when using these pliers. Always wear protective gloves and eye protection. Ensure the engine is off and the fuel system is cooled down before attempting any disconnections. Locate the fuel line connection, position the pliers around the fitting, and apply firm pressure to disconnect it. Avoid over-tightening to prevent damage.

No, regular pliers are not suitable for fuel line work. Regular pliers may not provide the necessary grip and can damage the fuel lines due to their design. Fuel line disconnect pliers are specifically engineered to handle the pressure and materials used in fuel systems.

Yes, there are various types of fuel line disconnect pliers available, including those for gasoline, diesel, and aviation fuel. The key is to choose the appropriate pliers for the fuel type and connection size. Different fuels may have varying connection sizes and materials, so selecting the right tool ensures a secure and safe disconnection.

After use, clean the pliers to remove any fuel residue. Inspect the pliers for any signs of wear or damage, especially the jaws and handles. Store them in a dry place, preferably in a tool box or case, to protect them from corrosion and accidental damage. Regular maintenance ensures their longevity and reliability.