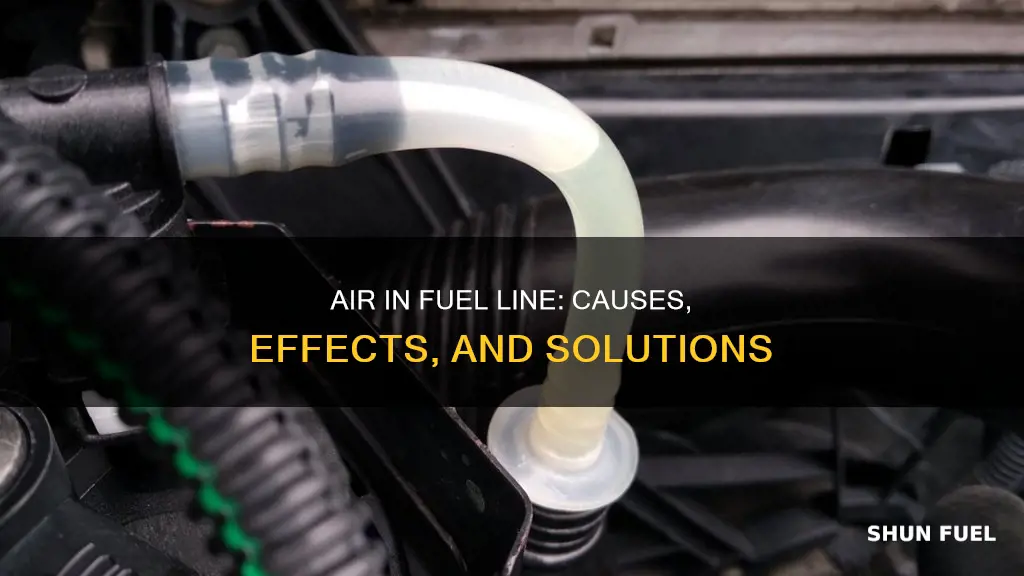

If air gets into your fuel line, it can cause a variety of issues with your vehicle's performance. Air bubbles in the fuel system can lead to reduced engine power, poor fuel efficiency, and even engine stalling. This happens because air is not as dense as fuel, so when it enters the fuel line, it displaces the fuel, leading to an improper fuel-to-air mixture in the engine. Over time, this can cause engine damage and may require professional diagnosis and repair.

| Characteristics | Values |

|---|---|

| Engine Stall | Air in the fuel line can cause the engine to stall or lose power. This happens because the air bubbles disrupt the fuel-air mixture, leading to improper combustion. |

| Reduced Performance | The presence of air can result in decreased engine performance, including reduced power, acceleration, and overall efficiency. |

| Rough Idling | You may notice a rough or erratic idle, as the engine struggles to maintain a stable fuel-air mixture. |

| Engine Misfire | Air bubbles can cause engine misfires, where the engine fails to ignite the fuel properly, leading to a loss of power and potential damage. |

| Hard Starting | Starting the engine may become difficult, especially in cold conditions, as air in the fuel line can restrict the flow of fuel to the engine. |

| Fuel System Damage | Over time, air in the fuel line can cause corrosion and damage to the fuel system, including the fuel pump and injectors. |

| Increased Emissions | Air bubbles can lead to higher emissions of pollutants, as the incomplete combustion affects the engine's performance. |

| Engine Overheating | In some cases, air in the fuel line can contribute to engine overheating due to improper fuel distribution and combustion. |

| Loss of Power | The engine may lose power, especially during acceleration, as the air disrupts the fuel flow and combustion process. |

| Engine Knock | Knocking or pinging sounds may be heard, indicating improper combustion and potential engine damage. |

What You'll Learn

- Engine Stall: Air in the fuel line can cause the engine to stall, leading to sudden stops or loss of power

- Reduced Performance: Fuel-air mixture imbalance results in decreased engine performance, including lower power and fuel efficiency

- Engine Knock: Air bubbles can cause engine knock, a loud sound, and potential engine damage due to premature combustion

- Carbon Build-up: Air-fuel mixture issues may lead to carbon build-up on valves and pistons, affecting engine performance and longevity

- Fuel System Damage: Prolonged air presence can damage fuel injectors, pumps, and lines, requiring costly repairs or replacements

Engine Stall: Air in the fuel line can cause the engine to stall, leading to sudden stops or loss of power

The presence of air in the fuel line can have a detrimental impact on engine performance, often resulting in a stall, which is a sudden and unexpected stop. This issue is particularly common in vehicles with fuel injection systems, where the precise timing and delivery of fuel are crucial for optimal operation. When air enters the fuel line, it creates a mixture that is less dense than the required fuel-air ratio, leading to a condition known as "lean mixture." This lean mixture can cause the engine to run inefficiently, as it may not be receiving the correct amount of fuel to sustain combustion.

As the engine continues to operate with this lean mixture, it may start to stall. The air bubbles in the fuel line can disrupt the consistent flow of fuel, causing the engine to lose power and eventually shut down. This can be a dangerous situation, especially when driving at high speeds or in heavy traffic, as it may result in sudden stops that could lead to accidents. The engine's ability to maintain stable operation is compromised, and it may struggle to restart, requiring a period of rest or a professional diagnosis.

One of the key signs that air has entered the fuel line is a noticeable loss of power during acceleration. The engine may hesitate or stall momentarily, especially when transitioning from a stationary position or when rapidly increasing speed. This is because the air bubbles disrupt the smooth fuel supply, causing the engine to temporarily lose its optimal operating conditions. In some cases, the engine may even shut off completely, requiring a restart to resume operation.

To address this issue, it is essential to check the fuel line for any signs of contamination or damage. Ensuring that the fuel filter is clean and free of debris is crucial, as it can trap air bubbles and prevent them from entering the engine. Regular maintenance, including fuel system inspections, can help identify and rectify potential issues before they cause a stall. Additionally, using a fuel additive designed to reduce air bubbles can be beneficial, especially for vehicles with high-performance engines that require precise fuel management.

In summary, air in the fuel line is a critical concern that can lead to engine stalls and sudden power loss. It is essential for vehicle owners to be aware of this potential problem and take preventive measures. By understanding the causes and symptoms, drivers can ensure their engines remain reliable and responsive, minimizing the risk of unexpected stalls on the road. Regular maintenance and the use of appropriate fuel additives can contribute to a smoother and more efficient driving experience.

Troubleshooting: When Your Fuel Line's Performance is Compromised

You may want to see also

Reduced Performance: Fuel-air mixture imbalance results in decreased engine performance, including lower power and fuel efficiency

If air gets into your fuel line, it can lead to a variety of performance issues with your engine, primarily due to the disruption of the fuel-air mixture. This mixture is crucial for proper combustion, as it determines the ratio of fuel to air that the engine requires to run efficiently. When this ratio is off balance, it can result in a condition known as a lean or rich mixture, both of which can negatively impact engine performance.

One of the most noticeable effects of air in the fuel line is a reduction in engine power. The engine may feel less responsive, and you might experience a decrease in horsepower and torque. This is because the air-fuel mixture is not as concentrated as it should be, leading to incomplete combustion. As a result, the engine doesn't receive the necessary energy to produce its full power output.

Fuel efficiency can also take a hit. When air is present in the fuel, the engine has to work harder to maintain optimal performance, which can lead to increased fuel consumption. This is because the engine is essentially 'wasting' fuel by trying to burn a mixture that is not as efficient as it should be. Over time, this can result in higher fuel costs and reduced overall efficiency.

The imbalance in the fuel-air mixture can also cause the engine to run roughly, with increased vibration and noise. This is often a sign of improper combustion, where the air-fuel mixture is not being burned effectively. Such symptoms can be indicative of other engine issues as well, but the presence of air in the fuel line is a common and often easily identifiable cause.

To address this problem, it is recommended to bleed the fuel system to remove any air bubbles. This process involves opening the fuel line and allowing the air to escape, ensuring that the fuel pump and injectors receive a consistent flow of fuel without any air contamination. Regular maintenance, such as checking and replacing the fuel filter, can also help prevent this issue and ensure optimal engine performance.

Unraveling the Mystery: Why Fuel Lines Break

You may want to see also

Engine Knock: Air bubbles can cause engine knock, a loud sound, and potential engine damage due to premature combustion

Engine knock, also known as 'pinging' or 'pinging' in the engine, is a common issue that can occur when air bubbles are present in the fuel line. This phenomenon is a result of the air-fuel mixture not being properly atomized and mixed, leading to incomplete combustion. When this happens, the engine's performance is significantly affected, and it can cause a range of problems.

The presence of air bubbles in the fuel line can lead to a variety of symptoms, including a loud, knocking sound during engine operation. This sound is often described as a metallic 'ping' or 'tap' and is caused by the rapid combustion of the air-fuel mixture in the engine's cylinders. The knock is a result of the air bubbles disrupting the normal combustion process, causing the fuel to ignite prematurely. This premature ignition can lead to a loss of power, reduced fuel efficiency, and even potential engine damage if left unchecked.

One of the primary causes of engine knock is the improper atomization of the fuel. When air bubbles are present in the fuel line, they can disrupt the fuel's ability to mix and atomize properly. This results in a less efficient combustion process, as the fuel does not burn completely. The incomplete combustion can lead to the formation of carbon deposits and other byproducts, further exacerbating the issue.

To address engine knock caused by air bubbles, it is essential to identify and rectify the root cause. One common solution is to ensure that the fuel system is properly maintained and free of any blockages or restrictions. This may involve cleaning or replacing the fuel filter, checking for any clogs in the fuel lines, and ensuring that the fuel pump is functioning correctly. Additionally, using a fuel additive designed to reduce air bubbles can be beneficial. These additives work by dispersing the air bubbles and improving the fuel's atomization, thus promoting a more complete combustion process.

In some cases, engine knock may be a sign of a more serious issue, such as a malfunctioning fuel pump or a problem with the engine's timing. If the knock persists or is accompanied by other symptoms, it is advisable to consult a professional mechanic. They can perform a thorough inspection and diagnose any underlying causes, ensuring that the engine receives the proper care and attention it needs to operate efficiently and reliably.

Understanding Fuel Line Connector Numbers: A Comprehensive Guide

You may want to see also

Carbon Build-up: Air-fuel mixture issues may lead to carbon build-up on valves and pistons, affecting engine performance and longevity

The presence of air in the fuel line can have significant consequences for an engine's performance and overall health. When air enters the fuel system, it disrupts the delicate balance of the air-fuel mixture, leading to a series of issues that can impact the engine's efficiency and longevity. One of the primary concerns is the potential for carbon build-up, which can have a detrimental effect on the engine's internal components.

Carbon build-up occurs when the air-fuel mixture, with an excess of air, is not properly burned during the combustion process. This results in the formation of carbon deposits on various parts of the engine, including the valves and pistons. Over time, these deposits can accumulate, leading to a range of problems. The carbon residue can cause a loss of power and performance as it restricts the smooth movement of engine components. Valves, which are crucial for controlling the airflow, may become clogged with carbon, leading to inefficient operation and potential valve damage.

The impact of carbon build-up on pistons is equally concerning. Piston rings, which seal the combustion chamber, can become coated with carbon, compromising their sealing ability. This results in increased engine oil consumption, as the oil is used to lubricate the pistons, and the engine may start losing power due to the inefficient transfer of power from the pistons to the crankshaft. Moreover, the carbon deposits can lead to increased engine wear, reducing the overall lifespan of the engine.

To address this issue, it is essential to ensure that the air-fuel mixture is properly balanced. This can be achieved by using a fuel injection system that delivers the correct amount of fuel based on the engine's needs. Regular maintenance, including fuel system cleaning and inspection, is crucial to prevent carbon build-up. Engine owners should also be vigilant about checking for any signs of air in the fuel line, such as engine misfires or reduced performance, and take prompt action to rectify the issue.

In summary, air in the fuel line can lead to carbon build-up, which has a direct impact on engine valves and pistons. This build-up can cause a decline in engine performance, increased wear and tear, and potential long-term damage. Proper air-fuel mixture management and regular maintenance are essential to mitigate these risks and ensure the engine operates optimally.

Unraveling the Mystery: Why Motorcycles Pop Pinholes in Fuel Lines

You may want to see also

Fuel System Damage: Prolonged air presence can damage fuel injectors, pumps, and lines, requiring costly repairs or replacements

The presence of air in a fuel line is a common issue that can have significant consequences for a vehicle's performance and longevity. When air enters the fuel system, it can lead to a range of problems, with one of the most critical being potential damage to the fuel system components. This is because air bubbles can disrupt the efficient flow of fuel, leading to a cascade of issues that may result in costly repairs or replacements.

One of the primary areas affected by air in the fuel line is the fuel injectors. These components are responsible for precisely metering and injecting fuel into the engine's cylinders. When air is introduced into the fuel stream, it can cause the injectors to malfunction. Over time, this can lead to clogged or damaged injectors, resulting in reduced engine performance, increased fuel consumption, and even engine misfires. In some cases, the air bubbles may cause the injectors to spray fuel inconsistently or not at all, leading to a complete loss of power and potential engine stall.

The fuel pump is another critical component that can be damaged by air. Fuel pumps are designed to deliver fuel from the tank to the engine at the required pressure. However, when air is present in the fuel line, it can cause the pump to work harder, leading to increased wear and tear. Prolonged exposure to air can result in pump failure, which may require a complete replacement. This is a significant issue as fuel pumps are not inexpensive, and the labor involved in replacing them can be considerable.

Air in the fuel line can also cause damage to the fuel lines themselves. Over time, the constant presence of air can lead to the deterioration of the fuel lines, causing cracks, leaks, or even ruptures. This can result in fuel leaking into the engine compartment, creating a fire hazard and potentially causing further damage to the engine and surrounding components. Additionally, fuel leaks can lead to environmental contamination, which is an illegal and dangerous practice.

To prevent these issues, it is essential to maintain a consistent and clean fuel supply. Regularly checking for and addressing any air bubbles in the fuel line is crucial. This can be done by ensuring that the fuel tank is properly sealed and that there are no leaks or damage to the fuel lines. Using a fuel filter and regularly replacing it can also help remove any contaminants, including air bubbles, from the fuel before it reaches the engine. By taking these preventative measures, vehicle owners can avoid the costly and inconvenient consequences of prolonged air presence in their fuel systems.

Unleash Engine Power: Understanding Fuel Line Cleaner's Magic

You may want to see also

Frequently asked questions

When air is introduced into the fuel line, it can lead to several performance issues in an engine. Air bubbles in the fuel can cause the engine to run poorly, as the mixture of fuel and air is not optimal for combustion. This may result in reduced power, poor acceleration, and even stalling.

One common sign of air in the fuel line is an engine that is difficult to start or stalls frequently. You might also notice a decrease in engine performance, such as reduced power and fuel efficiency. In some cases, you may hear a whistling or hissing sound coming from the fuel line when the engine is running.

Air intrusion in the fuel line can occur due to several reasons. One common cause is a loose or damaged fuel cap, which allows air to enter the fuel tank. Over time, fuel lines can also develop small holes or leaks, especially if they are old or have been subjected to vibration. Additionally, improper fuel system maintenance or a faulty fuel pump can contribute to this issue.

To resolve this issue, you can start by checking and tightening the fuel cap. If the problem persists, it is recommended to inspect the fuel lines for any visible damage or leaks. You may need to replace the fuel lines if they are found to be faulty. Ensuring that the fuel pump is functioning correctly is also crucial. Consulting a professional mechanic is advised for a thorough diagnosis and repair, especially if the issue is recurring.