The Harbor Freight Fuel Line Disconnect Tool is a handy device for safely and efficiently disconnecting fuel lines. This tool is designed to make the process of removing fuel lines from fuel tanks, pumps, or other fuel systems much easier and safer than traditional methods. By using this tool, you can avoid the risk of fuel spills, potential fires, and the hassle of dealing with stubborn connections. This guide will provide a step-by-step overview of how to effectively utilize the Harbor Freight Fuel Line Disconnect Tool, ensuring a quick and secure disconnection process.

| Characteristics | Values |

|---|---|

| Purpose | To safely disconnect fuel lines from tanks or pumps without spilling fuel |

| Compatibility | Harbor Freight fuel line disconnect tools are designed for use with specific fuel line sizes and types |

| Components | Typically includes a handle, a locking mechanism, and a fuel-resistant hose or tube |

| Safety Features | May include a built-in shut-off valve or a pressure relief valve to prevent fuel from spilling |

| Usage | 1. Locate the fuel line connection you want to disconnect. 2. Attach the disconnect tool to the fuel line. 3. Squeeze the handle to unlock the connection. 4. Pull the fuel line away from the connection. 5. Ensure the handle is released to secure the connection. |

| Maintenance | Regularly inspect the tool for wear and tear, especially the locking mechanism and hose connections |

| Storage | Keep the tool in a clean, dry place, away from direct sunlight and extreme temperatures |

| Applications | Useful for vehicle maintenance, fuel tank cleaning, or when replacing fuel lines |

What You'll Learn

- Safety First: Always wear protective gear and ensure the fuel source is turned off before disconnecting

- Tool Familiarity: Understand the parts and functions of the Harbor Freight fuel line disconnect tool

- Location Identification: Locate the fuel line and disconnect port on your vehicle

- Proper Technique: Use the tool's grippers to firmly hold the fuel line and disconnect it carefully

- Post-Disconnect Checks: Inspect the fuel line for damage and ensure the tool is clean and ready for reuse

Safety First: Always wear protective gear and ensure the fuel source is turned off before disconnecting

When working with fuel lines, safety should always be the top priority. Whether you're a professional mechanic or a DIY enthusiast, using a Harbor Freight fuel line disconnect tool can be a handy skill, but it requires careful attention to detail and a strong emphasis on safety. Here's a comprehensive guide to ensure your well-being during the process:

Protective Gear is Essential: Before you begin, make sure you have the appropriate personal protective equipment (PPE). Safety goggles are crucial to protect your eyes from any potential fuel splashes or debris. Additionally, wear gloves to safeguard your hands from sharp edges or hot surfaces. Consider a respirator or a dust mask if you're working in an enclosed space to avoid inhaling any fumes. These simple precautions can significantly reduce the risk of injury or health issues.

Turn Off the Fuel Source: This step is critical and cannot be overstated. Before attempting to disconnect any fuel line, ensure that the fuel source is turned off. Locate the fuel tank's shut-off valve and confirm that it is in the 'off' position. If you're working with a vehicle, locate the fuel pump relay and switch it off. This step is essential to prevent fuel from flowing during the disconnection process, which could lead to spills, fires, or explosions. Always double-check to ensure the fuel source is secure and will not restart unexpectedly.

Follow a Structured Approach: When disconnecting the fuel line, follow a systematic process. Start by identifying the specific fuel line you need to disconnect. Use a fuel line disconnect tool, typically a specialized socket or a pair of pliers, to loosen the fittings. Never use excessive force, as this can damage the fuel line or cause it to rupture. Work carefully, ensuring that you have a clear view of the connections and that there are no obstructions. If you encounter resistance, back off slightly and try again, ensuring you don't strip the threads or damage the fittings.

Stay Focused and Aware: Maintain a clear head and stay focused on the task at hand. Fuel line work can be intricate, and distractions can lead to accidents. Keep your workspace organized and well-lit to avoid tripping hazards. Be mindful of your surroundings, especially if you're working in a confined area. Regularly inspect your tools and equipment for any signs of damage or wear, and replace them if necessary.

Practice and Learn from Experience: Using a Harbor Freight fuel line disconnect tool effectively requires practice and familiarity with the process. Start with easier tasks and gradually move to more complex projects. Learn from experienced professionals or mentors who can provide guidance and tips. With time, you'll develop a keen sense of how to handle fuel lines safely and efficiently. Always remember that safety is a continuous learning process, and each task presents an opportunity to refine your skills.

2010 Multistrada Fuel Line Location: Left or Right?

You may want to see also

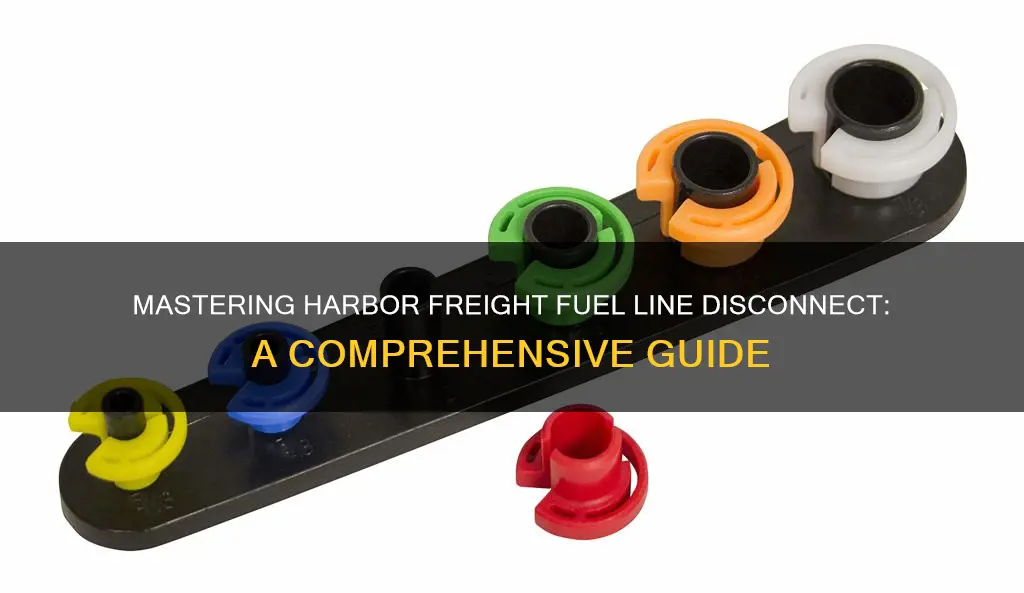

Tool Familiarity: Understand the parts and functions of the Harbor Freight fuel line disconnect tool

The Harbor Freight fuel line disconnect tool is a handy device designed to safely and efficiently disconnect fuel lines from vehicles, ensuring a secure and controlled process. Familiarity with its components and functions is essential to using it effectively and safely. Here's a breakdown of the key parts and their roles:

- Handle: The handle is the primary part of the tool that you'll grip and manipulate. It is typically made of durable materials like metal or high-impact plastic. The handle provides the necessary leverage to apply force to the disconnect process. Look for a comfortable grip, often with textured surfaces or ergonomic designs, to ensure a secure hold during use.

- Disconnect Pin: This is the critical component that physically disconnects the fuel line. It is usually a small, slender pin that fits into a corresponding socket or port on the fuel line. The pin is designed to be inserted and removed easily, allowing for quick and safe fuel line disconnections. It is essential to understand the size and type of disconnect pin your tool uses to ensure compatibility with the fuel lines you're working on.

- Socket or Connector: Depending on the model, the tool may feature a socket or connector that engages with the fuel line's disconnect port. This part is often made of sturdy materials to withstand the force applied during disconnection. The socket or connector should be securely attached to the handle, allowing for a precise and controlled movement when applying pressure.

- Safety Mechanism: Some Harbor Freight fuel line disconnect tools incorporate a safety mechanism to prevent accidental disconnections. This feature ensures that the tool can only be used when it is properly aligned and engaged with the fuel line. Understanding and utilizing this safety mechanism is crucial for safe operation, especially in busy workshops or garage environments.

- Instructions and Markings: Pay attention to any instructions or markings provided with the tool. These may include diagrams or text that highlight the correct orientation of the tool for disconnection. Following these guidelines will ensure that you use the tool correctly and safely, minimizing the risk of errors or damage.

By thoroughly understanding these parts and their functions, you'll be well-prepared to use the Harbor Freight fuel line disconnect tool effectively. This knowledge will enable you to work efficiently and safely, making it an invaluable asset in any vehicle maintenance or repair scenario. Remember, always prioritize safety and follow manufacturer guidelines when using any tool.

Metal Fuel Lines: Unlocking Engine Performance and Reliability

You may want to see also

Location Identification: Locate the fuel line and disconnect port on your vehicle

To locate the fuel line and disconnect port on your vehicle, you'll need to consult your vehicle's manual or a reliable online resource specific to your car's make and model. This is crucial as different vehicles have varying fuel systems and port placements. The fuel line is typically a rubber or plastic hose that connects the fuel tank to the engine, and the disconnect port is a small opening or fitting where the fuel line can be safely removed.

Start by inspecting the engine bay. Look for the fuel tank, which is usually a rectangular or cylindrical component mounted in the front or rear of the vehicle. The fuel line will run from the tank to the engine, often visible as a dark-colored hose. Identify the point where the fuel line enters the engine compartment, as this will be the closest to the disconnect port.

Locate the engine's fuel rail or injection system. This is where the fuel injectors are mounted, and it is a critical component of the fuel system. The fuel line will connect to the fuel rail, and you'll find a small fitting or port nearby, which is the disconnect port. It is essential to identify this port as it is designed for safe fuel line removal during maintenance or repairs.

In some cases, the disconnect port might be more challenging to find. If the fuel line is hidden behind other components or if your vehicle has a complex fuel system, you may need to remove certain parts to access the port. Always exercise caution when working on your vehicle and consider consulting a professional if you're unsure about any step.

Remember, the key to successfully using a Harbor Freight fuel line disconnect tool is knowing the exact location of the fuel line and disconnect port. Take your time to inspect the engine bay and fuel system, and if necessary, seek guidance from online forums or automotive experts to ensure you locate the correct port for your vehicle.

Unclogging the Miata: A Step-by-Step Guide to Removing the Fuel Line Filter

You may want to see also

Proper Technique: Use the tool's grippers to firmly hold the fuel line and disconnect it carefully

When using a Harbor Freight fuel line disconnect tool, it's crucial to employ the proper technique to ensure a safe and efficient process. The tool's design allows you to securely grip the fuel line, providing the necessary control to disconnect it without causing damage or spillage. Here's a step-by-step guide on how to achieve this:

Start by positioning the tool's grippers around the fuel line. Ensure that the grippers are firmly wrapped around the line, providing a secure hold. The key is to apply enough pressure to hold the line in place without causing any strain or damage to the fuel line itself. You want to create a stable base for the disconnection process.

Next, locate the disconnect point, which is typically a quick-release fitting or a clamp. Carefully align the tool's grippers with the disconnect point, ensuring that the fuel line is properly positioned. This step requires precision to avoid any accidental disconnections or damage to the fuel line.

Now, gently but firmly pull the disconnect fitting or clamp away from the fuel line. The tool's grippers should provide the necessary resistance to hold the line in place, preventing any sudden movements or spills. Take your time during this step to avoid any potential hazards.

As you disconnect the fuel line, maintain a steady grip with the tool's grippers. This ensures that the fuel line doesn't come loose accidentally, especially if there is any residual pressure in the system. By using the tool's grippers, you can carefully release the connection without the risk of fuel spraying out.

Remember, the goal is to safely and efficiently disconnect the fuel line. By following these steps and focusing on the proper technique, you can minimize the risk of accidents and ensure a smooth process. Always prioritize safety and take your time when working with fuel lines to avoid any potential hazards.

Jeep Grand Cherokee Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Post-Disconnect Checks: Inspect the fuel line for damage and ensure the tool is clean and ready for reuse

After disconnecting the fuel line using the Harbor Freight fuel line disconnect tool, it is crucial to perform a series of post-disconnect checks to ensure safety and proper maintenance. The first step is to inspect the fuel line for any signs of damage. Look for cracks, punctures, or any visible wear and tear along the length of the line. Even a small tear can lead to fuel leaks, which pose a significant safety hazard. If you notice any damage, it is essential to replace the fuel line immediately to prevent potential accidents.

Next, verify that the disconnect tool is clean and ready for its next use. Over time, fuel lines can accumulate dirt, debris, and contaminants, especially if the tool was not properly cleaned after the last use. To clean the tool, start by removing any residual fuel or debris from the fuel line. You can use a small brush or a compressed air canister to blow out any remaining particles. Ensure that the entire length of the line is cleared of any foreign matter. Then, wipe down the tool's surfaces with a clean cloth to remove any built-up grime. Proper cleaning ensures that the tool functions effectively and maintains its integrity for future use.

Additionally, check the tool's components for any signs of wear or damage. Inspect the quick-release mechanism, the clamp, and any other moving parts for any malfunctions. Ensure that the tool's locking mechanism is secure and functioning correctly to prevent accidental disconnections. If you notice any issues, consider replacing the tool or seeking professional assistance to ensure it operates safely and efficiently.

By following these post-disconnect checks, you can guarantee that the fuel line is in optimal condition and that the Harbor Freight fuel line disconnect tool is ready for its next use. This process is vital for maintaining a safe and efficient fuel system, reducing the risk of leaks and potential hazards associated with fuel handling. Regular maintenance and inspection will contribute to the longevity of your equipment and the safety of your operations.

Understanding Husqvarna Line Trimmer Fuel Mix: A Comprehensive Guide

You may want to see also

Frequently asked questions

Safety is crucial when working with fuel lines. Before starting, ensure you are in a well-ventilated area and wear protective gear, including gloves and safety goggles. Locate the fuel line you want to disconnect, and using the tool, carefully apply pressure to release the connection. Be cautious of any fuel that may spill, and have a suitable container ready to catch any leaks.

Yes, the Harbor Freight Fuel Line Disconnect Tool is designed to work with both gasoline and diesel fuel lines. However, it's important to check the compatibility of the tool with the specific fuel line you are working on, as different fuels may have varying connection types.

If you encounter resistance, do not force the tool. Apply steady pressure and ensure you are using the correct size and type of tool for the fuel line. If the connection is particularly stubborn, consider using a fuel line brush to clean and loosen the connection before attempting to disconnect it.

Regular maintenance will ensure the tool's longevity. After each use, clean the tool with a mild detergent and water solution to remove any fuel residue. Dry it thoroughly and store it in a clean, dry place. Periodically inspect the tool for any signs of wear and replace any damaged parts to maintain its effectiveness.

Absolutely! The Harbor Freight Fuel Line Disconnect Tool is also useful for reconnecting fuel lines. Simply follow the same steps in reverse, ensuring a secure and leak-free connection. Always double-check your work to ensure the fuel line is properly sealed before operating the vehicle.