If you're looking to tackle a project of restoring or modifying a 1971 Chevy truck, one of the key aspects to consider is the fuel system. Running fuel lines is a crucial step in ensuring your engine receives the necessary fuel for optimal performance. This process involves carefully routing the lines from the fuel tank to the engine, taking into account the truck's unique design and layout. In this guide, we'll walk you through the steps to properly install and secure the fuel lines, ensuring a reliable and efficient fuel supply for your classic Chevy truck.

What You'll Learn

- Preparation: Gather tools, materials, and safety gear for the project

- Routing: Plan a path for fuel lines, considering engine and body layout

- Clamps and Fittings: Choose appropriate clamps and fittings for secure connections

- Fuel Pump Installation: Mount the fuel pump and ensure proper fuel flow

- Testing: Check for leaks and proper fuel pressure after installation

Preparation: Gather tools, materials, and safety gear for the project

Before you begin the process of routing fuel lines on your 1971 Chevy truck, it's crucial to ensure you have all the necessary tools, materials, and safety equipment ready. This preparation will make the project smoother and safer. Here's a detailed guide on what you need to gather:

Tools:

- Fuel Line Cutter: Invest in a quality fuel line cutter or a set of sharp, heavy-duty scissors or knives. This tool is essential for making precise cuts in the fuel lines to the desired length.

- Fuel Line Crimper: A crimper is used to install fuel line fittings. Get a crimper that fits the type of fittings you'll be using. Ensure it has the necessary dies for your specific application.

- Hose Clamps: You'll need hose clamps to secure the fuel lines in place. Get a pack of adjustable hose clamps suitable for fuel line thickness.

- Pliers: Pliers are versatile tools for gripping and manipulating various components. Get a pair of adjustable pliers for general use and another pair specifically for fuel line fittings.

- Wrenches and Socket Set: A set of wrenches and sockets will be required for tightening and loosening nuts and bolts during the installation process.

- Tape Measure: Accurate measurements are vital. A flexible tape measure will help you determine the length of fuel lines needed.

- Safety Gear: Safety should always be a priority. Wear safety goggles to protect your eyes from any potential fuel splashes. Gloves will also provide grip and protection.

Materials:

- Fuel Lines: Purchase the correct size and length of fuel lines suitable for your truck's engine and fuel tank configuration. Ensure they are compatible with the fuel type (gasoline or diesel).

- Fittings: Gather the necessary fittings, such as fuel line connectors, bends, and adapters. Common types include 90-degree bends, straight connectors, and Y-splitters.

- Fuel Filter: If your truck doesn't already have one, consider installing a fuel filter to ensure clean fuel delivery.

- Fuel Pump: Depending on your project's scope, you might need a new fuel pump to ensure optimal fuel delivery to the engine.

Safety Gear:

- Gloves: Leather or heavy-duty rubber gloves will protect your hands from cuts and burns.

- Safety Goggles: As mentioned earlier, safety goggles are essential to shield your eyes from any potential hazards.

- Breathing Mask: If you're working in a confined space or near a fuel source, a breathing mask can be a valuable safety precaution.

- Fire Extinguisher: Keep a small fire extinguisher nearby as a safety measure in case of any accidental fuel-related incidents.

By gathering these tools, materials, and safety gear, you'll be well-prepared to tackle the task of running fuel lines on your 1971 Chevy truck. This preparation will ensure a more efficient and safer working environment during the project.

Choosing the Right Hose for Your 1.4-Inch Fuel Line

You may want to see also

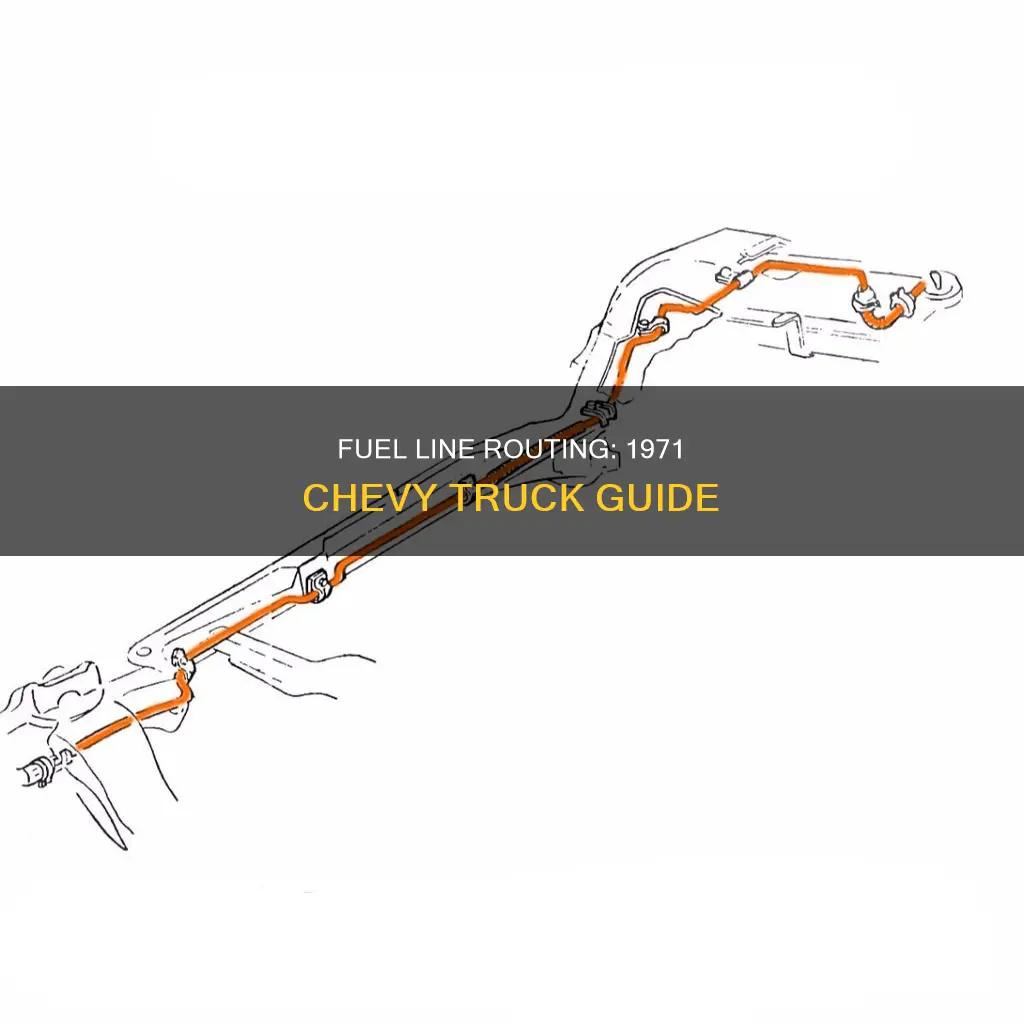

Routing: Plan a path for fuel lines, considering engine and body layout

When planning the route for fuel lines on a 1971 Chevy truck, it's crucial to consider the vehicle's engine and body layout for optimal performance and safety. Here's a step-by-step guide to help you navigate this process:

- Understand the Engine Bay: Begin by familiarizing yourself with the engine bay layout. Identify the location of the fuel tank, fuel pump, and the positions of the injectors or carburetor, if applicable. The fuel lines need to be routed in a way that ensures a direct and efficient path from the tank to the engine. Consider the engine's orientation; a V-shaped engine will have different routing considerations compared to a straight-six or inline engine.

- Assess Body Structure: The body of the truck will play a significant role in determining the fuel line route. Examine the frame rails, the firewall, and any other structural components that might restrict or guide the fuel lines. In a 1971 Chevy, the firewall is a critical element as it separates the engine bay from the passenger compartment. Ensure that the fuel lines are not routed too close to hot engine components or sharp bends that could cause damage or restrict flow.

- Plan the Route: Start at the fuel tank and visualize the path to the engine. Typically, the fuel pump is located close to the tank, and the lines should be routed downward and forward to reach the engine. Consider the following:

- Keep the lines as straight as possible to minimize pressure drops.

- Avoid tight bends that could lead to line collapse or reduced flow.

- Use rubber or plastic fuel line with sufficient diameter to handle the expected fuel pressure.

- Route the lines away from heat sources like exhaust manifolds or headers.

- Consider Mounting Options: Decide where to mount the fuel lines to ensure they remain secure and flexible. Common mounting points include the firewall, frame rails, or custom brackets. Ensure the mounts are sturdy enough to withstand engine vibrations and temperature changes.

- Check for Clearances: As you route the fuel lines, ensure they have adequate clearance from moving parts. This is crucial to prevent damage during engine operation and movement. Check for clearance around the transmission, driveshaft, and any other components that might come into contact with the lines over time.

Remember, the goal is to create a route that is both functional and durable. Proper planning will ensure that the fuel lines perform optimally and contribute to the overall reliability of your 1971 Chevy truck.

Safe and Effective Methods to Thaw Frozen Car Fuel Lines

You may want to see also

Clamps and Fittings: Choose appropriate clamps and fittings for secure connections

When working on fuel lines for a 1971 Chevy truck, selecting the right clamps and fittings is crucial for ensuring a secure and reliable fuel system. The goal is to create a tight, leak-free connection that can withstand the rigors of the road. Here's a detailed guide on choosing the appropriate clamps and fittings:

Understanding the System: Begin by familiarizing yourself with the specific fuel lines and components of your 1971 Chevy truck. Different fuel lines may have varying diameters and materials, so it's essential to identify the exact parts you're working with. Common materials for fuel lines include rubber, vinyl, or braided steel, each with its own advantages and compatibility.

Clamps: Clamps are the primary means of securing fuel lines to various components like the fuel tank, engine, and chassis. For this truck model, consider the following:

- Size and Material: Choose clamps that match the diameter of your fuel lines. Rubber or vinyl fuel lines often use rubber or vinyl clamps, while steel-braided lines might require stainless steel or brass clamps to ensure a tight grip without damaging the line.

- Adjustability: Look for adjustable clamps that can accommodate slight variations in line thickness. This feature ensures a secure fit without causing unnecessary strain on the fuel line.

- Durability: Opt for high-quality clamps that can withstand fuel temperatures and engine heat. Stainless steel or brass clamps are excellent choices for their corrosion resistance and longevity.

Fittings: Fittings are essential for connecting fuel lines to various components, such as fuel pumps, filters, and injectors. Here's how to select the right fittings:

- Thread Compatibility: Ensure the fittings match the thread size and type of your fuel lines. Common thread types include AN (aviation) and SAE (Society of Automotive Engineers) threads.

- Material and Finish: Fittings should be made from durable materials like stainless steel or aluminum to resist corrosion. Consider the finish as well; zinc plating or chrome plating can provide additional protection against wear.

- Flow Rate and Pressure: If your fuel system involves high-pressure or high-flow applications, choose fittings designed to handle these demands. Look for fittings with larger bore sizes and robust construction.

Installation Considerations: When installing clamps and fittings, follow these tips:

- Always clean the surfaces before applying clamps to ensure a proper bond.

- Avoid overtightening clamps, as this can damage the fuel lines. Use the appropriate tools to apply the necessary force.

- For fittings, ensure a tight connection by hand or with a wrench, but be careful not to overtighten, which can strip threads.

- Regularly inspect and replace worn or damaged clamps and fittings to maintain the integrity of your fuel system.

By carefully selecting the right clamps and fittings, you'll create a robust and reliable fuel system for your 1971 Chevy truck, ensuring optimal performance and peace of mind on the road. Remember, proper installation and regular maintenance are key to a long-lasting fuel system.

Unveiling the Mystery: The Essential Metal Tool for Fuel Line Disconnects

You may want to see also

Fuel Pump Installation: Mount the fuel pump and ensure proper fuel flow

When installing a fuel pump in your 1971 Chevy truck, it's crucial to follow a systematic approach to ensure a successful and safe setup. Here's a step-by-step guide to help you with the fuel pump installation and proper fuel flow management:

Mounting the Fuel Pump:

- Begin by locating the ideal position for your fuel pump. Typically, it should be mounted near the fuel tank or close to the engine for easier access and optimal performance. Ensure that the pump is securely attached to the vehicle's frame or a suitable mounting bracket to prevent vibrations and maintain stability.

- Connect the fuel pump to the fuel tank using appropriate fittings and hoses. The pump should be positioned in a way that allows for easy access to the necessary connections and provides a clear path for fuel flow.

- Use a suitable mounting system or brackets to secure the fuel pump in place. This step is essential to ensure the pump remains stable and does not move or vibrate excessively during operation, which could lead to premature wear and potential fuel leaks.

Ensuring Proper Fuel Flow:

- After mounting the pump, inspect the fuel lines for any potential issues. The lines should be free of kinks, bends, or any obstructions that might restrict fuel flow. Ensure that the lines are routed away from hot engine components to prevent damage and potential fuel vaporization.

- Check the fuel filter and ensure it is clean and free of debris. A clogged filter can restrict fuel flow and cause engine performance issues. Consider replacing the filter if it shows signs of wear or contamination.

- Verify that the fuel pump is functioning correctly by starting the engine and monitoring the fuel pressure. Use a fuel pressure gauge to check the pressure at different engine speeds. The pressure should be within the recommended range as specified by the vehicle's manufacturer.

- Inspect the fuel lines for any signs of leaks or damage. Tighten connections and replace any damaged lines to maintain a secure and efficient fuel supply.

Remember, proper mounting and fuel flow management are critical to the overall performance and longevity of your fuel system. Take the time to inspect and adjust the fuel pump and lines to ensure a smooth and reliable operation for your 1971 Chevy truck.

Fuel Line Sizing for Gokart Performance: A Comprehensive Guide

You may want to see also

Testing: Check for leaks and proper fuel pressure after installation

After completing the installation of the fuel lines on your 1971 Chevy truck, it's crucial to conduct a thorough testing process to ensure everything is functioning correctly and safely. The primary focus of this test is to check for any leaks and to verify that the fuel pressure is within the optimal range. Here's a step-by-step guide to help you through this process:

Step 1: Visual Inspection

Start by visually inspecting the fuel lines for any signs of damage, cracks, or kinks. Look for any areas where the lines might have been pinched or damaged during the installation process. Ensure that all connections are secure and that there are no visible leaks around the fittings. This initial check is essential as it can help identify potential issues before they become more serious problems.

Step 2: Leak Test

To check for leaks, you can use a simple method by starting the engine and spraying a soapy water mixture around the fuel lines. The mixture typically consists of dish soap and water. If you notice any bubbles forming on the surface of the lines, it indicates a leak. Bubbles signify that fuel is escaping at that particular point. Make sure to check all connections, including the fuel pump, injectors, and the fuel tank. If a leak is found, carefully tighten any loose fittings or consider replacing damaged sections.

Step 3: Fuel Pressure Measurement

Checking the fuel pressure is vital to ensure your engine receives the correct amount of fuel. You can use a fuel pressure gauge for this test. Start by locating the fuel pressure sensor, which is usually connected to the fuel pump. Disconnect the sensor and attach the gauge in its place. Turn on the engine and allow it to idle. Read the fuel pressure value on the gauge; it should be within the manufacturer's specified range for your truck model. If the pressure is too low, it could indicate a problem with the fuel pump or a restricted fuel line. If it's too high, you might need to adjust the fuel pressure regulator.

Step 4: Engine Performance Check

After addressing any leaks and ensuring proper fuel pressure, it's a good idea to start the engine and perform a basic check. Let the engine idle and observe for any unusual noises or vibrations. Check for any signs of fuel vapor escaping from the exhaust or other unusual emissions. If everything is functioning correctly, your truck should start smoothly and run without any issues.

Remember, proper testing is critical to the success of your fuel line installation. It ensures that your 1971 Chevy truck will run efficiently and safely, providing you with a reliable and enjoyable driving experience.

Determine Your Fuel Line Tube Size: A Quick Guide

You may want to see also

Frequently asked questions

Running fuel lines on a classic truck like the 1971 Chevy is a great project to improve performance and reliability. Here's a step-by-step guide: First, ensure you have the correct fuel line kit for your specific engine and truck model. Then, start by disconnecting the old fuel lines from the fuel tank and engine. Clean the fittings and ensure they are free of debris. Next, route the new fuel lines, typically following the original path, and secure them with ties or clips to prevent tangling. Make sure to use fuel-resistant clamps and ensure a tight seal. Finally, reconnect the lines to the fuel pump and engine, double-checking for any leaks.

For a 1971 Chevy truck, it's recommended to use high-quality rubber or silicone fuel lines. These materials are known for their durability and resistance to fuel degradation over time. You can find these lines in various sizes, so measure the existing lines or consult a diagram to determine the appropriate diameter. Opt for a slightly larger size to allow for some expansion and to ensure a secure fit.

While universal fuel lines might be tempting for a cost-effective solution, it's generally not recommended for a 1971 Chevy truck. Universal lines may not fit perfectly and could lead to issues with fuel pressure and engine performance. It's best to source fuel lines specifically designed for your truck's engine and year to ensure a proper fit and reliable fuel delivery.