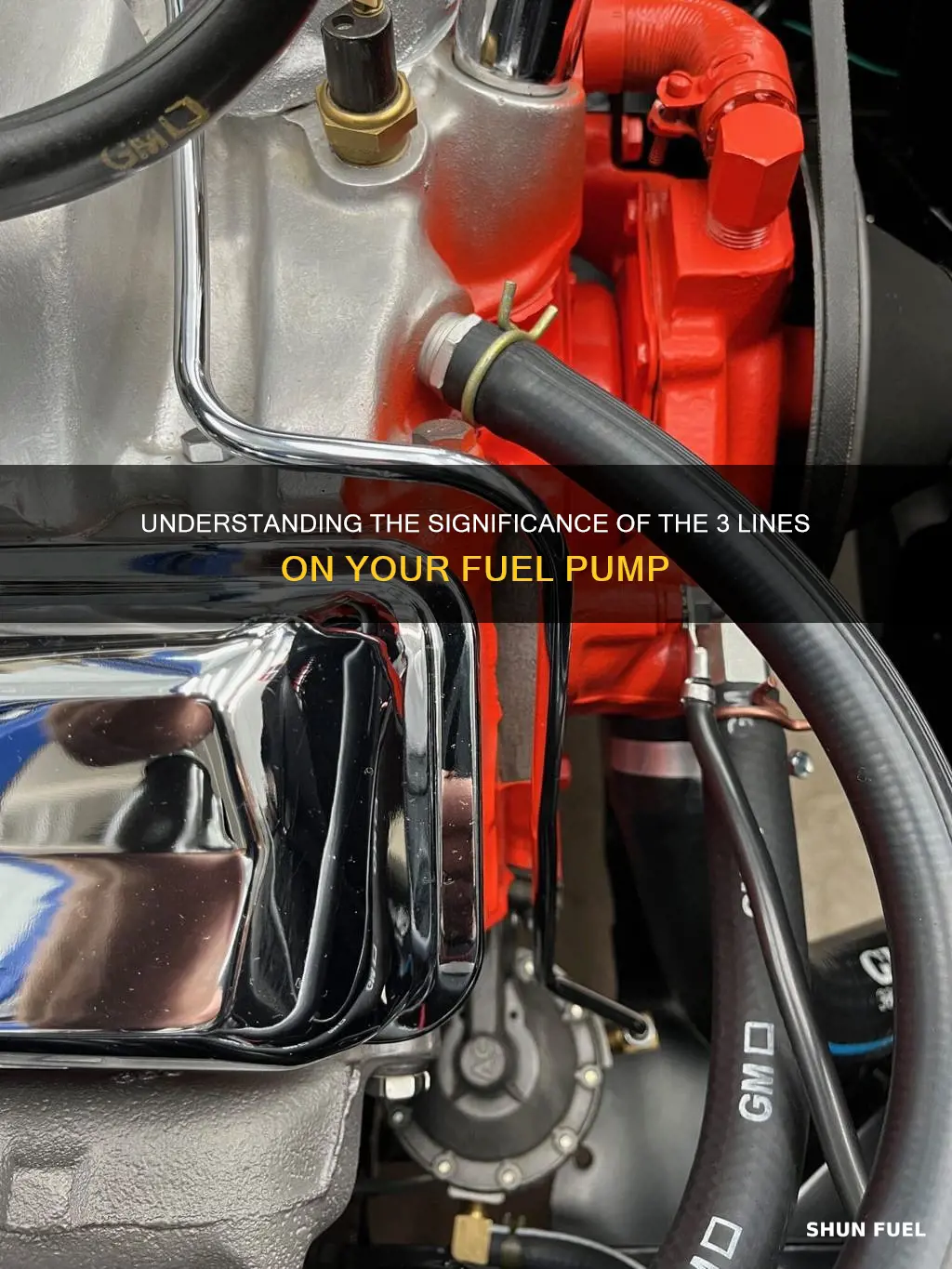

The three lines on a fuel pump are essential components that play a crucial role in the fuel delivery system of a vehicle. These lines, often referred to as the fuel lines, are responsible for transporting fuel from the tank to the engine. The primary function of these lines is to ensure a steady and controlled flow of fuel, allowing the engine to operate efficiently. Each line serves a specific purpose, such as providing a path for the fuel to travel, preventing fuel leaks, and maintaining the pressure required for optimal engine performance. Understanding the significance of these lines is vital for vehicle owners and mechanics to ensure proper maintenance and troubleshooting of the fuel system.

What You'll Learn

- Fuel Pump Components: The three lines on a fuel pump are typically the inlet, outlet, and return lines

- Fuel Flow Control: These lines regulate the flow of fuel from the tank to the engine

- Pressure Regulation: The lines help maintain proper fuel pressure for efficient operation

- Vacuum System: They are connected to the engine's vacuum system for fuel delivery

- Fuel Filter: The lines pass through a filter to ensure clean fuel reaches the engine

Fuel Pump Components: The three lines on a fuel pump are typically the inlet, outlet, and return lines

The three lines on a fuel pump are essential components that facilitate the transfer of fuel from the tank to the engine. These lines are crucial for maintaining the proper functioning of the fuel system and ensuring optimal engine performance. Understanding the roles of these lines is vital for anyone working on a vehicle's fuel system.

The first line, the inlet line, is responsible for delivering fuel from the fuel tank to the pump. It is typically a small-diameter tube that connects the pump's suction side to the tank's fuel level sensor. This line ensures that the pump receives the required amount of fuel to meet the engine's demands. When the engine is running, the inlet line allows fuel to flow into the pump, creating a continuous supply of energy to the engine.

Moving on to the second line, the outlet line, it plays a critical role in directing the fuel from the pump to the engine. This line is usually larger in diameter compared to the inlet line and is designed to handle the higher pressure generated by the pump. The outlet line connects the pump's discharge side to the engine's fuel injectors or carburetor. As the pump draws fuel from the tank, it increases the pressure, and the outlet line ensures that this pressurized fuel reaches the engine, where it is ignited to power the vehicle.

Lastly, the return line completes the fuel circuit by transporting any excess fuel back to the tank. This line is often overlooked but is equally important for maintaining the system's efficiency. The return line connects the pump's discharge side to the tank, allowing any unused or excess fuel to be recycled. This process ensures that the fuel level in the tank remains stable and that the pump operates within optimal parameters.

In summary, the three lines on a fuel pump—inlet, outlet, and return—work in harmony to deliver fuel from the tank to the engine and manage the fuel flow efficiently. Understanding these components and their functions is essential for mechanics and car enthusiasts alike, as it enables proper maintenance and troubleshooting of the fuel system, ensuring the vehicle's engine operates smoothly and reliably.

Nova Fuel Tank Lines: Unlocking Engine Power and Efficiency

You may want to see also

Fuel Flow Control: These lines regulate the flow of fuel from the tank to the engine

The three lines on a fuel pump are essential components that ensure the efficient and safe operation of a vehicle's fuel system. These lines play a critical role in regulating the flow of fuel from the tank to the engine, and understanding their functions is crucial for maintaining a vehicle's performance and longevity.

The first line, often referred to as the fuel supply line, is responsible for delivering fuel from the tank to the pump. This line is typically made of durable materials like steel or aluminum to withstand the pressure and temperature variations associated with fuel transport. It is designed to handle the volume of fuel required by the engine and is crucial for ensuring a steady supply of fuel to the pump.

The second line, known as the return line, plays a vital role in maintaining the pressure and quality of the fuel within the system. This line is connected to the pump and is responsible for returning any excess fuel or air to the tank. It helps to prevent fuel accumulation in the lines, which could lead to engine performance issues. The return line is often equipped with a filter to trap contaminants and ensure that only clean fuel re-enters the tank.

The third line, the pressure regulating line, is a critical component that manages the pressure within the fuel system. This line is designed to maintain optimal fuel pressure, ensuring that the engine receives the correct amount of fuel at the right pressure. It often includes a pressure regulator, which adjusts the fuel pressure based on engine load and speed. This line is essential for efficient combustion and engine performance, as it prevents over-pressure, which could damage the engine, and under-pressure, which could lead to poor performance.

These three lines work in harmony to ensure a continuous and controlled flow of fuel from the tank to the engine. Proper maintenance and regular checks of these lines are essential to prevent fuel-related issues and ensure the vehicle's overall reliability. Understanding the functions of these lines can empower vehicle owners to take proactive measures in maintaining their fuel systems.

Unveiling the Material Secrets of Metal Fuel Lines

You may want to see also

Pressure Regulation: The lines help maintain proper fuel pressure for efficient operation

The three lines on a fuel pump play a crucial role in ensuring optimal performance and efficient operation. One of the primary functions of these lines is pressure regulation, which is essential for maintaining the correct fuel pressure within the engine system. Proper fuel pressure is critical for the engine to operate efficiently and deliver optimal performance.

The lines are designed to manage the flow of fuel from the tank to the engine, ensuring a steady and controlled supply. The first line, often referred to as the suction line, draws fuel from the tank and transports it to the pump. This line is crucial as it initiates the process of fuel delivery, ensuring a continuous supply of fuel to the pump. The second line, the pressure line, carries the fuel under pressure from the pump to the engine. This line is vital for maintaining the required fuel pressure, which is typically measured in pounds per square inch (psi). The third line, the return line, is responsible for recycling the excess fuel that is not used by the engine. This line prevents fuel wastage and ensures that the fuel system operates efficiently.

The pressure regulation function of these lines is achieved through a combination of design and control mechanisms. The pump's internal components, such as the impeller and diffuser, create a pressure differential that draws fuel into the pump and then increases its pressure. This regulated pressure is then directed through the pressure line to the engine's fuel injectors or carburetor. The precision of this process is critical, as it ensures that the engine receives the correct amount of fuel at the right pressure, optimizing combustion and performance.

In addition to pressure regulation, these lines also contribute to the overall efficiency of the fuel system. By maintaining proper pressure, the engine can operate at its peak, resulting in improved fuel economy and reduced emissions. The lines' design and placement are carefully considered to minimize fuel loss and ensure a consistent supply, further enhancing the system's efficiency.

Understanding the role of these lines in pressure regulation is essential for maintaining and troubleshooting fuel pump systems. Regular inspection and maintenance of these lines can help ensure that the fuel pump operates efficiently, providing the engine with the necessary fuel pressure for optimal performance. This knowledge is particularly valuable for mechanics and car enthusiasts who aim to optimize their vehicle's fuel system.

VXR Pro 93 Fuel Line: Dimensions and Specifications

You may want to see also

Vacuum System: They are connected to the engine's vacuum system for fuel delivery

The vacuum system plays a crucial role in the fuel delivery process of an engine, and it is often connected to the fuel pump via a network of lines. These lines are an essential component of the engine's vacuum system, which harnesses the power of the engine's internal combustion to create a vacuum. This vacuum is then utilized to assist in the fuel injection process, ensuring efficient and precise fuel delivery.

The three lines connected to the fuel pump are typically referred to as the vacuum lines or the vacuum ports. These lines are designed to carry the engine's vacuum, which is created by the movement of air and fuel within the engine's cylinders. The vacuum lines are usually made of a flexible material, such as rubber or silicone, to accommodate the engine's vibrations and movements during operation.

One of the primary functions of these vacuum lines is to provide a controlled and consistent vacuum source for the fuel pump. The fuel pump is responsible for drawing fuel from the tank and delivering it to the engine's injectors or carburetor. By connecting the fuel pump to the engine's vacuum system, the pump can utilize the vacuum to create a negative pressure, which helps in drawing the fuel through the lines and into the engine. This process ensures that the fuel is delivered efficiently and at the right pressure, optimizing engine performance.

Additionally, the vacuum lines also serve as a means of communication between the engine and the fuel pump. They allow the engine to monitor the fuel pressure and adjust the vacuum accordingly. This feedback system ensures that the engine receives the correct amount of fuel, maintaining optimal performance and fuel efficiency. The vacuum lines are carefully routed to avoid any obstructions or restrictions, as this could impact the engine's ability to function properly.

In summary, the vacuum system's connection to the fuel pump is a critical aspect of engine design. The three vacuum lines provide the necessary vacuum source for fuel delivery, ensuring efficient and precise fuel injection. This setup allows the engine to harness the power of its own vacuum to optimize performance and fuel economy. Proper maintenance and inspection of these vacuum lines are essential to guarantee the engine's reliable operation.

Unveiling the Mystery: Small Lines Behind Fuel Filter in Cadillac SRX

You may want to see also

Fuel Filter: The lines pass through a filter to ensure clean fuel reaches the engine

The fuel pump is a critical component in any vehicle's fuel system, and its function is to deliver gasoline from the tank to the engine at the precise pressure required for efficient combustion. While the pump itself is a vital part, it's the fuel filter that plays a crucial role in maintaining the health and longevity of the engine.

The fuel lines, often referred to as the 'fuel filter lines', are the pathways that carry gasoline from the pump to the engine. These lines are typically made of durable materials like rubber or plastic and are designed to withstand the pressure and temperature variations encountered during operation. The primary purpose of these lines is to provide a continuous and reliable supply of fuel while also protecting the engine from contaminants.

As the fuel passes through these lines, it encounters the fuel filter, a crucial component in the fuel system. The filter is designed to trap and remove impurities, such as dirt, rust, and other debris, that may be present in the fuel. This is essential because even small amounts of contaminants can cause significant damage to the engine over time. The filter acts as a barrier, ensuring that only clean, high-quality fuel reaches the engine's combustion chambers.

The fuel filter is strategically positioned in the fuel line to allow for easy maintenance and replacement. This placement ensures that the filter can be easily accessed without disrupting the entire fuel system. Regular replacement of the fuel filter is recommended to maintain optimal engine performance and longevity. Over time, the filter can become clogged with contaminants, reducing its effectiveness. By replacing it at regular intervals, you ensure a continuous supply of clean fuel, promoting efficient engine operation.

In summary, the fuel filter is a vital component that works in conjunction with the fuel lines to ensure the engine receives clean and high-quality fuel. This simple yet effective mechanism is a key factor in maintaining engine health and performance, making it an essential aspect of vehicle maintenance. Understanding the role of the fuel filter and its integration with the fuel lines can help vehicle owners make informed decisions regarding their car's maintenance routine.

Understanding the Three Fuel Lines in an Engine: A Comprehensive Guide

You may want to see also

Frequently asked questions

The three lines on a fuel pump are typically color-coded and indicate different fuel types that the pump can handle. The most common colors are red, green, and yellow, representing gasoline, diesel, and other fuel types like aviation fuel. It's important to check the fuel pump's specifications and the vehicle's manual to ensure you are using the correct fuel.

The vehicle's manual or the fuel pump's label will provide clear instructions on which line to use. For example, if your car requires gasoline, you should connect it to the red line. If it's a diesel engine, you'll use the green line. These lines are designed to prevent cross-contamination and ensure your vehicle receives the appropriate fuel.

Yes, using the wrong fuel can cause significant issues with your vehicle's performance and even lead to engine damage. If you accidentally connect the wrong fuel to the fuel pump, it may not be immediately noticeable, but over time, it can result in engine problems. Always double-check the fuel type and line connections to avoid any potential harm to your vehicle.