A fuel impulse line is a crucial component in the fuel system of an engine, particularly in diesel engines. It serves as a vital link between the fuel tank and the fuel injectors, ensuring a steady and controlled supply of fuel to the engine. This line is designed to transmit fuel under pressure, allowing for precise injection timing and quantity, which is essential for optimal engine performance and efficiency. The impulse line plays a critical role in maintaining the engine's power output and overall reliability by ensuring a consistent and accurate fuel delivery process.

| Characteristics | Values |

|---|---|

| Definition | A fuel impulse line is a component in fuel injection systems, typically found in automotive applications. It is responsible for delivering high-pressure fuel from the fuel pump to the fuel injectors. |

| Function | To provide a precise and controlled amount of fuel to the engine's cylinders, ensuring optimal combustion and performance. |

| Pressure Regulation | It regulates the fuel pressure to maintain a consistent and accurate fuel-air mixture for efficient engine operation. |

| Impulse Control | The line is designed to create a 'fuel impulse' by rapidly opening and closing a valve, which helps in atomizing the fuel and improving spray quality. |

| Material | Often made of high-strength materials like steel or aluminum to withstand high pressure and temperature. |

| Design | Features a small diameter and a flexible construction to accommodate the rapid pressure changes and ensure efficient fuel delivery. |

| Applications | Common in modern gasoline and diesel engines, especially those with electronic fuel injection systems. |

| Advantages | Offers improved engine performance, better fuel efficiency, and reduced emissions compared to traditional carbureted systems. |

| Maintenance | Regular inspection and replacement are necessary to ensure optimal performance and prevent engine issues. |

What You'll Learn

- Fuel Impulse Line: Delivers fuel from the pump to the engine under high pressure

- Pressure Regulation: Maintains consistent fuel pressure to ensure optimal engine performance

- Fuel Atomization: Breaks down fuel into fine droplets for efficient combustion

- Flow Control: Regulates fuel flow rate to match engine demands

- Safety Mechanisms: Includes shut-off valves to prevent fuel leaks and ensure safety

Fuel Impulse Line: Delivers fuel from the pump to the engine under high pressure

The fuel impulse line is a critical component in the fuel delivery system of an engine, particularly in high-performance applications. Its primary function is to transport fuel from the fuel pump to the engine under high pressure, ensuring a precise and controlled supply of fuel to the combustion chambers. This high-pressure delivery is essential for efficient engine operation, especially in racing or high-load conditions where maximum power output is required.

In the context of an engine's fuel system, the impulse line acts as a conduit, connecting the fuel pump, which is typically located in the engine compartment, to the fuel injectors or carburetor. The pump's role is to increase the fuel pressure, often to several hundred or even a thousand psi, which is significantly higher than atmospheric pressure. This elevated pressure is necessary to overcome the resistance in the fuel lines and ensure that fuel reaches the engine at the required rate and volume.

The design of the fuel impulse line is crucial to maintaining this high pressure. It is typically constructed with a sturdy, flexible material that can withstand the pressure differentials and potential vibrations during engine operation. The line's diameter and length are carefully chosen to minimize pressure drops and ensure efficient fuel flow. Engineers often design these lines with multiple small-diameter passages to increase the surface area, which helps in reducing the pressure loss due to friction and turbulence.

When the engine is running, the fuel pump operates continuously, maintaining the high pressure in the impulse line. This pressure ensures that fuel is delivered directly to the engine's combustion chambers, where it is injected or mixed with air for combustion. The precise control of fuel delivery is vital for optimal engine performance, as it directly impacts power output, fuel efficiency, and emissions.

In summary, the fuel impulse line is a high-pressure fuel delivery system that plays a critical role in engine performance. Its design and functionality ensure that fuel is supplied efficiently and effectively to the engine, enabling it to produce the required power while maintaining optimal fuel economy and emissions standards. Understanding the role of this component is essential for anyone working on high-performance engines or seeking to optimize their vehicle's fuel system.

Choosing the Right Diameter Fuel Line for Your Yamaha Outboard

You may want to see also

Pressure Regulation: Maintains consistent fuel pressure to ensure optimal engine performance

A fuel impulse line is a critical component in the fuel delivery system of an engine, specifically designed to regulate and maintain consistent fuel pressure. This is a crucial function as it directly impacts the engine's performance, efficiency, and overall reliability. The primary role of the fuel impulse line is to ensure that the engine receives the correct amount of fuel at the right pressure, which is essential for optimal combustion and power output.

In an internal combustion engine, fuel pressure must be carefully managed to achieve the best possible performance. If the pressure is too low, the engine may not receive enough fuel, leading to poor acceleration, reduced power, and potential misfires. On the other hand, excessive fuel pressure can result in fuel spray issues, causing uneven combustion and potential engine damage. The fuel impulse line addresses this challenge by providing a controlled and consistent fuel supply.

The design of the fuel impulse line involves a series of precise components. It typically includes a fuel pump, a pressure regulator, and a series of filters to ensure clean fuel delivery. The pump draws fuel from the tank and increases its pressure, preparing it for the engine. The pressure regulator then maintains a steady pressure within a specified range, ensuring that the fuel is neither too strong nor too weak. This regulation is vital as it prevents the engine from receiving inconsistent fuel pressure, which could lead to performance issues.

By maintaining consistent fuel pressure, the fuel impulse line contributes to several key aspects of engine performance. Firstly, it ensures a more efficient combustion process, where the fuel-air mixture is precisely controlled, leading to better power output and reduced emissions. Secondly, consistent pressure helps in maintaining a stable engine operation, reducing the likelihood of stalling or sudden performance drops. This is particularly important in high-performance applications where engine response and reliability are critical.

In summary, the fuel impulse line's primary function is to regulate fuel pressure, ensuring that the engine operates with the correct amount of fuel at the right pressure. This regulation is essential for optimal engine performance, efficiency, and longevity. By carefully managing fuel pressure, the impulse line contributes to a well-balanced and responsive engine, making it a vital component in the overall fuel delivery system. Understanding its role highlights the importance of maintaining and regularly inspecting this system to ensure the engine's best possible performance.

C1500 Fuel Lines: A Comprehensive Guide to Identification

You may want to see also

Fuel Atomization: Breaks down fuel into fine droplets for efficient combustion

Fuel atomization is a critical process in internal combustion engines, where the fuel is broken down into extremely fine droplets to enhance combustion efficiency. This process is essential for optimizing engine performance and reducing emissions. When fuel is atomized, it increases the surface area of the fuel, allowing for more efficient mixing with air and subsequent combustion.

The primary goal of fuel atomization is to ensure that the fuel-air mixture is as homogeneous as possible before it enters the combustion chamber. This homogeneity is crucial because it directly impacts the combustion process. Incomplete combustion can lead to the formation of harmful byproducts, such as carbon monoxide and unburned hydrocarbons, which contribute to air pollution. By breaking the fuel into tiny droplets, atomization ensures that the fuel is evenly distributed, allowing for more complete and efficient burning.

This process is typically achieved using a fuel atomizer, which can be a mechanical device or an electronic sprayer. In older engines, mechanical atomizers, such as the fuel pump and injectors, were commonly used. These devices used the engine's pressure to atomize the fuel. However, with advancements in technology, electronic fuel injectors have become more prevalent. These injectors use precise electrical signals to control the fuel spray, allowing for even greater control over the atomization process.

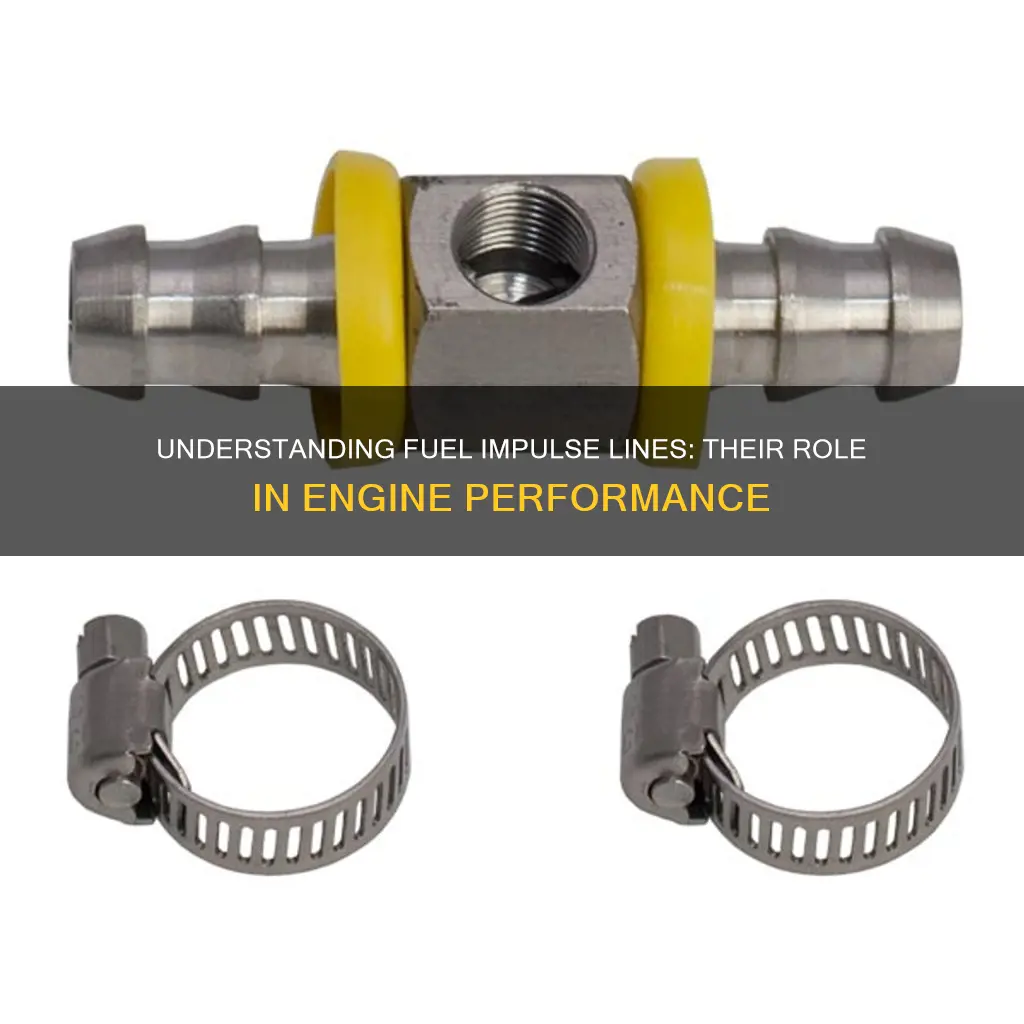

The fuel impulse line plays a vital role in this system. It is a high-pressure line that carries the fuel from the fuel tank or reservoir to the fuel injectors or atomizers. The impulse line ensures that the fuel is delivered at the required pressure and flow rate to the atomization device. This high-pressure fuel delivery system is designed to create a fine spray of fuel, which then undergoes further atomization within the engine's intake system.

By breaking down the fuel into fine droplets, the engine can achieve more efficient combustion, resulting in improved power output and reduced emissions. This process is particularly important in modern engines, where the demand for higher performance and lower environmental impact is ever-increasing. Fuel atomization is a key enabler in meeting these challenges, ensuring that engines can operate efficiently while minimizing their environmental footprint.

Exploring Rubber Fuel Line Hose Sizes: A Comprehensive Guide

You may want to see also

Flow Control: Regulates fuel flow rate to match engine demands

A fuel impulse line is a critical component in the fuel injection system of an engine, and its primary function is to regulate the fuel flow rate to match the engine's demands. This precise control is essential for optimal engine performance, ensuring that the right amount of fuel is delivered to the combustion chamber at the right time. The process begins with the fuel pump, which draws fuel from the tank and sends it through the impulse line to the fuel pressure regulator. This regulator is a key element in flow control, as it maintains a consistent fuel pressure within the system. By adjusting the pressure, it ensures that the fuel flow rate is regulated to meet the engine's requirements.

The impulse line itself is designed to provide a controlled and consistent fuel supply. It is typically made of a flexible material that can withstand high pressure and temperature, allowing it to transmit fuel efficiently while maintaining its structural integrity. The line's design often includes a series of small orifices or nozzles that further regulate the fuel flow. These orifices are carefully calibrated to restrict fuel passage, ensuring that the fuel exits the line at a precise rate, which is crucial for accurate fuel injection.

In the context of engine operation, the fuel flow rate must be adjusted rapidly to accommodate changing demands. For instance, during acceleration, the engine requires more fuel to meet the increased power demand. The fuel impulse line, in conjunction with the pressure regulator, responds swiftly to these changes. It modulates the fuel flow, ensuring that the engine receives the necessary amount of fuel without wastage or excess, which could lead to inefficient combustion or engine knock.

This regulation is particularly important in high-performance engines or those with variable valve timing and lift systems. These engines demand precise fuel injection timing and amount to optimize power output and fuel efficiency. The fuel impulse line's role in flow control becomes even more critical in such cases, as it directly impacts the engine's performance and longevity. By maintaining a steady and controlled fuel flow, it helps prevent issues like engine misfires, reduced power, and increased emissions.

In summary, the fuel impulse line's primary function is to act as a regulator of the fuel flow rate, ensuring that the engine receives the exact amount of fuel required at any given moment. This control is vital for maintaining engine performance, efficiency, and longevity, especially in modern vehicles with advanced fuel injection systems. Understanding and optimizing the design of the impulse line can lead to significant improvements in engine technology and overall vehicle performance.

Unveiling the Material Secrets of Diesel Fuel Lines

You may want to see also

Safety Mechanisms: Includes shut-off valves to prevent fuel leaks and ensure safety

A fuel impulse line is a critical component in the fuel delivery system of an engine, and its primary function is to ensure a precise and controlled supply of fuel to the engine's combustion chamber. This system is designed to maintain optimal fuel pressure and flow, which is essential for efficient engine operation and performance. One of the key safety mechanisms incorporated into fuel impulse lines is the use of shut-off valves. These valves play a crucial role in preventing fuel leaks and ensuring the overall safety of the fuel system.

The shut-off valves are strategically placed along the fuel impulse line, often at strategic points where potential leakages could occur. These valves are designed to close automatically or be manually operated to cut off the fuel supply in case of any issues or emergencies. By implementing this mechanism, engineers aim to minimize the risk of fuel leaks, which can have severe consequences, including engine damage, fire hazards, and environmental pollution. In the event of a malfunction or accident, the shut-off valves act as a failsafe, preventing the release of fuel and potential disasters.

These valves are typically made of durable materials that can withstand high pressure and temperature, ensuring their reliability and longevity. They are often equipped with advanced sealing technologies to create an airtight connection, further reducing the chances of fuel escaping. When the valves are closed, they create a secure barrier, preventing any fuel from flowing through the line, thus maintaining the integrity of the fuel system. This feature is especially important in high-performance engines or applications where fuel is under extreme conditions.

In addition to the shut-off valves, fuel impulse lines may also incorporate other safety features such as pressure regulators and filters. Pressure regulators help maintain a consistent fuel pressure, ensuring that the engine receives the correct amount of fuel at all times. Filters, on the other hand, trap contaminants and prevent them from entering the engine, further enhancing the safety and performance of the fuel system. These additional mechanisms work in conjunction with the shut-off valves to provide a comprehensive safety net.

In summary, the inclusion of shut-off valves in fuel impulse lines is a vital safety measure to prevent fuel leaks and potential disasters. These valves, along with other safety mechanisms, contribute to the overall reliability and efficiency of the fuel delivery system. By implementing such advanced designs, engineers ensure that engines operate safely and optimally, even in challenging conditions. Understanding and appreciating these safety features are essential for maintaining and optimizing the performance of any fuel-powered system.

Unraveling the Mystery: Understanding Fuel Pump Line Requirements

You may want to see also

Frequently asked questions

A fuel impulse line is a component in internal combustion engines, particularly in diesel engines, that plays a crucial role in the fuel injection process. It is a high-pressure fuel line that delivers fuel from the fuel pump to the injectors, ensuring precise and timely fuel delivery.

The fuel impulse line acts as a conduit for high-pressure fuel, which is generated by the fuel pump. It is designed to withstand the extreme pressure and temperature conditions within the engine. When the engine is running, the fuel pump creates a pulsating flow of fuel, and the impulse line transmits this pulsation to the injectors, ensuring efficient and accurate fuel injection.

In diesel engines, the fuel impulse line is essential for achieving proper combustion. It ensures that the fuel is injected at the correct timing and pressure, allowing for efficient burning of the fuel-air mixture. This results in improved engine performance, reduced emissions, and better overall efficiency.

A damaged or faulty fuel impulse line can lead to significant engine performance issues. If the line is cracked, leaking, or has reduced pressure, it may result in improper fuel injection. This can cause engine misfires, reduced power, poor fuel economy, and even potential engine damage over time. Regular maintenance and inspection of the fuel impulse line are necessary to prevent such problems.

Maintaining the fuel impulse line involves regular checks for any signs of damage, corrosion, or leaks. It is recommended to inspect the line for any visible wear and tear, especially in areas prone to heat and pressure. Proper fuel filter maintenance and regular engine servicing can also help ensure the longevity and optimal performance of the fuel impulse line.