If you're a homeowner with a push mower, you may have encountered the frustration of tight fuel lines, which can hinder your lawn care routine. Removing these tight fuel lines is a crucial step in maintaining your mower's performance and longevity. This guide will provide a step-by-step process to safely and effectively remove these fuel lines, ensuring your mower runs smoothly and efficiently.

What You'll Learn

- Identify the Problem: Check for fuel line kinks, clogs, or damage

- Locate the Lines: Find the fuel lines connecting the tank to the engine

- Release Pressure: Disconnect the lines and bleed the system to prevent splashing

- Replace or Repair: Inspect and replace damaged lines or fix clogs

- Reattach and Test: Reattach lines securely and start the mower to ensure proper fuel flow

Identify the Problem: Check for fuel line kinks, clogs, or damage

When dealing with a push mower that seems to have tight fuel lines, the first step is to carefully inspect the fuel system to identify the root cause of the issue. This initial assessment is crucial to ensure you address the problem effectively and safely. Start by examining the fuel lines for any visible signs of damage, such as cracks, leaks, or kinks. Fuel lines are typically made of flexible materials like rubber or plastic, and over time, they can wear out or become damaged due to various factors, including age, exposure to sunlight, or physical impact. Look for any bends or twists in the lines that might indicate a kink, which could restrict fuel flow. Additionally, check for any clogs or blockages that might be causing the fuel lines to feel tight. Debris, dirt, or even a buildup of varnish or fuel residue can obstruct the flow, leading to the perceived tightness.

To check for kinks, hold the fuel line and try to bend it at various points. Ensure that you do not apply excessive force, as this could damage the line. A kinked fuel line will feel stiff and may have a reduced diameter in the bent area. If you identify a kink, carefully straighten it by gently pulling and straightening the line. Be cautious not to over-bend it, as this could lead to a permanent deformation. For clogs, inspect the fuel lines for any visible obstructions. You might need to remove the lines from the mower to get a better view, especially if they are hidden under the machine's body or attached to complex components.

In some cases, the issue might be more subtle. For instance, the fuel pump could be failing, leading to inconsistent fuel delivery and the feeling of tight lines. To check for this, listen to the pump while the engine is running. A weak or failing pump might produce a faint humming or whining sound. If you suspect a pump issue, it's best to consult a professional or refer to the mower's manual for specific troubleshooting steps. Another potential cause of tightness is the accumulation of varnish or fuel residue inside the lines. Over time, these substances can build up, narrowing the passage and restricting fuel flow. Cleaning the fuel lines with a suitable solvent can help resolve this issue.

Identifying the problem through a thorough inspection is essential before proceeding with any repairs or replacements. This initial step ensures that you understand the nature of the fuel line tightness and can take the appropriate actions to resolve it effectively. Remember, proper diagnosis is key to avoiding unnecessary complications and ensuring the longevity of your mower's fuel system.

Fuel Line Break: Engine Chaos Unveiled

You may want to see also

Locate the Lines: Find the fuel lines connecting the tank to the engine

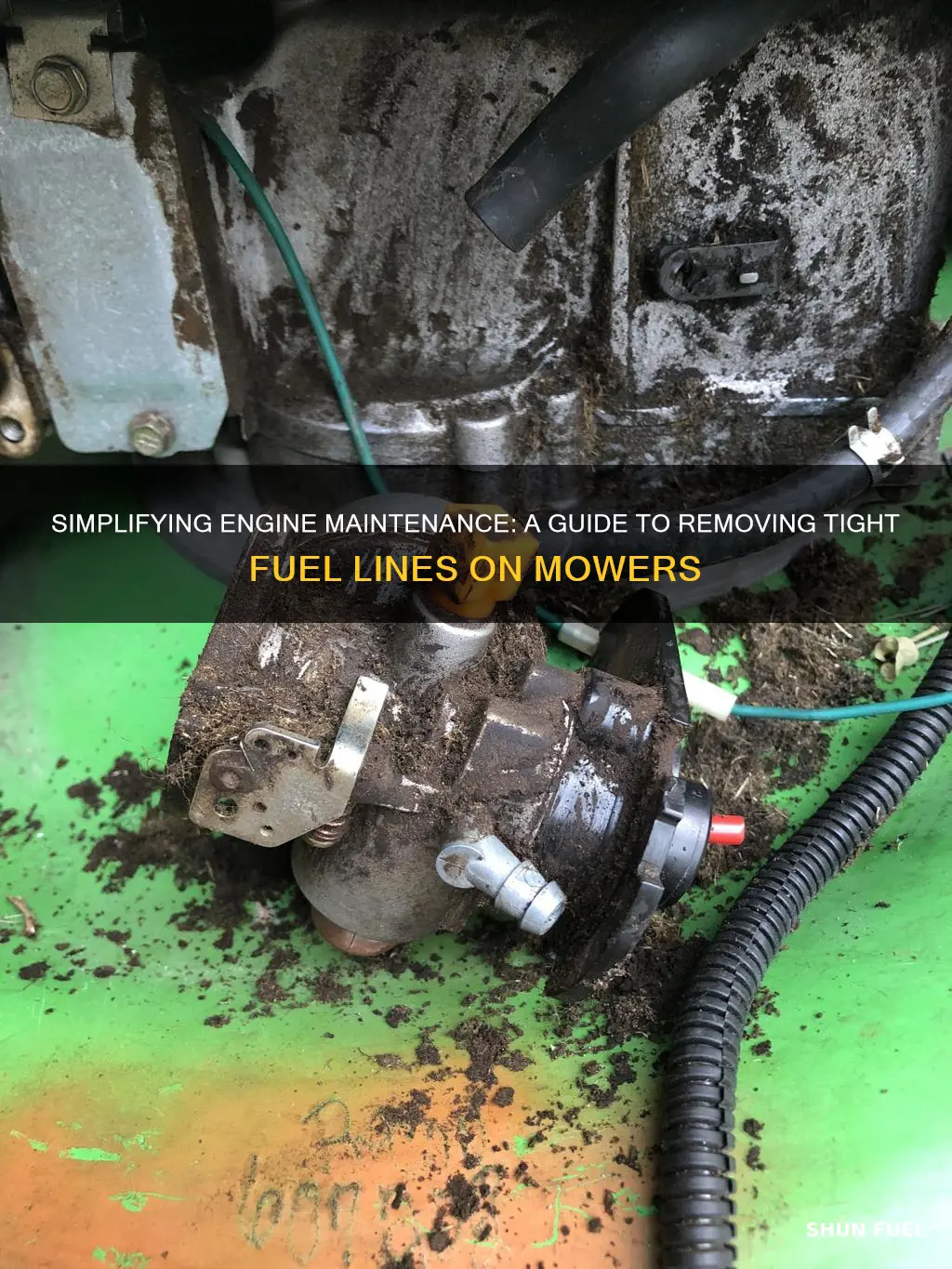

To locate the fuel lines on your push mower, you'll need to inspect the engine and the fuel tank. Start by identifying the fuel tank, which is typically a small, cylindrical container located near the engine. The fuel lines will run from the tank to the engine, delivering gasoline to the carburetor or fuel injection system.

Look for the fuel lines that are connected to the fuel tank. These lines are usually made of rubber or plastic and are often black or dark in color. They may be attached to the tank using clamps or brackets. Carefully inspect the lines for any signs of damage, cracks, or tight bends that could restrict fuel flow.

The fuel lines will then connect to the engine, where they will attach to the carburetor or fuel injection system. The carburetor is a component that mixes air and fuel for combustion, while the fuel injection system delivers fuel directly to the engine's cylinders. Locate the carburetor or fuel injection system, which is usually positioned near the engine's center.

Identify the specific points where the fuel lines connect to the engine. These connections may be in the form of quick-release clips, screws, or fittings. Carefully inspect these connections to ensure they are secure and not damaged. Look for any signs of fuel leakage around these points, as this could indicate a problem with the fuel lines or connections.

Remember to be cautious when handling fuel lines, as they can be fragile. Avoid kinking or bending the lines excessively, as this can lead to fuel restrictions or damage. If you encounter any tight bends or restrictions, consider using a fuel line straightener or a gentle force to release the tension. Always refer to your mower's manual for specific instructions and diagrams to ensure you locate and handle the fuel lines correctly.

Honda XR50 Fuel Line: Size and Compatibility Guide

You may want to see also

Release Pressure: Disconnect the lines and bleed the system to prevent splashing

When dealing with tight fuel lines on a push mower, it's crucial to release the pressure to avoid any potential splashing or damage during the removal process. Here's a step-by-step guide to achieving this:

Disconnect the Fuel Lines: Start by carefully disconnecting the fuel lines from the mower's fuel tank and the engine. Locate the fuel lines, which are typically made of rubber or plastic, and use the appropriate tools to loosen the connections. Ensure you have a clear understanding of the fuel flow direction to avoid any spills.

Bleed the System: After disconnecting the lines, it's essential to bleed the fuel system to release any built-up pressure. This process helps prevent fuel from splashing out when you remove the lines. Locate the fuel filter, which is often a small, cylindrical component attached to the fuel tank or the engine. Place a container or rag beneath the filter to catch any fuel that may drain. Open the fuel filter's bleed valve, usually a small screw or clip, and allow the fuel to drain slowly. This process might require some patience, as it can take a few minutes for the pressure to equalize.

Prevent Splashing: As you work on disconnecting the lines, be mindful of the fuel's potential to splash. To minimize this, gently rock the mower or use a small amount of force to release the tension in the lines. Avoid sudden movements that could cause fuel to spray out. If you notice any fuel leaking, quickly secure the lines with temporary clamps to prevent further splashing.

Safety Precautions: Always exercise caution when working with fuel. Wear protective gear, such as gloves and safety goggles, to avoid skin and eye irritation. Ensure proper ventilation in the work area to minimize inhaling fuel vapor. Keep children and pets away from the work zone to prevent accidental exposure.

By following these steps, you can effectively release the pressure from the fuel lines, ensuring a safer and more controlled process for removing tight fuel lines from your push mower. Remember, taking the time to bleed the system properly will contribute to a successful and safe maintenance task.

Understanding the Fuel Return Line's Route: A Comprehensive Guide

You may want to see also

Replace or Repair: Inspect and replace damaged lines or fix clogs

When dealing with tight fuel lines on a push mower, the first step is to inspect the lines thoroughly. Look for any signs of damage, such as cracks, leaks, or kinks. Check for any blockages or clogs that might be causing the tension. Start by identifying the fuel lines and their connections. Locate the fuel tank and the engine, as these are the primary components you'll be working with. Inspect the lines for any visible damage, especially where they connect to the tank and the engine. If you notice any cracks, leaks, or kinks, it's crucial to replace the affected lines immediately.

If the inspection reveals minor damage or clogs, you can attempt to repair them. For clogs, use a fuel line cleaner or a compressed air bulb to clear the obstruction. Ensure you follow the manufacturer's instructions for any cleaning products used. For minor damage, such as small cracks, you might be able to temporarily fix the issue by applying a fuel line sealant. However, it's essential to replace the line if the damage is significant. When repairing or replacing, ensure you have the correct replacement parts available, as different models may require specific fuel line sizes and types.

For more severe damage or if the inspection reveals multiple issues, it's best to replace the fuel lines entirely. Start by disconnecting the lines from the fuel tank and engine. Carefully remove any old lines, being mindful of any residual fuel that may spill. When installing new lines, ensure they are the correct length and size for your mower model. Secure the connections tightly, but be careful not to overtighten, as this can cause further damage. After replacing the lines, test the mower to ensure the fuel flows freely and the engine runs smoothly.

Remember, working with fuel lines requires caution to avoid spills and potential hazards. Always wear protective gear, and ensure your workspace is well-ventilated. If you're unsure about any step or encounter complex issues, it's advisable to consult a professional or refer to the mower's manual for specific guidance tailored to your model. Regular maintenance and inspections can help prevent such issues and ensure your mower operates efficiently.

Unveiling the Material Secrets of Micro Fuel Lines

You may want to see also

Reattach and Test: Reattach lines securely and start the mower to ensure proper fuel flow

Reattaching the fuel lines after you've loosened them is a crucial step in ensuring your push mower runs smoothly again. Here's a detailed guide on how to do it safely and effectively:

Reattachment Process:

- Prepare Your Workspace: Park your mower on a level surface and engage the parking brake for safety. Gather the necessary tools: a wrench or pliers for tightening, and possibly a fuel line connector kit if you need to replace any damaged parts.

- Reattach Fuel Lines: Carefully reconnect each fuel line to its respective port on the fuel tank and engine. Ensure a snug fit by tightening the connections securely. Use the appropriate tools to avoid over-tightening, which can damage the lines.

- Secure Connections: Double-check that all fuel lines are firmly attached and there are no leaks. Inspect the connections for any signs of damage or wear. If you notice any leaks, tighten the connections further or replace the affected lines.

Testing:

- Start the Engine: Once the fuel lines are reattached and secure, it's time to test the system. Carefully pull the starter cord or turn the key (depending on your mower's ignition system) to start the engine.

- Observe Engine Behavior: Pay close attention to the engine's performance. A properly functioning engine should start smoothly and run without hesitation. Listen for any unusual noises, such as backfires or excessive noise, which could indicate fuel line issues.

- Check for Fuel Flow: While the engine is running, check for fuel flow by placing your finger over the fuel line near the engine. You should feel a steady stream of fuel flowing. If there's no fuel flow, it could indicate a blockage or a line that needs further adjustment.

Troubleshooting:

If the engine doesn't start or runs poorly after reattaching the fuel lines, you may need to inspect for clogs, damaged lines, or issues with the fuel filter. If problems persist, consult your mower's manual or seek professional assistance to ensure a safe and effective repair.

Remember, proper reattachment and testing are essential to prevent fuel-related issues and ensure your mower operates efficiently.

Understanding the Key Differences: Brake vs. Fuel Lines

You may want to see also

Frequently asked questions

Removing tight fuel lines can be a challenging task, but with some patience and the right tools, it's definitely achievable. First, ensure you have the necessary tools like a fuel line cutter or a pair of sharp scissors. Locate the fuel lines that are causing the issue and identify the points where they are tightly secured. Loosen the connections by turning them counterclockwise, and then carefully cut the excess fuel line using the appropriate tool. Take your time to avoid any accidental cuts. Once the lines are cut, you can remove the tight sections by pulling them gently.

Absolutely! Working with fuel lines requires caution to prevent any accidents. Always wear protective gloves and safety goggles to safeguard your hands and eyes. Ensure you work in a well-ventilated area and avoid any open flames or sparks, as fuel is highly flammable. It's crucial to double-check your connections and ensure no fuel leaks occur during the process. If you're unsure, consider seeking assistance from a professional or an experienced friend.

It's recommended to use a fuel line cutter designed for the job. These tools are specifically made to cut through fuel lines without damaging them. They often have a sharp, precise blade that can cleanly sever the lines. If you don't have access to a fuel line cutter, a pair of sharp scissors or a utility knife can be used as a last resort, but ensure you're extremely careful to avoid any fuel leaks. Always prioritize safety and consider the tool's compatibility with the fuel line material.

If the fuel lines are corroded or damaged, it's best to replace them entirely rather than attempting to remove tight sections. Corrosion can lead to fuel leaks and potential engine damage. Inspect the lines for any signs of corrosion, cracks, or leaks. If you notice any issues, consult a professional mower repair service or a hardware store for suitable replacement lines. It's an opportunity to ensure your mower's fuel system is in optimal condition.

Regular maintenance can help prevent tight fuel lines problems. Keep your mower's fuel system clean and free of debris by using a fuel filter and changing the engine oil regularly. Check the fuel lines for any signs of wear and tear, especially after prolonged use or storage. If you notice any tight spots, address them promptly to avoid the need for removal. Additionally, ensure you use the correct fuel type recommended by the manufacturer to maintain optimal engine performance.