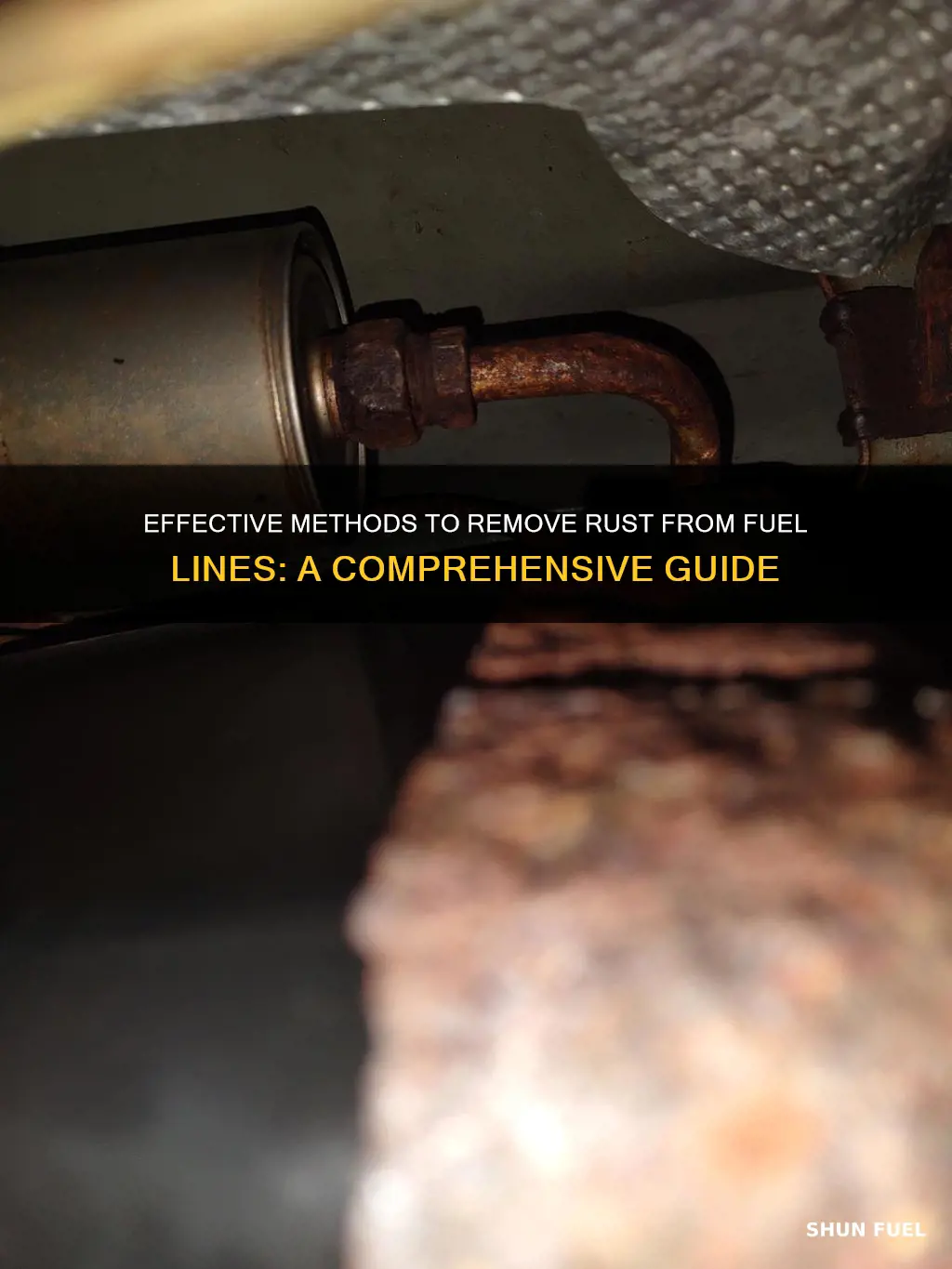

Rust in fuel lines can cause significant issues for vehicle performance and longevity. Removing rust from fuel lines is a crucial step in maintaining a vehicle's health and ensuring optimal fuel delivery. This process involves several methods, including using specialized cleaning solutions, mechanical techniques, and preventive measures to prevent future rust formation. Understanding these methods is essential for any vehicle owner to keep their car running smoothly and efficiently.

What You'll Learn

- Identify Rust: Inspect fuel lines for signs of rust, using a flashlight and clean cloth

- Clean Lines: Soak fuel lines in a rust remover solution, then scrub and rinse

- Replace Damaged Parts: If rust is severe, consider replacing affected fuel line segments

- Use a Rust Inhibitor: Apply a rust inhibitor to prevent future corrosion

- Test Fuel System: After cleaning, test the fuel system to ensure proper function

Identify Rust: Inspect fuel lines for signs of rust, using a flashlight and clean cloth

To effectively remove rust from fuel lines, it's crucial to first identify its presence. Start by thoroughly inspecting the fuel lines for any signs of rust. This process requires a keen eye and a systematic approach. Begin by using a flashlight to illuminate the fuel lines, especially in areas that are less accessible or where shadows might hide potential issues. Look for any discolored areas, which could indicate the presence of rust. These areas might appear as small spots, streaks, or even a general deterioration of the metal surface.

Once you've identified potential rust spots, use a clean cloth to carefully examine the affected areas. The cloth will help you assess the severity of the rust and determine if it has penetrated the metal surface. Rust often starts as a fine, powdery substance, but it can progress to a more corrosive form if left untreated. It's important to note that rust in fuel lines can lead to reduced fuel flow, engine performance issues, and even potential safety hazards.

When inspecting, pay close attention to the connections and bends in the fuel lines. These areas are more susceptible to rust due to the constant movement and potential exposure to moisture. If you notice any signs of rust, it's essential to take action promptly to prevent further damage. Remember, early detection can save you from more extensive and costly repairs in the future.

In addition to visual inspection, you can also use a magnifying glass or a small mirror to get a closer look at the fuel lines. This can help you identify very fine rust particles that might not be visible to the naked eye. By taking the time to inspect your fuel lines regularly, you can catch any signs of rust early and take the necessary steps to address the issue.

Keep in mind that the presence of rust in fuel lines is a common problem, especially in older vehicles or those exposed to harsh environmental conditions. By being proactive and identifying rust early, you can ensure that your vehicle's fuel system remains in optimal condition.

Yellow Fuel Line: Understanding Napa's Unique Fuel System

You may want to see also

Clean Lines: Soak fuel lines in a rust remover solution, then scrub and rinse

To effectively remove rust from fuel lines, a thorough and methodical approach is necessary. Here's a step-by-step guide to achieving clean and rust-free fuel lines:

Soaking and Preparation: Begin by acquiring a suitable rust remover, preferably one designed for fuel lines. These products often contain strong acids or chelating agents that can dissolve rust. Carefully measure and mix the remover according to the manufacturer's instructions. Ensure you wear protective gear, including gloves and safety goggles, to safeguard your skin and eyes from potential splashes. Once prepared, fill a large container or bucket with the remover solution, ensuring it is deep enough to submerge the fuel lines.

Immersing the Fuel Lines: Carefully lower the fuel lines into the rust remover solution. Ensure they are fully submerged, as this allows the remover to make contact with all rusted areas. Allow the lines to soak for an extended period, typically ranging from 30 minutes to several hours. The soaking process enables the remover to penetrate and loosen the rust, making it easier to remove.

Scrubbing and Cleaning: After the soaking period, remove the fuel lines from the solution. Use a stiff brush or scrubber specifically designed for rust removal. Aggressively scrub the fuel lines, paying close attention to areas with visible rust. Work in a circular motion, ensuring you cover all surfaces. The goal is to physically remove the rust particles and any loose corrosion. For stubborn rust, you may need to apply additional pressure and persistence.

Rinsing and Drying: Once you've scrubbed the entire length of the fuel lines, rinse them thoroughly with clean water. Ensure all traces of the rust remover and loose rust particles are washed away. Use a garden hose or a pressure washer to ensure a thorough rinse. After rinsing, allow the fuel lines to air dry completely. Avoid using heat sources like hairdryers, as they can accelerate evaporation and potentially damage the lines.

Reinstallation and Inspection: Once the fuel lines are dry, carefully reinstall them in the vehicle's fuel system. Ensure all connections are secure and properly sealed. After reinstallation, it's crucial to inspect the fuel lines for any remaining rust or signs of damage. If any issues are identified, repeat the soaking and scrubbing process until the lines are clean and free of corrosion. Regular maintenance and cleaning can help prevent future rust buildup.

Can JB Weld Fix Your Fuel Line Leaks?

You may want to see also

Replace Damaged Parts: If rust is severe, consider replacing affected fuel line segments

If you've noticed significant rust buildup in your fuel lines, it's crucial to address the issue promptly to prevent further damage to your vehicle's engine. In cases where the rust is severe and has caused significant deterioration of the fuel line material, replacing the affected segments is often the best course of action. Here's a step-by-step guide on how to approach this process:

- Inspect the Fuel Lines: Begin by thoroughly inspecting the fuel lines under your vehicle. Look for any visible signs of severe rust, such as a reddish-brown color, pitting, or flaking. Focus on areas where the fuel lines are most susceptible to moisture and corrosion, including the engine bay, under the vehicle, and near any fuel tanks or pumps.

- Identify Damaged Segments: Carefully examine the fuel lines to identify the specific segments that are heavily rusted. Rusted fuel lines can lead to reduced fuel flow, engine misfires, and potential safety hazards. Look for any discolored or weakened areas, as these may indicate internal corrosion that could compromise the structural integrity of the line.

- Gather the Necessary Tools and Materials: Before proceeding with the replacement, ensure you have the required tools and materials. You'll likely need a fuel line cutting tool or a sharp, clean blade to carefully sever the damaged section. Additionally, have a replacement fuel line segment that matches the specifications of your vehicle. It's essential to use high-quality materials to ensure a secure and reliable connection.

- Disconnect the Fuel Lines: Locate the fuel lines that need to be replaced and carefully disconnect them from the fuel source and any associated components. Take note of the connections and their positions to ensure proper reattachment later. When disconnecting, be cautious to avoid spilling any remaining fuel in the system.

- Cut and Remove the Rusted Section: Using the appropriate cutting tool, carefully sever the damaged fuel line segment at a point away from any bends or fittings. Ensure a clean cut to prevent any sharp edges that could damage surrounding components. Remove the rusted section, taking care not to damage the surrounding areas.

- Install the New Fuel Line Segment: Prepare the new fuel line segment by cleaning it and ensuring it is free of any debris or contaminants. Slide the new segment onto the fuel line, ensuring it fits snugly. Secure it in place using the appropriate clamps or fittings, following the manufacturer's instructions. Make sure the connection is tight and leak-free.

- Test and Reattach: After installing the new segment, start the vehicle and test the fuel system. Check for any leaks and ensure that the fuel flows correctly. Once confirmed, reattach the fuel lines to their respective components, securing them in place.

Remember, replacing severely rusted fuel line segments is a specialized task, and it's recommended to consult a professional mechanic if you're unsure about any step. Properly addressing rust issues in fuel lines is essential for maintaining your vehicle's performance and safety.

F250 Superduty Fuel Line Dimensions: 1999 Model Year Specs

You may want to see also

Use a Rust Inhibitor: Apply a rust inhibitor to prevent future corrosion

To prevent future corrosion and maintain the integrity of your fuel lines, applying a rust inhibitor is a highly effective method. This process involves using a specialized product designed to create a protective barrier on metal surfaces, inhibiting the formation of rust and other corrosive elements. Here's a step-by-step guide on how to use a rust inhibitor for this purpose:

Step 1: Preparation

Before applying the inhibitor, ensure the fuel lines are clean and free from any debris or old inhibitors. Use a suitable cleaner to remove any existing corrosion or residue. Rinse the lines thoroughly to eliminate any contaminants. This step is crucial as it ensures the inhibitor adheres properly and provides optimal protection.

Step 2: Application

Choose a rust inhibitor specifically formulated for fuel lines or metal surfaces. These products are typically in spray or liquid form. Apply the inhibitor directly to the fuel lines, ensuring complete coverage. Pay attention to all areas, including the connections and joints, as these are common spots for corrosion. Follow the manufacturer's instructions for the best application technique and coverage rate.

Step 3: Allow Drying

After application, allow sufficient time for the inhibitor to dry and penetrate the metal surface. This process might take a few hours, depending on the product and the thickness of the coating. Avoid any contact with the treated area during this time to ensure an even and effective barrier.

Step 4: Regular Maintenance

Rust inhibitors provide long-lasting protection, but regular maintenance is still essential. Periodically inspect the fuel lines for any signs of new corrosion, especially in areas with visible damage or wear. Reapply the inhibitor as needed to reinforce the protective layer and maintain its effectiveness.

By following these steps, you can effectively use a rust inhibitor to prevent corrosion in your fuel lines, ensuring the longevity and reliability of your vehicle's fuel system. This method is a proactive approach to maintenance, offering a simple yet powerful solution to a common automotive issue.

John Deere LA105 Fuel Line: Size Guide and Tips

You may want to see also

Test Fuel System: After cleaning, test the fuel system to ensure proper function

After you've thoroughly cleaned the fuel lines and ensured the removal of rust, it's crucial to test the fuel system to confirm its proper functionality. This testing process is essential to guarantee that the fuel lines are clear of any obstructions and that the fuel is flowing efficiently to the engine. Here's a step-by-step guide on how to test the fuel system:

- Engine Operation and Inspection: Start the engine and let it run for a few minutes. Pay close attention to any unusual noises, vibrations, or changes in the engine's performance. A properly functioning fuel system should provide a smooth and consistent power supply to the engine. If you notice any issues, such as rough idling, stalling, or excessive noise, it may indicate a problem with the fuel lines or other components.

- Pressure Testing: Use a fuel pressure gauge to measure the pressure in the fuel lines. Connect the gauge to the fuel rail or the fuel pump outlet, ensuring a secure connection. The pressure reading should be within the manufacturer's specified range. If the pressure is too low, it could suggest a restricted fuel flow, possibly due to a clogged fuel filter or a damaged fuel pump. Conversely, excessive pressure might indicate a problem with the fuel injectors or the engine's ability to regulate fuel pressure.

- Fuel Flow Verification: Check the fuel flow rate by using a flow meter or a calibrated container. Place the flow meter in the fuel line, ensuring it's positioned correctly to measure the fuel's volume over a specific time period. Compare the measured flow rate with the expected value based on the engine's specifications. An inconsistent or lower-than-expected flow rate could indicate a blockage or restriction in the fuel lines.

- Visual Inspection: Carefully inspect the fuel lines for any signs of damage, leaks, or further corrosion. Look for any visible corrosion, cracks, or kinks in the lines. Ensure that all connections are tight and secure. If any issues are found, address them accordingly, as they could impact the fuel system's performance.

- Professional Assistance: If you encounter any difficulties or are unsure about the testing process, it's advisable to consult a professional mechanic. They can provide expert guidance and ensure that the fuel system is functioning optimally.

By following these testing procedures, you can verify that the rust removal process has been successful and that the fuel system is now operating as intended. Regular maintenance and testing of the fuel system will help prevent potential issues and ensure the longevity of your vehicle's performance.

Malibu Fuel Line Location: A 1997 Guide

You may want to see also

Frequently asked questions

Rust in fuel lines can be a common issue, especially in older vehicles. A safe and effective method to remove rust is by using a fuel line cleaner or a rust remover specifically designed for this purpose. These products often contain acids that dissolve the rust, but it's crucial to follow the instructions carefully and wear protective gear to avoid any skin irritation.

While a wire brush can be used to remove heavy rust buildup, it's generally not recommended for fuel lines. The small diameter of the fuel lines can make it difficult to maneuver a wire brush without causing damage. Instead, opt for a cleaner that can penetrate and dissolve the rust, making it easier to wipe away.

In some cases, if the rust is extensive and has caused significant damage to the fuel lines, replacement might be necessary. However, for minor to moderate rust, cleaning and restoration can often resolve the issue. It's best to assess the condition of the fuel lines and consider seeking professional advice if you're unsure.

Regular maintenance is key to preventing rust buildup. It's recommended to clean your fuel lines at least once a year or whenever you notice any signs of rust, such as discolored fuel or reduced engine performance. Using a fuel system cleaner during routine maintenance can help keep the lines free of moisture and corrosion.