JB Weld, a well-known epoxy-based adhesive, is often used for various repair and bonding applications. However, its effectiveness in working on fuel lines is a topic of interest for many car enthusiasts and DIYers. While JB Weld can be used to repair small leaks or cracks in fuel lines, it is not typically recommended for this purpose due to the potential risks associated with using an epoxy in a fuel-carrying system. The material can be difficult to remove if it fails, and it may not be compatible with all types of fuel lines, potentially causing damage or reduced performance. Therefore, it is crucial to consider the specific requirements and potential risks before using JB Weld for fuel line repairs.

| Characteristics | Values |

|---|---|

| Brand | JB Weld |

| Material | Epoxy Resin |

| Application | Fuel Lines, Hose Repair |

| Temperature Resistance | Up to 300°F (149°C) |

| Drying Time | 24-48 hours |

| Strength | High Bond Strength |

| Flexibility | Good Flexibility |

| Chemical Resistance | Resistant to Fuel and Oil |

| Color | Gray |

| Package Size | Varies (e.g., 4 oz, 8 oz) |

| Usage | Temporary Repair, Not for Permanent Installation |

| Advantages | Easy to Apply, Quick Setting |

| Disadvantages | Not Suitable for Long-Term Use, May Require Reinforcement |

What You'll Learn

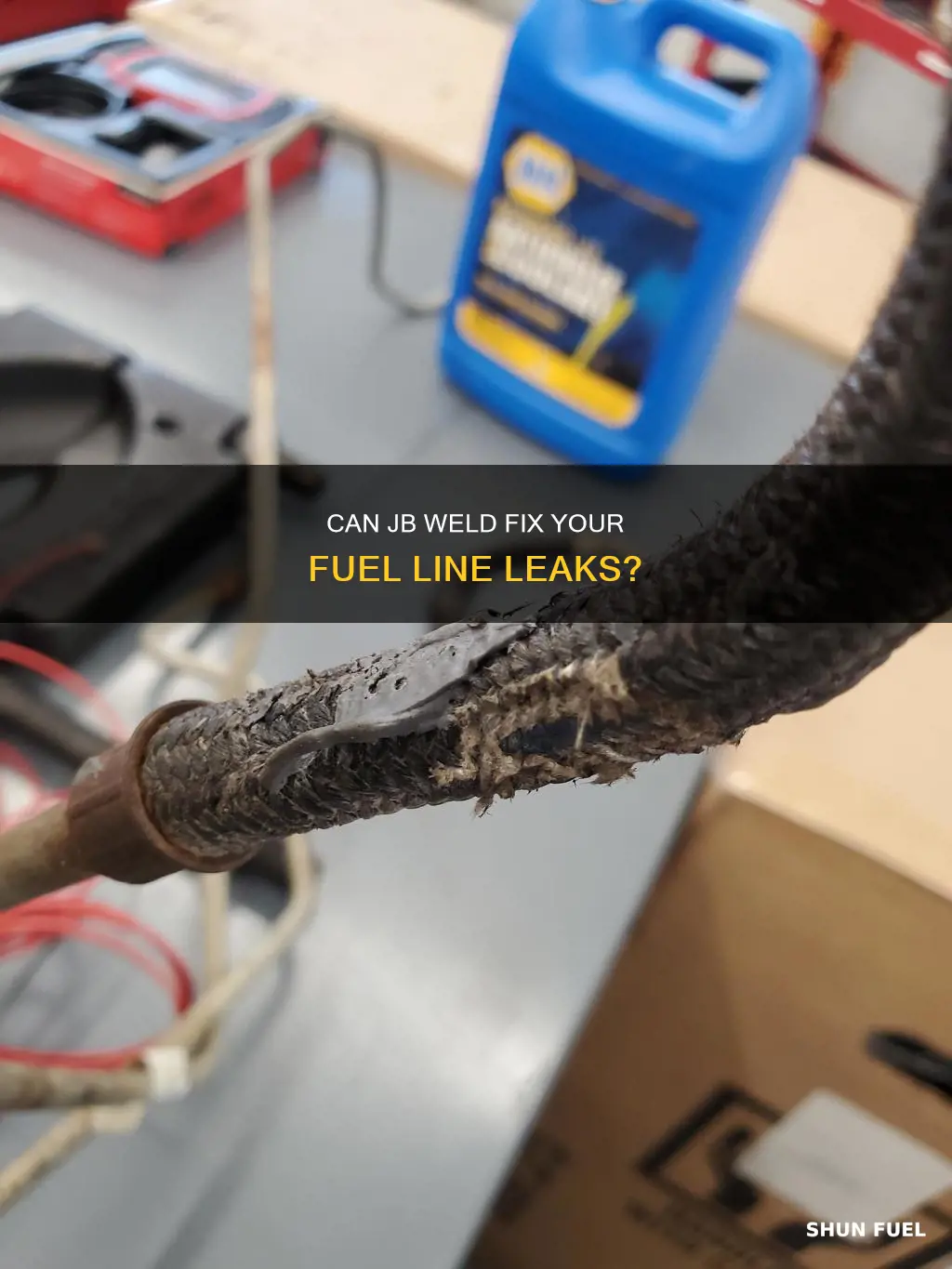

JB Weld's Fuel Line Repair: A Quick Fix for Leaks

If you're facing a fuel line leak, it's a critical issue that requires immediate attention to prevent further damage to your vehicle. While it might be tempting to opt for a quick-fix solution, it's essential to understand the limitations and effectiveness of certain products. One such product that has gained popularity for its versatility is JB Weld. This two-part epoxy system, known for its strong bonding capabilities, can be a temporary solution for fuel line repairs.

Understanding JB Weld's Application

JB Weld is primarily designed for bonding and sealing various materials, including metals, plastics, and ceramics. When applied to a fuel line, it creates a robust, durable bond that can effectively seal small to medium-sized leaks. The key to its success lies in its ability to form a strong, flexible bond that can withstand the pressure and movement associated with fuel lines.

Steps for Fuel Line Repair with JB Weld

- Prepare the Surface: Start by cleaning the fuel line and the surrounding area. Ensure there is no debris or contaminants that could interfere with the bonding process. Use a wire brush or sandpaper to create a rough surface, which will provide better adhesion.

- Apply JB Weld: Follow the manufacturer's instructions carefully. Typically, you'll need to mix the two-part epoxy and apply it to the leak area. Press the epoxy into the gap, ensuring it fills the entire void. Allow it to set according to the product's guidelines, usually for several hours or until it becomes rock-hard.

- Test and Reassemble: Once the JB Weld has cured, test the fuel line for leaks. If the issue is resolved, you can reassemble the fuel system. However, it's crucial to note that this repair is temporary and may not be suitable for long-term use.

Considerations and Limitations

While JB Weld can be an effective temporary fix, it's essential to understand its limitations. The repair might not be as reliable as a professional-grade solution, and it may not be suitable for all fuel line issues. For more severe or complex leaks, it's recommended to seek professional assistance. Additionally, JB Weld should not be used on fuel lines that are already compromised, as it may not provide the necessary structural integrity.

In conclusion, JB Weld can be a handy tool for quick fuel line repairs, offering a temporary solution to small to medium-sized leaks. However, for more critical issues or long-term repairs, consulting a professional mechanic is advisable to ensure the safety and reliability of your vehicle's fuel system. Always follow the manufacturer's instructions and consider the specific requirements of your fuel line when using any repair product.

Unveiling the Mystery: What's in the Fuel Line to Reduce NOx Emissions?

You may want to see also

JB Weld's Effectiveness: Can It Seal Fuel Lines?

The idea of using JB Weld, a well-known epoxy-based adhesive, to repair fuel lines is an intriguing one, especially for those seeking a quick fix without professional help. However, it's essential to approach this method with caution and a thorough understanding of its limitations. While JB Weld has proven effective in various bonding applications, its use on fuel lines requires careful consideration due to the critical nature of fuel systems in vehicles.

Fuel lines are designed to withstand high pressure and temperatures, and any repair or modification must adhere to strict safety standards. JB Weld, when applied correctly, can provide a robust and durable bond, but it is not inherently designed for the specific demands of fuel lines. The adhesive's performance can vary depending on the material of the fuel line and the surrounding environment. For instance, JB Weld might not adhere well to certain types of rubber or plastic commonly used in fuel lines, leading to potential failure over time.

One of the primary concerns with using JB Weld for fuel line repairs is the risk of leakage. Fuel lines are crucial for delivering gasoline or diesel to the engine, and any compromise in the sealing could result in engine misfires, reduced performance, or even dangerous situations. While JB Weld can create a strong bond, it may not provide the same level of flexibility and resilience as the original material, potentially leading to cracks or failures under stress.

To ensure the effectiveness and safety of the repair, it is recommended to consult the manufacturer's guidelines or seek professional advice. In some cases, a temporary fix might be acceptable, but for a long-lasting solution, professional repair methods should be considered. Additionally, regular maintenance and inspections of fuel lines are essential to identify and address any issues before they become major problems.

In summary, while JB Weld can be a temporary solution for sealing small leaks or temporary repairs, it is not a reliable or safe method for permanently fixing fuel lines. The potential risks and limitations make it crucial to explore professional alternatives or follow manufacturer recommendations for fuel line maintenance and repairs. Always prioritize safety and consult experts when dealing with critical vehicle components like fuel systems.

Choosing the Right Hose for Your 1.4-Inch Fuel Line

You may want to see also

Fuel Line Welding: JB Weld's Role in Preventing Leaks

When it comes to maintaining the integrity of your vehicle's fuel system, welding fuel lines is a critical task that can make or break your engine's performance. JB Weld, a well-known brand in the world of automotive repair, offers a range of products specifically designed for this purpose. These products are engineered to provide a strong, durable bond that can withstand the extreme conditions found under the hood.

The process of welding fuel lines is a delicate one, as any mistake can lead to costly repairs or even dangerous situations. JB Weld's line of epoxy-based products is specifically formulated to adhere to the materials commonly used in fuel lines, such as rubber and plastic. These products create a robust and flexible bond, ensuring that the fuel lines remain secure and leak-free. The key to successful fuel line welding is preparation. Before applying any adhesive, it's crucial to clean the surfaces thoroughly. This involves removing any dirt, grease, or old adhesive residue. JB Weld provides comprehensive instructions and guidelines for this process, ensuring that the preparation stage is executed flawlessly.

Once the surfaces are prepared, the JB Weld product is applied in a thin, even layer. The specific technique and amount of product used will depend on the size and complexity of the fuel line repair. For smaller, less intricate repairs, a single-part epoxy might be sufficient. However, for more complex applications, a two-part system could be necessary, requiring precise mixing and application. JB Weld's products are designed to cure rapidly, often within minutes, allowing for quick and efficient repairs.

One of the most significant advantages of using JB Weld for fuel line welding is its ability to provide a strong, leak-resistant seal. The epoxy bond created by these products is highly resistant to the corrosive effects of fuel, ensuring that the fuel lines remain intact and functional over time. Additionally, JB Weld's products are known for their flexibility, which is crucial in accommodating the natural movement and expansion of fuel lines, thus preventing cracks and breaks.

In conclusion, JB Weld plays a vital role in preventing leaks and ensuring the longevity of fuel lines. With its specialized products and easy-to-follow instructions, it empowers vehicle owners and mechanics to perform complex repairs with confidence. By following the manufacturer's guidelines and taking the necessary precautions, you can effectively weld fuel lines, keeping your engine running smoothly and safely. Remember, proper preparation and the use of high-quality products like JB Weld are essential to achieving a successful and long-lasting repair.

Optimizing LS Swap Fuel Lines: CJ's Guide to Performance

You may want to see also

JB Weld's Heat Resistance: Ideal for Fuel Line Repairs

JB Weld, a well-known brand in the world of automotive repair, offers a range of products designed to withstand extreme conditions, including high temperatures. When it comes to fuel line repairs, the heat resistance of JB Weld products becomes a crucial factor to consider. Fuel lines are exposed to intense heat from the engine, and any repair material must be able to endure these temperatures without compromising its structural integrity.

The heat resistance of JB Weld's epoxy systems is a key feature that makes it an excellent choice for fuel line repairs. These epoxy resins are specifically formulated to maintain their strength and flexibility even under extreme heat. This is essential for fuel line applications, as it ensures that the repair will not only hold up to the engine's operating temperatures but also remain stable and secure over time.

One of the advantages of using JB Weld for fuel line repairs is its ability to create a strong, durable bond. The epoxy system is designed to adhere to various surfaces, including metal, plastic, and rubber, which are commonly used in fuel line construction. This adhesion is critical to ensure that the repair is secure and will not lead to any leaks or failures. Moreover, JB Weld's products are known for their ease of use, allowing even novice repairers to achieve professional-quality results.

In addition to its heat resistance, JB Weld's epoxy systems offer excellent chemical resistance, which is another vital aspect of fuel line repairs. Fuel contains various additives and can be corrosive to certain materials. By using JB Weld, you create a protective barrier around the fuel line, safeguarding it from potential damage caused by the fuel's composition. This added layer of protection ensures the longevity of the repair and the overall health of the vehicle's fuel system.

When performing fuel line repairs, it is essential to choose a material that can withstand the rigors of the engine environment. JB Weld's heat resistance, combined with its strong bonding capabilities and chemical resistance, makes it an ideal solution. With proper application and curing, JB Weld can provide a reliable and long-lasting repair for fuel lines, ensuring the vehicle's performance and safety.

Understanding 3/8 Fuel Line Dimensions: Inside Diameter Explained

You may want to see also

DIY Fuel Line Repair: JB Weld's Application and Benefits

If you're a car enthusiast or a DIY mechanic, you might have encountered fuel line issues that require quick and effective solutions. JB Weld, a well-known brand in the world of automotive repair, offers a range of products that can be incredibly useful for fuel line repairs. Here's a detailed guide on how JB Welds can be applied to fix fuel lines and the benefits they offer.

Understanding the Problem:

Fuel lines are crucial components of your vehicle's engine, responsible for transporting fuel from the tank to the engine. Over time, these lines can develop cracks, leaks, or even break due to various factors like age, heat, or physical damage. Such issues can lead to reduced engine performance, increased fuel consumption, and even potential engine failure. Traditional methods of repair often involve replacing the entire fuel line, which can be costly and time-consuming. This is where JB Welds come into play as a convenient and cost-effective alternative.

Application of JB Welds:

JB Welds, specifically their epoxy-based products, are designed to create strong, durable bonds and can be used to repair fuel lines effectively. Here's a step-by-step guide on how to use JB Welds for this purpose:

- Prepare the Fuel Line: Start by cleaning the fuel line thoroughly. Remove any dirt, debris, or old adhesive residue. Ensure the surface is dry and free from contaminants.

- Apply JB Weld: Carefully cut or drill small holes along the length of the damaged fuel line. This allows the epoxy to penetrate and bond effectively. Then, apply a thin layer of JB Weld onto the prepared fuel line, ensuring complete coverage of the damaged area.

- Weld and Cure: Allow the JB Weld to set according to the manufacturer's instructions. Typically, it will require a period of curing, during which you should avoid any pressure or weight on the repaired area.

- Test and Reassemble: Once cured, test the fuel line for leaks. If no leaks are detected, reassemble the fuel system and ensure all connections are secure.

Benefits of Using JB Welds:

- Convenience: JB Welds offer a quick and easy solution for fuel line repairs, saving you time and effort compared to traditional replacement methods.

- Cost-Effective: Repairing fuel lines with JB Welds can be significantly cheaper than buying and installing a new fuel line, especially for those with limited budgets.

- Durability: The epoxy bond created by JB Welds is known for its strength and durability, ensuring a long-lasting repair.

- Accessibility: These products are widely available at auto parts stores and can be easily applied without specialized tools or extensive mechanical knowledge.

- Environmental Friendliness: By extending the life of your fuel lines, you reduce the need for new parts, contributing to a more sustainable approach to vehicle maintenance.

In summary, JB Welds provide an excellent DIY solution for fuel line repairs, offering convenience, cost savings, and a reliable fix. With proper application and curing, you can restore your fuel system's integrity and ensure optimal engine performance. Always remember to follow the manufacturer's guidelines for the best results.

Fuel Line Fabrication: Expert Services for Your Vehicle

You may want to see also

Frequently asked questions

JB Weld, also known as epoxy, can be used for fuel line repairs, but it is not the most ideal solution. While it can provide a temporary fix, it is not designed for the harsh environment of fuel systems and may not be as durable as specialized fuel line repair products.

It is not recommended to use JB Weld for permanent fuel line repairs. The high temperatures and pressure within fuel systems can cause the epoxy to crack or fail over time, leading to potential fuel leaks and engine issues.

Instead of using JB Weld, consider using fuel line repair kits or specialized epoxy compounds designed for fuel systems. These products are formulated to withstand the corrosive effects of fuel and provide a more reliable and long-lasting repair.

Using JB Weld on fuel lines is generally not safe due to the potential risks associated with fuel leaks and engine damage. It is always best to consult a professional mechanic or use products specifically designed for fuel line repairs to ensure a safe and effective solution.