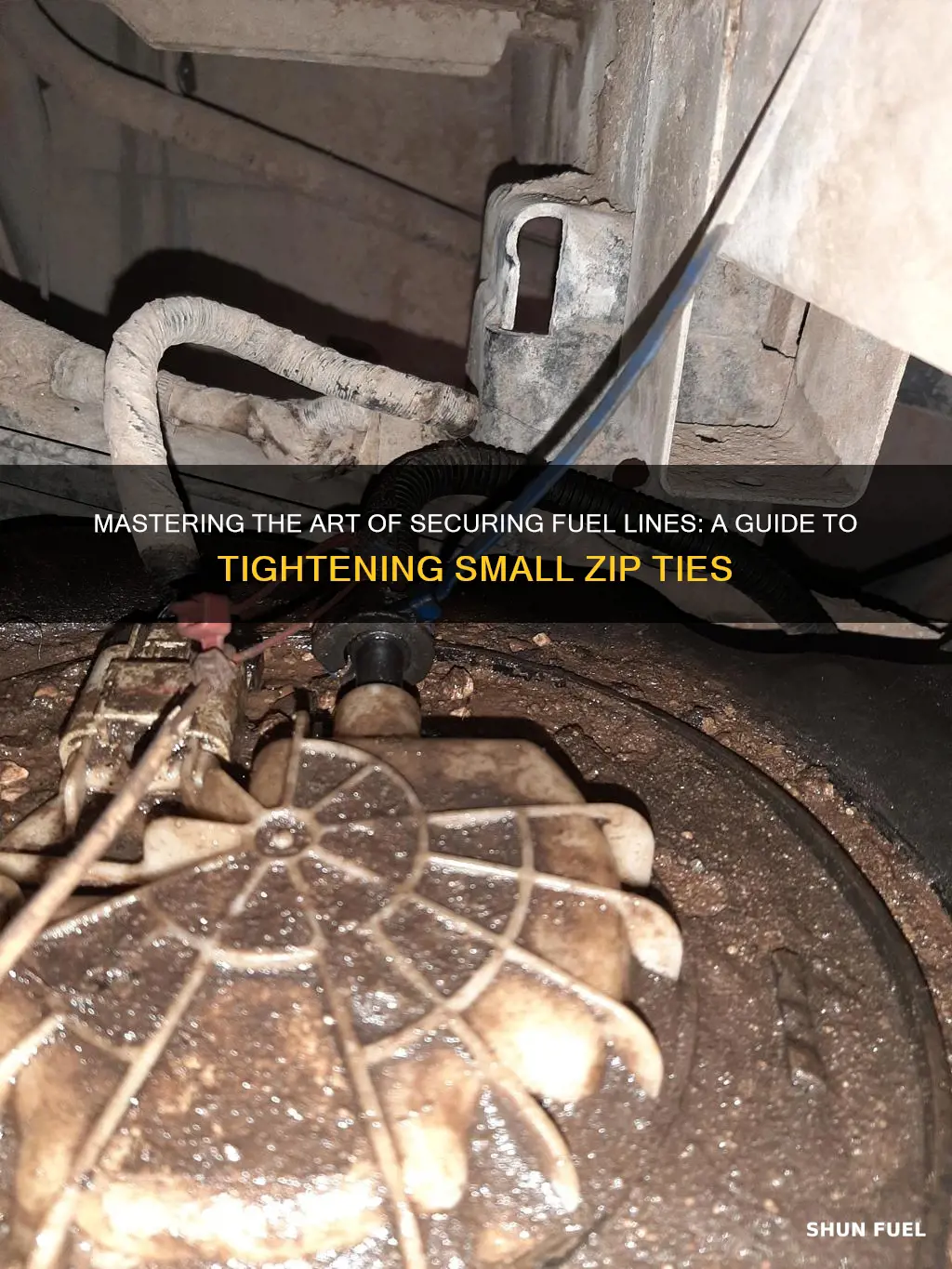

Tightening small zip ties on fuel lines is a crucial step in ensuring the safety and efficiency of your vehicle's fuel system. This process involves securing the fuel lines to prevent leaks and maintain a secure connection. Here's a guide on how to effectively tighten small zip ties on fuel lines: Begin by identifying the fuel lines you need to secure and ensuring you have the appropriate size of zip ties. Use a pair of pliers or a zip tie tool to grip the zip tie tightly around the fuel line, making sure it is snug but not overly tight to avoid damage. Apply a small amount of fuel line compound or tape to the zip tie for added protection. Finally, double-check the tightness and ensure the zip tie is secure, providing a reliable barrier against fuel leaks.

What You'll Learn

- Prepare the Tools: Gather small pliers, a wire brush, and a lubricant for the best results

- Clean the Zip Tie: Remove any dirt or debris with a wire brush to ensure a tight grip

- Apply Lubricant: Use a light lubricant to reduce friction and make tightening easier

- Tighten Gradually: Start with a quarter turn, then tighten in small increments to avoid over-tightening

- Test the Fit: After tightening, ensure the zip tie is secure by gently pulling on it to check for play

Prepare the Tools: Gather small pliers, a wire brush, and a lubricant for the best results

To effectively tighten a small zip tie on fuel lines, it's crucial to have the right tools. Start by gathering a pair of small pliers, preferably made of durable metal. These pliers should be designed to grip and twist small objects, ensuring you have the necessary leverage to tighten the zip tie without causing damage. Additionally, a wire brush is essential for removing any dirt or debris from the fuel lines and the zip tie itself. This step is vital to ensure a secure connection and prevent any potential leaks.

Next, you'll need a lubricant to facilitate the tightening process. A small amount of lubricant, such as a silicone-based spray or a specialized fuel line compound, will help reduce friction and make it easier to tighten the zip tie. Lubrication is key to ensuring a tight seal and preventing the zip tie from slipping or causing damage to the fuel lines over time.

Having these tools ready will significantly contribute to the success of your task. The small pliers provide the necessary grip and control, the wire brush ensures a clean surface, and the lubricant helps in creating a secure and long-lasting connection. By preparing these tools in advance, you'll be well-equipped to tackle the job efficiently and effectively.

Mastering the Art of Fuel Line Sealing: A Comprehensive Guide

You may want to see also

Clean the Zip Tie: Remove any dirt or debris with a wire brush to ensure a tight grip

To ensure a secure and effective zip tie on fuel lines, it's crucial to start with a clean and prepared tie. The first step is to inspect the zip tie and remove any dirt or debris that might hinder its grip. This process is essential as it ensures the tie can effectively hold the fuel lines in place without slipping or compromising the integrity of the connection.

Begin by using a wire brush to gently scrub the surface of the zip tie. This tool is ideal for removing any built-up dirt, rust, or corrosion that may have accumulated over time. Focus on the areas where the tie will come into contact with the fuel lines, as these points require the most attention to ensure a tight fit. Be thorough in your cleaning, as even a small amount of debris can lead to a less secure hold.

For an even more effective clean, consider using a fine-grit sandpaper to carefully remove any stubborn residue. This method is particularly useful for old or rusty zip ties that may have lost their original grip. Apply light, even pressure while sanding to avoid damaging the tie or the fuel lines. Once you've removed all visible dirt and debris, rinse the zip tie with clean water to eliminate any remaining particles.

After cleaning, allow the zip tie to air dry completely. This step is important to ensure that no moisture remains, which could affect the tie's ability to grip the fuel lines. You can speed up the drying process by using a soft cloth to gently pat the tie dry. Once dry, the zip tie is ready for the next step, where you will learn how to properly secure it to the fuel lines.

Remember, taking the time to thoroughly clean the zip tie is a critical part of the process. It ensures that the tie can provide a strong and reliable hold, which is essential for maintaining the safety and functionality of your fuel lines. By following these steps, you'll be well on your way to mastering the art of tightening small zip ties on fuel lines.

Fuel Line Swap: EFI to Carb Conversion Guide

You may want to see also

Apply Lubricant: Use a light lubricant to reduce friction and make tightening easier

When dealing with small zip ties on fuel lines, applying a lubricant is a crucial step to ensure a secure and effective tightening process. The primary goal is to reduce the friction between the zip tie and the fuel line, allowing for easier manipulation and a tighter grip. This method is especially useful when the zip tie is already in place and you need to adjust its tightness without causing any damage to the fuel line.

Start by selecting a suitable lubricant. A light, non-greasy lubricant is ideal as it will not leave any residue or mess. Silicone-based lubricants are excellent choices due to their ability to withstand high temperatures and provide a smooth, slippery surface. You can also use a small amount of dish soap or cooking oil, ensuring it is food-grade to avoid any potential contamination.

Now, take a small section of the fuel line where the zip tie is located. Carefully apply the lubricant to the area, ensuring an even coating. The lubricant should be applied directly to the metal surfaces of the zip tie and the fuel line, as this is where the friction occurs. Be generous but precise in your application to cover all the relevant areas.

Once the lubricant is applied, you'll notice a significant reduction in friction. This will make it easier to grip the zip tie and tighten it without straining or risking damage to the fuel line. Use pliers or your fingers to tighten the zip tie, ensuring it is secure but not overly tight. The lubricant will allow for a more controlled and precise tightening process.

Remember, the key to success is using the right amount of lubricant and applying it strategically. Over-lubricating can lead to mess and potential contamination, while under-lubricating may not provide the desired reduction in friction. Take your time, be methodical, and you'll find that tightening small zip ties on fuel lines becomes a much more manageable task.

Optimizing Fuel Flow: Choosing the Right Fuel Line Size for DSM

You may want to see also

Tighten Gradually: Start with a quarter turn, then tighten in small increments to avoid over-tightening

When working with small zip ties on fuel lines, it's crucial to approach the tightening process with precision and care. The goal is to secure the tie effectively without causing any damage to the fuel lines or the surrounding components. Here's a step-by-step guide on how to tighten the zip tie gradually:

Begin by locating the zip tie that needs to be tightened. Ensure you have a good grip on the tie and identify the direction you need to pull it in to create tension. Start with a quarter turn; this initial movement helps to loosen the tie slightly, providing a starting point for further adjustments. By doing this, you can assess the amount of tension required and avoid sudden, forceful tightening.

After the initial quarter turn, proceed with tightening the zip tie in small, controlled increments. Use a steady and consistent motion, applying gentle pressure with each turn. The key is to avoid over-tightening, which can lead to potential issues. Take your time and focus on making precise adjustments. With each turn, observe the change in tension and make minor modifications until you reach the desired level of tightness.

As you tighten the zip tie, pay close attention to the fuel lines and any connected components. Ensure that the tie is not causing any kinks or bends in the lines, as this could restrict fuel flow or potentially damage the lines over time. The goal is to secure the tie firmly while maintaining the integrity of the fuel system.

Remember, the process should be gradual and methodical. Take breaks if needed to reassess your progress and make fine-tuned adjustments. By tightening the zip tie in small increments, you can achieve a secure hold without the risk of over-tightening, which might lead to fuel line damage or reduced flexibility. This approach ensures a safe and effective tightening process.

Air in Diesel Fuel Line: Symptoms and Solutions

You may want to see also

Test the Fit: After tightening, ensure the zip tie is secure by gently pulling on it to check for play

After you've tightened the zip tie according to the manufacturer's instructions, it's crucial to verify its effectiveness. This step is essential to ensure the zip tie can withstand the forces it will encounter over time. Here's how to test the fit:

First, locate the zip tie and gently pull on it in both directions. You should feel a slight resistance, but no significant movement. If you encounter a lot of play or the tie comes loose, it needs to be retightened. This simple test will help you identify if the tie is secure enough to hold its position.

The key here is to check for any slack or movement. A well-fitted zip tie should provide a snug fit without allowing any excess movement. If you notice any play, it could indicate that the tie is not tight enough and may not provide the necessary support for the fuel lines.

When performing this test, pay attention to the direction of the pull. You should be able to move the tie back and forth without any binding or obstruction. This ensures that the tie is not only tight but also allows for some flexibility, which is important for the dynamic nature of fuel lines.

Remember, the goal is to achieve a secure yet flexible hold. By testing the fit, you can ensure that the zip tie is doing its job effectively, providing a reliable solution for securing fuel lines without causing any damage or restricting their movement. This simple check is a vital part of the process to guarantee the safety and functionality of your fuel system.

Troubleshooting Tips: When the Fuel Line Refuses to Uncouple

You may want to see also

Frequently asked questions

When working with fuel lines, it's crucial to use the right tools and technique to avoid any potential harm. Start by ensuring the zip tie is the appropriate size for the fuel line; a snug fit is essential. Use a pair of pliers to grip the zip tie and apply firm pressure, turning it clockwise until it's secure. Be cautious not to overtighten, as this can lead to damage. A good rule of thumb is to tighten it until it's just snug enough to hold the line in place.

If you encounter issues with the zip tie loosening, it might be due to the material of the fuel line or the angle of the tie. Try adjusting the position of the tie to ensure it's wrapped around the line at a right angle. You can also use a small amount of zip tie lubricant to help it grip better. However, if the problem persists, consider using a different type of tie or a more secure fastening method.

For tightening small zip ties, a simple pair of adjustable pliers or locking pliers can be very effective. These tools provide a firm grip and allow for precise control during the tightening process. Ensure the pliers have a smooth, non-serrated jaw to avoid scratching the fuel line. If you have access to a small ratchet or torque wrench, it can help ensure you're applying the correct amount of force.

Yes, zip ties can be used in cold weather, but take extra care. Cold temperatures can make the fuel lines more brittle, so be gentle when applying pressure. It's also a good idea to use a zip tie with a slightly larger diameter to accommodate any potential shrinkage of the fuel line. Always test the tightness after application to ensure it's secure without causing any damage.