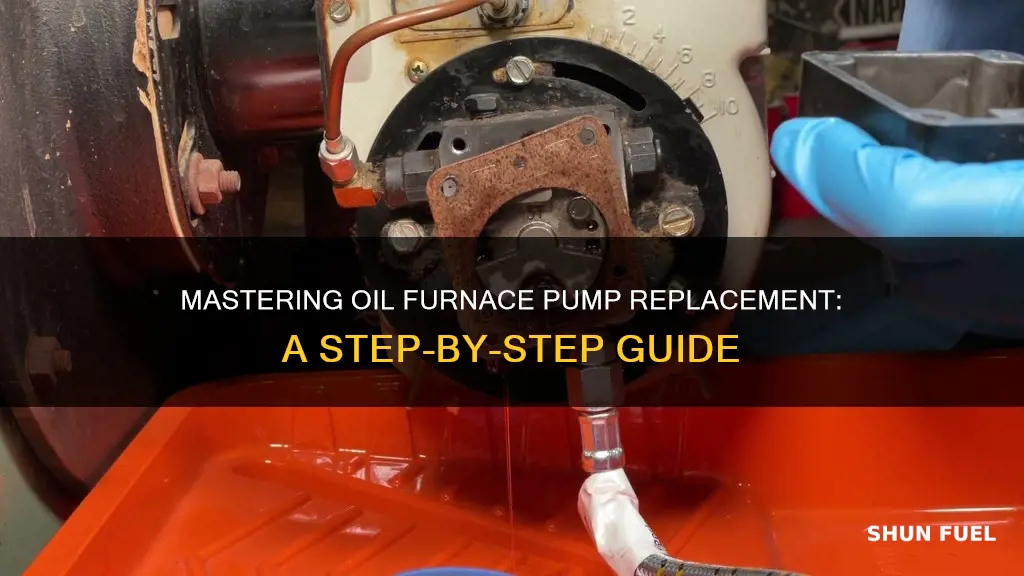

Oil furnace fuel pump replacement can seem daunting, but with the right tools and knowledge, it's a manageable task. This guide will walk you through the process step-by-step, ensuring you understand the importance of each step and the tools required. By following these instructions, you'll be able to replace the fuel pump, ensuring your furnace operates efficiently and safely. Let's get started!

What You'll Learn

- Access the Pump: Locate and safely remove the old pump to inspect and replace

- Prepare for Removal: Disconnect electrical connections and drain fuel lines before taking out the pump

- Install New Pump: Carefully align and secure the new pump, ensuring proper connections

- Test and Adjust: Verify pump functionality and calibrate for optimal performance

- Clean and Reassemble: Thoroughly clean the system and reinstall all components securely

Access the Pump: Locate and safely remove the old pump to inspect and replace

To access and replace the fuel pump in an oil furnace, you'll need to carefully follow these steps to ensure a safe and efficient process. Begin by locating the pump, which is typically positioned near the fuel tank or along the fuel line. It is crucial to identify the specific model and type of pump you are dealing with to ensure you have the correct replacement part. Once located, you'll need to shut off the power supply to the furnace to avoid any accidents. This might involve turning off the circuit breaker or disconnecting the power cord, depending on your furnace's setup.

After ensuring the power is off, it's time to remove the old pump. Start by disconnecting any electrical connections or hoses attached to the pump. Use the appropriate tools, such as screwdrivers or wrenches, to carefully loosen and remove the screws or fasteners securing the pump in place. Be gentle to avoid damaging the surrounding components. Once the fasteners are removed, gently lift the old pump out of its housing, setting it aside for inspection and comparison with the new pump.

When removing the pump, pay attention to any additional components that might need to be addressed. This could include fuel lines, filters, or other related parts that may require adjustment or replacement during the process. Take your time to carefully inspect the old pump and its surroundings to identify any potential issues or areas for improvement.

With the old pump removed, you now have access to inspect the fuel system thoroughly. Look for any signs of damage, corrosion, or wear that may have contributed to the pump's failure. This inspection will help you understand the root cause of the problem and guide your decision when choosing a replacement. Ensure that you clean the pump housing and any other affected areas to prepare for the new pump's installation.

Remember, safety is paramount during this process. If you encounter any challenges or are unsure about any step, consult the manufacturer's instructions or seek professional assistance. Properly disposing of or recycling the old pump and its components is also essential to minimize environmental impact. By following these detailed steps, you can effectively access and replace the fuel pump in your oil furnace, ensuring optimal performance and longevity.

Replacing RV Fuel Filler Neck: A Step-by-Step Guide

You may want to see also

Prepare for Removal: Disconnect electrical connections and drain fuel lines before taking out the pump

When preparing to remove the fuel pump from an oil furnace, it's crucial to prioritize safety and ensure a smooth process. Here's a step-by-step guide to help you get started:

Disconnect Electrical Connections: Begin by locating the electrical connections associated with the fuel pump. These connections are typically found near the pump's housing or along the fuel line. Carefully disconnect the wires, ensuring you identify the correct terminals and make a mental note of their positions. This step is essential to prevent any accidental damage to the wiring during the removal process.

Locate and Secure Fuel Lines: Next, you'll need to locate the fuel lines connected to the pump. These lines supply fuel to the furnace. Carefully inspect the connections and use clamps or ties to secure the lines temporarily. This step is vital to prevent fuel leakage, which could be hazardous and cause environmental damage.

Drain the Fuel Lines: To ensure a safe and clean removal process, it's imperative to drain the fuel lines. Locate the drain valves or ports, which are usually positioned near the pump or along the fuel lines. Open the valves to release any residual fuel, allowing the lines to empty completely. This step is critical to avoid spills and potential hazards during the removal.

By following these initial preparation steps, you'll create a safer and more organized environment for the fuel pump removal. It's essential to take these precautions to ensure a successful and safe replacement process. Remember, proper preparation is key to avoiding complications and ensuring the longevity of your oil furnace system.

Replacing the Fuel Pump Strainer in a 2002 Chevrolet Avalanche

You may want to see also

Install New Pump: Carefully align and secure the new pump, ensuring proper connections

When replacing the fuel pump in an oil furnace, proper alignment and secure installation are crucial to ensure optimal performance and prevent potential issues. Here's a step-by-step guide to help you through the process:

Start by locating the old pump and identifying its mounting points. Carefully inspect the pump for any signs of damage or wear. Take note of the connections, including the fuel lines, electrical wiring, and any other components attached to the pump. This information will be essential for the installation of the new pump.

Now, carefully lift the new pump into place, ensuring it aligns perfectly with the mounting points. Use the appropriate tools to secure the pump firmly in position. It is important to follow the manufacturer's guidelines for the correct torque specifications to avoid over-tightening, which can damage the pump or its components. Double-check that all connections are secure and that there is no movement or play in the pump once installed.

Pay close attention to the fuel lines. Ensure they are properly connected to the new pump and securely fastened. Check for any leaks or potential issues with the connections. If you notice any discrepancies, tighten the connections or adjust the lines as necessary.

Finally, verify the electrical connections. Ensure that the wires are correctly attached to the new pump and any relevant control modules. Double-check the polarity of the connections to avoid any electrical malfunctions. Once all connections are secure, test the pump's functionality by powering it on and monitoring its performance.

Remember, a well-installed pump is crucial for the efficient operation of your oil furnace. Take your time during the installation process, and if you encounter any challenges, consult the pump's manual or seek professional assistance to ensure a successful replacement.

Fuel Pump Fixes: 5 Effective Methods to Save Money

You may want to see also

Test and Adjust: Verify pump functionality and calibrate for optimal performance

When replacing the fuel pump in an oil furnace, it's crucial to thoroughly test and adjust the new pump to ensure optimal performance and prevent potential issues. Here's a step-by-step guide to verifying and calibrating the pump:

Initial Testing: After installing the new fuel pump, the first step is to test its functionality. Turn on the furnace and listen for the pump's operation. A properly functioning pump should produce a distinct humming or whirring sound. Check for any unusual noises, such as rattling or grinding, which could indicate improper installation or damage. Additionally, observe the fuel flow. The pump should deliver fuel at a steady rate, ensuring the furnace operates efficiently.

Pressure Testing: To further validate the pump's performance, conduct a pressure test. Connect a pressure gauge to the fuel line and measure the pressure at the pump's outlet. The pressure should meet the manufacturer's specifications for the particular furnace model. If the pressure is too low, it may indicate a clogged line or an issue with the pump's priming. Conversely, excessive pressure could suggest a malfunctioning pressure relief valve. Adjust the pump's settings or consult the manufacturer's guidelines to achieve the optimal pressure range.

Flow Rate Calibration: Accurate flow rate calibration is essential for efficient fuel delivery. Use a flow meter to measure the volume of fuel passing through the pump per unit of time. Compare this reading with the expected flow rate specified by the furnace manufacturer. If the flow rate is inconsistent or too low, it might be due to a partially clogged pump or a faulty check valve. Cleaning or replacing these components can often resolve the issue.

Fine-Tuning Adjustments: Based on the test results, make any necessary adjustments to fine-tune the pump's performance. This may involve calibrating the pump's speed, adjusting the fuel pressure, or modifying the pump's settings according to the manufacturer's recommendations. It's important to make these adjustments gradually and carefully, as incorrect settings can lead to inefficient operation or even damage to the pump.

Safety and Maintenance: Throughout the testing and adjustment process, ensure that all safety precautions are followed. Wear appropriate personal protective equipment, and work in a well-ventilated area when handling fuel. Regular maintenance, such as cleaning and inspecting the pump and fuel system, will also contribute to long-term reliability and performance.

Replacing a Diesel Engine Fuel Pump: A Step-by-Step Guide

You may want to see also

Clean and Reassemble: Thoroughly clean the system and reinstall all components securely

Before reassembling the oil furnace fuel pump system, it's crucial to ensure a clean and meticulous process to prevent any contaminants from causing future issues. Start by disconnecting the power supply to the furnace to ensure safety during the cleaning process. Then, carefully remove the access panels or covers to expose the fuel pump and its associated components.

Using a soft-bristled brush or a specialized cleaning tool, gently remove any built-up dirt, debris, or residue from the fuel pump's housing and internal components. Pay close attention to the pump's impeller and vanes, as these parts are susceptible to clogging and require thorough cleaning. Rinse the pump and housing with a mild detergent solution to eliminate any remaining contaminants. Ensure that no soap residue remains, as it can attract moisture and cause corrosion.

Once the fuel pump is thoroughly cleaned, inspect all the gaskets, seals, and O-rings for any signs of damage or wear. Replace any worn-out seals to maintain an airtight and watertight seal. Reinstall the fuel pump housing, ensuring that all components are properly aligned and secured. Tighten the fasteners gently but firmly to avoid over-tightening, which can damage the components.

Reassemble the access panels or covers, ensuring they are properly sealed and secured. Reconnect the power supply to the furnace, and test the fuel pump's functionality. Check for any leaks or unusual noises, and verify that the pump is operating efficiently. If everything functions correctly, you can proceed to the final steps of the replacement process, ensuring a clean and secure reassembly.

Remember, a thorough cleaning and proper reassembly are essential to the long-term performance and reliability of the oil furnace fuel pump system. By following these steps, you can ensure that the system operates efficiently and avoids potential issues caused by contaminants or improper reassembly.

Replacing Husqvarna Blower Fuel Line: Step-by-Step Guide

You may want to see also

Frequently asked questions

Over time, the fuel pump in your oil furnace can wear out or malfunction, leading to reduced heating efficiency or complete failure. Signs that your fuel pump may need replacement include unusual noises like grinding or whining, frequent cycling of the furnace, slow startup, or inconsistent heat output. If you notice any of these issues, it's best to consult a professional technician for an inspection.

While some DIY enthusiasts might attempt fuel pump replacement, it is generally recommended to hire a qualified technician or HVAC specialist for this task. Oil furnace fuel pumps can be complex to work with, and improper installation may lead to further issues or safety hazards. Professionals have the necessary tools, experience, and knowledge to ensure the job is done correctly and safely.

The process of replacing a fuel pump typically involves the following steps: First, locate the fuel pump assembly and disconnect the electrical connections. Then, drain any remaining fuel from the system to prevent spills. Carefully remove the old pump and prepare the new one for installation. Ensure you follow the manufacturer's instructions for the specific model of your furnace. Finally, reattach the pump, secure all connections, and test the system to ensure proper functionality.