Priming a boat's fuel line is a crucial step to ensure a smooth and efficient start to your boating experience. This process involves preparing the fuel system by introducing air into the line to remove any water or contaminants that may have accumulated during storage. By following a few simple steps, you can effectively prime your boat's fuel line, ensuring that your engine starts reliably and performs optimally on the water.

What You'll Learn

- Prepare the Boat: Ensure the boat is in a secure location and all safety measures are in place

- Fuel Line Inspection: Check for any damage, blockages, or leaks in the fuel line

- Prime Pump: Prime the fuel pump by cycling the engine or using a manual priming method

- Fuel Filter: Clean or replace the fuel filter to prevent contamination

- Test and Adjust: Test the fuel flow and adjust the priming as needed for optimal performance

Prepare the Boat: Ensure the boat is in a secure location and all safety measures are in place

Before you begin the process of priming your boat's fuel line, it is crucial to prioritize safety and ensure the boat is in a secure location. This step is essential to prevent any accidents or mishaps during the priming process. Here's a detailed guide on how to prepare your boat:

Secure the Boat: Choose a stable and level surface to work on your boat. If you're in a marina or a boatyard, ensure the boat is securely tied to the dock or lift. Use appropriate anchors or mooring lines to prevent the boat from moving or drifting. This is especially important if you're working on a larger vessel or in an area with strong currents or winds. By securing the boat, you minimize the risk of accidental movement, which could lead to damage or injury.

Safety Precautions: Priming a fuel line involves working with fuel, which can be hazardous if not handled properly. Here are some essential safety measures to implement:

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety goggles, gloves, and a respirator mask. This protects you from potential fuel spills, fumes, and any debris that might be present in the fuel line.

- Ventilation: Ensure the working area has good ventilation to prevent the inhalation of fuel vapors. If working indoors, open windows or use fans to create a cross-ventilation system.

- Fire Safety: Keep a fire extinguisher nearby and ensure it is rated for fuel or chemical fires. Always be cautious of potential sparks or flames, especially when using tools or equipment that may generate heat.

- Fuel Containment: Have a suitable container ready to catch any fuel that may spill during the priming process. This prevents environmental contamination and makes cleanup easier.

Inspect the Fuel System: Before priming, conduct a thorough inspection of the fuel system. Check for any signs of damage, leaks, or corrosion. Inspect the fuel lines for cracks, kinks, or blockages. If you notice any issues, address them before proceeding. Ensure that the fuel tank is clean and free of debris. This inspection is vital to identify potential problems and ensure a smooth priming process.

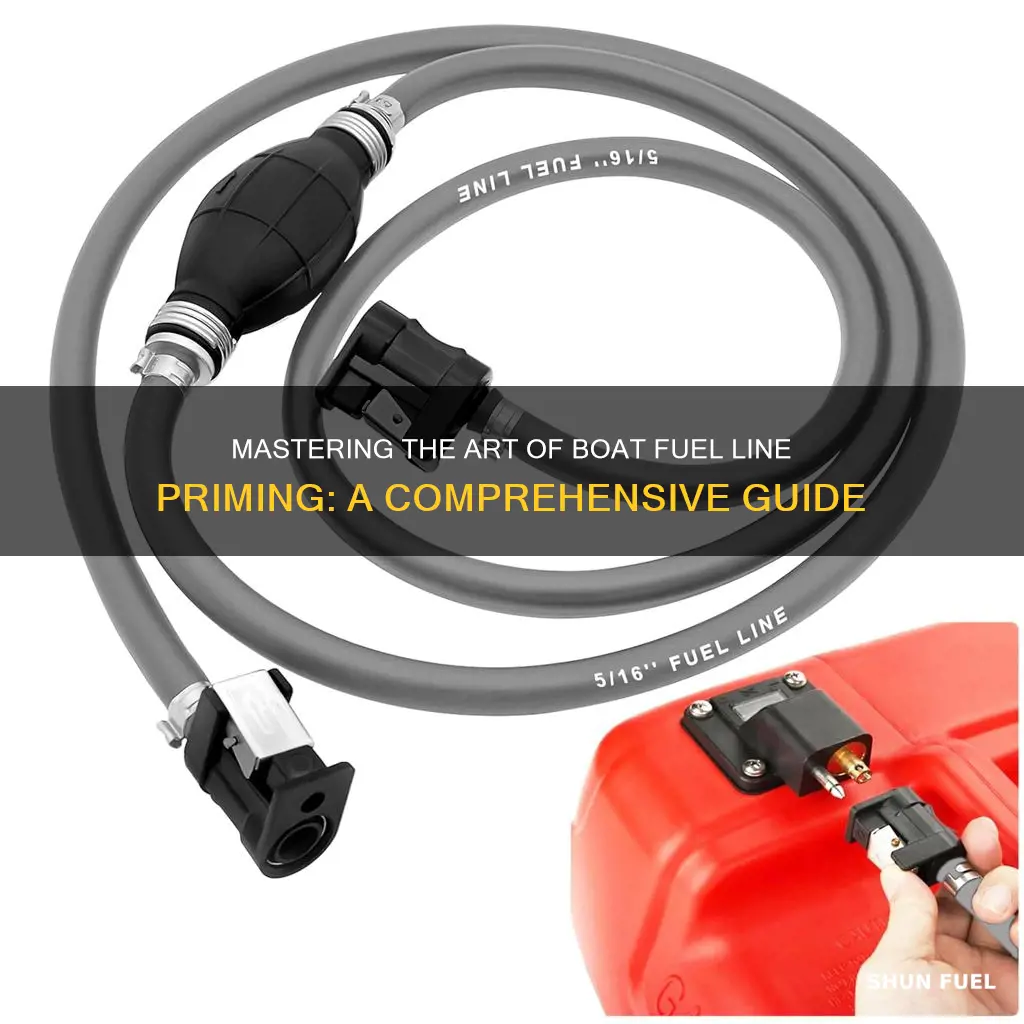

Gather the Necessary Tools: Prepare the required tools and equipment beforehand. This includes a fuel primer bulb, a fuel gauge (if applicable), a fuel filter (if replacing), and any necessary cleaning supplies. Having everything ready will make the priming process more efficient and organized.

By following these preparation steps, you create a safe and controlled environment for priming your boat's fuel line. It ensures that you can work effectively while minimizing potential risks associated with fuel handling. Remember, safety should always be the top priority when working on any marine projects.

Mastering Fuel Line Removal: A Step-by-Step Guide to Accessing Your Fuel Filter

You may want to see also

Fuel Line Inspection: Check for any damage, blockages, or leaks in the fuel line

When it comes to priming a boat's fuel line, a thorough inspection is crucial to ensure optimal performance and prevent potential issues. Here's a step-by-step guide to inspecting the fuel line for any damage, blockages, or leaks:

- Visual Inspection: Begin by visually examining the fuel line for any visible signs of damage. Look for cracks, punctures, or any discolored areas along the length of the line. Pay close attention to areas where the line connects to the fuel tank, pump, and engine. Even small tears or abrasions can lead to fuel leaks and potential engine issues. If you notice any damage, it's essential to address it immediately. Consider replacing the fuel line if the damage is significant or if it's near the end of its lifespan.

- Check for Blockages: Fuel line blockages can occur due to sediment buildup, debris, or clogs. Start by removing the fuel line's connectors and examining the interior. Use a bright flashlight to shine into the line to check for any obstructions. If you spot blockages, you can try to clear them by using a fuel line brush or a small, flexible tool. Ensure you clean the line thoroughly to prevent recurring blockages.

- Leak Detection: Leaks in the fuel line can be detrimental to your boat's performance and safety. To check for leaks, start the engine and listen for any unusual sounds, such as hissing or roaring. Inspect the fuel line connections and fittings for any signs of fuel seepage. You can also use a soapy water solution and carefully wipe the fuel line connections to create a foam. If bubbles appear, it indicates a leak. Address any leaks promptly to prevent fuel wastage and potential engine damage.

- Pressure Testing: Consider performing a pressure test to ensure the fuel line's integrity. Attach a pressure gauge to the fuel line's outlet and start the engine. Monitor the gauge to check for any pressure drops or fluctuations. This test can help identify potential issues with the fuel pump or line restrictions. If the pressure test reveals any problems, further investigation and potential repairs may be necessary.

- Regular Maintenance: Regular maintenance is key to keeping your boat's fuel line in optimal condition. Schedule periodic inspections, especially before the boating season, to catch any issues early. Keep an eye out for any changes in engine performance, such as reduced power or erratic behavior, which could be indicators of fuel line problems. By staying proactive, you can ensure a smooth and safe boating experience.

Mastering the Fuel Line Mystery: Supply vs. Return

You may want to see also

Prime Pump: Prime the fuel pump by cycling the engine or using a manual priming method

To prime your boat's fuel pump, you can either cycle the engine or use a manual priming method. Both techniques are effective and can help ensure your boat's engine starts smoothly and runs efficiently. Here's a detailed guide on how to prime the fuel pump using both methods.

Cycling the Engine:

- Start by ensuring your boat is in a secure and level position. This is important for safety and to avoid any spills or accidents.

- Locate the fuel pump, which is typically located near the engine. It might be a separate component or integrated into the engine itself.

- Turn the key or pull the starter handle to start the engine. If the engine doesn't start immediately, it's a sign that the fuel pump needs priming.

- Keep the engine running and listen for any hissing or bubbling sounds from the fuel lines. These sounds indicate that the fuel pump is drawing fuel from the tank and priming the system.

- If you hear these sounds, the priming process is successful. You can now shut off the engine and proceed to the next step to ensure the fuel system is ready for use.

Manual Priming Method:

- Begin by locating the fuel tank and identifying the fuel pump. The pump might be a small, electric or manual device connected to the fuel lines.

- If your boat has a manual priming valve, locate it and open it. This valve allows you to manually prime the fuel pump by forcing air into the system.

- Use a priming bulb or a similar tool to draw fuel from the tank and inject it into the fuel lines. Squeeze the bulb to draw fuel, then release it to push air out of the lines. Repeat this process several times until you hear the fuel pump priming.

- For electric fuel pumps, you may need to locate the priming mechanism, which is often a small, manual valve or button. Press and hold this button while priming the bulb to ensure the pump receives the necessary fuel.

- Once you've heard the priming sounds or seen the fuel flow, close the priming valve and secure the priming tool. Your fuel pump is now primed and ready for use.

Remember, priming the fuel pump is crucial to ensure your boat's engine receives the correct fuel volume and pressure. Both methods are effective, and you can choose the one that suits your boat's design and your personal preference. Always exercise caution when working with fuel to avoid any accidents or damage.

Mastering Fuel Line Clamps: A Comprehensive Guide to Crimping

You may want to see also

Fuel Filter: Clean or replace the fuel filter to prevent contamination

The fuel filter is a critical component in your boat's fuel system, acting as a barrier to trap contaminants and ensure clean fuel reaches the engine. Over time, this filter can become clogged or contaminated, leading to reduced engine performance and potential damage. Regular maintenance, including cleaning or replacing the fuel filter, is essential to keep your boat running smoothly and prevent costly repairs.

Here's a step-by-step guide on how to maintain your fuel filter:

- Locate the Fuel Filter: Familiarize yourself with your boat's fuel system layout. The fuel filter is typically located near the engine, often along the fuel line. Consult your boat's manual or online resources for specific locations, as they can vary depending on the make and model.

- Cleaning the Fuel Filter: If your fuel filter is accessible and shows signs of dirt or debris accumulation, you can attempt to clean it. Start by draining the fuel tank to remove any sediment. Then, carefully remove the filter and inspect it. Use a filter cleaning tool or compressed air to blow out any remaining contaminants. Ensure you clean all surfaces, including the inside of the filter housing. After cleaning, reattach the filter securely.

- Replacing the Fuel Filter: If the filter is heavily contaminated, damaged, or past its recommended replacement interval, it's best to replace it. Purchase a new fuel filter compatible with your boat's model. Locate the old filter's mounting points and use a fuel line connector to attach the new filter. Ensure a tight seal to prevent fuel leaks.

- Preventative Maintenance: To avoid frequent filter replacements, consider the following:

- Regularly check for signs of contamination, such as fuel discoloration or engine performance issues.

- Use fuel stabilizers in your boat's fuel tank to inhibit contamination.

- Schedule routine engine maintenance to ensure overall system health.

By following these steps, you can effectively manage your boat's fuel filter, ensuring a clean fuel supply and optimal engine performance. Remember, proper maintenance can save you from potential breakdowns and costly repairs.

Air in Fuel Line: Impact on Diesel Engine Performance

You may want to see also

Test and Adjust: Test the fuel flow and adjust the priming as needed for optimal performance

When priming a boat's fuel line, the 'Test and Adjust' phase is crucial to ensure the system is functioning optimally. This step involves evaluating the fuel flow and making any necessary adjustments to the priming process. Here's a detailed guide on how to approach this:

Testing Fuel Flow: Begin by starting the boat's engine and observing the fuel flow. A properly functioning fuel line should deliver a steady stream of fuel to the engine. If the flow is inconsistent or weak, it indicates a potential issue with the priming. Listen for any unusual noises, such as a gurgling sound, which could suggest air bubbles in the line. Check the fuel gauge to ensure it's at the correct level, as low fuel might impact the priming process.

Adjusting Priming: Adjusting the priming process is an art that requires patience and a systematic approach. Start by ensuring the fuel pump is running correctly and delivering fuel to the carburetor or fuel injection system. If the engine doesn't start or struggles to start, you might need to increase the priming pressure. This can often be done by adjusting the fuel pump's settings or using a priming bulb (if applicable). Gradually increase the priming pressure and observe the engine's response.

Fine-Tuning: Fine-tuning the priming process might involve several steps. Check the fuel filter for any blockages and replace it if necessary. Ensure the fuel line is not kinked or damaged, as this can restrict flow. Consider using a fuel additive to improve combustion and engine performance. After making adjustments, retest the fuel flow and engine response. Repeat the adjustment process until you achieve a consistent and strong fuel flow, ensuring the engine starts smoothly and runs optimally.

Troubleshooting: If the engine still doesn't start or performs poorly after adjustments, troubleshooting is necessary. Check for any fuel leaks in the system, as they can cause poor performance. Inspect the carburetor or fuel injectors for blockages or damage. Sometimes, a simple cleaning or replacement of these components can resolve priming issues. It's essential to identify and address any underlying problems to ensure the boat's fuel system operates efficiently.

Remember, priming a boat's fuel line requires a methodical approach, and adjustments might be necessary until the system is optimized for your specific vessel and engine. Always refer to the boat's manual for specific guidance and safety instructions during the priming process.

Fitech Fuel Line Sizing: Feed and Return Line Guide

You may want to see also

Frequently asked questions

Priming a boat fuel line is essential to ensure that the fuel system is ready for operation and to prevent air bubbles from entering the system. It helps to create a vacuum in the fuel line, allowing the engine to start efficiently and smoothly.

If your boat has been sitting idle for a while, or if you've recently changed the fuel, it's a good practice to prime the fuel line. You can also check for any signs of air bubbles, such as a sputtering engine or difficulty starting.

You will need a fuel primer bulb, which is typically a small, hand-operated pump attached to a flexible tube. Some boats may also require a fuel filter and a fuel gauge to ensure proper priming.

Yes, priming can often be done without removing the fuel tank. You can connect the primer bulb to the fuel line and pump the bulb to create the necessary vacuum. However, in some cases, especially with older boats, you might need to remove the fuel tank for easier access.

Yes, it's important to ensure the engine is turned off and the boat is in a secure position before priming. Always wear protective gear, such as gloves and goggles, to avoid any potential fuel spills or splashes. Additionally, make sure to prime in a well-ventilated area to avoid inhaling fuel vapor.