Fixing a fuel line leak is a crucial task for vehicle owners to ensure their safety and prevent potential engine damage. A fuel line leak can occur due to various reasons, such as wear and tear, corrosion, or accidental damage. This guide will provide a step-by-step approach to repairing a fuel line leak, covering the necessary tools, safety precautions, and the process of replacing or repairing the affected part. By following these instructions, you can effectively address the issue and restore your vehicle's performance.

What You'll Learn

- Locate the Leak: Identify the exact spot where the fuel line is leaking using a visual inspection and a fuel-scented soap solution

- Prepare the Vehicle: Ensure the car is parked on a level surface, and turn off the engine to prevent further fuel loss

- Contain the Fuel: Use a container or absorbents to catch any remaining fuel and prevent environmental contamination

- Repair or Replace: Decide whether to repair the damaged section or replace the entire fuel line based on the severity of the leak

- Secure Connections: Tighten any loose connections and ensure all components are properly aligned to prevent future leaks

Locate the Leak: Identify the exact spot where the fuel line is leaking using a visual inspection and a fuel-scented soap solution

To effectively address a fuel line leak, the first crucial step is to pinpoint the exact location of the issue. This process involves a methodical visual inspection and a clever use of a fuel-scented soap solution. Here's a detailed guide on how to locate the leak:

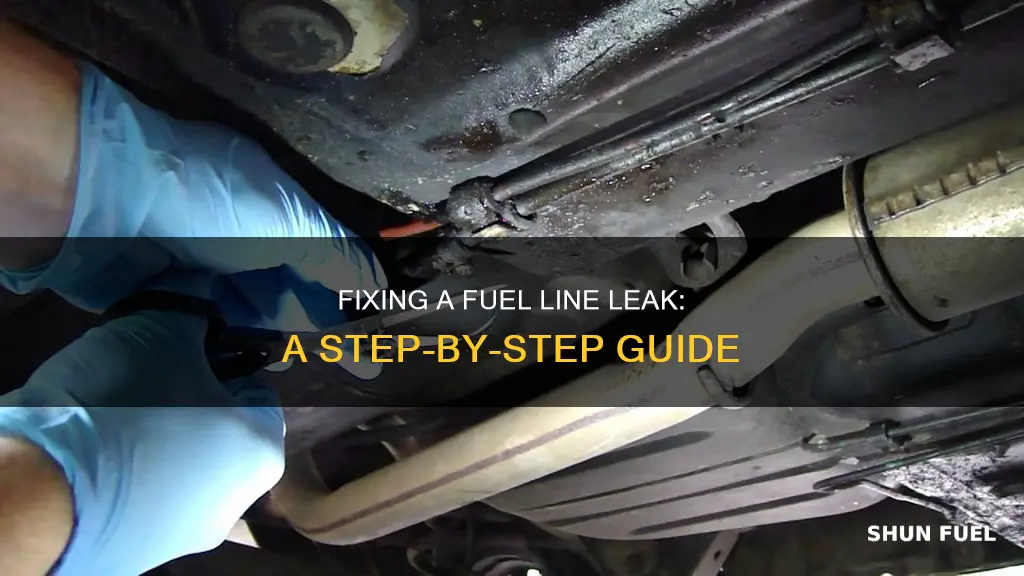

Visual Inspection: Begin by thoroughly examining the fuel line for any visible signs of damage or deterioration. Fuel lines are typically located beneath the vehicle, running from the fuel tank to the engine. Look for any cracks, punctures, or frayed areas along the line. Pay close attention to bends and joints, as these are common spots for leaks due to stress and wear. Use a bright flashlight to illuminate dark areas and ensure you don't miss any potential issues. Keep in mind that fuel lines can be hidden behind various components, so carefully move these parts aside to get a clear view.

Using a Fuel-Scented Soap Solution: This is a clever technique to detect fuel leaks that might not be immediately visible. Here's how it works:

- Mix a small amount of a mild, non-toxic detergent (like dish soap) with water. Add a few drops of a fuel-scented soap or a few drops of fuel itself to the mixture. Ensure the solution is not too concentrated, as it should be safe for your skin.

- Spray the solution onto the fuel line, starting from the fuel tank and moving towards the engine. Pay close attention to the areas where the line bends or connects to other components.

- As you spray, observe the fuel line carefully. If there is a leak, you will likely notice a small, steady stream of fuel escaping. The scent of fuel will also help you pinpoint the exact location. If the leak is more significant, you might see a larger pool of fuel forming around the affected area.

- If you find a potential leak site, mark it with a temporary marker or tape to ensure you don't miss it during the repair process.

By combining a thorough visual inspection with the fuel-scented soap solution, you can accurately identify the source of the leak. This precise location will then guide you in choosing the appropriate repair method, whether it's a simple fix or a more extensive replacement of the damaged fuel line. Remember, safety should always be a priority when working with fuel, so ensure proper ventilation and take the necessary precautions during the repair process.

Unveiling the Mystery: What's in the Fuel Line to Reduce NOx Emissions?

You may want to see also

Prepare the Vehicle: Ensure the car is parked on a level surface, and turn off the engine to prevent further fuel loss

Before attempting to fix a fuel line leak, it's crucial to ensure your safety and that of your vehicle. Start by parking your car on a level, firm surface, preferably in a well-ventilated area. This is essential to prevent any potential hazards associated with fuel leaks, such as fire or explosion. Once the vehicle is securely positioned, turn off the engine and allow it to cool down. This step is vital as it minimizes the risk of injury from hot engine components and reduces the chances of fuel vapor igniting.

With the car stationary and the engine off, you can now inspect the fuel line for the source of the leak. Locate the fuel lines, which are typically made of rubber or plastic and run from the fuel tank to the engine. Inspect these lines for any visible damage, cracks, or signs of deterioration. Look for any discolored or wet spots on the ground beneath the vehicle, as these could indicate a leak. If you notice any issues, it's important to address them promptly to prevent further fuel loss and potential engine damage.

If the leak is minor and you feel confident in your ability to fix it, you can proceed with the necessary repairs. Ensure you have the required tools and materials, such as a fuel line repair kit, which typically includes a replacement section of fuel line, clamps, and sealing compounds. Clean the affected area to remove any debris or contaminants. Then, carefully cut the damaged section of the fuel line and prepare the ends for the new connection. Insert the replacement section, ensuring it is the correct size and securely clamp it in place. Apply the sealing compound to create a tight, leak-free seal.

For more significant leaks or if you're unsure about the repair process, it's highly recommended to seek professional assistance. Automotive mechanics have the expertise and specialized tools to identify and fix fuel line issues safely and effectively. They can also ensure that the repair is done correctly, preventing potential future problems. Always remember that working with fuel requires caution, and it's better to consult a professional to avoid any accidents or further damage to your vehicle.

Understanding Fuel Line Flare: A Comprehensive Guide

You may want to see also

Contain the Fuel: Use a container or absorbents to catch any remaining fuel and prevent environmental contamination

When dealing with a fuel line leak, containing the fuel is crucial to prevent any environmental damage. Here's a step-by-step guide on how to effectively manage the situation:

Step 1: Identify the Source

Before attempting to contain the fuel, locate the exact source of the leak. This could be a damaged fuel line, a loose connection, or a faulty fuel pump. Understanding the origin will help you choose the appropriate containment method.

Step 2: Gather Materials

You'll need a few essential items to contain the fuel effectively:

- Container: Use a sturdy, leak-proof container specifically designed for fuel storage. Ensure it is large enough to hold the amount of fuel that might spill. Plastic or metal containers with tight-fitting lids are ideal.

- Absorbent Materials: Place absorbent pads, cat litter, or commercial fuel absorbents around the leak area. These materials will help soak up any spilled fuel, preventing it from spreading.

- Gloves and Safety Gear: Protect yourself by wearing gloves, safety goggles, and a respirator to avoid direct contact with fuel and any potential fumes.

Step 3: Contain and Absorb

- Place the container securely under the leak to catch any fuel that escapes. Ensure it is positioned to avoid any fuel entering drains or water sources.

- Sprinkle or spread the absorbent materials around the leak, allowing them to come into contact with the fuel. This process will help absorb and neutralize the fuel, preventing it from spreading further.

- Continuously monitor the absorbent materials and replace them as needed to maintain their effectiveness.

Step 4: Prevent Further Spillage

While containing the fuel, take additional measures to prevent further leaks:

- Turn off the fuel supply to the affected area if possible. This could involve shutting off the fuel pump or disconnecting the fuel line temporarily.

- Secure any loose connections or damaged parts to prevent additional fuel from escaping.

- If the leak is significant, consider contacting emergency services or environmental response teams for assistance, especially if the fuel is near water bodies or sensitive ecosystems.

Remember, when dealing with fuel leaks, time is of the essence. Act quickly to contain the fuel and minimize the potential environmental impact. Always prioritize safety and follow local regulations regarding fuel handling and disposal.

Understanding Aluminum Fuel Line Ratings: A Comprehensive Guide

You may want to see also

Repair or Replace: Decide whether to repair the damaged section or replace the entire fuel line based on the severity of the leak

When dealing with a fuel line leak, it's crucial to assess the situation carefully to determine whether the damaged section can be repaired or if the entire fuel line needs to be replaced. The decision should be based on the severity and location of the leak, as well as the overall condition of the fuel line. Here's a step-by-step guide to help you make the right choice:

Assess the Leak's Severity: Start by evaluating the size and rate of the leak. A small, slow drip might be manageable with a temporary fix, while a large, rapid leak could indicate a more significant issue. If the leak is causing fuel to spill onto the ground or if it's accompanied by a strong odor, it's best to replace the fuel line immediately to prevent potential hazards and further damage.

Inspect the Fuel Line: Visually examine the fuel line for any visible signs of damage, such as cracks, punctures, or corrosion. Check for any signs of deterioration, especially if the fuel line is older or has been exposed to harsh conditions. If the damage is confined to a small section, repairing it might be feasible. However, if the leak is near a critical component or if the line shows extensive wear, replacement could be necessary.

Consider the Repair Option: If the leak is minor and the fuel line appears relatively intact, you can attempt to repair the damaged section. This typically involves cutting out the affected part, cleaning the area, and using specialized fuel line repair kits. These kits often include adhesive, sealant, and clamps to secure the new section. Ensure you follow the manufacturer's instructions carefully for a successful repair.

Evaluate the Replacement Option: Replacing the entire fuel line is a more drastic measure but may be required in certain cases. If the leak is widespread, the fuel line is severely damaged, or there are concerns about the overall integrity of the line, it's best to replace it. This process involves removing the old fuel line and installing a new one, ensuring proper connections and fittings. It's a more complex task and should be done by a professional to guarantee safety and functionality.

Safety Precautions: Regardless of whether you choose to repair or replace the fuel line, safety should be a top priority. Always work on a level surface, wear protective gear, and ensure the engine is cool before starting any repairs. If you're unsure about any step, consult a professional mechanic to ensure the job is done safely and effectively.

Remember, the decision to repair or replace should be made based on a thorough assessment of the situation. While temporary repairs might be possible, prioritizing safety and long-term reliability often leads to the replacement of the entire fuel line to avoid potential hazards and further complications.

Understanding the Role of the Diesel Fuel Return Line

You may want to see also

Secure Connections: Tighten any loose connections and ensure all components are properly aligned to prevent future leaks

When dealing with a fuel line leak, one of the most crucial steps is to ensure that all connections are secure and properly aligned. This process involves a systematic approach to identifying and addressing potential issues. Start by inspecting the fuel lines and connections for any visible signs of damage, corrosion, or wear. Look for frayed or damaged lines, as well as any areas where the line might be pinched or kinked. These issues can lead to leaks, so it's essential to address them immediately.

The first step in tightening loose connections is to gather the necessary tools. You'll typically need a set of wrenches or pliers of various sizes, depending on the type of connections you're dealing with. For example, if you're working with fuel injectors, you might need a specific-sized socket or wrench. It's important to have the right tools to ensure you don't damage the components while tightening them.

Now, let's go through the process of tightening connections. Locate the fuel line connections and inspect them for tightness. If you find any loose connections, apply firm pressure with your wrench or pliers and tighten them further. Ensure that you don't overtighten, as this can cause damage to the threads or the fuel line itself. The goal is to achieve a secure, snug fit without applying excessive force.

In addition to tightening connections, it's crucial to check the alignment of all components. Fuel lines should run smoothly and not be kinked or bent in a way that could cause leaks. Inspect the route of the fuel line for any obstacles or sharp bends that might lead to damage. If you notice any misalignment or potential stress points, adjust the line to ensure a smooth, straight path. Proper alignment helps prevent leaks and ensures the efficient flow of fuel.

Finally, after tightening and aligning all connections, take a moment to double-check your work. Verify that all components are secure and that there are no visible leaks. Start the engine and monitor for any signs of fuel loss. If the leak persists, you may need to further investigate and potentially replace damaged parts. By following these steps, you can effectively secure connections and prevent future fuel line leaks.

Is a Larger Return Fuel Line Necessary for Your Chevy Lumina?

You may want to see also

Frequently asked questions

A fuel line leak can be identified by the presence of fuel odor, especially if you notice a strong smell around the engine or under the car. You might also see fuel stains or puddles around the vehicle, especially in the garage or driveway. Additionally, a hissing or bubbling sound near the fuel tank or lines could indicate a leak.

Fuel line leaks can occur due to several reasons. Common causes include age and wear, as fuel lines can deteriorate over time, especially if they are made of rubber or plastic. Cracks, punctures, or damage from sharp objects or accidents are also potential causes. Corrosion and rust can weaken the fuel line, leading to leaks.

For minor leaks, such as small cracks or punctures, you might be able to temporarily fix the issue by using a fuel line repair kit, which typically involves clamping the damaged area and applying a sealant. However, for more significant leaks or if you're unsure about the extent of the damage, it's best to consult a professional mechanic. They have the expertise and tools to safely and effectively repair the fuel lines.

Driving with a fuel line leak can lead to several problems. The most immediate risk is the potential for a fire hazard due to the flammable nature of fuel. Leaks can also cause engine misfires, reduced performance, and even complete engine failure if the leak is significant. Additionally, fuel can contaminate other vehicle fluids, leading to further mechanical issues. It is crucial to address a fuel line leak promptly to ensure your safety and the proper functioning of your vehicle.