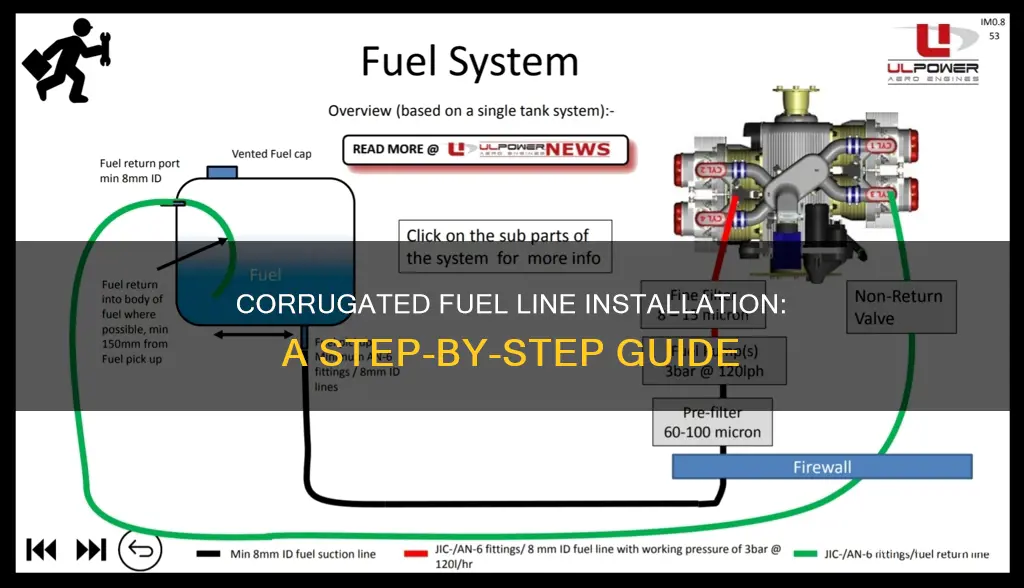

Installing corrugated fuel lines is a crucial step in ensuring the safe and efficient delivery of fuel to your vehicle's engine. This process involves carefully routing the fuel line through the engine bay, often in a corrugated or flexible design, to withstand the rigors of the road. The installation requires attention to detail, as the fuel line must be securely attached to the vehicle's frame and engine components while maintaining a clear path to the fuel tank. Proper installation is essential to prevent fuel leaks and ensure optimal engine performance. This guide will provide a step-by-step approach to help you successfully install corrugated fuel lines, covering the necessary tools, safety precautions, and techniques to achieve a reliable and long-lasting fuel system.

| Characteristics | Values |

|---|---|

| Material | Corrugated metal or plastic |

| Diameter | Typically 3/8" to 1/2" |

| Length | Varies based on engine and vehicle layout |

| Flexibility | Corrugated design provides flexibility for engine movement |

| Durability | Resistant to fuel leaks and engine vibrations |

| Installation | Requires careful alignment and secure fastening |

| Compatibility | Specific to vehicle's fuel system |

| Maintenance | Regular inspection for cracks or damage |

| Safety | Prevents fuel leaks and potential fire hazards |

| Cost | Varies depending on material and brand |

| Availability | Automotive parts stores or online retailers |

What You'll Learn

- Prepare Tools: Gather necessary tools: fuel line, connectors, wrenches, and cleaning supplies

- Clean Line: Remove old fuel line, clean surfaces, and ensure no debris remains

- Connect Line: Attach new fuel line to engine, using appropriate connectors and securing properly

- Test System: Start engine, check for leaks, and ensure proper fuel flow

- Secure Line: Use clamps or brackets to firmly hold fuel line in place

Prepare Tools: Gather necessary tools: fuel line, connectors, wrenches, and cleaning supplies

Before you begin the installation process, it's crucial to have all the necessary tools and materials ready to ensure a smooth and efficient job. Here's a breakdown of the tools you'll need:

Fuel Line: The primary component you'll be working with is the corrugated fuel line. This type of fuel line is designed to withstand the rigors of fuel transport and is commonly used in automotive applications. Ensure you have the appropriate length and diameter of fuel line for your specific setup.

Connectors: These are essential for securely attaching the fuel line to various components, such as the fuel tank, engine, and other fuel system parts. Get the right connectors that fit your fuel line and the specific connections you need to make. Common types include quick-connect fittings, barbed fittings, and compression fittings.

Wrenches: You'll require a set of wrenches to tighten and secure the connectors and any other fasteners involved in the installation. Make sure you have various sizes, including metric and imperial measurements, to accommodate different bolt and nut sizes.

Cleaning Supplies: Keeping the work area and fuel system components clean is vital. Gather cleaning supplies such as a degreaser or fuel line cleaner to remove any contaminants or old fuel residue. A soft cloth or brush will also be useful for wiping down surfaces and ensuring a clean installation.

Having all these tools and materials prepared beforehand will make the installation process more organized and efficient. It's always a good practice to double-check your inventory to ensure you haven't missed any critical items before starting the project.

C5 Corvette Fuel Line: Quick Disconnect Removal Guide

You may want to see also

Clean Line: Remove old fuel line, clean surfaces, and ensure no debris remains

To begin the installation of a new corrugated fuel line, it is crucial to properly remove the old one. Start by disconnecting the fuel line from the engine and the fuel tank. Use appropriate tools to carefully loosen any fittings or clamps holding the old line in place. Take note of the layout and positioning of the old fuel line to ensure a smooth installation of the new one. Once disconnected, carefully pull the old fuel line out of the engine bay, being mindful of any sharp edges or protruding parts that might damage the new line.

After removing the old fuel line, it is essential to clean the surfaces to ensure a proper bond and installation. Start by cleaning the engine bay and the surrounding areas. Use a mild detergent and water solution to wash away any dirt, grease, or grime. Pay close attention to the areas where the old fuel line was attached, as these spots may have accumulated debris or residue. Rinse the entire area thoroughly to remove any cleaning agents and allow the surfaces to dry completely.

When cleaning the fuel line itself, you can use a degreaser or a specialized fuel line cleaner. Apply the cleaner to the interior of the old line and let it sit for a few minutes to dissolve any built-up contaminants. Then, use a brush or a cleaning tool to gently scrub the inside of the line, removing any debris or residue. Ensure that you also clean the fittings and connectors, as any remaining dirt could affect the performance of the new fuel line.

Once the cleaning process is complete, inspect the fuel line and the surrounding areas to ensure there are no remaining debris or contaminants. Use a soft cloth or a compressed air tool to blow away any loose particles. Make sure that all surfaces are clean and free from any foreign matter that could interfere with the installation. This step is crucial to guarantee a smooth and secure connection between the new fuel line and the engine components.

By following these steps, you can effectively remove the old fuel line, clean the surfaces, and ensure that no debris remains, providing a solid foundation for the installation of the new corrugated fuel line. Proper preparation will contribute to a successful and long-lasting fuel system upgrade.

Cap Off Fuel Line: Ford F-150 '95 Guide

You may want to see also

Connect Line: Attach new fuel line to engine, using appropriate connectors and securing properly

When attaching the new corrugated fuel line to your engine, it's crucial to follow a systematic approach to ensure a secure and reliable connection. Begin by locating the appropriate connectors designed for your specific fuel line and engine model. These connectors should be compatible with the fuel line's diameter and material to ensure a tight and leak-free seal.

Carefully slide the connector onto the fuel line, ensuring it covers the entire length of the line where it will be connected to the engine. The connector should have a secure locking mechanism to keep the line in place. Once the connector is in position, use the provided screws or clips to fasten it securely to the engine block or frame. Tighten the screws firmly, but be cautious not to overtighten, as this can damage the fuel line.

After attaching the connector, inspect the connection for any signs of strain or stress on the fuel line. Ensure that the line is not kinked or pinched, as this can restrict fuel flow and potentially cause damage over time. The fuel line should be positioned away from any moving parts or heat sources to prevent damage and ensure optimal performance.

To further secure the fuel line, consider using additional support straps or brackets, especially if the line runs along a long distance or has multiple bends. These accessories can help maintain the line's shape and prevent it from sagging or coming loose over time. Regularly check and adjust these straps as needed to accommodate any changes in the engine's position or operating conditions.

Finally, double-check all connections and ensure that the fuel line is properly secured and aligned. Test the fuel system by starting the engine and monitoring for any leaks or unusual noises. If everything is functioning correctly, you've successfully installed the corrugated fuel line, ensuring efficient and reliable fuel delivery to your engine.

Troubleshooting Fuel Line Connector Issues: A Step-by-Step Guide

You may want to see also

Test System: Start engine, check for leaks, and ensure proper fuel flow

Before you begin the testing phase, ensure you have all the necessary tools and equipment, including the corrugated fuel line, fuel pump, and any required adapters or fittings. It's crucial to have a well-prepared workspace to facilitate a smooth testing process.

Start by attaching the corrugated fuel line to the fuel pump and then securely connect it to the engine's fuel injection system or carburetor, following the manufacturer's instructions. Make sure the connections are tight and free from any potential leaks. Once connected, it's time to ignite the engine.

With the engine running, your primary focus should be on identifying and addressing any potential leaks. Inspect all connections thoroughly, including the fuel pump, lines, and the engine's fuel system. Look for any signs of fuel escaping, such as hissing sounds or visible fuel droplets. If you detect a leak, immediately stop the engine and tighten or replace the affected connections to prevent further issues.

In addition to leak detection, ensure that the fuel flow is optimal. Check the fuel pressure using a gauge to verify that it meets the engine's requirements. Proper fuel flow is essential for efficient engine performance, so any deviations from the expected pressure should be addressed promptly. Adjust the fuel pump settings or consider replacing the pump if necessary to maintain the correct fuel flow rate.

After addressing any leaks and confirming the fuel flow, start the engine again and let it run for a while. Monitor the engine's behavior and listen for any unusual noises. A properly installed and tested corrugated fuel line should provide a smooth and efficient fuel supply, allowing the engine to run smoothly without any issues. Regularly check the engine's performance during this testing phase to ensure everything is functioning as expected.

Replacing the Fuel Line: A Step-by-Step Guide for the FS55R

You may want to see also

Secure Line: Use clamps or brackets to firmly hold fuel line in place

When installing a corrugated fuel line, ensuring it is securely fastened is crucial to prevent leaks and maintain the integrity of the fuel system. One effective method to achieve this is by using clamps or brackets. These components provide a reliable and adjustable means of holding the fuel line in place, allowing for a customized fit that accommodates the unique shape and size of the corrugated fuel line.

Clamps are typically made of durable materials such as metal or plastic and feature a clamping mechanism that grips the fuel line tightly. They are available in various sizes and styles, including ring-type, U-clip, and quick-release clamps. When selecting clamps, consider the diameter of the fuel line and choose a size that provides a secure but gentle grip to avoid damaging the line. It's important to position the clamps at regular intervals along the length of the fuel line to ensure even tension and prevent the line from shifting or sagging.

Brackets, on the other hand, offer a more permanent solution by attaching directly to the fuel line or the surrounding structure. These brackets can be made of metal or plastic and often feature a mounting hole or slot to secure them in place. Brackets are particularly useful when the fuel line needs to be positioned at a specific angle or when additional support is required. By using brackets, you can create a stable and secure mounting point for the fuel line, reducing the risk of movement or damage.

To install the clamps or brackets, start by cleaning the fuel line and the mounting surfaces to ensure a proper bond. Then, position the fuel line in the desired location and apply the appropriate number of clamps or brackets, ensuring they are securely fastened. Tighten the clamps or brackets according to the manufacturer's instructions, being careful not to overtighten, as this can cause damage to the fuel line. Regularly inspect the clamps and brackets for any signs of wear or damage, especially in areas where the fuel line bends or turns, and replace them if necessary to maintain the security of the fuel line.

By employing clamps or brackets, you can effectively secure the corrugated fuel line, ensuring a reliable and safe fuel supply. This method provides a practical and adjustable solution, allowing for easy installation and maintenance while minimizing the risk of fuel leaks or system failures. Remember to follow the manufacturer's guidelines and best practices for fuel line installation to ensure optimal performance and safety.

Mastering Fuel Line Bleeding: A Guide for the 2555JD

You may want to see also

Frequently asked questions

Corrugated fuel lines are designed to provide a flexible and durable solution for transporting fuel in various automotive applications. They are commonly used in high-performance vehicles, racing cars, and classic car restoration projects due to their ability to withstand high pressure and temperature changes.

The size of the fuel line should be based on the flow rate requirements of your engine and the vehicle's fuel system. Typically, larger engines or those with higher performance demands will require larger diameter corrugated fuel lines to ensure efficient fuel delivery. It's important to consult the vehicle's manual or seek professional advice to choose the appropriate size.

While it is possible for experienced DIY enthusiasts to install corrugated fuel lines, it is generally recommended to seek professional assistance. Fuel line installation requires precision and knowledge of the vehicle's fuel system to ensure a secure and leak-free connection. Professional mechanics have the expertise to identify potential issues and ensure proper installation.

The installation process will require a few essential tools, including fuel line cutters, crimping tools, pipe wrenches, and fuel line connectors. It is important to have the correct size and type of connectors that match your vehicle's fuel system. Additionally, you will need cleaning supplies to ensure the fuel lines are free from contaminants before installation.

Regular maintenance is crucial to ensure the longevity of corrugated fuel lines. It is recommended to inspect the lines periodically for any signs of damage, cracks, or leaks. Keep the fuel lines clean and free from debris, and avoid using sharp objects that could puncture the lines. Properly storing the vehicle and fuel when not in use can also help prevent potential issues with the fuel lines.