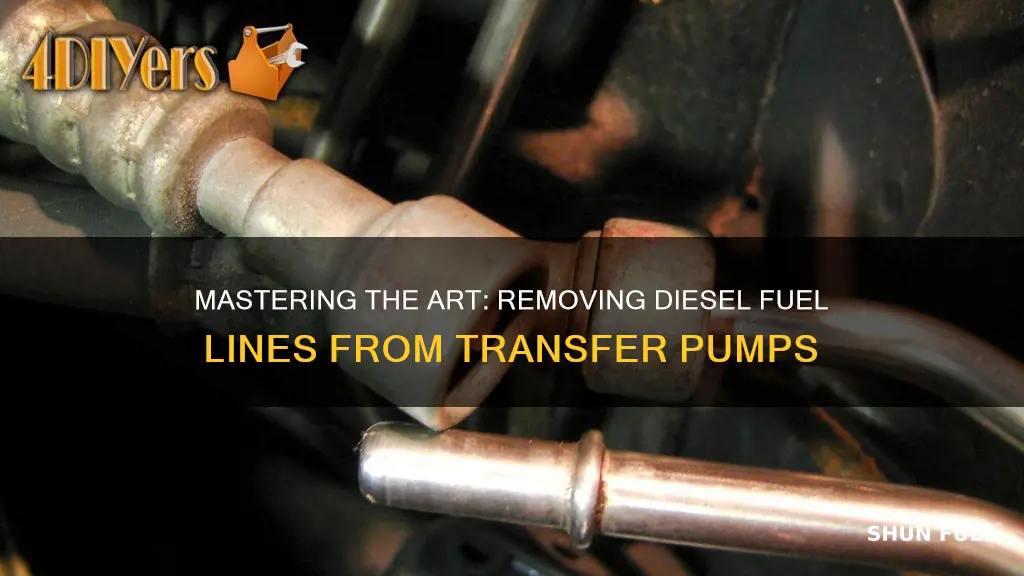

Getting the diesel fuel line out of a transfer pump can be a tricky task, but with the right approach, it's definitely achievable. This guide will provide a step-by-step process to safely and effectively remove the fuel line, ensuring you have a clear understanding of the process and can tackle it with confidence.

| Characteristics | Values |

|---|---|

| Accessing the Fuel Line | Locate the transfer pump and identify the fuel line connection. This is usually a quick-connect fitting or a threaded port. |

| Preparation | Ensure the engine is off and cooled down. Release the fuel pressure by opening the fuel tank vent or using a fuel pressure release valve. |

| Removing the Line | Use appropriate tools like a fuel line disconnect tool or a pair of pliers to carefully remove the fuel line from the transfer pump. Be cautious not to damage the pump or surrounding components. |

| Fuel Line Material | Diesel fuel lines are typically made of rubber or synthetic materials. Ensure you have the correct tools for the specific line material to avoid damage. |

| Safety Precautions | Wear protective gear, such as gloves and safety goggles, to prevent contact with hot engine parts and potential fuel spills. |

| Reinstallation | When reinstalling, ensure a secure and tight connection. Check for any leaks and test the fuel system before starting the engine. |

| Maintenance | Regularly inspect and maintain the fuel lines to prevent clogs and ensure optimal engine performance. |

What You'll Learn

- Prepare the Pump: Ensure the pump is cool and secure, disconnect power and fuel lines

- Loosen Connections: Use a wrench to loosen fuel line connections, being careful not to break seals

- Remove Lines: Carefully pull the fuel lines away from the pump, avoiding damage to fittings

- Extract the Pump: With lines removed, lift the pump out of the transfer unit

- Clean and Inspect: Thoroughly clean the pump and lines, then inspect for any damage or wear

Prepare the Pump: Ensure the pump is cool and secure, disconnect power and fuel lines

Before attempting to remove the diesel fuel line from the transfer pump, it is crucial to prioritize safety and ensure the pump is in a controlled and secure state. Start by allowing the pump to cool down. If the pump has been in use, let it rest for a while to prevent any potential injuries from hot components. Once cooled, secure the pump in a stable position. You can use jack stands or a sturdy platform to support the weight of the pump, especially if it is heavy or bulky. This step is essential to prevent any accidental movement or damage during the disassembly process.

Next, disconnect the power supply to the pump. Locate the power source, which could be a battery, a switch, or a fuse, depending on the setup. Carefully disconnect the power to ensure the pump doesn't accidentally start during the fuel line removal process. This step is a critical safety measure to prevent any unexpected operation of the pump.

Now, focus on the fuel lines. Identify the diesel fuel line connected to the transfer pump and locate the other end, which should lead to the fuel tank or another component in the fuel system. Carefully disconnect the fuel line from the pump, ensuring you have a clear understanding of the fuel flow direction to avoid any spills or mess. Use the appropriate tools, such as fuel line disconnects or clips, to safely remove the line without causing damage.

Once the power and fuel lines are disconnected, you can proceed with the specific steps to remove the fuel line from the transfer pump. This may involve loosening screws or bolts, prying off covers, or using specialized tools to access the fuel line connection points. Take your time and be gentle to avoid forcing components, as this can lead to damage. Proper preparation and a systematic approach will make the process smoother and safer.

Can You Cover a Fuel Line with PVC Pipe? Unveiling the Truth

You may want to see also

Loosen Connections: Use a wrench to loosen fuel line connections, being careful not to break seals

To access the diesel fuel line from a transfer pump, it's essential to start by loosening the connections carefully. This process requires a methodical approach to avoid any potential damage to the fuel system. Begin by identifying the fuel line connections that need to be loosened. These are typically located at the pump and may be secured with nuts, bolts, or clips.

Using a wrench is the recommended tool for this task. Select a wrench that fits the size of the nuts or bolts holding the fuel line in place. Apply a steady force to loosen the connections, turning the wrench in a counterclockwise direction. It's crucial to use a gentle and controlled approach to avoid forcing the wrench, which could lead to damage. Work on one connection at a time, ensuring that the fuel line is not under excessive tension.

As you loosen the connections, pay close attention to the seals. These seals are critical components that prevent fuel leaks. Carefully inspect the seals for any signs of damage or wear. If you notice any cracks or deterioration, it may be necessary to replace the seals to ensure a proper seal when reinstalling the fuel line. Take your time with this step to ensure you don't accidentally damage the seals further.

Once the connections are loosened, you can carefully remove the fuel line from the transfer pump. Guide the fuel line away from the pump and inspect it for any signs of contamination or damage. This step is crucial to ensure that the fuel line is ready for any necessary repairs or replacements. Remember to keep the fuel line secure and prevent it from coming into contact with sharp edges or surfaces that could cause further damage.

By following these steps and taking a careful approach, you can effectively loosen the connections and remove the diesel fuel line from the transfer pump without causing any unnecessary harm to the fuel system. This process requires patience and a gentle touch to ensure a successful outcome.

Locating the Fuel Filter: 2004 Pontiac Montana Guide

You may want to see also

Remove Lines: Carefully pull the fuel lines away from the pump, avoiding damage to fittings

To remove the fuel lines from a diesel transfer pump, you need to follow a systematic approach to ensure you don't cause any damage. Here's a step-by-step guide:

Step 1: Prepare the Work Area

Before you begin, ensure you have a clean and well-lit workspace. Gather the necessary tools, including a pair of pliers or a fuel line removal tool, which can help grip and pull the lines without causing damage. It's also a good idea to have some rags or towels ready to wipe away any fuel spills.

Step 2: Locate the Fuel Lines

Identify the fuel lines connected to the transfer pump. These lines are typically made of rubber or a flexible material and are often black or dark-colored. They may have fittings or connectors that secure them to the pump.

Step 3: Loosen the Fittings

Carefully inspect the fittings where the fuel lines are attached to the pump. Use the appropriate tool to loosen any screws or nuts that hold the fittings in place. Be gentle to avoid stripping the threads. Once loosened, you might need to wiggle the fittings to break the seal, allowing the fuel lines to be pulled out.

Step 4: Pull the Fuel Lines

Now, gently but firmly pull the fuel lines away from the pump. You may need to apply some force, but be careful not to twist or kink the lines. Work your way around the pump, pulling each line straight and avoiding any sharp bends. If the lines are stubborn, you can use the pliers or fuel line removal tool to grip and pull them without causing damage.

Step 5: Inspect for Damage

As you remove the fuel lines, inspect them for any signs of damage, such as cracks, leaks, or excessive wear. If you notice any issues, it's best to replace the lines to ensure safe and efficient operation.

Remember, patience and a gentle approach are key when removing fuel lines from a transfer pump. Take your time, and if you encounter any difficulties, consult a professional or refer to the pump's manual for specific instructions tailored to your model.

Mastering the Quick Release Fuel Line Tool: A Comprehensive Guide

You may want to see also

Extract the Pump: With lines removed, lift the pump out of the transfer unit

Once you've successfully removed the fuel lines from the transfer pump, the next step is to extract the pump itself from the transfer unit. This process requires careful handling to avoid any damage to the pump or the surrounding components. Here's a step-by-step guide to help you through this task:

- Prepare the Work Area: Ensure you have a clean and well-lit workspace. Place a suitable jack and jack stands beneath the transfer unit, positioned to support the weight of the pump. This step is crucial for safety and to prevent any accidents during the extraction process.

- Loosen Fasteners: Identify the fasteners (usually bolts or screws) that secure the pump to the transfer unit. Loosen these fasteners using the appropriate tools. Be cautious not to over-tighten, as this can lead to damage. You may need to apply some force, especially if the fasteners have seized over time.

- Lift the Pump: With the fasteners loosened, carefully lift the pump out of the transfer unit. This might require some muscle power, especially if the pump is heavy. Ensure that you have a firm grip and lift with your legs to engage the major muscle groups. Avoid twisting or turning the pump abruptly, as this could strain the connections.

- Inspect for Damage: Before placing the pump aside, inspect it for any signs of damage or wear. Check for cracks, leaks, or any other issues that might have occurred during the removal process. This step is essential to ensure the pump's continued functionality and safety.

- Secure the Pump: Place the pump in a safe location, preferably on a clean surface. Cover it with a cloth or a soft material to prevent scratches or dust accumulation. This step is particularly important if you plan to store the pump temporarily.

By following these steps, you'll be able to extract the pump from the transfer unit efficiently and safely. Remember, patience and careful handling are key during this process to ensure the longevity of your equipment.

Unraveling the Mystery: What Material Fuels the Hardest Fuel Lines?

You may want to see also

Clean and Inspect: Thoroughly clean the pump and lines, then inspect for any damage or wear

Before you begin the process of removing the diesel fuel line from the transfer pump, it is crucial to ensure that the pump and the associated lines are in optimal condition. Start by thoroughly cleaning the pump and the fuel lines. This step is essential to prevent any contamination or residue buildup that could interfere with the removal process or cause further issues. Use a suitable cleaning agent or solvent recommended for diesel fuel systems. Apply the cleaner to the pump and lines, ensuring that you cover all surfaces and nozzles. Allow the cleaner to work for the specified time, which may vary depending on the product and the severity of the contamination.

During the cleaning process, pay close attention to the fuel lines. These lines can become clogged or damaged over time, especially if the fuel contains water or other contaminants. Use a suitable brush or cleaning tool to gently scrub the interior of the lines, removing any built-up debris or residue. Rinse the lines thoroughly with clean diesel fuel or a suitable solvent to ensure no cleaning agents remain.

Once the cleaning is complete, inspect the pump and fuel lines for any signs of damage or wear. Check for cracks, leaks, or any visible deterioration in the lines. Inspect the pump's housing and components for any signs of corrosion or damage. Look for any loose connections or fittings that may need tightening or replacement. It is crucial to identify any issues early on to prevent further complications during the removal process.

If you notice any damage or wear, address it promptly. Replace any damaged lines or components to ensure the integrity of the fuel system. Consider using new, high-quality parts to ensure a proper fit and reliable performance. Additionally, check the condition of the fuel filter and consider replacing it if it appears clogged or worn. A clean and well-maintained fuel filter is essential for optimal engine performance.

By thoroughly cleaning and inspecting the pump and fuel lines, you create a safe and efficient environment for the removal process. This proactive approach ensures that you can proceed with the task of removing the diesel fuel line from the transfer pump with confidence, knowing that you have addressed potential issues beforehand.

Ford Econoline 2004 Fuel Line Drain: A Step-by-Step Guide

You may want to see also

Frequently asked questions

To remove the diesel fuel line from the transfer pump, you'll need to follow these steps: First, ensure the engine is cool and the vehicle is parked on a level surface. Locate the fuel line connection to the pump, which is typically a quick-connect fitting or a threaded coupling. Loosen the fitting or coupling by hand, then use a fuel line removal tool (also known as a fuel line cutter or line puller) to carefully cut or pull the line away from the pump. Take note of the orientation of the line to ensure proper reattachment later.

The tools required for removing the diesel fuel line from the transfer pump include a fuel line removal tool, also known as a fuel line cutter or line puller. This tool helps to grip and cut the fuel line without damaging the pump or surrounding components. You may also need a wrench or socket set to loosen any threaded connections and a rag or cloth to protect your hands and the pump during the process.

Yes, safety is crucial when working with fuel lines. Always wear protective gloves and eye protection to avoid contact with hot or sharp components. Ensure the engine is turned off and the vehicle is in a secure position to prevent accidental movement. Be cautious when using tools to avoid any sharp edges or protruding parts that could cause injury. Additionally, have a container ready to catch any spilled fuel to prevent environmental contamination.