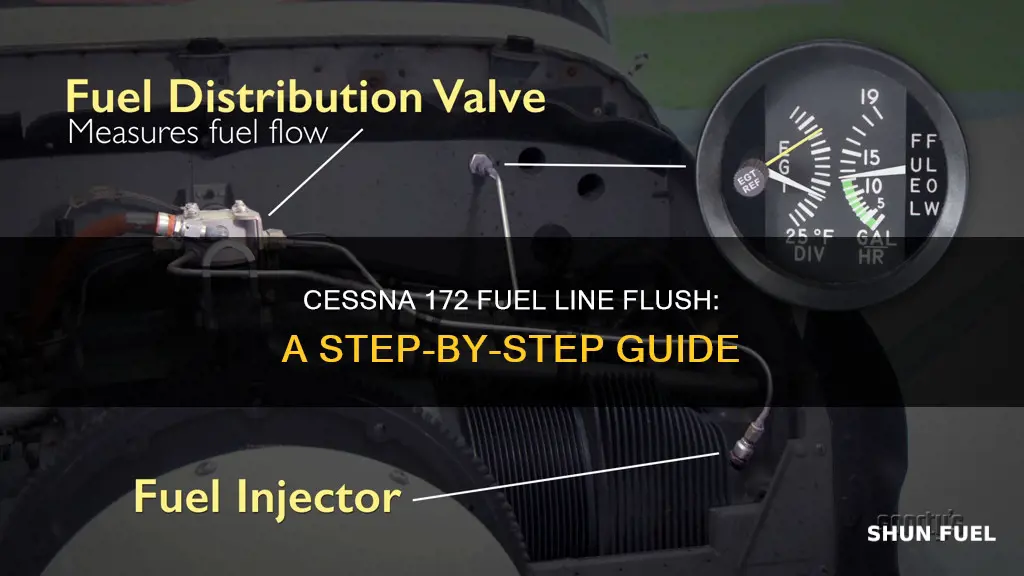

Flushing the fuel lines in a Cessna 172 is a crucial maintenance task to ensure optimal engine performance and longevity. This process involves removing any contaminants or old fuel from the system, which can accumulate over time and lead to reduced engine efficiency or even damage. By following a systematic approach, you can effectively clean the fuel lines, ensuring a fresh and clean supply of fuel to the engine. This guide will provide a step-by-step process, including the necessary tools and procedures, to help you flush the fuel lines of your Cessna 172, promoting a reliable and safe flying experience.

| Characteristics | Values |

|---|---|

| Fuel System Type | Carbureted |

| Fuel Tank Capacity | 7.5 US gallons (28.3 liters) |

| Fuel Line Diameter | 3/8" (9.5 mm) |

| Fuel Filter Location | In the fuel tank |

| Fuel Pump Type | Electric |

| Fuel Line Material | Copper or brass |

| Fuel Line Routing | From the tank to the carburetor |

| Fuel Line Length | Varies by model, typically 3-4 feet |

| Fuel Line Flushing Procedure | 1. Drain the fuel tank. 2. Remove the fuel filter. 3. Disconnect the fuel lines. 4. Use a fuel line cleaner or solvent. 5. Rinse the lines with water. 6. Reassemble and refill the tank. |

| Tools Required | Funnel, rag, fuel line cleaner, water, air pump (optional) |

| Time Required | 1-2 hours |

| Safety Precautions | Wear gloves and goggles. Ensure the aircraft is on a level surface. Disconnect the battery. |

| Additional Tips | Use a fuel line brush for stubborn deposits. Test the fuel system after flushing. |

What You'll Learn

- Preparation: Ensure the aircraft is on a level surface, and the fuel system is isolated

- Fuel Removal: Drain the fuel tanks to prevent contamination during the flushing process

- Flushing Solution: Use a dedicated fuel line cleaner or a mixture of water and fuel

- Flow Rate: Control the flushing rate to avoid damage to the fuel system

- Filtration: Filter the fuel to remove contaminants after the flushing process

Preparation: Ensure the aircraft is on a level surface, and the fuel system is isolated

To begin the process of flushing the fuel lines in a Cessna 172, it is crucial to prioritize safety and ensure a controlled environment. Firstly, locate a suitable area where the aircraft can be safely positioned. It is essential that the aircraft is placed on a level surface to facilitate an even distribution of fuel and prevent any potential spillage or overflow. This step is critical to avoid any accidents or damage to the surrounding area.

Once the aircraft is securely positioned, the next step is to isolate the fuel system. This involves cutting off the fuel supply to the engine. Locate the fuel shut-off valve, typically found near the fuel tank or along the fuel lines. Turn the valve to the 'off' position to prevent any fuel from entering the system during the flushing process. It is important to note that this step should only be performed when the engine is not running to avoid any potential hazards.

With the fuel system isolated, you can now proceed to prepare the necessary tools and materials. Gather the required equipment, such as a fuel line cleaner or a suitable solvent, a fuel filter, and any necessary adapters or connectors. Ensure that you have the appropriate safety gear, including gloves and eye protection, to safeguard yourself during the procedure.

Before initiating the flushing process, it is recommended to consult the Cessna 172's maintenance manual for specific instructions tailored to your aircraft model. This manual will provide detailed guidance on the recommended cleaning methods and any unique considerations for your particular aircraft. Following the manufacturer's guidelines will ensure that you are using the correct procedures and products for your Cessna 172.

By taking the time to properly prepare and isolate the fuel system, you create a safe and controlled environment for the fuel line flushing process. This meticulous approach ensures that the procedure is carried out efficiently and effectively, minimizing any potential risks associated with fuel handling.

Fixing a Broken Fuel Line: Lawn Mower Repair Tips

You may want to see also

Fuel Removal: Drain the fuel tanks to prevent contamination during the flushing process

To ensure a thorough and effective fuel line flush for your Cessna 172, it's crucial to start with a clean slate, and that means removing the fuel from the tanks. This step is essential to prevent any contamination that could occur during the flushing process, as it helps to avoid introducing old, dirty fuel into the freshly cleaned lines. Here's a detailed guide on how to drain the fuel tanks:

Preparation: Before you begin, ensure you have the necessary tools and equipment, including a fuel drain valve key, a bucket or container for collecting the fuel, and a suitable drain pan. It's also a good idea to wear protective gear, such as gloves and goggles, to safeguard yourself from any potential fuel spills.

Locate the Drain Valves: The Cessna 172 typically has two fuel tanks, and each tank has a drain valve. These valves are usually located near the fuel tank's bottom and are often covered by a small access panel. Carefully remove any covers or panels to expose the drain valves.

Drain the Fuel: Position the bucket or container beneath the drain valve of one of the tanks. Insert the fuel drain valve key into the valve and turn it counterclockwise to open it. Allow the fuel to flow into the container until it is full. Repeat this process for the other tank, ensuring that you drain all the fuel from both tanks. Be cautious and patient during this process to avoid any spills.

Secure the Fuel: Once both tanks are empty, securely close the drain valves. This step is important to prevent any residual fuel from leaking out during transportation or storage. You can use a small piece of tape or a temporary plug to keep the valves closed if needed.

Safety Precautions: When handling aviation fuel, always exercise caution. Ensure that the area is well-ventilated, and avoid any open flames or sparks, as aviation fuel is highly flammable. If you're working in a confined space, consider using a fume hood to minimize the risk of inhalation of fuel vapors.

By following these steps, you'll effectively remove the fuel from your Cessna 172's tanks, creating a clean environment for the subsequent fuel line flushing process. This approach ensures that the flushing process is as efficient and safe as possible.

2001 Neon Fuel Line: Size and Compatibility Guide

You may want to see also

Flushing Solution: Use a dedicated fuel line cleaner or a mixture of water and fuel

Flushing your fuel lines is an important maintenance task to ensure optimal performance and longevity of your aircraft's fuel system. For a Cessna 172, using a dedicated fuel line cleaner or a carefully prepared mixture of water and fuel is an effective method to achieve this. Here's a step-by-step guide on how to proceed:

Start by acquiring a suitable fuel line cleaner, which is specifically designed for aviation use. These cleaners are formulated to dissolve and remove contaminants, such as water, varnish, and fuel system deposits, without causing damage to the fuel lines. Alternatively, you can create a homemade solution by mixing a specific ratio of water and fuel. The general rule is to use a 50/50 mixture of water and aviation fuel, but always refer to your aircraft's maintenance manual for the exact proportions recommended for your model.

Before beginning the flush, ensure that the aircraft is parked on a level surface and the fuel tank is full. This ensures that you have a complete and accessible fuel system to work with. Then, locate the fuel line connectors and disconnect them to access the fuel lines. It is crucial to wear protective gear, including gloves and safety goggles, to protect yourself from any potential splashes or fumes.

Now, carefully inject the fuel line cleaner or your homemade mixture into the fuel lines, starting from the fuel tank and moving towards the engine. You can use a dedicated fuel line cleaning tool or a simple syringe for this process. Apply pressure to ensure the solution reaches all areas of the fuel system. Allow the cleaner to circulate and work its way through the lines for an extended period, as per the manufacturer's instructions.

After the recommended dwell time, typically around 15-30 minutes, reconnect the fuel lines and secure them. Then, start the aircraft's engine and let it run for a while, allowing the cleaner to be burned off. This step ensures that any remaining cleaner is eliminated from the system. Finally, shut down the engine and allow the aircraft to cool down before reassembling any removed components.

Remember, regular fuel line maintenance is essential to prevent issues like fuel contamination, reduced performance, and potential engine damage. By following these steps and using the appropriate flushing solution, you can effectively maintain your Cessna 172's fuel system.

Understanding 1-2A Fuel Line Tubing: A Comprehensive Guide

You may want to see also

Flow Rate: Control the flushing rate to avoid damage to the fuel system

When flushing the fuel lines of a Cessna 172, it is crucial to pay close attention to the flow rate to prevent any potential damage to the fuel system. The flushing process should be conducted with precision and care to ensure the integrity of the aircraft's fuel infrastructure.

The flow rate refers to the speed at which the cleaning fluid, typically a fuel-based solvent, is delivered through the fuel lines. It is essential to maintain a controlled and steady rate to avoid excessive pressure or rapid movement of the solvent. High-pressure flushing can lead to several issues. Firstly, it may cause the solvent to exceed the recommended pressure limits of the fuel system components, potentially damaging fuel injectors, pumps, or lines. Secondly, rapid movement of the solvent can lead to cavitation, a process where the solvent's bubbles collapse, creating small, sharp particles that can erode the fuel system's internal surfaces.

To control the flow rate effectively, start by selecting a suitable flushing fluid and ensuring it is compatible with the aircraft's fuel system. Then, use a flushing kit or a specialized tool that allows for precise control over the fluid's flow. Gradually introduce the cleaning fluid into the fuel system, starting from the lowest point to ensure a consistent flow. Monitor the pressure gauge during the process, aiming for a steady and controlled rate. Adjust the flow rate as needed, slowing down if you notice any signs of excessive pressure or rapid movement.

A good practice is to flush the fuel lines in stages, working from one section to another. This approach allows for better control and ensures that the solvent effectively cleans each part of the fuel system. Take your time and be patient, as rushing the process can lead to mistakes. Remember, the goal is to remove contaminants while preserving the fuel system's integrity.

In summary, controlling the flow rate during fuel line flushing is critical to prevent damage to the Cessna 172's fuel system. By maintaining a steady and controlled rate, you can ensure a thorough cleaning process without causing any harm to the aircraft's fuel infrastructure. Always refer to the manufacturer's guidelines and seek professional advice if needed to ensure the best practices are followed.

Backflushing Ford Diesel Fuel Lines: A DIY Guide

You may want to see also

Filtration: Filter the fuel to remove contaminants after the flushing process

After you've completed the fuel line flushing process for your Cessna 172, it's crucial to ensure that the fuel system is free from any contaminants that may have accumulated during the flushing procedure. This step is often overlooked, but it's essential to maintain the health and longevity of your aircraft's fuel system. Here's a detailed guide on how to filter the fuel effectively:

Fuel Filtration Process:

- Prepare the Equipment: You'll need a fuel filter, a suitable container for collecting the filtered fuel, and a funnel to ensure a smooth transfer. Ensure you have the appropriate tools and materials before beginning.

- Locate the Fuel Filter: Access the fuel filter, which is typically located near the fuel tank. It might be a separate unit or integrated into the tank itself. Familiarize yourself with the filter's location to proceed with the filtration process efficiently.

- Drain and Filter: Start by draining any remaining fuel from the lines into the container. This step ensures that you're not introducing contaminants back into the system. Once drained, carefully pour the fuel into the filter, allowing it to pass through and collect any debris or contaminants.

- Check for Contaminants: As you filter the fuel, inspect the collected contaminants. You may notice dirt, water, or even small particles that have been loosened during the flushing process. This visual inspection is crucial to understanding the condition of your fuel system.

- Replace or Clean the Filter: Depending on the severity of contamination, you might need to replace the filter or clean it thoroughly. If the filter is reusable, follow the manufacturer's guidelines for cleaning and reinstallation. Ensuring the filter is free from debris will allow it to effectively trap contaminants in the future.

- Reinstall and Test: After successful filtration, reinstall the fuel filter and ensure all connections are secure. Then, refill the fuel tank and run the engine to test the system's functionality. This step confirms that the flushing and filtration process has been effective.

By following these steps, you can guarantee that your Cessna 172's fuel system remains clean and efficient, reducing the risk of performance issues caused by contaminants. Regular maintenance, including fuel filtration, is a vital part of aircraft ownership and ensures a safe and reliable flying experience.

Understanding Gas Tank Fuel Lines: A Comprehensive Guide

You may want to see also

Frequently asked questions

Flushing the fuel lines in a Cessna 172 is a routine maintenance task that helps ensure the fuel system's cleanliness and performance. Here's a step-by-step guide: First, ensure the aircraft is on a level surface and the fuel tank is full. Then, locate the fuel line bleeder valves, typically found near the fuel tank and the engine. Open the bleeder valves to release any air or contaminants from the lines. Next, attach a fuel line flush kit or a suitable cleaning solution to the fuel inlet valve. Gradually open the valve to allow the flush liquid to enter the system. Continue the process until the desired amount of flush liquid has been introduced. After flushing, close the bleeder valves and run the engine for a few minutes to distribute the cleaning solution. Finally, drain the system and refill the fuel tank with fresh fuel to complete the process.

The Cessna 172's fuel system is designed to be flushed with a suitable fuel system cleaner or a low-temperature fuel system cleaner. These specialized fluids are formulated to dissolve and remove contaminants, such as water, varnish, and debris, from the fuel lines and tank. It's important to use the manufacturer's recommended fluid to avoid any potential damage to the fuel system. Common brands include Avgas Fuel System Cleaner or similar products designed for aviation fuel systems.

Yes, it is possible to flush the fuel lines without completely removing the fuel tank. This process typically involves using a fuel line flush kit, which includes a flexible hose with a nozzle that can be inserted into the fuel inlet valve. By attaching the kit to the fuel inlet, you can introduce the flush fluid directly into the system. However, for a more thorough flush, especially if the fuel tank is heavily contaminated, it might be necessary to remove the tank and perform a complete flush inside and out. Always refer to the Cessna 172's maintenance manual for specific instructions and recommendations.