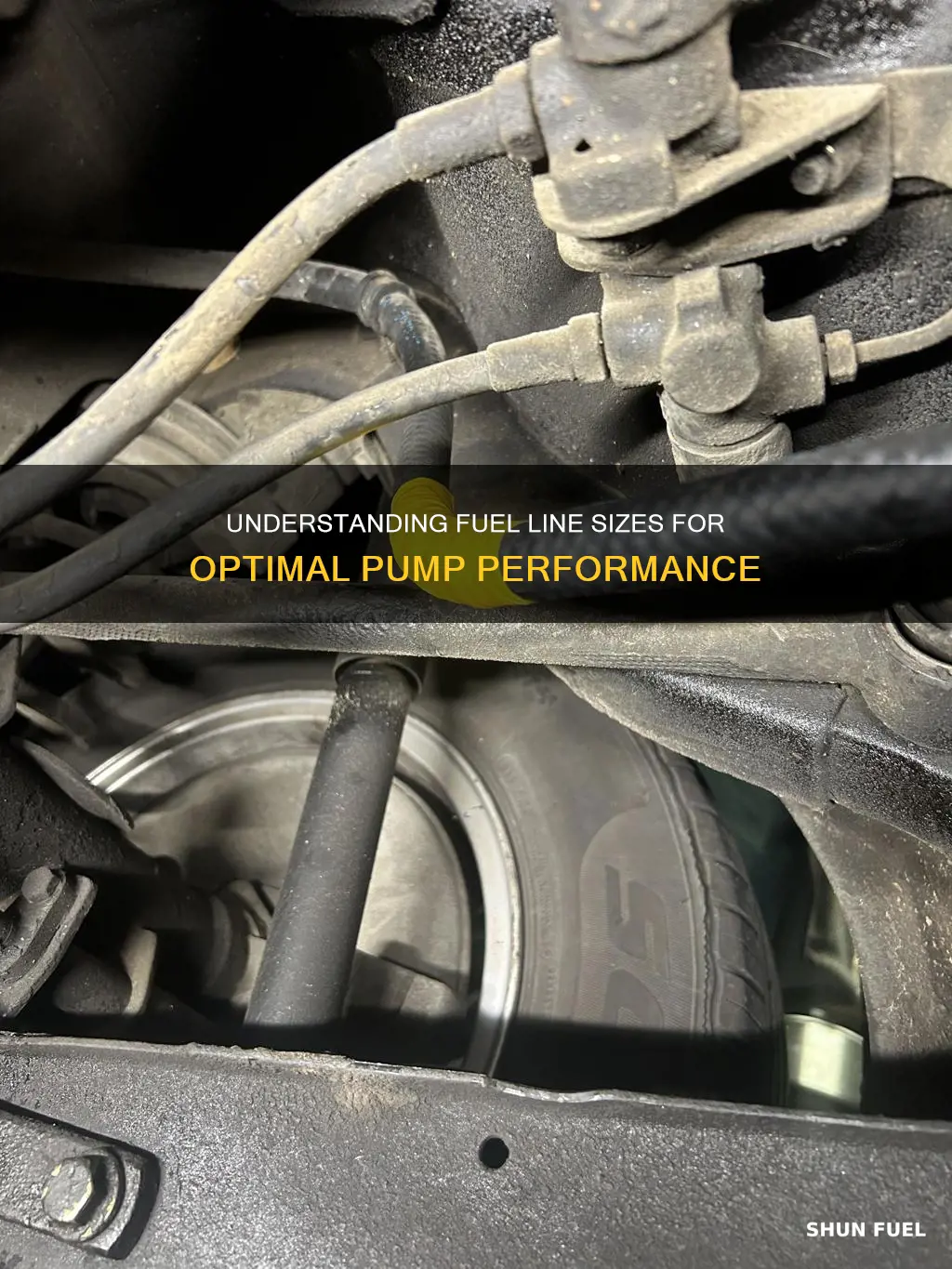

The size of the fuel line connecting to a fuel pump is a critical component in any vehicle's fuel system. This line is responsible for transporting fuel from the tank to the pump, which then sends it to the engine. The diameter of the fuel line directly impacts the flow rate of fuel, which in turn affects the engine's performance and efficiency. Understanding the appropriate size of the fuel line is essential for ensuring optimal fuel delivery and maintaining the vehicle's overall health.

| Characteristics | Values |

|---|---|

| Typical Diameter | 3/8" to 1/2" (9.5 to 12.7 mm) |

| Length | Varies based on vehicle model and fuel tank location |

| Material | Steel, aluminum, or braided rubber |

| Pressure Rating | Up to 100 psi (pounds per square inch) |

| Compatibility | Specific to the vehicle's fuel system and pump |

| Color | Often black or blue |

| Flexibility | Required to accommodate engine movement |

| Temperature Range | Varies, but typically -40°F to 250°F (-40°C to 121°C) |

| Installation | Direct connection to the fuel pump and fuel tank |

What You'll Learn

- Fuel Pump Location: Identify the fuel pump's position in the vehicle's fuel system

- Fuel Line Diameter: Determine the appropriate diameter for the fuel line

- Fuel Pressure: Understand the required fuel pressure for optimal performance

- Fuel Filter: Consider the role of a fuel filter in maintaining fuel quality

- Fuel Pump Capacity: Assess the fuel pump's capacity to meet the vehicle's needs

Fuel Pump Location: Identify the fuel pump's position in the vehicle's fuel system

The fuel pump is a critical component of a vehicle's fuel system, responsible for delivering fuel from the tank to the engine. Its location can vary depending on the vehicle's make and model, but understanding its position is essential for maintenance and troubleshooting.

In many modern vehicles, the fuel pump is typically located inside the fuel tank. This design is common in cars and trucks, where the pump is often integrated into the tank itself. When the engine is running, the pump creates a vacuum, drawing fuel from the tank and sending it through the fuel lines to the engine. This internal placement ensures that the pump is always submerged in fuel, which helps prevent air from entering the system and promotes efficient operation.

For vehicles with an external fuel pump, it is usually positioned near the fuel tank, often in the engine compartment. This type of setup is more common in older vehicles or those with larger engines. The external pump is connected to the fuel tank via a fuel line, which delivers fuel to the engine as needed. Its location is carefully chosen to ensure that the pump can handle the required fuel flow without excessive strain on the fuel lines.

Identifying the fuel pump's position is crucial for several reasons. Firstly, it allows for easier access during maintenance and repairs. Knowing where the pump is located enables mechanics to perform tasks such as replacing the pump, checking for blockages, or inspecting the fuel lines without causing unnecessary damage. Secondly, understanding the pump's position can help in diagnosing fuel-related issues. If a vehicle is experiencing fuel problems, such as poor performance or difficulty starting, locating the pump can aid in determining if it is functioning correctly or if there are any associated issues.

In summary, the fuel pump's location is a critical aspect of a vehicle's fuel system. Whether it is integrated into the fuel tank or positioned externally, its placement is designed to optimize fuel delivery to the engine. By understanding the pump's location, vehicle owners and mechanics can ensure proper maintenance, troubleshoot issues effectively, and keep the fuel system operating efficiently.

Understanding the Fuel Tank Return Line: A Comprehensive Guide

You may want to see also

Fuel Line Diameter: Determine the appropriate diameter for the fuel line

When it comes to determining the appropriate diameter for the fuel line connecting the fuel tank to the fuel pump, several factors come into play. The primary consideration is ensuring efficient and reliable fuel delivery to the engine while maintaining optimal performance and safety. Here's a detailed guide on how to determine the right fuel line diameter:

Understanding Fuel Flow Requirements: The first step is to understand the fuel flow rate required by your vehicle's engine. This information is typically available in the vehicle's manual or can be determined by consulting a reliable source specific to your car model. The flow rate is measured in liters per minute (L/min) or gallons per minute (GPM). Higher-performance engines or those with larger displacement may require more fuel, thus necessitating a larger diameter fuel line.

Calculating Required Diameter: The formula to calculate the required diameter (D) of the fuel line is based on the principle of fluid dynamics. It is given by the equation: D = (4 * Q) / (π * V), where D is the diameter, Q is the flow rate, and V is the velocity of the fuel. For most automotive applications, a velocity of approximately 1-2 meters per second is considered safe and efficient. Using this formula, you can calculate the minimum diameter required to handle the specified flow rate.

Considering Pump Capacity: The fuel pump's capacity also plays a crucial role in determining the fuel line diameter. The pump's output should match the required flow rate to ensure efficient fuel delivery. If the pump's capacity is lower than the calculated flow rate, it may struggle to deliver the required fuel, leading to potential performance issues. Therefore, it's essential to choose a fuel pump that can handle the expected fuel flow rate.

Safety and Performance: Safety is a critical aspect when selecting the fuel line diameter. A smaller diameter fuel line may lead to increased pressure drop, which can cause fuel starvation during high-load conditions. On the other hand, an oversized fuel line might lead to unnecessary fuel wastage and potential performance losses. The goal is to find a balance that ensures smooth and efficient fuel delivery while maintaining safety standards.

Standard Sizes and Considerations: Common fuel line diameters for automotive applications range from 3/8 inch to 1/2 inch (9.5 to 12.7 mm) for smaller vehicles and 5/8 inch (15.8 mm) or larger for high-performance or larger engines. However, it's essential to consider the specific requirements of your vehicle and consult with automotive experts or manufacturers to ensure compatibility and optimal performance.

Optimizing Performance: Choosing the Right Dual Fuel Line for Your Holley Avenger Carb

You may want to see also

Fuel Pressure: Understand the required fuel pressure for optimal performance

When it comes to optimizing engine performance, understanding the role of fuel pressure is crucial. The fuel pressure required for your vehicle's engine depends on several factors, including the engine type, displacement, and the specific vehicle model. Generally, the ideal fuel pressure range for most modern engines is between 40 and 80 psi (pounds per square inch). This range ensures efficient combustion and optimal power output.

In the context of fuel lines and pumps, the size of the fuel line is an essential consideration. The fuel line's diameter should be appropriate for the required fuel flow rate to the pump. A common rule of thumb is that the fuel line's diameter should be at least 1/4 inch for efficient operation. However, this can vary depending on the engine's specifications and the pump's capacity. For high-performance engines or those with larger fuel pumps, a larger diameter fuel line might be necessary to handle the increased fuel volume and pressure.

The fuel pump is a critical component in the fuel delivery system, responsible for supplying fuel to the engine at the required pressure. The pump's capacity and efficiency are directly linked to the fuel pressure it can deliver. A properly sized fuel line ensures that the pump can deliver fuel at the optimal pressure without causing excessive wear or performance issues.

To determine the correct fuel pressure, it's essential to consult the vehicle's manual or seek professional advice. Each engine has unique requirements, and using the right pressure ensures that the fuel is atomized correctly, promoting efficient combustion. This, in turn, leads to improved performance, better fuel economy, and reduced emissions.

In summary, understanding the required fuel pressure is vital for maintaining and optimizing engine performance. The size of the fuel line plays a significant role in ensuring the pump can deliver the necessary pressure. By considering the engine's specifications and consulting relevant resources, vehicle owners can ensure their engines operate at their full potential while maintaining longevity and reliability.

Unveiling the Car Fuel Line: Visual Guide

You may want to see also

Fuel Filter: Consider the role of a fuel filter in maintaining fuel quality

The fuel filter is a critical component in any vehicle's fuel system, serving as a guardian against contaminants that could potentially damage the engine. Its primary function is to ensure that the fuel supplied to the engine is clean and free from impurities, which is essential for optimal engine performance and longevity. This is particularly important in modern vehicles, where engines are designed to operate on high-octane fuels, and any impurities can lead to reduced power, poor fuel economy, and even engine damage.

In the context of the fuel line leading to the fuel pump, the fuel filter plays a pivotal role. The fuel line is responsible for transporting fuel from the tank to the pump, and any debris, water, or contaminants present in the fuel can be effectively captured and removed by the filter. Over time, fuel lines can accumulate sediment, rust, and other particles, especially if the fuel contains water or has been exposed to air. These contaminants can cause blockages, leading to reduced fuel flow and potential pump damage.

A well-maintained fuel filter ensures that the fuel reaching the pump is clean and dry, preventing any potential issues. It acts as a barrier, trapping particles as small as 20 microns, which includes dirt, rust, and other impurities. By doing so, it helps to maintain the engine's performance and extends the life of the fuel pump. Regular replacement of the fuel filter is a recommended practice to ensure its effectiveness. Neglecting this maintenance task can result in a buildup of contaminants, leading to increased engine wear and potential breakdowns.

The design of the fuel filter also considers the flow rate and pressure of the fuel. It is engineered to allow a specific volume of fuel to pass through while retaining impurities. This ensures that the fuel system operates efficiently without any backpressure issues. Additionally, some fuel filters are equipped with a bypass valve, which allows fuel to pass through when the filter is clogged, providing a temporary solution while still protecting the engine.

In summary, the fuel filter is a vital component in the fuel system, especially when considering the fuel line's role in delivering fuel to the pump. Its primary function is to maintain fuel quality by removing contaminants, ensuring the engine operates efficiently and reliably. Regular maintenance and replacement of the fuel filter are essential practices to safeguard the vehicle's performance and longevity.

Mastering Fuel Line Sizing: The Ultimate Guide to 3/8" Fuel Line Fitting

You may want to see also

Fuel Pump Capacity: Assess the fuel pump's capacity to meet the vehicle's needs

When assessing the capacity of a fuel pump, it's crucial to consider the vehicle's requirements to ensure optimal performance and prevent potential issues. The fuel pump's capacity is typically measured in terms of its flow rate, which indicates the volume of fuel it can deliver per minute. This is a critical factor, as it directly impacts the vehicle's fuel supply and, consequently, its performance.

To determine the appropriate fuel pump capacity, you should start by examining the vehicle's specifications. Each vehicle has a specific engine that requires a certain amount of fuel to operate efficiently. The engine's fuel requirements are often listed in the vehicle's manual or can be found through online resources. These specifications will provide the necessary baseline for selecting an appropriate fuel pump. For instance, a high-performance engine might demand a higher flow rate to meet its power demands, while a more standard engine may have less stringent requirements.

The fuel pump's capacity should be at least equal to or slightly exceed the vehicle's engine requirements. This ensures that the pump can deliver the necessary fuel volume to the engine without straining the system. It's important to note that having a slightly higher flow rate can provide a buffer, allowing for better performance and potential future upgrades without the need for immediate replacement.

Additionally, consider the vehicle's fuel tank size and the pump's location. If the fuel pump is located far from the engine, the fuel line's length and diameter will impact the flow rate. Longer fuel lines may require larger-diameter lines to maintain sufficient pressure and flow. This is where the initial research on fuel line sizes comes into play, as it helps determine the optimal dimensions for the fuel line to ensure efficient fuel delivery.

In summary, assessing the fuel pump's capacity involves understanding the vehicle's engine requirements, comparing them to the pump's flow rate, and considering the fuel system's design. By carefully evaluating these factors, you can ensure that the fuel pump meets the vehicle's needs, providing efficient and reliable fuel delivery for optimal performance. This process is essential for maintaining the vehicle's overall health and longevity.

Unveiling the Mystery: What Exactly is 6AN Fuel Line?

You may want to see also

Frequently asked questions

The size of the fuel line can vary depending on the specific vehicle and its engine requirements. Common sizes for fuel lines range from 3/8 inch to 1/2 inch in diameter. It's crucial to match the fuel line size to the pump's specifications to ensure optimal fuel flow and prevent pressure drops.

To find the appropriate fuel line size, you should consult the vehicle's service manual or the manufacturer's guidelines. These resources will provide detailed information about the recommended fuel line specifications for your particular make and model. Using the correct size ensures efficient fuel delivery and maintains the integrity of the fuel system.

Using a different-sized fuel line is not recommended as it can lead to performance issues and potential damage to the fuel pump. The fuel line size is carefully chosen to match the pump's flow rate and pressure requirements. Mismatched sizes may result in inadequate fuel supply, reduced engine performance, or even fuel pump failure. It's best to adhere to the manufacturer's recommendations for optimal and safe operation.