Fixing a fuel line or fuel hose can be a straightforward process if you follow the right steps. Whether you're dealing with a small tear or a more significant damage, having the necessary tools and supplies on hand will make the repair easier. In this guide, we'll walk you through the process of repairing a fuel line or hose, ensuring your vehicle runs smoothly and safely.

What You'll Learn

- Identify the Issue: Inspect for cracks, leaks, or damage to the fuel hose

- Prepare Tools: Gather necessary tools: fuel line repair kit, hose clamp, and cleaning supplies

- Clean the Line: Remove old fuel, clean the line, and ensure no debris remains

- Replace the Hose: Cut the damaged hose, insert the new piece, and secure with a clamp

- Test and Verify: Check for leaks, start the engine, and ensure proper fuel flow

Identify the Issue: Inspect for cracks, leaks, or damage to the fuel hose

When it comes to identifying issues with your fuel hose, a thorough inspection is crucial. Start by visually examining the hose for any visible signs of damage or deterioration. Look for cracks, tears, or any other form of physical damage that could compromise its integrity. Check for any bends or kinks that might have occurred during installation or use, as these can lead to reduced performance and potential leaks. Pay close attention to the connections between the hose and other components, such as the fuel pump or the fuel tank. Ensure that these connections are secure and free from any corrosion or debris that could impede the flow of fuel.

Leakage is another critical aspect to consider. If you notice any fuel seeping or dripping around the hose connections, it could indicate a damaged or worn-out hose. Over time, fuel hoses can degrade due to exposure to heat, sunlight, and chemicals present in the fuel. Look for any signs of swelling, hardening, or discoloration, as these could be indicators of internal damage. Additionally, check for any signs of moisture or condensation inside the hose, as this might suggest a breach in its protective layer.

In some cases, the issue might not be immediately apparent. For instance, a small crack or hole in the hose might not be visible to the naked eye. In such scenarios, it's essential to listen for any unusual noises, such as hissing or roaring, which could indicate a fuel leak. If you suspect a hidden issue, it's best to consult a professional mechanic who can employ specialized tools to detect and identify problems accurately.

Remember, regular maintenance and inspections can help prevent unexpected breakdowns and ensure the longevity of your fuel system. By taking the time to inspect the fuel hose for cracks, leaks, and damage, you can address potential issues before they escalate into more significant problems.

Chevy Fuel Line Disconnection: A Step-by-Step Guide

You may want to see also

Prepare Tools: Gather necessary tools: fuel line repair kit, hose clamp, and cleaning supplies

Before you begin any fuel line repair, it's crucial to have the right tools and materials on hand. Here's a step-by-step guide on preparing the necessary tools:

Fuel Line Repair Kit: This is the primary tool you'll need for the job. A fuel line repair kit typically includes all the components required to fix a damaged fuel hose or line. It usually consists of a replacement hose, various sizes of hose clamps, and sometimes a fuel line connector kit. The kit ensures you have everything needed to make a proper repair. Look for a kit that is compatible with your vehicle's fuel system and the specific type of hose you are working with.

Hose Clamp: Hose clamps are essential for securing the repaired or replaced fuel hose in place. They come in different sizes, so it's important to choose the appropriate one for your hose diameter. A standard V-band or U-joint hose clamp is commonly used for fuel lines. Ensure you have a few extra clamps in case of any adjustments or if the hose needs to be tightened further.

Cleaning Supplies: Cleaning the fuel system is an often-overlooked but crucial step in the repair process. You'll need a fuel line cleaner or a suitable solvent to remove any contaminants or old fuel residue from the hose and surrounding areas. This ensures a clean and reliable repair. Additionally, have some cleaning rags or brushes to wipe down the hose and prepare it for the new connection.

By gathering these tools and supplies, you'll be well-prepared to tackle the fuel line repair. It's always a good idea to inspect your kit before starting the work to ensure you have all the necessary components. Having the right tools on hand will make the repair process smoother and more efficient.

Fixing a Fuel Line Leak: A Step-by-Step Guide

You may want to see also

Clean the Line: Remove old fuel, clean the line, and ensure no debris remains

To effectively clean the fuel line and hose, a methodical approach is necessary. Begin by disconnecting the fuel line from the fuel tank and the engine. This step is crucial to ensure that you can access the entire length of the line and hose without any obstructions. Once disconnected, locate the fuel pump and disconnect it as well. This will allow you to remove any residual fuel that might have accumulated in the system.

Next, you'll want to drain the fuel tank. This process may vary depending on your vehicle, but generally, you'll need to locate the drain valve and open it to release the fuel. It's important to have a container ready to collect the drained fuel, as it can be hazardous if not handled properly. After draining, replace the fuel tank's cap and secure it.

Now, it's time to clean the fuel line. Start by using a fuel line cleaner, which can be purchased from most auto parts stores. This cleaner is designed to dissolve any built-up fuel, varnish, and debris within the line. Follow the instructions on the cleaner's packaging for the best results. Typically, you'll need to spray the cleaner into the line and let it sit for a specified amount of time before flushing it out with a garden hose. Ensure that you flush the entire length of the line to remove any residue.

While cleaning the line, pay close attention to any bends or kinks in the hose. These areas can often accumulate debris and are more prone to damage. Use a soft brush or a small tool to gently clean these sections, ensuring that you don't cause any further damage. Once you've cleaned the entire line, rinse it thoroughly with clean water to remove any remaining cleaner.

Finally, inspect the fuel line and hose for any signs of damage or wear. Ensure that there are no cracks, holes, or leaks. If you notice any issues, it may be necessary to replace the affected parts. After cleaning and inspecting, reassemble the fuel system, reconnecting the fuel pump and line to the engine and tank. By following these steps, you can effectively clean the fuel line and hose, ensuring optimal performance and longevity.

Aluminum Fuel Line Pressure Test: 50 PSI Challenge

You may want to see also

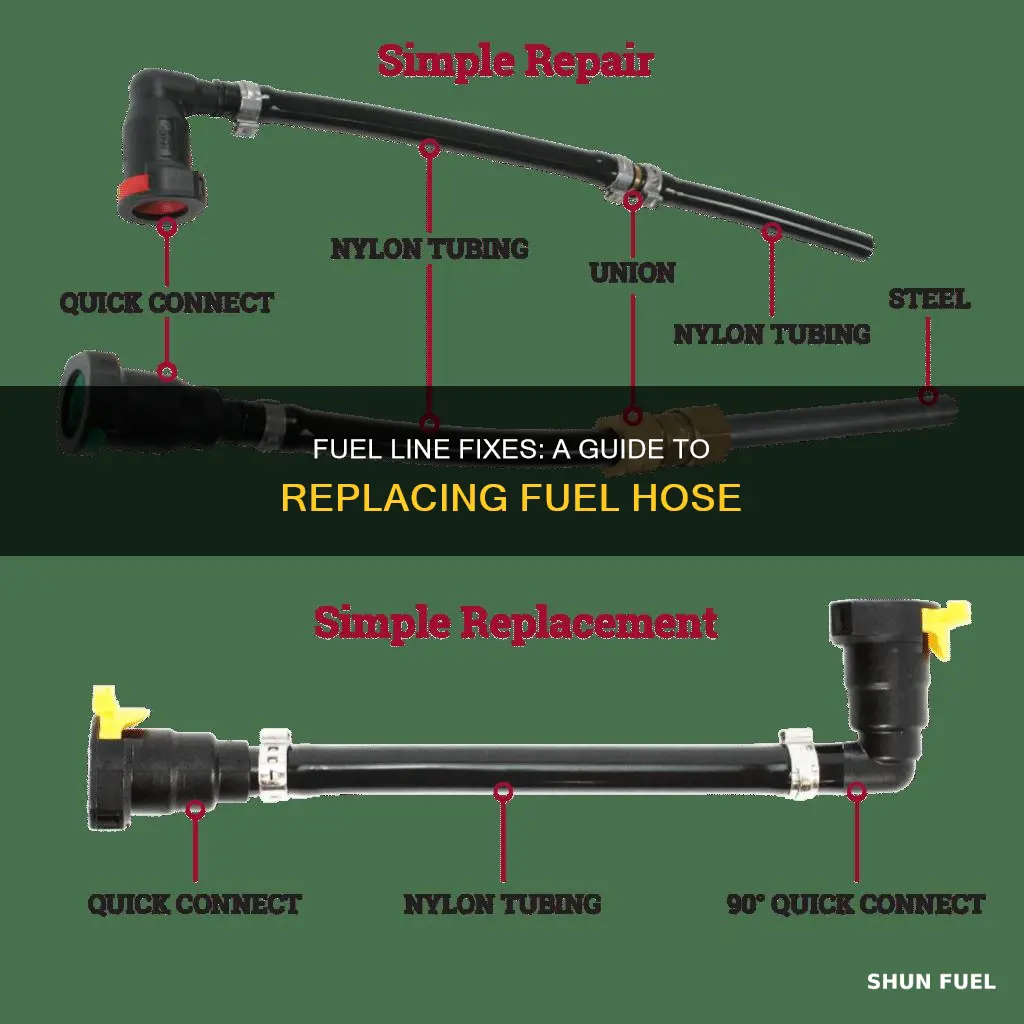

Replace the Hose: Cut the damaged hose, insert the new piece, and secure with a clamp

When dealing with a damaged fuel hose, replacing it is often the best solution to ensure your vehicle's engine runs smoothly and safely. Here's a step-by-step guide to replacing the hose:

Step 1: Prepare the Necessary Tools and Materials

Before you begin, gather the required tools and materials. You'll need a new fuel hose that is compatible with your vehicle's make and model, a fuel line cutter or a sharp knife, a fuel line clamp, and some cleaning supplies like a degreaser and a rag. Ensure you have the right size and type of hose to avoid any issues with fitment.

Step 2: Locate the Damaged Hose

Inspect your vehicle's fuel system to identify the damaged hose. It might be located under the car, along the frame, or near the fuel tank. Look for any signs of wear, cracks, leaks, or damage caused by rust, heat, or physical impact.

Step 3: Cut the Old Hose

Once you've identified the damaged section, carefully cut the hose using the fuel line cutter or a sharp knife. Make sure to cut straight and clean the edges to prevent any sharp fragments from causing further damage. Take your time to ensure an accurate cut.

Step 4: Prepare the New Hose

Take the new fuel hose and ensure it is the correct length to replace the damaged section. If necessary, adjust the hose's length by carefully cutting it to size. Clean the interior of the old hose and the new hose's interior to remove any debris or old fuel residue.

Step 5: Insert and Secure the New Hose

Slide the new hose onto the fuel line, ensuring it is properly aligned with the existing fuel lines. Insert it through any necessary fittings or connectors. Once it's in place, use the fuel line clamp to secure the hose firmly. Tighten the clamp by hand, then use a wrench to ensure a secure hold without causing damage to the hose.

Step 6: Test and Verify

After securing the new hose, start the vehicle's engine and check for any leaks. Ensure that the fuel system is functioning correctly and that there is no fuel leakage around the new hose connection. If everything is in order, you've successfully replaced the damaged fuel hose.

Fuel Line Air Check: A Step-by-Step Guide

You may want to see also

Test and Verify: Check for leaks, start the engine, and ensure proper fuel flow

Before you begin the testing and verification process, it's crucial to ensure that the fuel line and hose are properly prepared and connected. Start by inspecting the fuel line for any visible damage, cracks, or signs of deterioration. If you notice any issues, it's best to replace the affected section to ensure a reliable fuel supply. Once the fuel line is in good condition, proceed with the following steps:

Check for Leaks: Begin by applying a small amount of diesel fuel or a suitable leak detection fluid along the length of the fuel line, including connections and fittings. Use a rag or cloth to wipe the fuel line and observe for any signs of leakage. Leaks can occur at connections, bends, or where the fuel line joins the fuel pump. If you detect any leaks, tighten connections, or consider replacing damaged sections. Ensure that all fittings are secure and properly sealed to prevent fuel from escaping.

Start the Engine: With the fuel line prepared, it's time to test the engine. Ensure that the vehicle's ignition is turned off and that the engine has cooled down if it has been running. Locate the fuel pump relay and switch it off to temporarily shut down the fuel supply. Start the engine and allow it to idle for a few minutes. Listen for any unusual noises and observe the engine's behavior. A properly functioning fuel system should start smoothly and run without any issues. If the engine struggles to start or exhibits erratic behavior, it may indicate a problem with the fuel flow or delivery.

Ensure Proper Fuel Flow: After the engine has started, monitor the fuel flow to ensure it is adequate. Check for any signs of fuel starvation or excessive fuel pressure. If the engine runs rich (with too much fuel), it may result in black smoke and poor performance. Conversely, a lean condition (too little fuel) can cause the engine to stall or misfire. Adjust the fuel-air mixture if necessary, and consider using a fuel pressure gauge to measure the pressure at the fuel injectors or carburetor (depending on the engine type). Proper fuel flow is essential for optimal engine performance and longevity.

During this testing phase, it's important to be methodical and observe any changes in the engine's behavior. If any issues arise, they may require further investigation and potential adjustments to the fuel system. By following these steps, you can verify the effectiveness of your fuel line repair and ensure that the engine operates efficiently and reliably.

Locating the Fuel Line: A Guide for Mazda B4000 Owners

You may want to see also

Frequently asked questions

There are several signs that may indicate a problem with your fuel line or hose. These include fuel leaks, engine misfires or poor performance, reduced fuel efficiency, and sometimes, you might notice a strange smell coming from the engine compartment. If you experience any of these issues, it's best to inspect the fuel system for any visible damage or corrosion.

Fuel lines can develop problems due to various reasons. Common causes include age and wear, especially in older vehicles, as rubber hoses can degrade over time. Corrosion and rust from fuel contamination or moisture can also lead to fuel line deterioration. Additionally, physical damage from accidents, road debris, or improper installation can cause fuel line leaks.

For small cracks or holes, temporary repairs can be made using fuel line tape or a fuel line repair kit. These kits provide a quick fix and can be useful for minor damage. However, it's important to note that these repairs are not permanent solutions, and it's recommended to replace the entire fuel hose if the damage is significant or if the issue persists.

Replacing a fuel line or hose is a task that requires careful attention to detail. First, locate the damaged section and disconnect the fuel line from the engine and the fuel tank. Then, remove the old hose and install a new one, ensuring proper sizing and routing. Make sure to bleed the fuel system to remove any air bubbles, and double-check all connections. It's advisable to seek professional help or consult a mechanic's guide for specific vehicle models to ensure a proper installation.