Fixing a metal fuel line is a crucial task for maintaining the performance and safety of your vehicle. Metal fuel lines can develop leaks or become damaged over time due to various factors such as age, corrosion, or impact. This guide will provide a step-by-step approach to repairing a metal fuel line, ensuring you have the necessary tools and knowledge to tackle the job effectively. Whether you're dealing with a small puncture or a more extensive damage, the following instructions will help you address the issue and restore the integrity of your fuel system.

What You'll Learn

Identify the Issue: Check for leaks, corrosion, or damage

When dealing with a metal fuel line, the first step is to thoroughly inspect it for any signs of damage, corrosion, or leaks. This initial assessment is crucial as it helps identify the root cause of any potential issues. Start by visually examining the fuel line for any visible cracks, rust, or discolouration. Metal fuel lines can be susceptible to corrosion over time, especially in environments with high humidity or exposure to chemicals. Look for any signs of deterioration, such as a rusty appearance or a powdery substance on the line's surface. These could indicate advanced corrosion that may require more extensive repairs.

Leaks are a common problem with fuel lines and can be caused by various factors, including damage, age, or improper installation. Check for any wet spots or stains around the fuel line, as these could be indicators of a leak. Often, fuel lines are located close to the ground or under the vehicle, so inspect these areas carefully. If you notice any moisture or fuel residue, it's essential to investigate further. Use a soapy solution to test for leaks by applying the mixture to the fuel line and observing if any bubbles form. Bubbles indicate the presence of a leak, and you should address this issue promptly.

In addition to visual inspection, pay attention to the flexibility and integrity of the fuel line. Over time, metal fuel lines can become brittle and more susceptible to damage. Feel the line for any areas that feel soft, spongy, or damaged. These signs could indicate internal corrosion or damage that might be affecting the line's ability to transmit fuel efficiently. If you suspect any issues, it's best to replace the fuel line to ensure optimal performance and safety.

Remember, early detection is key to successful repairs. By carefully checking for leaks, corrosion, and damage, you can identify potential problems and address them before they escalate. This initial inspection sets the foundation for the subsequent steps in fixing the metal fuel line, ensuring a thorough and effective repair process.

Chevy Cobalt Fuel Lines: A Comprehensive Guide

You may want to see also

Prepare the Line: Disconnect and drain fuel

Before you begin any repair work on a metal fuel line, it's crucial to ensure your safety and take the necessary precautions. Start by disconnecting the fuel line from the fuel tank and the engine. Locate the fuel line, which is typically a metal tube, and identify the connections. Use the appropriate tools, such as wrenches or fuel line disconnecting tools, to carefully loosen and remove the fittings. Make sure to label or mark the positions of the fittings to ensure proper reattachment later. Once the fittings are removed, you should have access to the fuel line.

Next, you'll need to drain the fuel from the line to prevent any spills or accidents during the repair process. Place a suitable container, such as a bucket or a fuel can, under the fuel line to catch any residual fuel. Slowly open the fuel line by turning it counterclockwise or using the appropriate tool, allowing the fuel to flow into the container. Be cautious and patient during this step to avoid any sudden bursts of fuel. As you drain, keep an eye on the container to ensure it doesn't overflow.

While draining, inspect the fuel line for any signs of damage, corrosion, or leaks. Look for rust, pitting, or any visible holes or tears in the metal. Also, check for any signs of fuel leakage around the fittings or where the line connects to the tank and engine. If you notice any issues, it's essential to address them before proceeding with the repair. Take notes or photographs of the damaged areas for reference during the repair process.

Once the fuel has been drained and you've inspected the line, you can proceed with the rest of the repair or replacement process. Ensure that all fuel has been safely contained and disposed of according to local regulations. Properly disposing of fuel is essential for environmental and safety reasons. Remember, working with fuel requires caution, and it's always a good practice to wear protective gear, such as gloves and safety goggles, to minimize any potential hazards.

Tribeca Fuel Line Removal: A Step-by-Step Guide for 2006 Models

You may want to see also

Clean and Inspect: Remove debris and inspect for damage

When dealing with a metal fuel line, the first step in the repair process is to ensure it is clean and thoroughly inspected for any signs of damage or deterioration. This initial step is crucial as it helps identify potential issues and ensures the effectiveness of any subsequent repairs. Here's a detailed guide on how to clean and inspect the fuel line:

Removing Debris: Start by identifying any visible debris or contaminants along the length of the fuel line. This could include dirt, rust particles, or even small foreign objects that may have entered the line during installation or due to external factors. Use a soft-bristled brush or a small air hose to gently remove the debris. Be careful not to apply excessive force, as this might damage the fuel line's inner surface. For hard-to-reach areas, consider using a flexible brush or a compressed air gun to dislodge any stubborn particles.

Inspecting for Damage: After cleaning, it's essential to inspect the fuel line for any signs of damage or wear. Look for cracks, corrosion, or any areas where the metal has become thin or distorted. Pay close attention to bends and joints, as these are common areas for deterioration. If you notice any damage, mark its location for reference. For minor issues, such as small cracks, you might be able to repair them using specialized metal fuel line repair kits. However, for more severe damage, it may be necessary to replace the affected section of the fuel line.

During the inspection, also check for any signs of fuel leakage. Even a small leak can indicate a more significant issue and should be addressed promptly. If you detect any fuel escaping, ensure you have adequate ventilation and consider using a fuel leak detector to identify the source of the leak.

Remember, a thorough cleaning and inspection are fundamental to ensuring the fuel line's functionality and safety. This process allows you to identify potential problems early on, making it easier to implement the necessary repairs or replacements.

Unraveling the Smelly Mystery: Why Braided Fuel Lines Stink

You may want to see also

Replace or Repair: Use appropriate materials and tools

When dealing with a damaged metal fuel line, the decision to replace or repair it depends on the extent of the damage. If the line is severely corroded, punctured, or significantly damaged, replacement is often the best course of action. However, for minor issues like small holes or leaks, repair might be feasible. Here's a step-by-step guide on how to approach this task:

Materials and Tools:

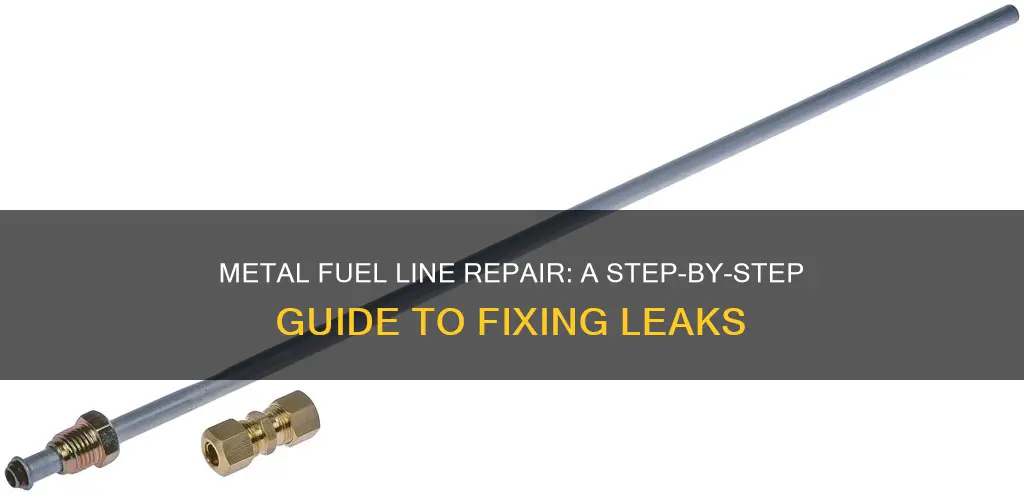

- For replacement, you'll need a new metal fuel line that is compatible with your vehicle's system. Ensure it has the correct dimensions and fittings. You might also need fuel line connectors, clamps, and any necessary tools for cutting and joining the new line.

- If repairing, you can use a metal fuel line repair kit, which typically includes a sleeve or patch that can be slid over the damaged area to seal it. You'll also need a fuel line clamp or adhesive to secure the repair.

Replacement Process:

- Locate the damaged fuel line and mark its position for removal. Carefully cut the line a few inches beyond the damage to ensure a clean break.

- Prepare the new fuel line by cleaning the ends and ensuring they are free of debris. Use a fuel line cutter to make precise cuts if needed.

- Slide the new line into place, ensuring it is aligned correctly with the fittings. Secure it using the appropriate connectors and clamps, making sure they are tight and secure.

- Test the system by starting the vehicle and checking for any leaks.

Repairing a Fuel Line:

- Inspect the damaged area and clean it thoroughly. Ensure there is no debris or contaminants that could interfere with the repair.

- Measure the damaged section and cut the repair sleeve to fit. Slide the sleeve over the damaged portion, ensuring it covers the entire length.

- Apply the fuel line adhesive or tape as per the kit instructions to secure the repair. Make sure it is firmly in place.

- Use a fuel line clamp to hold the repair in position temporarily, then tighten it securely. Test the vehicle to ensure the leak has been sealed.

Remember, when working with fuel lines, safety is paramount. Always ensure the vehicle is in a well-ventilated area, and wear protective gear if necessary. It's crucial to follow manufacturer guidelines and best practices to ensure a successful repair or replacement.

Unraveling the Mystery: Why Motorcycles Pop Pinholes in Fuel Lines

You may want to see also

Reinstall and Test: Securely reconnect and test for leaks

Once you've gathered the necessary tools and parts, it's time to reinstall the metal fuel line. Start by carefully aligning the new line with the existing connections, ensuring it is properly positioned and secure. Use the appropriate tools to tighten the fittings and connections, but be cautious not to overtighten, as this can cause damage. Tighten each connection securely, but remember that over-tightening can lead to damage, so use a steady hand and a gentle force.

After reinstalling the fuel line, it's crucial to test for any potential leaks. Locate the fuel tank and the engine's fuel system. Using a soapy water solution, carefully apply the mixture to all the connections and joints of the fuel line. Pay close attention to any areas where the line connects to the tank, the engine, or other components. If you notice any bubbles forming, it indicates a potential leak. If a leak is detected, tighten the connection further or consider replacing the affected part.

When testing for leaks, ensure you have a clear understanding of the fuel system's layout. Start by checking the connections between the fuel tank and the line, then move to the engine's fuel injectors or carburetor, depending on the system. Inspect each joint and fitting, and if you find any, address them immediately. It's important to identify and fix leaks promptly to prevent potential engine issues and ensure the safety of your vehicle.

If you're unsure about any step during the reinstallation process, consult the vehicle's manual or seek professional assistance. Properly securing the fuel line is essential to maintain the integrity of the fuel system and prevent any hazardous situations. Remember, a well-maintained fuel line is crucial for the optimal performance and longevity of your engine.

Nitrile Rubber and PVC: The Ultimate Fuel Line Materials?

You may want to see also

Frequently asked questions

Repairing a metal fuel line requires careful assessment and the right tools. If the damage is minor, such as small holes or punctures, you can use a metal fuel line repair kit. These kits typically include a sealing compound and a patch that can be applied over the damaged area to create a secure seal. For more severe damage, it's best to replace the entire fuel line. This process involves cutting out the damaged section, cleaning the area, and then soldering or welding the new fuel line into place. Ensure you follow safety guidelines and consider seeking professional help for complex repairs.

Metal fuel lines can leak due to several factors. Over time, the lines can corrode or deteriorate due to exposure to fuel, heat, or vibration. This corrosion can lead to small cracks or holes, allowing fuel to escape. Additionally, fuel lines may develop leaks if they are damaged during installation or due to the natural wear and tear of the vehicle's aging process. Regular inspections and prompt repairs are essential to prevent fuel leaks, which can pose safety risks and cause environmental damage.

While a temporary fix is possible, it's crucial to understand that it's not a long-term solution. For a temporary repair, you can use a fuel line clamp or a temporary seal, but these are only meant for short-term use. Clamps can be used to secure the line and prevent immediate fuel loss, but they may not provide a reliable seal. It's recommended to replace the fuel line permanently as soon as possible to ensure the safety and efficiency of your vehicle's fuel system.

Maintaining metal fuel lines is essential for their longevity. Regularly inspect the lines for any signs of damage, corrosion, or wear. Keep the fuel lines clean and free from debris by using a fuel line cleaner or a compressed air gun. Ensure that all connections are tight and secure. It's also beneficial to use fuel line protectants or lubricants to reduce friction and prevent damage. If you notice any issues, address them promptly to avoid more extensive repairs.