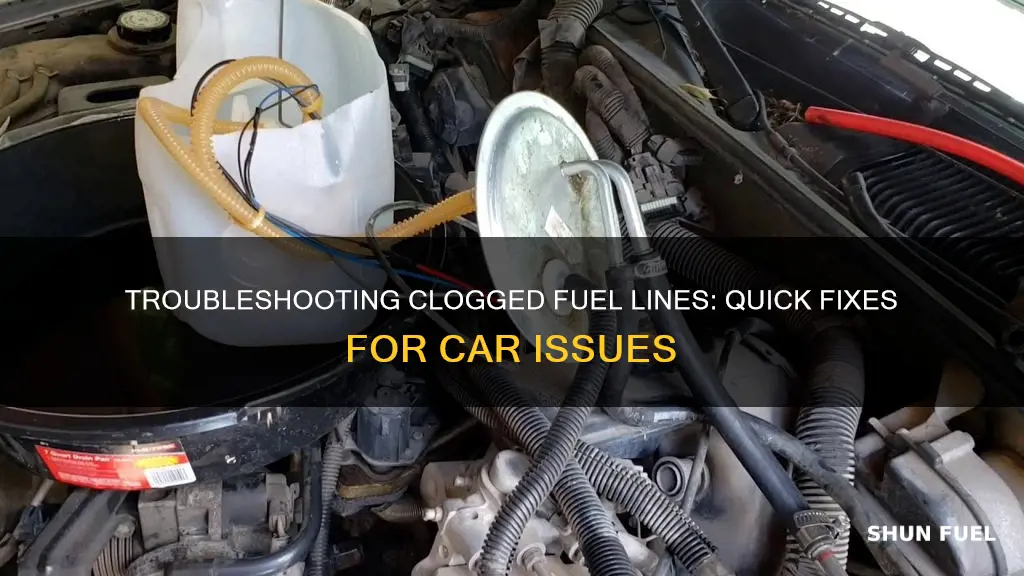

A clogged fuel line can be a frustrating issue for vehicle owners, often leading to poor performance and potential engine problems. Fortunately, fixing a clogged fuel line is a manageable task that can be tackled with the right tools and a bit of know-how. This guide will provide a step-by-step approach to identifying and resolving the issue, ensuring your vehicle runs smoothly and efficiently. By following these instructions, you can save time and money, potentially avoiding more extensive and costly repairs.

What You'll Learn

- Identify Clog: Inspect fuel line for blockages, debris, or kinks

- Clear Debris: Use a fuel line cleaner or compressed air to remove obstructions

- Replace Damaged Parts: Inspect and replace any damaged or worn-out components

- Flush System: Run a fuel line flush to remove contaminants and old fuel

- Test and Reinstall: After cleaning, test the line and reinstall it securely

Identify Clog: Inspect fuel line for blockages, debris, or kinks

To identify a clogged fuel line, a thorough inspection is essential. Start by locating the fuel line, which is typically a rubber or plastic hose that connects the fuel tank to the engine. It runs along the frame and may be hidden under various components. Visually examine the fuel line for any signs of damage, cracks, or discolouration. Look for areas where the hose might be pinched, kinked, or compressed, as these can restrict fuel flow. Check for any visible debris or contaminants along the length of the fuel line, as these can cause blockages.

Kinks and bends in the fuel line should be carefully inspected. Over time, the line can develop kinks due to movement or impact from other components. These kinks may cause the fuel to flow erratically or block it entirely. Ensure that the fuel line is not twisted or bent excessively, as this can lead to fuel restriction. Use your hands to feel for any hard spots or areas of resistance along the hose, indicating potential blockages or clogs.

Debris, such as dirt, rust, or even small stones, can accumulate inside the fuel line, especially if it has been exposed to harsh conditions. Remove any visible debris by carefully cleaning the fuel line. You can use a soft-bristled brush or a small, flexible brush to gently scrub the interior of the hose, removing any built-up contaminants. Take note of any blockages found and consider the source to prevent future occurrences.

If the fuel line is difficult to access or inspect, consider using a fuel line inspection camera. This tool can provide a clear view of the interior of the hose, allowing you to identify blockages or issues that might not be visible to the naked eye. Insert the camera into the fuel line and observe the footage to detect any obstructions or damage. This method is especially useful for long or hidden fuel lines.

Remember, regular maintenance and inspection of the fuel line can prevent clogs and ensure optimal engine performance. By identifying and addressing blockages early on, you can avoid potential issues related to fuel delivery, such as engine misfires or reduced power.

Fixing Rusted Fuel Lines: A Step-by-Step Guide to Prevent Engine Damage

You may want to see also

Clear Debris: Use a fuel line cleaner or compressed air to remove obstructions

When dealing with a clogged fuel line, one of the primary steps is to clear any debris or obstructions that might be causing the issue. This process involves using either a fuel line cleaner or compressed air, both of which are effective methods to ensure a thorough cleaning. Here's a detailed guide on how to proceed:

Using a Fuel Line Cleaner:

Fuel line cleaners are specifically designed to dissolve and remove deposits, varnish, and other contaminants that can accumulate inside the fuel lines over time. These cleaners are typically in the form of a liquid or gel and can be applied directly to the clogged area. Start by purchasing a high-quality fuel line cleaner from a reputable automotive store. Ensure you follow the instructions on the product carefully, as different cleaners may have varying application methods and timings. Typically, you'll need to pour or spray the cleaner into the fuel line, allowing it to sit for a specified duration to break down the deposits. After the recommended time has passed, start the vehicle's engine and let it run for a few minutes to ensure the cleaner circulates through the system. Then, shut off the engine and check for any remaining debris or cleaner that might need to be flushed out. This method is particularly useful for stubborn clogs and can help restore optimal fuel flow.

Using Compressed Air:

Compressed air is an excellent alternative for those who prefer a more mechanical approach. This method involves using an air compressor to blow air through the fuel line, dislodging and removing any debris or blockages. Here's a step-by-step process: First, locate the fuel line that needs cleaning. You might find it under the vehicle or along the frame, depending on the make and model of your car. Then, use a fuel line brush or a small, flexible brush to clear any visible debris from the line. Next, attach a compressed air nozzle to the air compressor and carefully direct the air stream into the fuel line. Apply moderate pressure to ensure the air reaches the clogged area. The force of the air should dislodge any debris, and you may hear or see it being expelled from the line. Continue this process until you've cleared the entire length of the fuel line. Compressed air is a quick and effective way to remove larger particles and can be a handy tool for regular maintenance.

Both methods are essential tools in your arsenal for fixing a clogged fuel line. Using a fuel line cleaner ensures a thorough clean, especially for stubborn deposits, while compressed air provides a mechanical approach to dislodge larger debris. It's important to remember that regular maintenance and cleaning can prevent future clogs, ensuring your vehicle's fuel system operates efficiently.

Inline Primer Bulb: Powering Your Engine with Hand Fuel Lines

You may want to see also

Replace Damaged Parts: Inspect and replace any damaged or worn-out components

When dealing with a clogged fuel line, a thorough inspection is crucial to identify the root cause and ensure effective repairs. Start by visually examining the fuel line for any visible signs of damage, such as cracks, leaks, or corrosion. Pay close attention to areas where the line connects to the fuel pump, filter, and injectors, as these are common problem spots. If you notice any damage, it's essential to replace the affected section promptly.

The fuel pump is a critical component that needs regular maintenance. Over time, it can wear out or become clogged, leading to fuel delivery issues. Inspect the pump for any signs of debris or damage. If you find any blockages or wear, consider replacing the pump to ensure optimal fuel flow. Additionally, check the fuel filter, as a clogged or damaged filter can restrict fuel passage. Replace it if it appears dirty, damaged, or if it has exceeded its recommended lifespan.

In some cases, the issue might originate from the fuel injectors. These delicate components can become clogged or damaged due to contaminants in the fuel or system malfunctions. Inspect the injectors for any blockages or signs of wear. If you suspect an issue, it's advisable to clean or replace the injectors to restore proper fuel atomization and combustion. Remember, proper maintenance and regular cleaning of these parts can prevent future clogs.

When replacing damaged parts, ensure you use high-quality replacements that meet or exceed the manufacturer's specifications. Properly secure all connections and double-check for any leaks. It's also a good practice to flush the fuel system with a cleaner to remove any debris or old fuel, especially after major repairs. This step ensures that the newly installed parts function optimally and helps prevent future clogs.

Remember, regular maintenance and prompt attention to any issues can save you from more extensive and costly repairs. By inspecting and replacing damaged components, you can effectively resolve clogged fuel line problems and maintain optimal engine performance.

Marine Fuel Line Sealant: Choosing the Right Material for Your Boat

You may want to see also

Flush System: Run a fuel line flush to remove contaminants and old fuel

A clogged fuel line can be a common issue for vehicle owners, often leading to reduced performance and potential engine problems. One effective method to address this issue is by performing a fuel line flush, which involves removing contaminants and old fuel from the system. This process is straightforward and can be done by following a few simple steps.

To begin, you'll need to locate the fuel line that needs to be flushed. This line typically runs from the fuel tank to the engine, and it's important to identify the specific section that requires cleaning. You can use a fuel line inspection tool or a mirror to visualize the line and its connections. Once located, you'll need to drain the fuel from the tank to ensure a thorough flush. This can be done by opening the fuel tank drain valve, usually found at the bottom of the tank, and allowing the old fuel to drain into a suitable container. It's crucial to dispose of the drained fuel responsibly, following local environmental regulations.

After draining the fuel, you can proceed with the flush. Purchase a fuel line flush product from an automotive store. These products are designed to dissolve and remove contaminants. Follow the instructions on the product carefully, as the process may vary depending on the brand. Typically, you'll need to add the flush product to the fuel tank and run the engine for a specified duration to allow the chemical to circulate through the fuel lines. This process helps to break down and remove any built-up deposits and contaminants.

During and after the flush, it's essential to monitor the vehicle's performance. You may notice a temporary decrease in power and fuel efficiency due to the cleaning process. This is normal and should resolve once the flush is complete. After the flush, it's recommended to refill the fuel tank with fresh fuel to ensure optimal performance.

By following these steps, you can effectively clean a clogged fuel line and improve your vehicle's overall performance. Regular maintenance, including fuel line flushes, can help prevent future issues and ensure your car runs smoothly. Remember to always consult the vehicle's manual or seek professional advice for specific instructions tailored to your make and model.

Primer Bulb Fuel Line: Understanding the Walbro Connection

You may want to see also

Test and Reinstall: After cleaning, test the line and reinstall it securely

After you've thoroughly cleaned the fuel line, it's crucial to test its functionality and ensure it's properly installed to prevent future clogs. Here's a step-by-step guide on how to test and reinstall the fuel line:

Testing the Fuel Line:

- Fuel Pressure Check: Start by using a fuel pressure gauge to measure the pressure in the fuel line. Compare it to the manufacturer's recommended specifications. If the pressure is significantly lower than the recommended range, it could indicate a clogged line or a faulty fuel pump.

- Spray Test: Use a spray bottle filled with a fuel line cleaner or a mixture of vinegar and water. Spray the cleaner into the fuel line, and observe if the spray exits the line freely. If the spray is blocked, it confirms the presence of a clog.

- Engine Test: Start the engine and listen for any unusual noises. A clogged fuel line might cause the engine to run roughly or stall. If the engine runs smoothly, the issue is likely resolved.

Reinstalling the Fuel Line:

- Secure Connections: Ensure all connections are tight and secure. Use the appropriate tools to tighten the fuel line fittings and clamps. Make sure there are no loose connections that could cause the line to become dislodged.

- Reattach the Fuel Pump: Carefully reattach the fuel pump to the engine. Ensure it is properly aligned and secured. Check that all electrical connections are intact and firmly attached.

- Final Test: Before starting the engine, double-check all connections and fittings. Then, start the engine and monitor its performance. The engine should now run smoothly, indicating that the clogged fuel line has been successfully resolved.

Remember, proper reinstallation is crucial to prevent future clogs and ensure optimal engine performance. If you encounter any issues during the testing or reinstallation process, it's best to consult a professional mechanic for further assistance.

Power Limits: How Much Horsepower Can Your Fuel Line Handle?

You may want to see also

Frequently asked questions

A clogged fuel line can lead to various performance issues in your vehicle. Common signs include difficulty starting the engine, frequent stalling, poor acceleration, and a noticeable decrease in power. You might also experience a strong smell of gasoline or fuel vapor, especially when the engine is running.

Temporary fixes can help get you to a mechanic or a safe location. One method is to use a fuel line cleaner or a fuel line flush kit, which can help clear blockages. You can also try using a high-pressure air compressor to blow out any debris or clogs. However, these solutions are only temporary, and a professional diagnosis and repair are recommended.

Fuel lines can become clogged due to several reasons. Over time, fuel lines can accumulate deposits of varnish, fuel gum, or carbon buildup, especially if the fuel contains ethanol, which can attract moisture. Additionally, fuel line clogs can result from physical damage, such as kinks or bends, or from debris and contaminants entering the line, especially if the fuel filter is clogged or damaged.