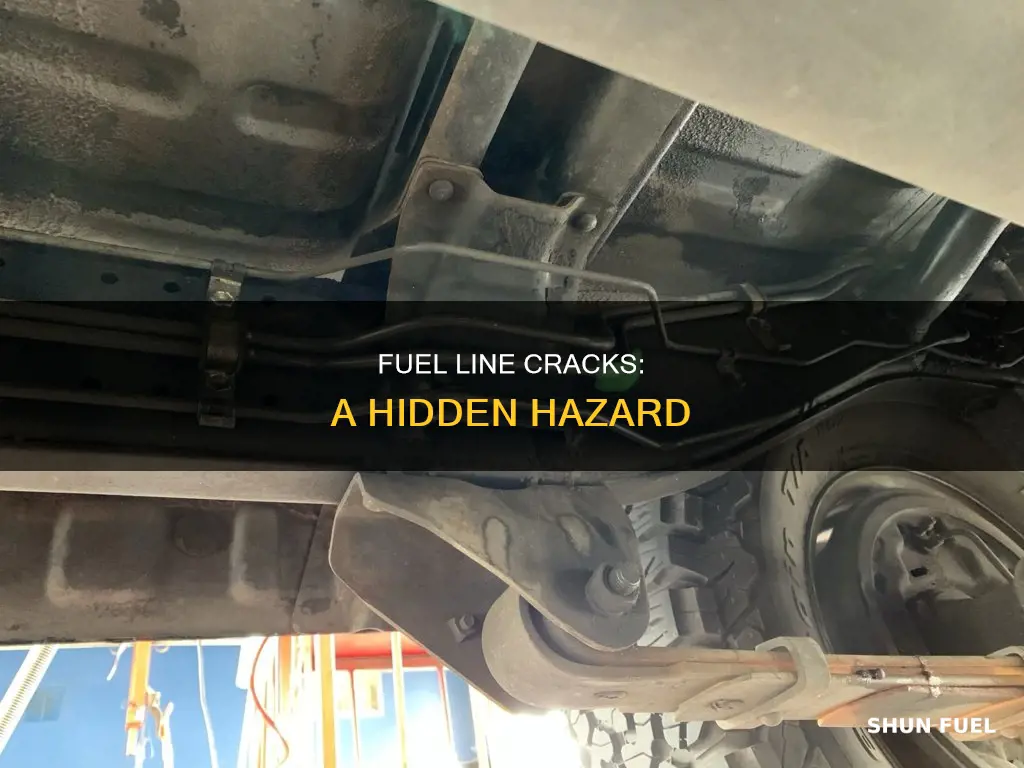

A fuel line crack can be a serious issue for vehicle owners, as it can lead to a variety of problems. Cracks in the fuel line can cause fuel to leak, which can result in engine misfires, reduced performance, and even engine failure. Additionally, fuel leaks can pose a safety hazard, as they can lead to fires or explosions. It is important to regularly inspect the fuel lines for any signs of damage or wear and to have them repaired or replaced as needed to ensure the safe and efficient operation of the vehicle.

What You'll Learn

- Fuel Line Material: Cracks can occur in various materials like rubber, plastic, or metal

- Environmental Factors: Temperature extremes, UV exposure, and chemicals can accelerate cracking

- Vibration and Impact: Frequent vibrations and impacts can weaken fuel lines over time

- Age and Wear: Older fuel lines are more prone to cracking due to material degradation

- Maintenance and Inspection: Regular checks and maintenance can prevent cracks and ensure fuel system safety

Fuel Line Material: Cracks can occur in various materials like rubber, plastic, or metal

Fuel lines are an essential component of any vehicle's fuel system, responsible for transporting fuel from the tank to the engine. While these lines are designed to be durable, they are not immune to damage, and cracks can develop over time due to various factors. Understanding the materials used in fuel lines and the potential causes of cracking is crucial for maintaining a vehicle's performance and safety.

The primary materials used in fuel lines include rubber, plastic, and metal. Rubber is a common choice due to its flexibility and resistance to heat and chemicals. Plastic fuel lines are also widely used, offering advantages in terms of weight reduction and corrosion resistance. However, both rubber and plastic can be susceptible to cracking under certain conditions. Metal fuel lines, typically made of steel or aluminum, are less common but can be used in specific applications where flexibility is not a primary concern.

Cracks in fuel lines can occur due to several reasons. One common cause is the natural degradation of the material over time. Rubber and plastic can become brittle and crack as they age, especially when exposed to sunlight, heat, or cold temperatures. This process is known as thermal aging and can lead to fuel leaks, which pose a significant safety risk. Additionally, the constant vibration and movement within a vehicle can cause stress on the fuel lines, potentially leading to cracks, especially at points where the lines are more susceptible to damage, such as bends or connections.

Another factor contributing to fuel line cracks is the presence of contaminants in the fuel. Over time, fuel can accumulate deposits, water, or other impurities, which can corrode the fuel line material, especially in plastic lines. This corrosion can weaken the fuel line, making it more prone to cracking. Regular fuel filter maintenance and the use of fuel additives can help mitigate this issue.

In the case of metal fuel lines, corrosion is a significant concern. Metal lines can develop cracks due to exposure to fuel contaminants or the vehicle's electrical system, which may contain acidic components. Proper grounding and the use of corrosion-resistant coatings can help prevent this type of damage.

To prevent fuel line cracks, regular inspections are essential. Vehicle owners should look for any signs of damage, such as brittleness, cracks, or leaks, and address issues promptly. Maintaining a clean fuel system and ensuring proper fuel storage conditions can also help extend the life of the fuel lines.

Exploring RV Fuel Lines: Does Love's in Mims Have One?

You may want to see also

Environmental Factors: Temperature extremes, UV exposure, and chemicals can accelerate cracking

Extreme temperatures, whether hot or cold, can significantly impact the integrity of fuel lines. High temperatures can cause the fuel lines to expand and contract rapidly, leading to stress and potential cracking. This is especially true for fuel lines made from materials like rubber or plastic, which are more susceptible to thermal degradation. In contrast, cold temperatures can make the fuel lines brittle, increasing the risk of cracking when the fuel is pumped through them. This phenomenon is often observed in regions with varying climates, where sudden temperature changes can cause the fuel lines to crack, leading to fuel leaks and potential engine issues.

Ultraviolet (UV) radiation from the sun is another environmental factor that can accelerate the cracking process. UV exposure can cause the degradation of the fuel line's material, particularly if the lines are not protected by a suitable coating or shielding. Over time, the constant exposure to UV rays can lead to the breakdown of the fuel line's structure, making it more prone to cracks and leaks. This is a common issue in outdoor settings, where fuel lines are exposed to direct sunlight for extended periods.

Chemicals present in the fuel or the surrounding environment can also contribute to the cracking of fuel lines. Certain additives in gasoline or diesel, such as ethanol, can cause swelling and softening of the fuel line material, making it more susceptible to damage. Additionally, exposure to corrosive chemicals, such as those found in industrial settings or near marine environments, can lead to the deterioration of the fuel line's protective coatings, resulting in cracks and potential fuel contamination.

To mitigate these environmental factors, it is essential to choose fuel lines made from durable materials that can withstand temperature extremes and UV exposure. Proper insulation and shielding can also help protect the fuel lines from the damaging effects of UV radiation. Regular maintenance and inspections are crucial to identify and replace any cracked or damaged fuel lines, ensuring the safe and efficient operation of the vehicle or equipment.

In summary, environmental factors play a critical role in the cracking of fuel lines. Temperature extremes, UV exposure, and chemicals can all contribute to the degradation of the fuel line material, leading to potential engine issues and safety hazards. Understanding these factors and implementing appropriate measures can help prevent fuel line cracking and ensure the longevity of the fuel system.

Honda Civic Fuel Line Location: A Comprehensive Guide

You may want to see also

Vibration and Impact: Frequent vibrations and impacts can weaken fuel lines over time

Vibration and impact are significant factors that can contribute to the deterioration of fuel lines over time. Fuel lines are crucial components in a vehicle's fuel system, responsible for transporting fuel from the tank to the engine. However, they are susceptible to damage due to the harsh conditions they endure during regular use. Frequent vibrations and impacts can have a cumulative effect on these lines, leading to potential cracks and failures.

In vehicles, vibrations are an inevitable byproduct of the engine's operation. As the engine runs, it generates vibrations that travel through various components, including the fuel lines. Over time, these vibrations can cause the fuel lines to become loose or develop small cracks. The constant back-and-forth motion of the engine can exert stress on the fuel lines, especially at connection points and bends. This stress can lead to the deterioration of the fuel line material, making it more prone to cracking.

Impact, on the other hand, refers to sudden and forceful blows that the vehicle may encounter during its operation. This can include driving over potholes, speed bumps, or other road irregularities. Each impact can create a temporary stress on the fuel lines, potentially causing damage. The fuel lines may twist, bend, or even break at the point of impact, especially if the force is sufficient. Repeated impacts can weaken the fuel lines further, making them more susceptible to cracks and leaks.

The combination of vibration and impact can be particularly harmful to older vehicles or those with pre-existing issues. In these cases, the fuel lines may already be more fragile due to age or previous damage. The continuous vibrations and impacts can accelerate the degradation process, leading to cracks that may go unnoticed until it's too late. This can result in fuel leaks, which not only cause performance issues but also pose safety risks due to the potential for fuel-air mixture explosions.

To mitigate these risks, it is essential to ensure regular maintenance of the vehicle's fuel system. This includes checking for any signs of damage, such as cracks or leaks, and replacing worn-out fuel lines promptly. Additionally, addressing any underlying issues that may contribute to excessive vibrations or impacts, such as worn-out suspension components, can help prolong the life of the fuel lines and ensure optimal vehicle performance.

Poulan Pro's Unique Fuel Line: Unlocking the Mystery

You may want to see also

Age and Wear: Older fuel lines are more prone to cracking due to material degradation

The longevity of a vehicle's performance and safety is heavily reliant on the condition of its fuel system, and one critical component that can be affected by age and wear is the fuel line. Over time, these lines, which are responsible for transporting fuel from the tank to the engine, can develop cracks due to various factors.

One primary reason for this issue is the natural degradation of the material used in the fuel lines. Most fuel lines are made from rubber or a synthetic rubber compound, which can break down over the years due to exposure to heat, sunlight, and the constant vibration and movement within the vehicle. As the material ages, it becomes more susceptible to cracking, especially at points where the line bends or flexes, such as near the fuel tank and along the engine's mounting points.

The environmental conditions also play a significant role in the deterioration of fuel lines. Prolonged exposure to high temperatures can accelerate the breakdown of the rubber, leading to cracks. Similarly, harsh weather conditions, like extreme cold, can cause the fuel to thicken and put additional stress on the fuel lines, potentially causing them to crack.

Regular maintenance and inspections are essential to prevent fuel line issues. Vehicle owners should look out for any signs of damage, such as cracks, leaks, or discoloration, and address these problems promptly. Replacing old fuel lines with new ones made from improved materials can also help extend the life of the vehicle and ensure optimal performance.

In summary, the age and wear of fuel lines are significant factors in their propensity to crack. Material degradation, environmental factors, and the natural aging process all contribute to this issue. By understanding these factors, vehicle owners can take proactive measures to maintain their fuel systems and ensure the overall reliability and safety of their vehicles.

Ethanol's Impact: Fuel Line Concerns and Solutions

You may want to see also

Maintenance and Inspection: Regular checks and maintenance can prevent cracks and ensure fuel system safety

Regular maintenance and inspections are crucial for preventing fuel line cracks and ensuring the overall safety of your vehicle's fuel system. Fuel lines are susceptible to damage over time due to various factors, including age, temperature fluctuations, and the corrosive nature of fuel itself. Ignoring these potential issues can lead to dangerous consequences, such as fuel leaks, engine misfires, and even fires. Therefore, it is essential to establish a routine maintenance schedule to address these concerns proactively.

One of the primary methods to maintain fuel system integrity is through regular visual inspections. Start by examining the fuel lines for any visible signs of damage, such as cracks, punctures, or kinks. These issues can often be identified by looking for discolored or brittle areas along the line. It is also important to check for any signs of corrosion or rust, especially if your vehicle operates in harsh environments or has been exposed to saltwater. Additionally, inspect the fuel tank for any leaks or damage, as a compromised tank can lead to fuel contamination and further system deterioration.

During your inspections, pay close attention to the connections between the fuel lines and other components, such as the fuel pump, engine, and fuel tank. Over time, these connections can loosen or corrode, leading to potential fuel leaks. Ensure that all connections are tight and secure, and consider using thread seal tape or pipe dope to reinforce the joints. Regularly checking and tightening these connections can prevent fuel line cracks and maintain the system's efficiency.

In addition to visual inspections, it is beneficial to perform pressure tests on the fuel system. These tests involve using specialized equipment to measure the fuel pressure and ensure it meets the manufacturer's specifications. Low fuel pressure can indicate potential issues with the fuel pump, lines, or injectors, which may lead to cracks or blockages. By identifying these problems early on, you can take the necessary steps to repair or replace the affected components, preventing further damage.

Furthermore, keeping your vehicle's fuel system clean is essential for long-term maintenance. Over time, fuel lines can accumulate deposits and contaminants, especially if using lower-quality fuels or in regions with poor fuel quality. These deposits can restrict fuel flow, reduce engine performance, and even cause cracks in the lines. Regularly using fuel system cleaners and ensuring proper fuel filtration can help prevent such issues. Additionally, maintaining a clean engine bay and addressing any oil or coolant leaks promptly will contribute to the overall health of the fuel system.

Mastering Fuel Line Removal: A Guide for 1997 Ford F150 Owners

You may want to see also

Frequently asked questions

A cracked or damaged fuel line can lead to several issues. Common signs include fuel leaks, which may appear as a hissing sound or a visible trail of fuel around the car. You might also notice a decrease in engine performance, such as reduced power, acceleration, or fuel efficiency. Additionally, a cracked fuel line can cause the engine to stall or misfire, especially during acceleration.

A compromised fuel line can significantly impact engine operation. When a fuel line cracks, it can lead to an improper fuel-air mixture, causing the engine to run lean. This results in reduced power, poor fuel efficiency, and potential engine misfires. In some cases, the engine may even stall due to the lack of proper fuel supply.

Absolutely. A fuel line crack can lead to dangerous situations. Fuel is highly flammable, and a leak can create a fire hazard, especially if the leak occurs near the engine compartment or under the vehicle. In the event of a collision or impact, a damaged fuel line may also lead to fuel spills, posing environmental and safety risks.

Fuel lines can crack due to several factors. Age and wear are common causes, as fuel lines degrade over time. Extreme temperatures, both hot and cold, can also contribute to cracking. Additionally, physical damage from accidents, road debris, or improper installation can lead to fuel line cracks.

Preventive measures are essential to avoid fuel line issues. Regular vehicle maintenance, including checking for any signs of damage or wear, is crucial. Ensure that all fuel system components are properly secured and protected. Avoid driving over rough terrain or potholes, as these can cause physical damage. It's also recommended to use fuel line protectants and to have the fuel system inspected by a professional mechanic periodically.