Disconnecting a plastic fuel line can be a necessary step when performing vehicle maintenance or repairs. This process requires careful handling to ensure safety and prevent fuel spills. Here's a brief guide on how to safely disconnect a plastic fuel line: Start by locating the fuel line, which is typically found near the fuel tank or engine. Use the appropriate tools, such as a fuel line disconnect tool or a pair of pliers, to carefully release the fittings or clips that hold the line in place. When disconnecting, be mindful of the fuel flow to avoid any spills. Ensure you have a clean and dry work area to prevent contamination. After disconnecting, double-check to make sure the line is secure and properly sealed to prevent any fuel leaks. Always follow safety precautions and consult the vehicle's manual for specific instructions tailored to your make and model.

What You'll Learn

- Prepare the Tools: Gather necessary tools like a fuel line disconnect tool, wrench, and safety gloves

- Locate the Fuel Line: Identify the plastic fuel line on the fuel tank or engine

- Turn Off Fuel Supply: Shut off the fuel supply valve to prevent spills

- Loosen Connections: Use the tool to loosen and remove the fuel line connectors

- Remove the Line: Carefully pull the plastic fuel line away from the connections and dispose of it safely

Prepare the Tools: Gather necessary tools like a fuel line disconnect tool, wrench, and safety gloves

Before you begin the process of disconnecting a plastic fuel line, it's crucial to ensure you have the right tools and equipment to make the job efficient and safe. Here's a step-by-step guide on preparing the necessary tools:

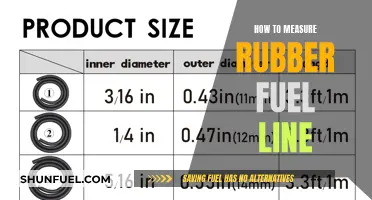

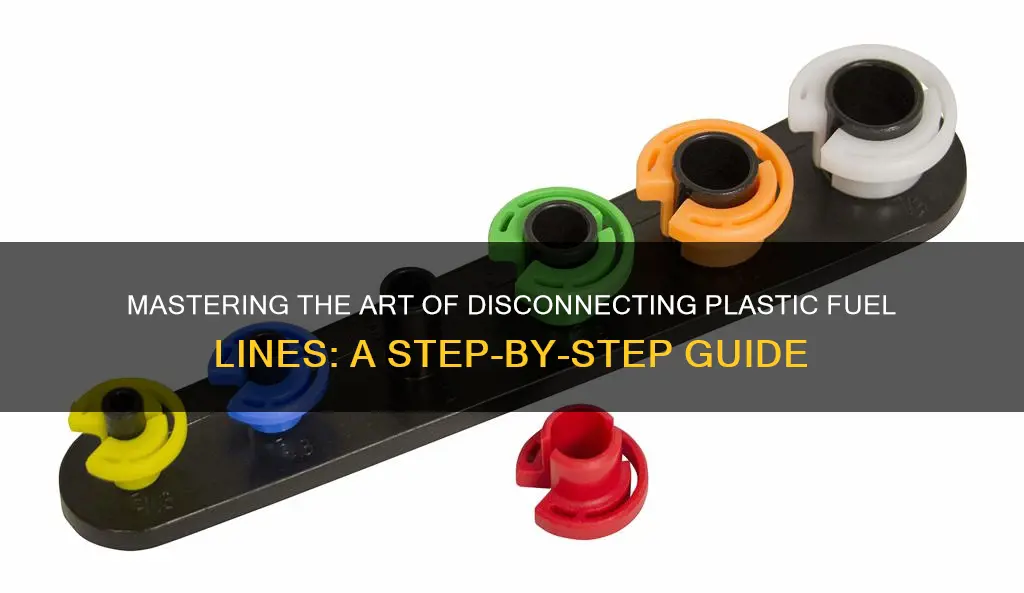

Fuel Line Disconnect Tool: This specialized tool is designed to safely and effectively disconnect plastic fuel lines. It typically features a set of jaws or a clamp that can grip the fuel line securely. Look for a tool that is compatible with the size of your fuel line. Having the right tool will make the disconnection process much easier and reduce the risk of damage to the fuel line.

Wrench: A standard wrench is essential for tightening or loosening nuts and fittings. You'll need a wrench that fits the size of the fasteners holding the fuel line in place. Ensure you have a good grip on the wrench to apply the necessary force without slipping.

Safety Gloves: Protecting your hands is a priority when working with fuel lines. Safety gloves will shield your hands from potential hazards, including sharp edges, hot surfaces, and fuel spills. Opt for gloves made from durable materials like leather or heavy-duty synthetic fabrics to ensure they can withstand the rigors of the task.

Additionally, consider having a rag or cloth to wipe away any fuel spills and keep the work area clean. It's also a good idea to have a second pair of hands to assist with the process, especially if you're working on a tight space or a complex fuel system. By gathering these tools and equipment, you'll be well-prepared to safely and efficiently disconnect the plastic fuel line.

Where to Find 1/4 Clear Fuel Lines: A Comprehensive Guide

You may want to see also

Locate the Fuel Line: Identify the plastic fuel line on the fuel tank or engine

When it comes to disconnecting a plastic fuel line, the first step is to locate the fuel line itself. This line is typically made of flexible plastic and is used to transport fuel from the tank to the engine. It is an important component of the fuel system, and identifying its location is crucial for a safe and successful disconnection.

Start by inspecting the fuel tank, which is usually located beneath the vehicle. Look for any visible connections or attachments to the tank. The fuel line will likely be connected to a fuel pump or a fuel filter, which are essential components of the fuel system. These parts are often made of metal and may have a distinct appearance, making it easier to identify the fuel line's path.

If the fuel tank is not easily accessible, you may need to inspect the engine bay. The plastic fuel line can run along the bottom of the engine or be routed through various compartments. Carefully examine the engine bay for any signs of the fuel line, as it might be hidden behind other components. In some cases, you may need to remove certain parts or lift the engine to gain better access.

Look for any signs of wear and tear or damage on the fuel line. Over time, the plastic can degrade, leading to cracks or leaks. Identifying these issues is important to ensure a safe disconnection and prevent fuel leaks. If you notice any damage, it is recommended to replace the fuel line before proceeding with the disconnection.

Once you have identified the fuel line, take note of its position relative to other components. This information will be useful when you need to reconnect the line or perform further maintenance on the fuel system. Remember to be gentle when handling the fuel line to avoid any damage, especially if it is still connected to the fuel tank or engine.

F150 Fuel System: Vent Line Mystery Solved

You may want to see also

Turn Off Fuel Supply: Shut off the fuel supply valve to prevent spills

When working with a plastic fuel line, it's crucial to turn off the fuel supply to ensure safety and prevent any potential spills or accidents. Here's a step-by-step guide on how to do this:

Locate the fuel supply valve, which is typically found near the fuel tank or the engine. This valve is designed to control the flow of fuel into the system. It might be a small, screw-on cap or a larger, more visible valve, depending on the vehicle or equipment you're working on. If you're unsure of its location, consult the vehicle's manual or seek guidance from a professional mechanic.

Once you've identified the fuel supply valve, shut it off by turning it clockwise. This action will close the valve and stop the flow of fuel. Ensure that you tighten it securely to prevent any accidental opening. It's essential to exercise caution at this stage, as any pressure built up in the system could lead to spills or damage.

After turning off the fuel supply, it's a good practice to release any remaining pressure from the fuel line. You can do this by slightly loosening the valve and then tightening it again. This process allows any residual fuel to drain out, reducing the risk of spills during the disconnection process.

Now, you can proceed with disconnecting the plastic fuel line. Carefully detach the fuel line from the fuel supply valve and the corresponding port on the fuel tank or engine. Take note of the connection method; some fuel lines might require a specific tool for removal. Ensure that you handle the disconnected fuel line with care to avoid any damage.

Remember, when working with fuel, always prioritize safety. By turning off the fuel supply valve, you create a controlled environment, minimizing the chances of accidents and spills. This simple step is often overlooked but is a critical part of any fuel-related maintenance or repair task.

Can Rubber Hose Fuel Lines to Carbs on Outboards Be Used Safely?

You may want to see also

Loosen Connections: Use the tool to loosen and remove the fuel line connectors

To safely disconnect a plastic fuel line, it's crucial to start by loosening the connections. This process requires a specific tool designed for this purpose. Here's a step-by-step guide:

Gather the Right Tools: You'll need a fuel line disconnect tool, often referred to as a fuel line disconnecting tool or fuel line release tool. These tools are typically designed with a clamp-like mechanism that grips the fuel line securely.

Locate the Connectors: Identify the fuel line connectors you need to disconnect. These are usually located near the fuel tank and the engine. Carefully inspect the connectors to ensure they are in good condition and free of any debris or corrosion.

Apply Pressure and Loosen: Position the disconnect tool over the fuel line connector. Apply firm pressure to the tool's handle, allowing it to grip the fuel line. This action will loosen the connector from its attachment point. Be cautious and apply steady pressure to avoid damaging the fuel line.

Remove the Connector: Once the connector is loosened, you should be able to remove it from the fuel line. Gently pull the connector straight off, ensuring you don't twist or force it, as this could damage the fuel line.

Repeat for Other Connections: If there are multiple fuel line connections, repeat the process for each one. Take your time and be patient, as loosening and removing connectors can require some force and dexterity.

Remember, when working with fuel lines, always exercise caution and wear protective gear if necessary. If you're unsure about any step, consult a professional mechanic to ensure a safe and successful disconnection.

Mastering Fuel Line Removal: A Guide for 1997 Ford F150 Owners

You may want to see also

Remove the Line: Carefully pull the plastic fuel line away from the connections and dispose of it safely

Before you begin the process of disconnecting the plastic fuel line, it's crucial to understand the importance of handling this task with care. Plastic fuel lines are designed to transmit fuel efficiently, but they can also be delicate and require careful removal to avoid damage. Here's a step-by-step guide to safely disconnecting the plastic fuel line:

- Gather the Necessary Tools: You'll need a pair of gloves to protect your hands and a small pair of pliers or a fuel line disconnect tool. Having the right tools will make the process easier and safer.

- Locate the Fuel Line Connections: Identify the points where the plastic fuel line is connected to the fuel tank, engine, and any other components. Typically, these connections are made with quick-release clips or small fasteners. Carefully inspect the connections to ensure you understand the layout.

- Release the Connections: Start by releasing the quick-release clips or fasteners at each connection point. Gently pull the clips apart to separate the fuel line from the attachment points. Take note of the order in which you remove the connections to ensure you can reattach them correctly later.

- Carefully Pull the Fuel Line: Once all the connections are released, you can begin pulling the plastic fuel line away from the engine and fuel tank. Work carefully to avoid pulling on the connections, as this can damage the fuel line or the components it is connected to. Pull the line straight and steadily to minimize the risk of tangling or kinking.

- Dispose of the Fuel Line Safely: As you remove the fuel line, ensure that you are doing so in a well-ventilated area away from any open flames or sparks. Plastic fuel lines can contain volatile substances, so proper disposal is essential. Dispose of the fuel line according to local regulations and guidelines for hazardous waste. Clean the area around the connections to prevent any residual fuel from causing issues during reassembly.

Remember, when working with fuel lines, it's crucial to prioritize safety and take your time. Rushing the process can lead to mistakes and potential hazards. By following these steps, you can safely disconnect the plastic fuel line and ensure a smooth and efficient repair or maintenance process.

Optimizing Performance: Choosing the Right Fuel Line for Your SBC 350

You may want to see also

Frequently asked questions

Disconnecting a plastic fuel line requires caution to avoid fuel spills and potential hazards. First, ensure the engine is off and the vehicle is in a stable position. Locate the fuel line, typically found under the car near the fuel tank or engine compartment. Use a fuel line disconnect tool or a pair of pliers to carefully release the fittings on both ends of the line. Be gentle to avoid damaging the fuel line. Once disconnected, wipe the ends clean and store the fuel line in a safe place.

You will need a few essential tools to safely disconnect the plastic fuel line. A fuel line disconnect tool, also known as a fuel line cutter or fuel line release tool, is the most common and effective method. These tools have a sharp blade that cuts through the fuel line without damaging it. Alternatively, you can use a pair of adjustable pliers with a smooth jaw to grip and release the fittings. Ensure you have a clean, dry workspace to prevent any contamination.

Absolutely, safety is crucial when working with fuel lines. Always wear protective gear, such as gloves and safety goggles, to protect your hands and eyes from potential splashes or spills. Ensure the vehicle is parked on a level surface to prevent any accidental movement. Before starting, check for any signs of damage or corrosion on the fuel line and fittings. Avoid smoking or using open flames in the vicinity of the fuel line, as it may contain volatile substances.

If the fuel line is damaged or torn during the disconnection process, it is essential to handle it with care. Do not attempt to reconnect the damaged section as it may lead to fuel leaks and potential hazards. Instead, replace the entire fuel line with a new one of the same specifications. Seek professional assistance if you are unsure about the replacement process, as they have the necessary tools and expertise to ensure a safe and proper installation.