If you're looking to disconnect the fuel injector line on a 1998 S-10, it's important to follow a few key steps to ensure a smooth and safe process. This guide will provide a step-by-step breakdown of how to safely disconnect the fuel injector line, including the necessary tools and safety precautions to take before and during the process. By following these instructions, you can efficiently and effectively disconnect the fuel injector line, making it easier to perform maintenance or repairs on your vehicle.

| Characteristics | Values |

|---|---|

| Vehicle Model | 1998 Chevrolet S-10 |

| Fuel Injector Location | Front of the engine, typically on the driver's side |

| Tool Required | Fuel Injector Line Disconnect Tool or a pair of adjustable pliers |

| Steps | 1. Park the vehicle on a level surface and engage the parking brake. 2. Locate the fuel injector line, which is usually a black or dark-colored hose. 3. Using the disconnect tool or pliers, carefully grip the line and pull it away from the fuel injector. 4. If the line is difficult to remove, you may need to gently pry it loose with a flat-head screwdriver or similar tool. 5. Once disconnected, you can replace or repair the fuel injector or line as needed. |

| Precautions | - Ensure the engine is cool before attempting any fuel system work. - Wear safety gloves and eye protection to avoid fuel splashes. - Check for any fuel leaks before and after disconnecting the line. |

| Additional Tips | - Refer to the vehicle's service manual for specific instructions and diagrams. - If you're unsure, consult a professional mechanic to avoid any potential damage. |

What You'll Learn

Locate the fuel injector line, typically near the engine

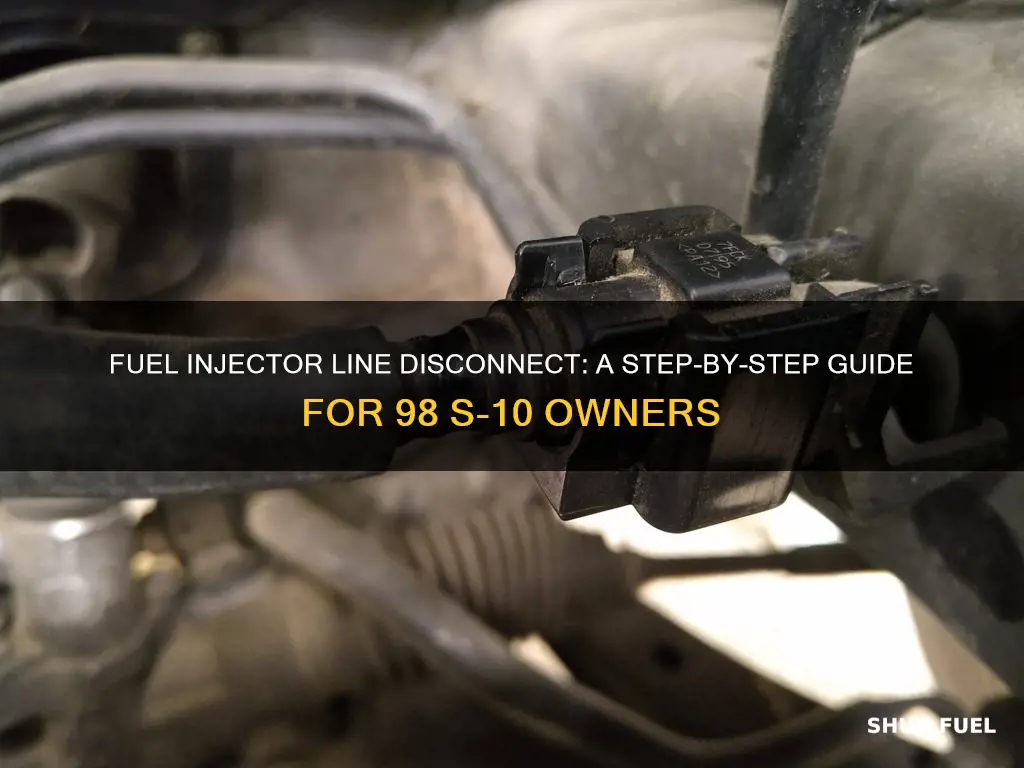

To begin the process of disconnecting the fuel injector line on your 1998 S-10, you'll need to locate the fuel injector line, which is typically positioned near the engine. This line is responsible for delivering fuel from the fuel tank to the engine's injectors. Start by inspecting the engine bay and locate the fuel rail, which is a metal bracket that holds the fuel injectors in place. The fuel injector line will be connected to the fuel rail and will have a distinct appearance, often with a larger diameter compared to other fuel lines.

Once you've identified the fuel rail, carefully inspect the area around it. The fuel injector line will usually be connected to a small, cylindrical fitting called a fuel injector connector. This connector is designed to securely hold the fuel line in place. It is often made of a durable plastic or metal material and may have a unique color or marking to distinguish it from other engine components.

To disconnect the fuel injector line, you'll need to locate the appropriate tools. A fuel line disconnect tool or a pair of adjustable pliers can be used to release the pressure and disconnect the line. Carefully insert the tool into the connector, ensuring it fits snugly. Apply gentle pressure to the tool, turning it counterclockwise to loosen the connection. Be cautious not to overtighten or force the tool, as this can damage the connector.

Once the connector is loosened, you should be able to pull the fuel injector line straight off the fuel rail. Take note of the position of the line to ensure proper reattachment later. It is recommended to clean the fuel rail and the surrounding area to remove any debris or old fuel residue. This step ensures a smooth and secure reconnection of the fuel line.

Remember, when working with fuel lines, it's crucial to exercise caution to avoid any fuel spills or engine damage. Always refer to your vehicle's manual for specific instructions and safety guidelines related to your particular model.

Optimizing Performance: Choosing the Right Fuel Line Size for Trans Lines

You may want to see also

Use a fuel line disconnect tool to loosen the clamp

When it comes to disconnecting the fuel injector line on your 1998 S-10, using a fuel line disconnect tool is a crucial step to ensure a smooth and safe process. This tool is specifically designed to help you loosen the clamp that secures the fuel line, allowing for easy disconnection without causing any damage or spillage. Here's a step-by-step guide on how to effectively use this tool:

Start by locating the fuel line that connects to the fuel injector. It is typically a black or dark-colored line that runs from the fuel tank to the engine. Identify the clamp that holds this line in place. The clamp is usually made of a durable plastic or metal material and is designed to provide a secure seal.

Now, it's time to employ the fuel line disconnect tool. These tools are often in the shape of a long, slender pliers with a smooth, curved jaw. Insert the curved end of the tool into the gap between the clamp and the fuel line. Ensure that the tool fits snugly around the clamp, providing a firm grip. Apply gentle but firm pressure to the handle of the tool, using it as a lever to loosen the clamp. You should feel a slight resistance as the clamp starts to come off. Be careful not to force it too much, as you want to avoid damaging the fuel line or the clamp itself.

As you continue applying pressure, the clamp should gradually loosen, allowing you to create a small gap between the clamp and the fuel line. Once the clamp is sufficiently loosened, you can now carefully pull the fuel line away from the clamp. Take note of the position of the fuel line to ensure proper reattachment later.

Remember, the key to successfully disconnecting the fuel line is to use the fuel line disconnect tool correctly. It provides the necessary leverage to loosen the clamp without causing any unnecessary strain on the fuel line or surrounding components. Always exercise caution when working with fuel lines to prevent any accidents or fuel leaks.

John Deere Tractor Fuel Lines: Unveiling the Brass Mystery

You may want to see also

Carefully pull the line away from the injector

To safely disconnect the fuel injector line on your 1998 S-10, it's crucial to follow a methodical approach. Begin by locating the fuel injector line, which is typically positioned near the engine's front side. This line connects the fuel pump to the injector, delivering fuel for combustion.

Once you've identified the line, carefully inspect it for any signs of damage or corrosion. If you notice any issues, address them before proceeding. Ensure you have the necessary tools, such as a wrench or pliers, to loosen the connections.

Now, the key step: Gently but firmly pull the line away from the injector. This action requires patience and a steady hand. Avoid forcing the line, as it can be delicate and prone to damage. Work slowly, ensuring you don't pull too hard, as this could strain the connections.

Take your time and be methodical. If the line is particularly stubborn, consider using a lubricant to ease the process. Once you've successfully separated the line from the injector, you'll have access to the fuel injector itself, allowing you to proceed with further maintenance or repairs. Remember, patience and a gentle touch are essential to avoid any potential complications.

Optimizing Performance: Choosing the Right Fuel Line for Your Waverunner

You may want to see also

Inspect the line for damage before reinstalling

Before you proceed with reinstalling the fuel injector line on your 1998 S-10, it's crucial to inspect the line for any signs of damage or wear. This step is often overlooked but is essential to ensure the proper functioning of your vehicle's fuel system and to prevent potential issues down the line. Here's a detailed guide on how to inspect the line effectively:

Start by locating the fuel injector line, which is typically a rubber or plastic hose that connects the fuel injectors to the fuel rail or pump. Carefully examine the line for any visible damage, such as cracks, tears, or bulges. Inspect the entire length of the line, paying close attention to areas where it may have been stressed or subjected to heat or pressure. Look for any signs of deterioration, especially around fittings, bends, and where the line passes through the engine compartment.

Check for any signs of leakage or damage at the connections. Ensure that all fittings and clamps are secure and intact. If you notice any cracks or damage to the line itself, it's crucial to replace it rather than attempting to repair it. Even small tears or punctures can lead to fuel leaks, which pose a serious safety risk.

Use a bright flashlight to illuminate the line and inspect it thoroughly. This will help you identify any hidden damage or small tears that might not be visible to the naked eye. Also, check for any signs of corrosion or rust, especially if the line has been exposed to moisture or harsh environmental conditions.

If you find any damage, it's best to replace the fuel injector line. You can purchase a replacement line from an automotive parts store or online retailer. Ensure that the new line is compatible with your specific vehicle model and year. When reinstalling, follow the same procedure as when disconnecting, taking care to route the new line correctly and secure all connections.

By thoroughly inspecting the fuel injector line for damage before reinstalling, you can ensure the reliability and safety of your vehicle's fuel system. This simple yet crucial step can help prevent costly repairs and potential hazards associated with fuel leaks.

Mastering the Art of Removing Yellow Fuel Line Clips: A Step-by-Step Guide

You may want to see also

Tighten the clamp securely to ensure a proper seal

When working on disconnecting the fuel injector line on your 1998 S-10 truck, it's crucial to pay close attention to the final step: tightening the clamp securely. This step is often overlooked but is essential for ensuring a proper seal and preventing any potential issues down the line. Here's a detailed guide on how to do it effectively:

Start by locating the fuel injector line that you want to disconnect. It is typically positioned near the engine, running alongside the fuel rail or injection system. Once you've identified the correct line, you'll need to locate the clamp that holds it in place. This clamp is usually made of metal or a durable plastic material and is designed to create a tight seal around the fuel line.

With the clamp in hand, carefully position it over the fuel injector line. Ensure that the clamp is aligned properly, covering the entire length of the line where it needs to be disconnected. Use your fingers or a small tool to gently push the clamp onto the line, creating a snug fit. The goal is to apply enough pressure to make the clamp grip the line securely without causing any damage.

Now, it's time to tighten the clamp. Use a wrench or a pair of pliers to turn the clamp counterclockwise, tightening it firmly. Apply steady pressure and ensure that the clamp doesn't slip or become too tight, as this could damage the fuel line. The key is to tighten it just enough to create a secure seal. You should feel a noticeable resistance when turning the clamp, indicating that it is being tightened effectively.

After tightening the clamp, inspect it to ensure it is secure. Check that the clamp is not twisted or misaligned, as this could compromise the seal. Also, verify that the fuel line is straight and not kinked, as any bends or twists could affect the flow of fuel. With the clamp tightened and the line secure, you've successfully disconnected the fuel injector line, and your vehicle is now ready for further maintenance or repairs.

Understanding LSX Fuel Return Lines: Essential or Optional?

You may want to see also

Frequently asked questions

Disconnecting the fuel injector line on a 1998 S-10 requires caution and a systematic approach. First, ensure the engine is cool to avoid burns. Locate the fuel rail, which is typically mounted on the engine block. Use a fuel rail separator tool or a flathead screwdriver to carefully pry the fuel rail off the injector line. Once the rail is removed, you can disconnect the line by unscrewing the fittings or cutting the line with a fuel line cutter, being mindful of any fuel remaining in the system.

Yes, having the right tools is essential. You'll need a fuel rail separator or a flathead screwdriver for prying the rail off. Additionally, a fuel line cutter or a set of adjustable pliers can be useful for disconnecting the line. It's also a good idea to have a fuel filter bypass tool or a temporary fuel line adapter to maintain fuel flow during the process.

Fuel leaks can be a serious issue, so it's important to address them promptly. If you notice any fuel escaping, immediately stop the process and locate the source of the leak. You can use a cloth or paper towel to absorb the fuel and then carefully clean the area. Ensure you work in a well-ventilated area and consider wearing protective gear. If the leak is significant, it's best to consult a professional mechanic to safely repair the fuel system.