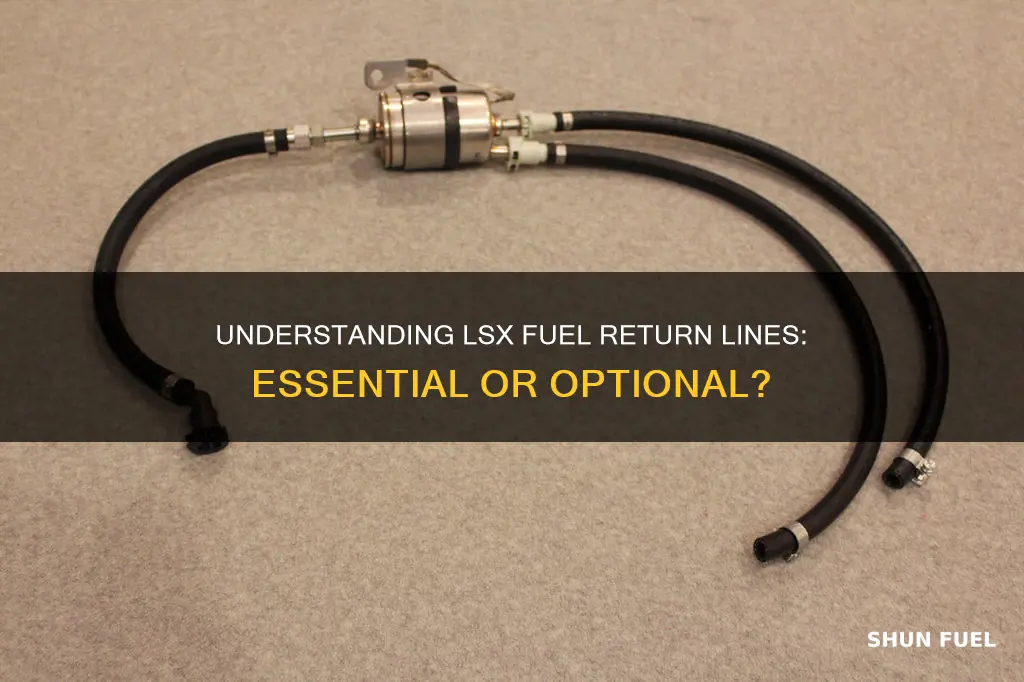

When it comes to modifying or building a LSX engine, one of the key components to consider is the fuel return line. This component plays a crucial role in ensuring efficient fuel delivery and combustion. In this paragraph, we will explore the importance of the fuel return line and whether it is necessary for LSX engines. We will discuss the benefits of having a fuel return line, such as improved fuel efficiency, reduced emissions, and enhanced engine performance. Additionally, we will address common misconceptions and provide insights into the installation process to help you make an informed decision about whether a fuel return line is essential for your LSX engine build.

| Characteristics | Values |

|---|---|

| Fuel Return Line Function | Prevents fuel from boiling and returning to the tank, ensuring proper fuel flow and engine performance |

| LSX Engine Compatibility | Applicable to LSX engines, including the LS3, LS7, and LS9 |

| Fuel System Design | Part of the fuel system's return mechanism, often used in high-performance applications |

| Material | Typically made of steel or aluminum, durable and compatible with fuel |

| Installation | Usually located near the fuel pump and connected to the fuel tank |

| Engine Performance | Enhances engine efficiency and power output by maintaining optimal fuel pressure |

| Maintenance | Regular inspection and replacement are recommended to prevent fuel system issues |

| Common Issues | Clogging, leaks, or damage can lead to fuel starvation and engine misfires |

| Customization | Some LSX engines may require custom fuel return lines for specific modifications |

What You'll Learn

- Fuel Return Line Basics: Understanding the purpose and function of a fuel return line

- LSX Engine Compatibility: Identifying if your LSX engine requires a fuel return line

- Performance Benefits: Improved fuel efficiency and reduced engine strain

- Installation Process: Step-by-step guide to installing a fuel return line

- Troubleshooting Common Issues: Tips for diagnosing and fixing fuel return line problems

Fuel Return Line Basics: Understanding the purpose and function of a fuel return line

The fuel return line is an essential component in any engine system, especially those with a LSX (Long Stroke eXtra) configuration. This line plays a crucial role in ensuring efficient fuel management and performance. When you google 'do I need a fuel return line on LSX', you'll find that many enthusiasts and mechanics emphasize its importance.

In simple terms, the fuel return line is responsible for directing the excess fuel from the injectors back to the fuel tank. This process is vital for maintaining optimal fuel pressure and ensuring that the engine receives the correct amount of fuel at all times. Without a fuel return line, fuel can accumulate in the injectors, leading to potential issues such as fuel starvation, misfires, and reduced engine performance.

The primary purpose of this line is to create a closed loop system for fuel flow. When the engine is running, the fuel injectors spray fuel into the combustion chamber, and some of this fuel may not be completely burned, resulting in excess. The return line captures this excess fuel and sends it back to the tank, preventing wastage and maintaining a steady fuel supply. This is particularly important in high-performance engines where fuel efficiency and precision are critical.

Its function becomes even more significant during acceleration and deceleration. When you step on the gas pedal, the engine demands more fuel, and the return line ensures that the fuel supply can quickly adapt to these changes. Similarly, when you release the pedal, the line helps regulate the fuel flow, preventing an excess of fuel from accumulating in the system. This dynamic process is key to maintaining smooth engine operation and optimizing fuel economy.

In summary, the fuel return line is a critical component for any LSX engine setup. It ensures efficient fuel management, prevents issues related to fuel accumulation, and contributes to overall engine performance and longevity. Understanding its purpose and function is essential for any vehicle owner or mechanic working with high-performance engines.

Metal Fuel Lines: Unlocking Engine Performance and Reliability

You may want to see also

LSX Engine Compatibility: Identifying if your LSX engine requires a fuel return line

The LSX engine, a popular choice for performance enthusiasts, is renowned for its versatility and power. When modifying or building an LSX engine, one crucial aspect to consider is fuel management, specifically the need for a fuel return line. This component is essential for efficient fuel delivery and can significantly impact engine performance.

A fuel return line is a dedicated conduit that allows excess fuel from the injectors to return to the fuel tank. In high-performance applications, where fuel flow rates are high, the engine's fuel system can sometimes generate more fuel than it can immediately use. This excess fuel, if not properly managed, can lead to various issues. Firstly, it can cause fuel to accumulate in the lines, leading to potential blockages and reduced fuel pressure. Secondly, without a return line, the engine may experience fuel starvation during high-load conditions, resulting in poor performance or even engine failure.

Identifying the need for a fuel return line on your LSX engine involves understanding the specific requirements of your fuel system setup. Here are some key considerations:

- Fuel Pump Location: The placement of the fuel pump is critical. If the pump is located near the engine, it can draw fuel from the tank and supply it directly to the injectors. However, if the pump is positioned lower, it may require a return line to ensure efficient fuel flow.

- Fuel Injector Type: Different injector types have varying flow rates and spray patterns. High-flow injectors, often used in performance builds, can generate more fuel than the engine can consume at once. In such cases, a return line becomes essential.

- Engine Modifications: Any modifications to the engine, such as adding a supercharger or turbocharger, can increase fuel demand. These modifications often require a well-designed fuel system, including a return line, to handle the additional fuel requirements.

To determine if your LSX engine needs a fuel return line, start by examining the fuel pump's location and the type of fuel injectors used. Consult the engine's manual or seek advice from experienced builders to understand the specific fuel system design. If your engine has a high-performance setup with powerful fuel injectors, a return line is likely necessary. Additionally, consider any planned modifications to ensure your fuel system can accommodate the increased fuel needs.

In summary, for LSX engine compatibility, a fuel return line is a vital component to ensure optimal performance and fuel management. By understanding the engine's fuel system design and considering factors like pump location, injector type, and potential modifications, enthusiasts can make informed decisions about their LSX engine's fuel requirements. Proper fuel management will contribute to a more reliable and powerful engine.

Perfect Fuel Line Size for Harley-Davidson Crossover: Expert Guide

You may want to see also

Performance Benefits: Improved fuel efficiency and reduced engine strain

The presence of a fuel return line on LSX (Late-Model Small-Block Chevrolet V8) engines is a crucial component that significantly impacts performance and efficiency. This line is responsible for directing excess fuel from the carburetor or fuel injection system back to the fuel tank, ensuring optimal fuel management and engine operation. By implementing a fuel return line, you can achieve several performance benefits that enhance the overall driving experience.

One of the primary advantages is improved fuel efficiency. LSX engines, known for their power and performance, often require precise fuel management to optimize combustion. Without a fuel return line, excess fuel can accumulate in the carburetor or fuel bowl, leading to inefficient fuel usage. This inefficiency results in wasted fuel and increased emissions, negatively impacting both performance and environmental impact. With a fuel return line, excess fuel is recycled back to the tank, ensuring that only the required amount is delivered to the engine, thus improving fuel economy.

Additionally, a fuel return line plays a vital role in reducing engine strain. LSX engines are powerful, and proper fuel management is essential to prevent strain on the engine's components. When excess fuel is left in the carburetor or fuel system, it can lead to over-fuelling, causing the engine to run rich and potentially causing engine knock or pre-ignition. This can result in reduced power, increased engine wear, and even potential damage to the engine's internal components. By routing excess fuel back to the tank, the fuel return line ensures that the engine operates at the optimal air-fuel ratio, reducing strain and promoting smoother performance.

The implementation of a fuel return line also contributes to better throttle response and overall engine responsiveness. With efficient fuel management, the engine can quickly adjust to throttle inputs, providing a more responsive driving experience. This is particularly beneficial for high-performance driving, where quick acceleration and precise throttle control are essential.

In summary, installing a fuel return line on LSX engines offers significant performance advantages. It improves fuel efficiency by ensuring optimal fuel usage and reduces engine strain by preventing over-fuelling and promoting efficient combustion. With better fuel management, LSX engines can deliver improved throttle response and overall engine performance, making it a valuable upgrade for enthusiasts seeking to enhance their vehicle's capabilities.

Clear Tubing: A Viable Fuel Line Solution?

You may want to see also

Installation Process: Step-by-step guide to installing a fuel return line

The LSX engine platform, known for its reliability and performance, often requires specific modifications to ensure optimal fuel management. One such modification is the installation of a fuel return line, which can significantly enhance the engine's performance and longevity. This guide will provide a detailed step-by-step process for installing a fuel return line on your LSX engine, ensuring a smooth and efficient process.

Step 1: Preparation

Before beginning the installation, ensure you have the necessary tools and materials. You will need a fuel return line, which can be purchased from specialized automotive parts stores or online retailers. Additionally, gather the required tools such as wrenches, pliers, and a fuel pump primer bulb. It is crucial to work in a well-ventilated area and wear protective gear, including gloves and safety goggles, to ensure your safety during the process.

Step 2: Locate the Fuel Pump and Reservoir

Locate the fuel pump and reservoir on your LSX engine. The fuel pump is typically located behind the engine, and the reservoir is usually found near the front of the engine bay. Identify the fuel lines connected to the pump and reservoir, as you will need to disconnect these lines to install the return line.

Step 3: Disconnect the Existing Fuel Lines

Carefully disconnect the fuel lines from the fuel pump and reservoir. Take note of the positions and orientations of these lines to ensure proper reattachment later. When disconnecting, be mindful of any fuel that may spill, and have a container ready to catch any overflow.

Step 4: Install the Fuel Return Line

Now, you can install the fuel return line. Start by routing the line from the fuel pump to the fuel rail or the intake manifold, depending on your engine's configuration. Secure the line using appropriate clamps or ties to ensure it remains in place. Ensure the line is routed away from any moving parts to prevent damage or interference.

Step 5: Reattach the Fuel Pump and Reservoir Lines

After installing the return line, reattach the fuel pump and reservoir lines to their respective connections. Tighten the connections securely, but be careful not to overtighten, as this can cause damage. Check for any leaks at each connection point and ensure all lines are properly aligned and secure.

Step 6: Test and Verify

Once the installation is complete, start the engine and check for any leaks. Ensure that the fuel pump is functioning correctly and that the engine is running smoothly. Test-drive the vehicle to confirm that the fuel return line is working as intended, and make any necessary adjustments to the fuel pressure or flow.

By following these detailed steps, you can successfully install a fuel return line on your LSX engine, improving its performance and overall efficiency. Remember to take your time and be meticulous during the installation process to ensure a successful outcome.

Mastering Fuel Line Maintenance: A Guide to Removing Crimp Clamps

You may want to see also

Troubleshooting Common Issues: Tips for diagnosing and fixing fuel return line problems

When dealing with fuel return line issues on LSX engines, a systematic approach to troubleshooting is essential. Here's a guide to help you diagnose and resolve these problems effectively:

Step 1: Visual Inspection

Start by visually inspecting the fuel return line for any obvious signs of damage or leaks. Look for cracks, punctures, or disconnections along the line. Sometimes, a simple visual check can reveal the source of the problem. Inspect the line for any signs of corrosion or degradation, especially if the vehicle is older.

Step 2: Check for Leaks

If you suspect a leak, it's crucial to identify its location. Remove the fuel return line and inspect the connections. Use a soapy water solution to test for leaks around the fittings and joints. If you notice bubbles forming, it indicates a potential leak. Additionally, check the fuel tank for any signs of fuel loss or contamination.

Step 3: Inspect the Pump and Injectors

Fuel return lines play a vital role in ensuring proper fuel circulation. If the line is functioning correctly, fuel should be directed back to the tank after being used by the injectors. Inspect the fuel pump and injectors for any signs of malfunction. A weak pump or clogged injectors can lead to improper fuel flow, causing the return line to overwork.

Step 4: Test the Line's Pressure

Use a fuel pressure gauge to measure the pressure in the return line. Low pressure might indicate a restriction or blockage in the line. If the pressure is significantly lower than the expected value, it could be a sign of a damaged line or a problem with the fuel pump. Ensure that the gauge is properly connected and calibrated for accurate readings.

Step 5: Consider the Engine's Behavior

Pay close attention to the engine's performance. Does it hesitate, stall, or have reduced power? These symptoms can be indicative of fuel-related issues. If the engine's behavior suggests a problem with fuel delivery or circulation, it's likely related to the return line. Keep a record of the engine's behavior to help narrow down the potential causes.

Step 6: Seek Professional Assistance

If the problem persists or you're unsure about any step, consulting a professional mechanic is advisable. They can provide specialized tools and expertise to diagnose and repair fuel return line issues accurately. A mechanic can also ensure that any repairs or replacements are done correctly, preventing further complications.

Poulan Chainsaw Fuel Lines: Location and Installation Guide

You may want to see also

Frequently asked questions

A fuel return line is a crucial component in fuel injection systems, especially for LSX (Longitudinal Split-Planar) engines. It is a small diameter line that connects the fuel rail to the fuel pump, allowing excess fuel to return from the injectors back to the tank. This line ensures that the fuel pressure remains stable and prevents the engine from running rich, which can lead to reduced performance and potential engine damage.

In an LSX engine, the fuel return line plays a vital role in maintaining optimal fuel pressure. When the injectors spray fuel into the engine, any excess fuel that is not immediately used by the cylinders is collected in the fuel rail. The return line then carries this excess fuel back to the fuel pump, which recirculates it to the tank. This process helps to regulate the fuel pressure, ensuring a consistent and precise fuel-air mixture for efficient combustion.

While it is technically possible to omit the fuel return line in some LSX engine setups, it is generally not recommended. Without a fuel return line, excess fuel may accumulate in the fuel rail, leading to increased pressure and potential issues. This can result in poor engine performance, reduced power, and even engine knock. It is best to install a fuel return line to maintain proper fuel management and ensure the engine operates optimally.