Patching a hole in a fuel line can be a crucial step in maintaining the integrity of your vehicle's fuel system. Whether you're dealing with a small puncture or a larger tear, it's important to address the issue promptly to prevent fuel leaks and potential engine damage. This guide will provide a step-by-step approach to repairing a damaged fuel line, ensuring your vehicle remains reliable and safe on the road.

What You'll Learn

- Identify the Hole: Inspect the fuel line for the damaged area, ensuring you locate the exact hole

- Prepare Materials: Gather necessary tools and replacement parts like fuel line tape or clamps

- Clean the Line: Remove any debris or old tape to ensure a clean patch

- Apply the Patch: Carefully wrap the fuel line tape around the hole, ensuring a secure fit

- Test and Inspect: Check for leaks and ensure the patch is secure before driving

Identify the Hole: Inspect the fuel line for the damaged area, ensuring you locate the exact hole

When dealing with a damaged fuel line, the first crucial step is to identify the hole with precision. Start by carefully examining the fuel line for any visible signs of damage. Look for small punctures, tears, or gaps in the material. These holes can be caused by various factors, such as debris, rodents, or even previous repair attempts gone awry. The key is to be thorough and methodical in your inspection.

Use a bright flashlight or a mirror to illuminate the area and get a clear view of the damage. Pay close attention to any areas where the fuel line is exposed or where it has been cut or punctured. Sometimes, the hole might be hidden beneath a layer of insulation or protective covering, so be prepared to remove any excess material to get a better view.

The goal is to pinpoint the exact location and size of the hole. Note the distance from any connections, bends, or fittings along the fuel line. This information will be vital for the next steps in the repair process. If the hole is near a fitting, you might need to adjust your approach to ensure a secure and effective patch.

In some cases, the hole might be small and not easily visible to the naked eye. In such instances, consider using a magnifying glass or a small camera to get a closer look. This extra step ensures that you don't miss any potential damage, especially if the fuel line has been compromised by corrosion or other subtle issues.

Remember, the accuracy of your initial inspection directly impacts the success of the repair. Take your time, and don't rush the process. By carefully identifying the hole, you set the foundation for a successful patch job, ensuring the fuel line is secure and functional once again.

Understanding the Fuel Lines in a Yukon XL Gas Tank

You may want to see also

Prepare Materials: Gather necessary tools and replacement parts like fuel line tape or clamps

Before you begin the process of repairing a fuel line, it's crucial to gather all the necessary tools and materials to ensure a successful and safe fix. Here's a step-by-step guide on what you should prepare:

Tools and Equipment:

- Start by ensuring you have a set of basic automotive tools. This includes a fuel line cutter or a sharp knife with a protective guard to cut the damaged section of the fuel line. You'll also need a pair of pliers or a fuel line clamp to secure the new connection.

- Get a fuel line tape or a specialized fuel line repair kit. These kits often include the tape, clamps, and possibly a primer or adhesive to ensure a strong bond.

- Have a set of gloves and safety goggles ready to protect your hands and eyes during the repair process.

- Consider using a fuel line inspection mirror to help you visualize the damage and ensure a proper repair.

Replacement Parts:

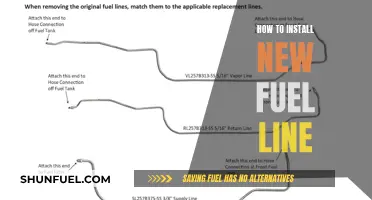

- Measure the damaged section of the fuel line to determine the length of replacement needed. It's essential to have a slightly longer piece to allow for adjustments.

- Purchase a replacement fuel line that matches the original's diameter and material. You can find these at auto parts stores or online.

- Along with the replacement line, get the appropriate fuel line tape or clamp. The tape is used to create a secure bond, while the clamp ensures a tight seal.

- If you're using a repair kit, ensure it includes all the necessary components for a complete fix.

Safety Precautions:

- Before starting, ensure the engine is off and the vehicle is in a secure position. Fuel lines can be under pressure, so it's crucial to work safely.

- If you're unsure about any step, consult a professional mechanic or refer to a trusted online resource for guidance.

By gathering these tools and materials, you'll be well-prepared to tackle the fuel line repair, ensuring a safe and effective solution. Remember, proper preparation is key to a successful DIY project.

Silverado Fuel Line Replacement: A Step-by-Step Guide for DIY Mechanics

You may want to see also

Clean the Line: Remove any debris or old tape to ensure a clean patch

When preparing to patch a hole in a fuel line, it's crucial to start with a clean and debris-free surface. This initial step is often overlooked but is essential for a successful repair. Here's a detailed guide on how to ensure your fuel line is ready for the patch:

Step 1: Identify and Access the Hole

Locate the damaged section of the fuel line. It might be a small hole or a larger tear, but it's important to determine the exact location and size of the damage. Carefully inspect the area to ensure you understand the extent of the issue.

Step 2: Remove Debris and Old Tape

Start by removing any visible debris from the fuel line. This could include dirt, rust, or any foreign objects that might have accumulated over time. Use a small brush or a compressed air canister to gently clean the area, ensuring you don't push any debris further into the line. Additionally, check for any old tape or adhesive remnants that might be present. Carefully peel off any remaining tape, being mindful not to damage the fuel line further. This step is critical to ensure a clean and smooth surface for the patch.

Step 3: Inspect for Further Damage

While cleaning, take the opportunity to inspect the fuel line for any additional damage. Look for signs of corrosion, cracks, or weak spots that might require further attention. This thorough inspection will help you understand the overall condition of the fuel line and ensure you address any potential issues before applying the patch.

Step 4: Prepare the Patch

Once the line is clean and free of debris, you can now prepare the patch. Ensure you have the appropriate materials and tools ready, including the patch kit, primer, and any necessary adhesives. This step ensures that you have everything required to make the repair efficiently.

By following these steps, you'll create a clean and prepared surface, making the patching process more effective and long-lasting. This initial cleaning process is a vital part of the repair process, ensuring the patch adheres properly and the fuel line functions optimally.

Sioux Chief Diesel Vinyl Fuel Line: Flexibility and Durability Unveiled

You may want to see also

Apply the Patch: Carefully wrap the fuel line tape around the hole, ensuring a secure fit

Before you begin the patching process, it's crucial to gather the necessary materials. You'll need fuel line tape, which is specifically designed to be heat-resistant and durable enough to withstand the pressures and temperatures found in fuel lines. Ensure you have the right size and length of tape to cover the hole adequately. Additionally, have a small amount of fuel line adhesive or a suitable sealant ready, as this will provide extra security and prevent any potential leaks.

Now, carefully inspect the fuel line and the hole you need to patch. Clean the area around the hole to ensure the tape adheres properly. Remove any dirt, debris, or old tape remnants. If the hole is small, you might be able to use a simple wrapping technique. For larger holes, consider using a small piece of tape to create a temporary patch before applying the main repair.

Start by cutting a piece of fuel line tape slightly longer than the diameter of the hole. This extra length will allow you to wrap it around the hole multiple times for added strength. Begin wrapping the tape around the hole, ensuring that each layer overlaps the previous one by a small margin. Continue this process, creating a series of overlapping layers, until the tape completely covers the hole. Make sure the tape is tight and secure, but be careful not to overtighten it, as this could cause damage to the fuel line.

As you wrap the tape, apply gentle pressure to ensure a good bond. If using fuel line adhesive, apply a small amount to the tape and press it firmly into place. Allow the adhesive to set according to the manufacturer's instructions. Once the tape is securely in place, test the fuel line for any leaks. If no leaks are detected, your repair is successful.

Remember, this is a temporary fix, and it's essential to have the fuel line inspected and potentially replaced by a professional mechanic as soon as possible. The tape provides an effective seal, but it may not last indefinitely, especially under high-pressure conditions. Regular maintenance and timely repairs are crucial to ensure the safety and reliability of your vehicle's fuel system.

Smart Fortwo Fuel Line: Size Matters for Optimal Performance

You may want to see also

Test and Inspect: Check for leaks and ensure the patch is secure before driving

After you've patched the hole in your fuel line, it's crucial to thoroughly test and inspect the repair to ensure it's secure and won't cause any further issues. Here's a step-by-step guide to help you through this process:

Step 1: Visual Inspection

Start by giving the patched area a careful visual inspection. Look for any signs of damage or wear around the patch site. Ensure that the patch is properly aligned and that there are no visible gaps or misalignments. Check for any debris or foreign objects that might have entered the fuel line during the repair process and could cause further damage.

Step 2: Leak Test

The most critical part of the inspection is to check for leaks. Fuel leaks can be dangerous and lead to fires or explosions. Here's how to perform the leak test:

- Spray with Water: Use a spray bottle filled with water to gently mist the patched area. Pay close attention to the area where the patch was applied. If you notice any water seeping through, it indicates a potential leak.

- Use a Soapy Solution: Mix a small amount of dish soap with water and spray it on the patched area. If bubbles appear, it confirms a leak, as the soap will create a visible reaction.

- Pressure Test (Optional): For a more comprehensive test, you can use a fuel pressure gauge to check the pressure in the fuel line. If the pressure drops significantly when you turn the ignition on, it suggests a leak.

Step 3: Ensure Securement

Make sure that the patch is securely attached to the fuel line. Check the following:

- Tighten Connections: Ensure all connections are tight and secure. Use the appropriate tools to tighten any fasteners or clamps.

- No Movement: Feel around the patched area to ensure there is no movement or play in the connection. The patch should be firmly in place.

- No Rubbing or Friction: Check that the patch doesn't rub against any other components, as this could cause wear and potential failure.

Step 4: Drive and Monitor

After confirming the patch's integrity, it's time to drive the vehicle and monitor for any unusual behavior:

- Drive Slowly: Start the car and drive at a slow, steady speed. Pay attention to any unusual noises, vibrations, or smells.

- Check Engine Light: Keep an eye on the dashboard for any warning lights, especially the check engine light. This could indicate a problem with the fuel system.

- Fuel Efficiency: Monitor your fuel gauge and note any changes in fuel efficiency. A properly patched fuel line should not significantly impact fuel consumption.

Remember, proper testing and inspection are essential to ensure the safety and reliability of your vehicle's fuel system. Always follow these steps to guarantee a successful repair.

Understanding the LQ4 Haf Fuel Return Line: A Comprehensive Guide

You may want to see also

Frequently asked questions

For a temporary fix, you can use a fuel line clamp or a rubber hose clamp to secure the hole and prevent fuel leakage. Ensure the clamp is tight enough to create a seal but not so tight that it causes damage to the line. This method provides a quick solution until a more permanent repair can be made.

To permanently patch a fuel line, you'll need a few essential materials. Firstly, obtain a fuel line repair kit, which typically includes a specialized adhesive and a protective sleeve or patch. Additionally, have some cleaning supplies like acetone or a fuel line cleaner to ensure a proper bond. It's crucial to follow the manufacturer's instructions for the repair kit to ensure a successful and safe fix.

While it is possible to repair a small hole in a fuel line yourself, it is generally recommended to seek professional assistance for a more complex or large-scale repair. Fuel lines can be intricate, and improper repair may lead to further issues. Professionals have the expertise and tools to ensure a safe and effective fix, minimizing the risk of fuel leaks and potential engine damage.